Synthetic fibers are artificial fibers ; they are made from synthetic polymers, which come from oil, coal, and other petrol-based chemicals (monomers). The process of joining these monomers is known as polymerisation, and then the mixed polymers are spun (twisted) into yarns.

Synthetic fibers fall into groups based on the polymer that the fibers are made from, such as the three that are most commonly used in textiles: acrylic, polyamide (Nylon), polyester. There are others you may be aware of such as elastane (Lycra), polyvinyl chloride (PVC) and polypropylene (used in carpets). Synthetic fibers , which are made in chemical plants by a range of companies across the world, are given trade names. For example, the elastane fibers produced by DuPont has the trade name Lycra and the polyamide invented by DuPont in 1938 is named Nylon.

Microfibers are thin hair-like fibers made from polyamide or polyester. These fibers can be made up to 60 times thinner than a human hair, which makes them lightweight; they are strong and water repellent but also absorbent, breathable and have a very good handle or feel. The most common products made from microfibers are underwear, sportswear, hosiery, and water-repellent outdoor wear, but designers are using these fibers more and more in their fashion collections. Tactel Micro is often seen today as a label on sportswear or underwear; Meryl Micro is used in active sportswear.

Tactel Aquator was designed by DuPont for its moisture management properties. It is a non-absorbent fibers that takes moisture away from the body.

Hi-tech, very strong fibers such as Kevlar and Cordura were developed for industrial use, but they are now being used for active outerwear for many extreme sports and activities that require a high degree of resistance to abrasion.

- Synthetic fibers are artificial and use up natural resources such as coal and oil

- Synthetic fibers can be made to have many properties and are very versatile

- Synthetic fibers are poor absorbers of liquids owing to their polymer origins (polymer is very like plastic)

Main properties of Synthetic fibers and fabrics

Synthetic fibers can be developed to have many different appearances and properties. They can be made as filament or staple fibers ; they can be bulked or comped to give more volume; they can be made up as microfibers; and they can encapsulate chemicals, perhaps to give antibacterial properties or to be perfume scented.

Because synthetic fibers are plastics based, they have thermosetting and thermoplastic properties. These allow the fibers to be manipulated using heat, to create permanent pleats in fabrics and add textures, similar to some listed below:

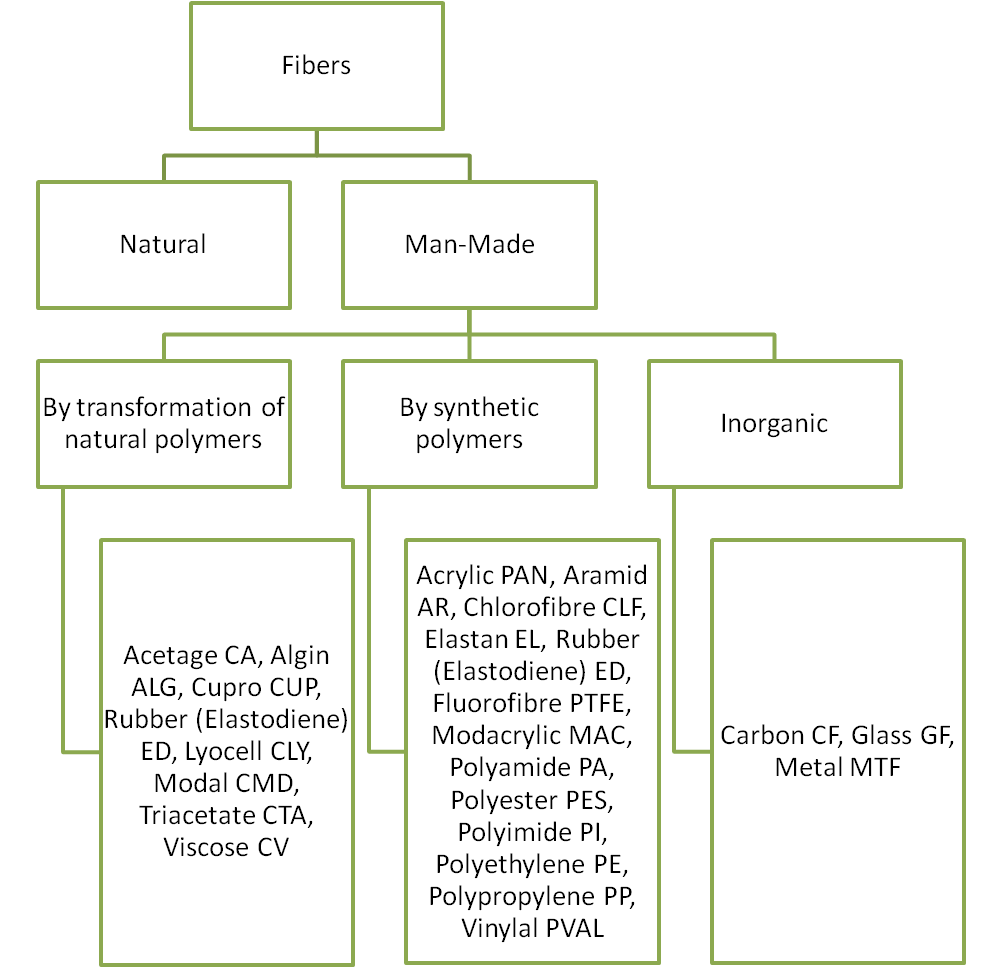

Man-made fibers are fibers in which either the basic chemical units have been formed by chemical synthesis followed by fiber formation or the polymers from natural sources have been dissolved and regenerated after passage through a spinneret to form fibers. This fibers came to success when the researchers obtained a product by condensation of molecules presenting two reactive aminic groups with molecules characterised by two carboxylic reactive groups.

The fiber came to success when the researchers obtained a product (polymerized amide, from which the name polyamide) by condensation of molecules presenting two reactive aminic groups (hexamethylenediamine) with molecules characterized by two carboxylic reactive groups (adipic acid). In order to be differentiated from other polymers belonging to the same chemical class, this polymer was marked with the acronym 6.6 which indicates the number of carbon atoms (that is 6) in the two molecules forming the repetitive polymer unit.

Polyester fiber

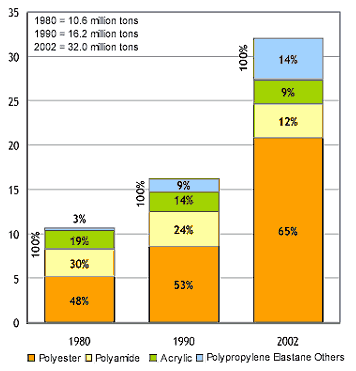

This is the most important man-made fiber, with a production of 22 million tons in 2003 (58% continuous filament/42% staple fiber), which since some years overcame cotton production. The number of plants installed in the world is estimated already now at more than 500.

Another aspect of considerable importance under the geographic-economic point of view is the fact that 75% of the production is located in Asia. Polyester wrung the record of most produced synthetic fiber out from the polyamide fiber already in 1972 when it reached a share of 65% in the synthetic fiber market. Its success is due to its particular characteristics, to its versatility in the various application sectors and to the relatively low raw materials and production costs.

- Physical: Very strong when wet and dry, flame resistant, thermoplastic, does not decompose, Resists more alkalis unless very concentrated, but is damaged by strong acids

- Aesthetic: Versatile, can be made into many finishes

- Fabric names: Terylene, Polyester fleece, Trevira, Finesse, Miratec, Dacron

- End-use: Wide range of textile products

- Advantages: Strong when wet, dries quickly, Cheap, Hard0wearing, Resists bacteria

- Disadvantages: Very poor absorbency

Polyamide fiber

This fiber category practically opened the textile market to fibers with no connection to the world of nature.

The production, performed worldwide by about 300 plants, amounts to 3,9 million tons (2003) and is distributed into polyamide type 6 (about 60%) and polyamide type 6.6 (about 40%); it is composed mainly of the continuous filament (85%), against 15% of staple fiber. The major producing countries are still Europe and USA (45% of the market).

- Physical: Strong, hard-wearing, good elasticity, thermoplastic, does not decompose, melts as it burns, resists most alkalis, but can be damaged by strong acids

- Aesthetic: Versatile, can be made into many finishes

- Fabric names: Nylon, Tactel, Tactel Micro

- End use: Clothing, Ropes, Carpets and rugs, Seat-belts, and sports belting

- Advantages: Strong when wet, Durable, Reasonably inexpensive, Resists bacteria

- Disadvantages: Poor absorbency, Can be damaged by sunlight, making it discolour and become weaker.

Acrylic fiber

The production of this fiber is estimated at 2,6 million tons (2003) and West Europe is still today the area with the highest production (30%).

This fiber found its main use in the traditional wool sectors and is being produced in practice only in form of discontinuous or staple fiber.

It shows negligible production increases and consequently, its share in the man-made fiber market fell from 20% in 1970 to 9% in 2002.

- Physical: Strong but weaker when wet, thermoplastic, shrinks from heat and burns slowly, then melts

- Aesthetic: Soft, can be made into fine and coarse staple fibers

- Fabric names: Caourtelle, Amicor

- End-use: Knitwear and knitted jersey fabrics, Toys, fake-fur products, Upholstery fabrics, Anti-bacterial socks and sportswear

- Advantages: Can be made warm, insulating and soft

- Disadvantages: Poor absorbency

Polypropylene fiber

This is the last-born man-made fiber and, as it is used also in near sectors (as in the plastic industry), its importance in the textile sector was not always adequately monitored. In fact, even excluding such sectors, the production for merely textile uses (carpeting, clothing, technical uses) can be estimated at 3,0 million tons and shows steady growth rates. The most significant producer areas are Europe and USA.

Elastane fiber

Within the group of fibers with high-tech performance, the elastane fiber (spandex) stands out for its characteristics of elongation and elasticity: its consumption in 2001 has been estimated at 160.000 tons.

- Physical: Very elastic, lightweight but still very strong, resists chemicals and biological damage from perspiration, Very hard-wearing

- Aesthetic: Medium to coarse filament fibers

- Fabric names: Lycra

- End-use: Swimwear, sportswear and all clothing that may require extra elasticity, such as easy fit jeans or fitted blouses (Elastane fibers are always combined with a higher percentage of another fibers in these products, e.g. stretch jeans are 96% cotton/4% elastane)

- Advantages: Very stretchy, keeps its shape, can resist sun and sea, lightweight but strong

- Disadvantages: Very poor absorbency

Aramid fiber

Aramid fiber is one of the most famous materials among super fibers in addition to carbon fiber.

It is divided into para-aramid and meta-aramid.

Para-aramid has high elasticity and ultra-high strength, and meta-aramid has excellent heat resistance, flame retardancy and chemical resistance

Read more: https://vnpolyfiber.com/polymer-fiber/

Usage:

– Para-aramid : Body armor, Military combat suit, Optical cable shield, Composite material (Construction, civil engineering, automobile, aircraft, hull, etc.), Automotive parts (brake pads, clutches, etc.)

– Meta-aramid : Protective clothing (heat resistant suit, fire suit), Filters, Aircraft interior materials (blankets, sheets), Automobile parts (tire frame, hose reinforcement, speaker damper), Electrical insulation tape

Aramid fibers are appreciated for their mechanical and fireproof properties (consumption estimate in 2001: 33.000 tons), while carbon fibers are used in composite materials for hi-tech applications estimated consumption in 2001: 13.000 tons).

Elastane is produced mainly in Korea and in Taiwan (other producers: USA, Japan, Germany); aramid and carbon fibers are mostly produced in the USA and in Japan.

Man-made Fibers

The history of man-made fibers is less than a century old; until 1910, there were no synthetic or chemical fibers. Today, by mixing different components, manufacturers can take the basic fibers listed below and make them more waterproof or more absorbent, warmer or cooler, thicker or thinner, stiffer or more supple. Some, like polyester and spandex, combine well with natural fibers, making fabrics that wrinkle less or are more form-fitting.

Man-made Fiber Classification

By Chemical Composition

According to the chemical composition of synthetic fibers, they can be divided into two categories: inorganic synthetic fibers and organic synthetic fibers. Examples of inorganic synthetic fibers are carbon fibers, glass fibers, boron fibers, etc. Examples of organic synthetic fibers are aramid fibers, polyester fibers, polyamide fibers, acrylic fibers, and so on.

By Aspect Ratio

According to the aspect ratio, it is divided into short fiber and long fiber. Aspect ratio is defined as the ratio of fiber length to diameter. Short fibers, also called discontinuous fibers, have an aspect ratio between 20-60. Long fibers, also called continuous fibers, have an aspect ratio between 200-500.

Novel Synthetic Fibers

With the development of fiber manufacturing technology, some novel synthetic fibers have also received extensive attention, such as easily dyeable synthetic fibers, microfibers, high-performance fibers and nanofibers, etc. Dyeable synthetic fibers mainly include cationic dyeable polyester fibers, cationic deep-dyed polyamide fibers, and acid dyeable polyacrylonitrile fibers and polypropylene fibers. The linear density of ultra-fine fiber is 0.11-0.55 dtex, and it can be produced by two-component composite splitting method, sea-island method, and melt-blown method. High-performance fibers are usually distinguished by their special properties, such as high strength and high modulus, high adsorption, high elasticity, high temperature resistance and flame retardant, light guide, electrical conductivity, high efficiency separation, radiation protection, reverse osmosis, corrosion resistance, medical and Drug fiber and other fiber materials. Nanofibers generally refer to fibers less than 100 nm in diameter, which may have surface effects, small size effects, or quantum size effects.

Advantages And Disadvantages

Synthetic fibers generally have the following advantages and disadvantages compared to natural fibers.

Advantages

- Long lasting

- Readily pick-up to various dyes

- Stretchable

- Waterproofing

- Non biodegradability

- Moisture resistance

- Strain and wear resistance

Disadvantages

- Flammable

- Prone to heat damage

- Melt easily

- Not eco-friendly

- Cause for microplastic pollution

- Not suitable for hot washing

- Poor insulation capacity

Properties

Here are some performance references for common synthetic fibers.

| Fiber type | Fiber Diameter (0.001 in) | Specific Gravity | Tensile Strength (Ksi) | Elasticity Modulus (Ksi) | Elongation at Break (%) | Water Absorption (%) | Melting Point (°C) | Maximum Working Temp (°C) |

|---|---|---|---|---|---|---|---|---|

| Steel | 4-40 | 7.8 | 70-380 | 30,000 | 0.5-3.5 | nil | 1370 | 760 |

| Glass | 0.3-0.8 | 2.5 | 220-580 | 10,400-11,600 | 2-4 | N/A | 1300 | 1000 |

| Carbon | 0.3-0.35 | 0.90 | 260-380 | 33,400-55,100 | 0.5-1.5 | nil | 3652-3697 | N/A |

| Nylon | 0.9 | 1.14 | 140 | 750 | 20-30 | 2.8-5.0 | 220-265 | 199 |

| Acrylics | 0.2-0.7 | 1.14-1.18 | 39-145 | 2,500-2,800 | 20-40 | 1.0-2.5 | Decomp | 180 |

| Aramid | 0.4-0.5 | 1.38-1.45 | 300-450 | 9,000-17,000 | 2-12 | 1.2-4.3 | Decomp | 450 |

| Polyester | 0.4-3.0 | 1.38 | 40-170 | 2,500 | 8-30 | 0.4 | 260 | 170 |

| Polypropylene | 0.8-8.0 | 0.9 | 65-100 | 500-750 | 10-20 | nil | 165 | 100 |

| Polyethylene Low High | 1.0-40.0 | 0.92 0.95 | 11-17 50-71 | 725 | 25-50 20-30 | nil nil | 110 135 | 55 65 |

Characteristics and usage of Man-made Fibers

| Type | Characteristic | Major Uses |

|---|---|---|

| ACETATE |

|

|

| ACRYLIC |

|

|

| ARAMID |

|

|

| BICOMPONENT |

|

|

| LYOCELL |

|

|

| MELAMINE |

|

|

| MODACRYLIC |

|

|

| NYLON |

|

|

| OLEFIN |

|

|

| POLYESTER |

|

|

| PBI |

|

|

| RAYON |

|

|

| SPANDEX |

|

|

Read more:

https://vnpolyfiber.com/classification-of-textile-fibers/

https://vnpolyfiber.com/all-about-synthetic-fibers-and-fabrics/

https://vnpolyfiber.com/synthetic-fibers-vs-man-made-fibers-definitions-and-classifications/

https://vnpolyfiber.com/what-is-natural-fibers/

https://vnpolyfiber.com/all-about-fibers-definition-types-and-applications/