The PP fiber is made by spinning a high-quality polypropylene raw material through a high temperature melting and then a spinning system composed of a spinneret and an external circular transverse blowing system, and then being formed by a barrel, a draft, a curl, a cut, and the like. PP fiber has excellent moisture permeability and fast drying property and is resistant to acid and alkali. It is generally used in the fields of thermal insulation materials, textile garments, industrial geotextiles, etc.

The process of PP fiber seems simple and convenient, but if there is a slight error in operation, it will have a greater impact on the finished product, such as the problem of excessive polypropylene fiber elongation.

Excessive elongation of PP fibers can cause many hazards. And in blending, it will also affect the strength of the yarn.

In spinning, the strength of the yarn after blending was found to be poor, such as the quality index of pure polypropylene 2808, the polypropylene 50% cotton blend index 1950, the polypropylene 50% cotton blend index 2193,215 the pure cotton quality index 2336. From the above data, pure spun polypropylene yarn has the highest strength, much higher than cotton, but after blending with cotton, it is not as high as pure cotton. Although this situation may be related to the unevenness of PP fibers and cotton, it is also related to polypropylene The short fiber is difficult to control the elongation, so the seemingly simpler process is also a test of the manufacturer.

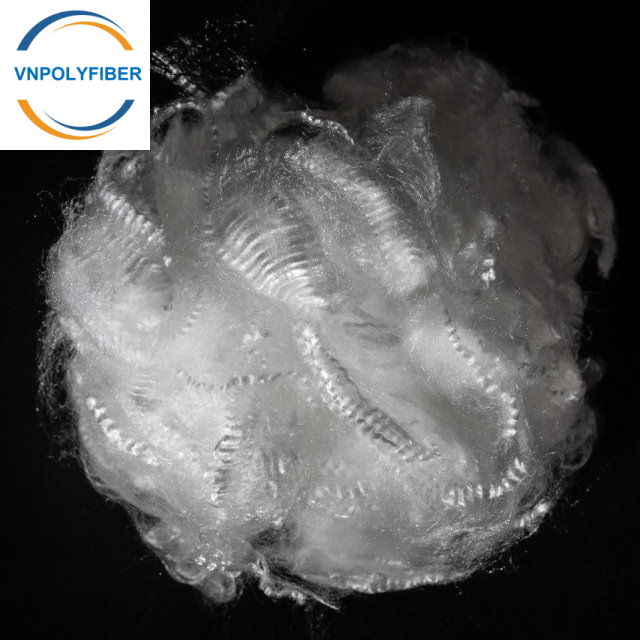

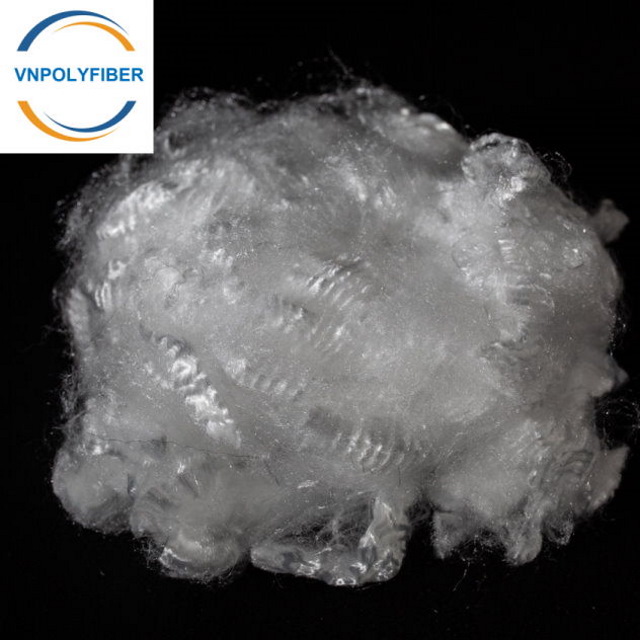

Definition of PP fiber

PP fiber looks like a mass of cotton from the outside. It is soft and has a certain degree of elasticity. PP fiber has a large elongation property, which is easy to control in production. The elongation will be over 60%, except for its polypropylene macromolecule In addition to its own structural factors, it may be insufficiently stretched during the production process. Due to the large non-uniformity of the yarn, it is easy to wrap around the roller and break it when the stretching ratio is increased, or it may be retracted after pulling. It is often found in production that the retraction of the yarn between the second and third stretchers when stopping will pull three and five rolls upside down, indicating that after orientation, the internal stress of the fiber is very large and there is shrinkage. These can be improved by tension heat setting or proper heat treatment.

PP fiber has excellent moisture permeability and fast drying property, good combability and spinning performance, acid and alkali resistance, and fast dissolution, good filling and sound insulation. Therefore, the application of PP fiber is relatively wide, mainly reflected in the following three aspects.

PP Fiber Properties

PP fiber has good bulkiness and resilience, and its anti-fouling property is very high quality (especially after proper chemical conversion), so that PP fiber is more suitable for the manufacture of carpet.

Polypropylene elastic fabric is different from elastic fabrics of other materials. It has the fluffiness of acrylic fiber, the antifouling property of polyester and the softness of nylon. PP fibercan be used to produce elastic knitting with high elasticity and softness. And woven fabrics, the production process and method are more concise than spandex.

(1) The raw fabric can be easily obtained from polypropylene DTY, SDY and POY. The fabric having good stretchability can also be obtained by weaving under the premise of a decent amount of the fabric, and the hand feel is good. In addition, it is also possible to produce a fabric having good performance by blending polypropylene and other fibers such as PET, acetate, acrylic, cotton, wool, or nylon.

(2) Weaving of PP fibers, similar to polypropylene filaments, is that knitted fabrics are still woven fabrics, and can also be made from batik yarns.

PP fiberhas the pressure of dyeing at room temperature. The recommended temperature for batik is 110 degrees Celsius. The temperature of batik can be adjusted according to the type of dye used. It is because this root is made with wool and tussah. Cotton, nylon, and other fiber blends or interwoven with greater strengths.

PP fiber is a kind of short fiber made by melt spinning, drawing, crimping, heat setting and cutting with polypropylene PP as raw material and has various colors and various functions.