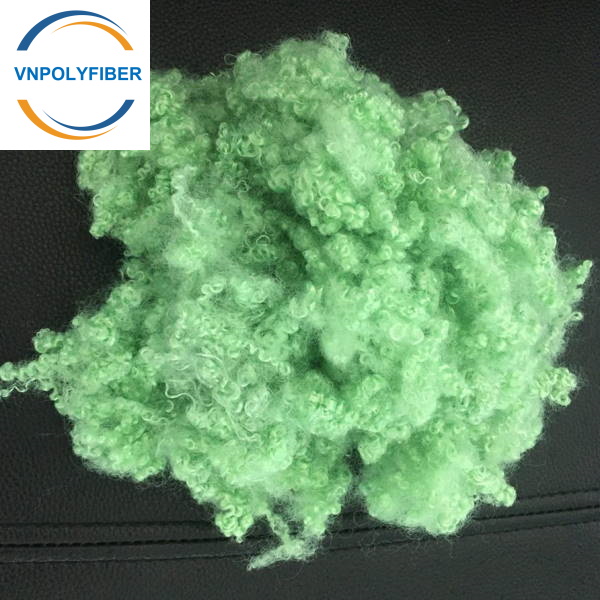

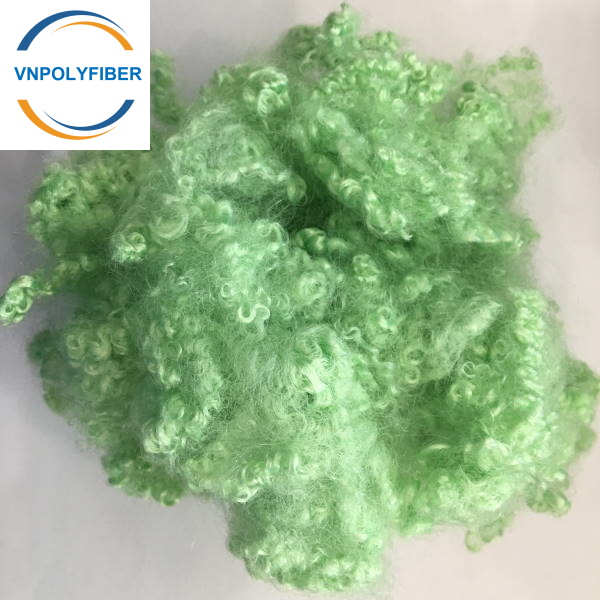

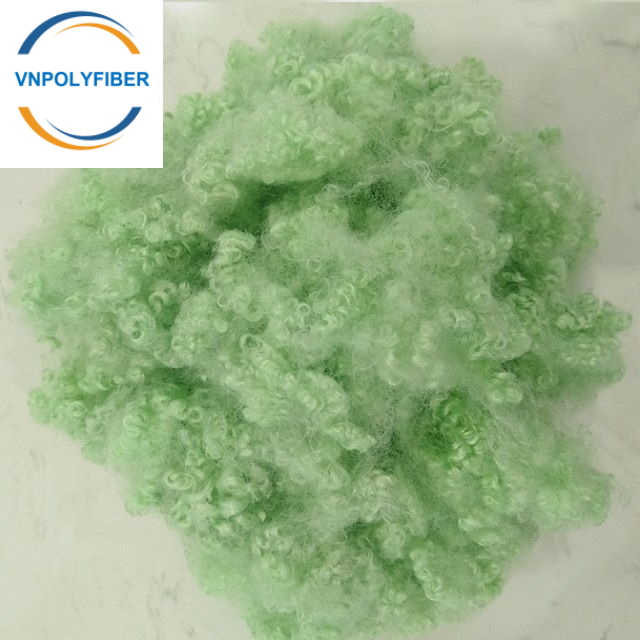

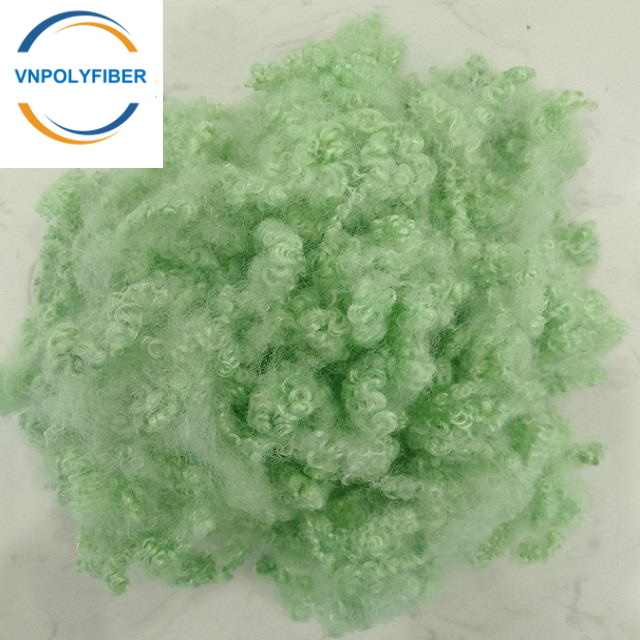

Recycled Green Polyester Fiberfill

- Hollow PSF has better loft, recovery and warmth retention property than solid PSF, because there is a hole in single fiber, it can save some air.

- Our hollow PSF is easy to be carded and good at bonding with low melting fiber.

- It’s mainly used for fiberfill, filtration, padding, wadding, insulation etc.

Specification

- Denier: 6D-15D

- Type: Hollow Mechanical crimp

- Grade: Recycle, First quality

- Color: white, optical white,

- Cut Length: 32mm-76mm

- Finish: silicon, slick, dry, FR, antibacterial, low shrinkage

- Application: Filling, Wadding, fiberfill, insulation, filtration etc.

PRODUCT DETAIL

Polyester Fiberfill

Polyester fiberfill was originally developed by Imperial Chemical Industries (ICI) in partnership with DuPont. Over time, it has become a widely accepted material for various applications due to its affordability and versatility.

Polyester fiberfill, that fluffy, resilient material nestled within our pillows, cushions, and stuffed toys, is a ubiquitous yet often underappreciated component of modern life. Its versatility, affordability, and comfort-enhancing properties have made it a staple in numerous industries. This post delves into the world of polyester fiberfill, exploring its properties, manufacturing, applications, and the reasons behind its enduring popularity.

Polyester fiberfill is a synthetic filling material composed of fine, crimped polyester fibers. These fibers are engineered to create a lightweight, lofty, and resilient fill that provides cushioning, support, and warmth. Unlike natural fills like down or feathers, polyester fiberfill is hypoallergenic, resistant to mold and mildew, and easy to care for.

How to make polyester fiberfill

The journey of polyester fiberfill begins with the same raw materials as other polyester fibers: PTA and MEG. These are polymerized into PET chips, which are then melted and extruded through spinnerets. However, the extrusion process for fiberfill is specifically designed to create crimped fibers. Crimping involves creating a wave-like or spiral shape in the fibers, which significantly increases their bulk and resilience.

After extrusion, the fibers are often siliconized, a process that involves coating them with a silicone finish. This treatment enhances the fiber’s softness, smoothness, and loft. The fibers are then processed into a loose, fluffy fill, ready for use in various applications.

Key Properties of Polyester Fiberfill

- Loft and Resilience: The crimped fibers create a high degree of loft, providing excellent cushioning and support. The fibers’ resilience allows them to spring back into shape after compression, maintaining their bulk over time.

- Softness and Smoothness: Siliconization contributes to a soft, smooth texture, enhancing comfort.

- Hypoallergenic: Polyester fiberfill is inherently hypoallergenic, making it an ideal choice for individuals with allergies or sensitivities.

- Resistance to Mold and Mildew: Polyester’s hydrophobic nature prevents moisture absorption, inhibiting the growth of mold and mildew.

- Warmth and Insulation: The trapped air within the fiberfill provides excellent thermal insulation, keeping users warm and comfortable.

- Lightweightness: Polyester fiberfill is lightweight, making it easy to handle and transport.

- Durability and Longevity: Polyester fibers are strong and durable, ensuring that the fill maintains its properties over time.

- Easy Care: Polyester fiberfill is machine washable and dryable, simplifying cleaning and maintenance.

- Affordability: Compared to natural fills, polyester fiberfill is relatively inexpensive, making it a cost-effective option.

Applications of Polyester Fiberfill

Polyester fiberfill’s versatility has led to its widespread use in numerous applications:

- Bedding: Pillows, comforters, mattress toppers, and quilts rely on polyester fiberfill for its comfort, support, and warmth.

- Furniture: Upholstery cushions, sofa pillows, and furniture padding utilize polyester fiberfill for its cushioning and resilience.

- Toys and Stuffed Animals: Polyester fiberfill is the primary filling material for toys and stuffed animals, providing a soft, safe, and durable fill.

- Crafts and Sewing: Polyester fiberfill is used in various craft projects, including quilting, sewing, and toy making.

- Automotive Interiors: Seat cushions, headrests, and other automotive interior components utilize polyester fiberfill for its comfort and support.

- Outdoor Gear: Sleeping bags, camping pillows, and other outdoor gear benefit from polyester fiberfill’s warmth, lightweightness, and moisture resistance.

- Filtration: Some coarser grades of polyester fiberfill are used in filtration applications.

Advantages of Polyester Fiberfill

- Consistent Quality: The manufacturing process ensures consistent quality and performance.

- Versatility: Polyester fiberfill can be engineered to meet specific requirements, offering a range of loft, softness, and resilience.

- Easy Maintenance: Machine washability and dryability simplify cleaning.

- Cost-Effectiveness: Polyester fiberfill is an affordable filling material.

- Hypoallergenic and Safe: Free from allergens and resistant to mold and mildew.

Considerations and Variations

- Hollow Conjugated Siliconized (HCS) Fiberfill: This type of fiberfill features a hollow core and a conjugate structure, further enhancing loft and resilience.

- Microfiber Fill: Finer polyester fibers are used to create a softer, more luxurious fill.

- Recycled Polyester Fill: Increasingly, recycled polyester is used to produce fiberfill, reducing the environmental impact.

The Future of Polyester Fiberfill

Polyester fiberfill will continue to be a vital material in numerous industries. Ongoing research and development focus on improving its sustainability, exploring bio-based alternatives, and enhancing its performance characteristics. As consumers seek comfortable, affordable, and easy-care products, polyester fiberfill will remain a staple in our daily lives. Recent advancements in polyester fiberfill include the development of blends that combine polyester staple fibers with binder fibers, allowing for thermally bonded products with improved durability and resilience. These advancements aim to enhance the performance of polyester fiberfill while maintaining its softness and aesthetic appeal.

Read more:

https://vnpolyfiber.com/what-is-fiberfill-what-is-poly-fil/

https://vnpolyfiber.com/what-is-polyester-fiberfill/

Virgin vs Recycled Polyester Filling?

Virgin polyester fiberball is made of petroleum oil which will harm the environment while recycled will be more eco friendly.

Features: high bulkiness and easy open, excellent tenacity, high resilience and durability, feather touch, light and soft;Environmentally friendly, excellent filling power, anti-static, durable

Application: Pillows, blankets, comforter, toys, filling material for bedding, furniture, spray-bonded cotton, polyester wadding, padding, non-woven, filling quilt, cushion, home textile, etc.

Why choose Polyester Fiberfill

Premium Polyester Fiberfill is absolutely the best performing fiberfill for pillows, dolls, stuffed toys and crafts. It offers a superior resiliency, smooth consistency, and will not bunch. It’s made from recycled materials, and it is hypoallergenic and machine-washable. Add it to toys, pillows, and much more!

white 100% polyester product that is ideal for toys, pillows and crafts. It is non-allergenic and hand washable.

Use Premium Polyester Fiberfill for stuffed animals and dolls.

5 advantages of polyester staple fiber you need to know

Are you considering using polyester staple fiber (PSF) for your production?

Whether it is virgin or recycled polyester, they all have 5 key advantages below. Also remember we can supply filling material HCS PSF made in Viet Nam at very competitive price.

1. Does not warp:

Neither stretches nor shrinks. It has a resilience that other natural fibres do not have; for example, it does not wrinkle. This is why Lafayette Sports Stretch technology textiles are mostly made of polyester and lycra.

2. It can be combined with other materials:

As rayon, cotton, wool, nylon or viscose, increasing the quality of the final product and allowing a multiplicity of uses. That is why a company offers me a functional textile in which it takes advantage of the naturalness of cotton and combines it with the durability of polyester.

3. It is light:

This does not prevent it from being a solid and durable material.

4. Absorbs less moisture:

This allows it to repel fungus, mould and bacteria. This not only increases its durability but prevents the generation of bad odors, qualities that we have taken advantage of to protect technology.

5. Better absorb the inks:

Polyester garments usually have brighter and more durable colors and prints. For this reason, the offer of textiles for shirts, blouses and dresses, is composed mostly of polyester.

Both natural fibres and synthetic fibres have different characteristics and advantages; the main difference is the technology with which textiles are created, always taking into account the final use they want to give them

How to make Virgin Polyester Staple Fiber

Virgin Polyester Staple Fiber a synthetic man-made fibre that is manufactured from PTA & MEG through polymerization performed at a high temperature and pressure

After the spinning and drawing process, polymer becomes staple fibers when cut short into the form of cotton or filament yarns when made into the form of yarn.

Staple fibers are widely used for industrial use as well as for clothing.

They are not only used for filling of clothing, bedding and furniture in the form of cotton or for spinning after twisting cotton into yarn but they are also fabricated into non-woven fabrics through compression and used for a wide range of applications, including automobile, construction, furniture, sanitary materials and agriculture, gradually expanding their scope of application.

Application of virgin PSF

Automobile, Furniture, Sanitary products, Cleaner Filter, Various non-woven fabrics, Civil/construction materials, Clothing Sport wear, Premium padding, Inner wear, Bedding Accessory Interior

Polyester benefits

- Polyester fills are typically less expensive to produce than down and feather or microfiber fills making them practical and cost efficient

- Polyester fills are hypoallergenic and are ideal for products designed for allergy sensitive sleepers

- When it comes to easy maintenance, polyester fills are tough to beat and easy-to-care-for

- Adding a silicon finish to polyester fills provides a slick hand similar to down and feather fills

Application:

Features: high bulkiness and easy open, excellent tenacity, high resilience and durability, feather touch, light and soft;Environmentally friendly, excellent filling power, anti-static, durable

Application: Pillows, blankets, comforter, toys, filling material for bedding, furniture, spray-bonded cotton, polyester wadding, padding, non-woven, filling quilt, cushion, home textile, etc.

Advantage of Viet Nam PSF HCS Hollow Conjugate Fiber Siliconized :

– Warm keeping :The hollow polyester staple fiber is lighter by 20% than ordinary fiber with its hollow Construction. It makes no air convection in fiber to keep warm. It can keep body warm by wrapping warm air and isolating cold air. The fiber is light and good in warm keeping.

– Good hygroscopicity :Hollow polyester staple fiber can discharge the moisture quickly in the body skin and keep dry and warm, reduce the un comfortable sticky feeling with its advantages of special wicking effect and large surface.

– Soft feeling in hand, good fall :It bright soft and comfortable feeling in hand to touch the hollow polyester staple fiber fabric. Compared with the daily heavy thermal fabric, it is more easily wet, dry and comfortable. It is very soft and excellent in pendency.

– Wide application: Hollow polyester staple fiber is a high quality material for the high-grade fabric. Blended with cotton, wool and viscose fiber, it is widely used to make thin thermal underwear, warm winter casual wear and sportswear with good warm keeping, soft feeling and soft luster. It is also used to make soft and thermal socks and gloves with wear resistance. It is also used to make light and soft tweeds.

Polyester Staple Fiber used in Non-woven Industry

| Luster | Denier | Cross Section | End-Use |

| SD | 1.5, 1.7, 2, 3, 4, 6 & 15 | Solid | Nonwoven Interlining, Sanitary Material, Microfiber and Thermal Bonding |

| FBR (Black) | 1.5, 1.7 & 3 | Solid | Needlepunch, Resin Bonding & Fiberfill |

| SD | 1.5 & 4.5 | Solid | Dyeable Fabric & High-Pile |

| SD | 6, 8 & 15 | Hollow and Hollow-Siliconized | Resin Bonding, Needlepunch, Fiberfill, Flame Retardant Fabric, Anti Bacteria & Platinum Photon Fiber |

| SD, BR,OBBR | 0.7, 1.1, 1.2, 1.4, 2.0, 6, 8, 12, 15 & 20 | Solid | Low Pilling, Knitting, Fiberfill, Thermal Bonding, Needlepunch, Infrared Fiber & Resin Bonding |

| SD | 2, 3, 4.5, 7, 12 & 15 | Hollow Conjugate | Resin Bonding, Needlepunch & Fiberfill |

| SD | 7 | Hollow Conjugate | Anti-Bacteria |

Polyester Staple Fiber as per Direct End Use

| Type | Denier | Section | End Use |

| Anti Pilling | 1.4, 1.5, 2, 2.5 & 3 | Solid & Hollow | Sportswear, Underwear, Casual wear |

| Bamboo Charcoal | 1.5, 1.7 & 6 | Hollow | Bedding, Shoe pad, Cushion, Thermal Sock |

| Spinning Use | 1.3, 1.4, 1.5 & 1.7 1.5 | Solid Hollow | Sportwear, Casual Wear, Underwear |

| Dopedyed Black | 1.5, 2 & 3 | Solid | Nonwoven, Casual wear, Sport wear, Underwear |

| Flame Retardant | 1.4 | Solid | Home, Comfort & Clothing textiles |

| Micro Fiber | 0.8 – 1.0 | Solid | Cloth & Fleece |

| High Tenacity | 1.2 | Solid | Yarn, Cloth & Water transport |

| High Void Conjugate | 3, 7, 12 & 15 | Hollow | Toy Padding, Badding, Furniture Cushion, etc |

| Regular Fiber | 2, 2.5, 3, 6 & 15 | Solid | Nonwoven, Filter medics, Padding, etc. |

Other keywords:

Fibras discontinuas de poliéster 15d * 64mm hueca siliconada

Blanco barato relleno de fibra de poliéster lavable hsc Guata de poliéster de fibra

Discontinuas de poliéster de fibra de poliéster de residuos-La sra.

Technical Parameter

| Product type | Recycled Polyester Staple Fiber |

| Fineness | 7D / 15D |

| Cut length | 32mm / 51mm / 64mm |

| Luster | semi dull |

| COLOR | Raw white |

| Pattern | Hollow Siliconized & Hollow Non-Siliconized |

| Raw Material | 100% PET flakes |

| Grade | Recycled, AAA grade |

| Packing details | 250kg-350kg/PP woven bag/bale |

| Delivery time | 5-20days after 30% deposit |

| Payment Term | TT30/70; L/C at sight |

| MOQ | 1x40HQ; 22 – 23 tons/container |

| Quality | First quality |

Specifications of Polyester Staple Fiber Viet Nam

Denier Size: 3D, 6D, 7D, 10D, 15D

Cut length: 32mm, 51mm, 64mm, 76mm,

Feel: siliconised or non siliconised soft as well as harsh feel

Tensile strength: 3.5 to 4.5 gm/Denier

Elongation: 40 to 60%

Oil Pickup: minimum 0.20% to 0.35%

Crimps: 3 to 5 per cm

Shades: All shades available

Color Fastness: 4+

Quality: Hollow Conjugate Siliconised Fiber, Hollow Non-Conjugate Siliconised Fiber, Solid Fiber Siliconised/non Siliconised

Application: Cushions – Pillows – Quilts – Toys – Jacket – Mattress – Non woven carpet – Automotive felts, speaker felts, geo textiles, polyfill wadding, filter fabrics and other acoustics as well.

FAQ

1. What do you offer?

We produce recycled hollow conjugated siliconized and non-siliconized polyester staple fiber mainly, we can make hollow fiber (HS/ HD) and virgin polyester staple fiber HCS as well.

2. What is it used for?

Our fiber is widely used in filling, non-woven fabric

3. Are you a factory or a trading company?

We are a factory specialized in polyester staple fiber for many years but now we also have our own professional trading company. We will source many types of textile products such as yarn, PP fibers from others to supply our own customers as well. We also provide our own customers with other related products such as: Foam, Pillows, Cushions, Toys, Down/ Feather,…

4. Where is your factory location?

Our factory locates in the north and the south of Vietnam. You can visit us from Ho Chi Minh City and Hanoi City, Vietnam. You could contact our salesman to fetch you if visiting.

5. Can you accept free sample?

Yes, the hand sample is free when not exceed 1 kilograms. Upon price confirmation, we will provide a sample within 2-3 days; the freight cost will be charged to client.

6. Can you provide ODM service?

Yes, we work on ODM orders. Which means size, material, quantity, design, packing solution, etc, will depend on your requests, and your logo will be customized on our products.

7. How about your quality? What’s the minimum order Quantity (MOQ)?

Please try a trial order, you will know it. The MOQ is 23,000 Kilograms/order, but the price will be lower if you order bulk volume.

8. Can I mix different items in one order?

Sure, you can mix any products we can provide.

9. How can you guarantee the product quality?

We have experienced QC team. We control not only productive process but also raw material. In addition, we have different kinds of testing instrument to help us guarantee the product quality.

10. What’s the payment terms?

L/C at sight, 30% TT in advance are mostly accepted; other terms shall be negotiable by both sides

For more information, please feel free to contact :

Mr. Tony Tan

Mobile number: +84 90 466 5251 (Whatsapp/Wechat/Viber/Signal)