Introduction of leather material

Leather has been around since the beginning of mankind. Hunting animals and using their skins has been part of all cultures throughout human history due to its durability, accessibility, and variety of uses. Although cow leather is the most commonly known and used type of leather, leather is classified as the skin of any animal. The term hide is used to describe larger animals like cowhide or horsehide, and skin refers to smaller animals like kidskin. Leather is an animal skin having undergone a complex transformation process, namely via tanning, in order to make it rot proof. Materials which are not made from animal skin can therefore not be referred to as leather.

Prices of leather and leather products vary drastically based on different factors such as the breed of animal, where and how the animal was raised, what part of the skin and type of dyeing is used, and amount of craftsmanship involved. Leather has the versatility to be dyed to a range of colours and also be embossed and stamped with different textures, effects, and patterns.

While leather is sourced from all areas of the world and from a variety of animals, over half of the world’s raw leather is supplied from developing countries in Asia, Africa and South America. China is the leading country for buying and processing leather, as well as producing and exporting footwear.

In 2017, the total market value of leather in America was $217.49 billion. It is expected to reach $271.21 billion by 2021.

The largest hide producers are China, India, and then Brazil.

95% of the leather industry is a by-product of the meat and dairy industries.

Animal Properties

- Cow: Cowhide is the most common leather source and is easy to care for and durable. It can be stiff and rougher in texture than other leathers but breaks in easily.

- Sheep: Sheepskin and lambskin leather is very soft to the touch. They are comfortable, pliable and finely grained in texture. Sheepskin leathers are often used for luxury leather garments.

- Goat: Goatskin is softer and tougher than cow leather and is an economical and durable leather. It is flexible, durable and lightweight.

Properties of leather

- Can biodegrade

- Durable

- Long lasting

- Warm and breathable

- Flexible and mouldable

- Easily dyed

Prices of leather and leather products vary drastically based on different factors such as the breed of animal, where and how the animal was raised, what part of the skin and type of dyeing is used, and amount of craftsmanship involved. Leather has the versatility to be dyed to a range of colours and also be embossed and stamped with different textures, effects, and patterns.

While leather is sourced from all areas of the world and from a variety of animals, over half of the world’s raw leather is supplied from developing countries in Asia, Africa and South America. China is the leading country for buying and processing leather, as well as producing and exporting footwear.

Many forms of leather

Not all leather is equal in price, quality, texture or use. When designing around leather it is important to consider certain factors to maximise the material’s usability. Sourcing the correct leather is important, and the quality and texture changes based on the animal breed and also the geographical location of where and how it was raised. The skill of the processing and tanning also plays a large impact on the outcome of the raw material. Different products require different cuts of the hide depending on suppleness, texture (full grain, split) or durability.

1. Full grain

Comes from the top layer of the animal and shows the animal’s natural grain. It is the most robust and expensive leather on the market and develops a patina as it ages.

2. Top grain

This is the second grade of available leather and is mainly used in premium, luxury products. The top layer of the skin is split away to remove any imperfections and to make the leather smoother and more flexible while still remaining durable.

3. Corrected grain

Split leather is the layer that remains once the top part of the skin is removed. This leather tends to be rougher than full or top grain leather and is used for applications that don’t require as much suppleness.

4. Bonded

The is the most inexpensive leather option available and is created with the offcuts and shavings of the hide. The left-overs are bonded together with PU or latex on a fibre sheet and then treated to mimic the appearance of leather.

Types of leather

Aniline leather

The most natural leather, dyed in translucent and water soluble dye that emphasizes the skin’s natural markings. It is one of the most expensive leathers that also requires regular upkeep.

Antique grain leather

Also referred to as distressed leather, it gives off the appearance of vintage or worn leather. The surface is partially applied with a coating to make it look uneven and rugged.

Bi-cast leather

Bi-cast leather is similar to bonded leather in its manufacturing process and properties. It is made by blending split or composite leather and adding polyurethane to bind the leather parts together to give the appearance of a full- grain leather but with less durability or comfort.

Corrected grain pigmented leather

This is the most commonly used leather globally. The hides are sanded or buffed to remove visible imperfections or markings and then the new smooth surface is treated with an artificial grain and sealed with a top-coat.

Pigmented leather

Pigmented leather is often used to make furniture and upholstery due to its robust durability. The polymer coating applied can produce different looks and properties desired while retaining its strength.

Nubuck leather

Nubuck leather has a velvety look and touch. The top grain of the hide is lightly sanded to create this appearance and often has a high consumer value.

Patent leather

Patent leather is coated with a lacquer to give a wet-look, mirror-like finish. The coat can be applied to different thicknesses of leather.

Saffiano leather

Saffiano leather has a shallow cross-hatch texture with a wax finish. It is most often used on small leather goods,bags, and book bindings.

Semi-aniline leather

Stronger than aniline leather without compromising on the natural leather look, despite having a light surface coating.

Suede leather

Suede is made from the underside of the animal and has a slight hairy texture finish. Suede, although a very desirable material, is not very durable or water resistant.

5 things to consider when working with leather

Leather is a durable and versatile material with a lot of desirable properties. Unfor- tunately, its current practices are linked to a lot of environmental issues – namely as a by-product of the meat industry. The livestock industry contributes to deforest- ation, land and water misuse and overuse, and high gas emissions, as well as affect- ing local communities.

The tanning stage is the most detrimental phase in the leather production process and regulations have forced tanneries in Europe and USA to close. However, devel- oping countries are still being subjected to the slurry of chemicals and gasses being emitted through tanning, with arsenic and contaminated effluent water making its way into local waterways.

1. Tanning

Look for vegetable tanned leather or hides processed with aldehyde chemicals. They take longer than the chemical process, but are less harmful, using bark, roots and wood to colour and preserve are growing in popularity.

2. Traceability

Ask questions and look for supply chain transparency back to the slaughter house- where the leather is coming from and where the hide is processed.

3. Forests

Deforestation is an issue within the leather industry, due to clearing for cattle ranches. See if you can check where the hides come from to ensure they are not sourced from protected lands or areas that have been newly cleared.

4. Water treatment

Look for tanneries with water effluent treatment facilities to ensure proper treatment and discharge of water containing pollutants and hazardous chemicals.

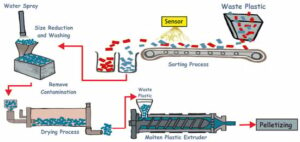

5. Leather alternatives

Explore sourcing either recycled or upcycled leather or consider leather alternatives such as mushroom, coconut or pineapple leather.

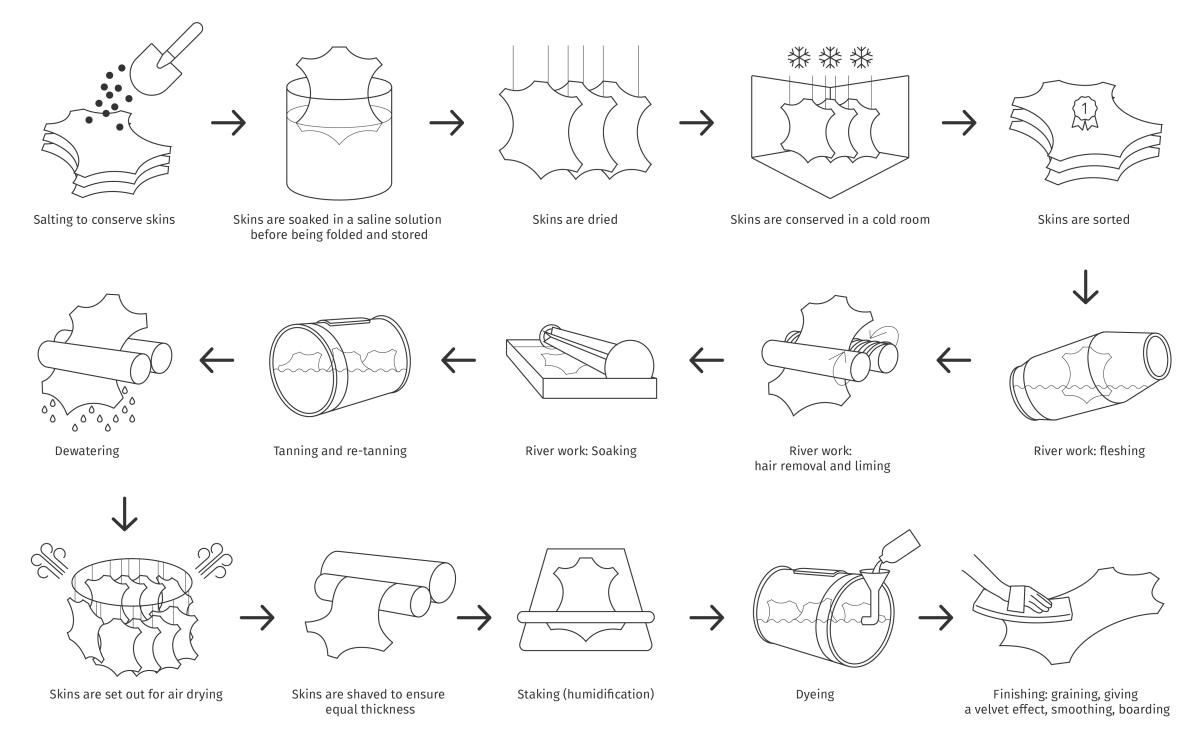

The production process of leather

1. Curing / Salting

This is where the raw-hide is dehydrated to preserve it. Salt is immediately added to the freshly removed hide to remove water and dry the skin.

2. Rewetting

The hide is then soaked to restore the moisture and to remove dirt, debris, and excess fat, to clean the skins

3. Dehairing & Defleshing

The hide is passed through a machine to remove all unwanted parts left attached to the skin such as fat, muscle, and excess flesh and different rollers or blades then remove hair. The fibres of the skin are loosened and the skin becomes more absorbent and ready for tanning.

4. Splitting

To achieve a uniform thickness, leather is split horizontally into two layers. The top layer is the grain side and bottom is suede or split leather. Some leathers are surface dyed, whilst others need dyes to completely penetrate. Skins are sorted according to species / races, weight and quality.

5. Pickling

In drums, the hide is treated with enzymes to remove non-fibrous proteins to enhance the smoothness of the skin and then soaked in acids and salts for preservation and in sulphuric acid to lower the pH. This also helps to prepare for the tanning stage as it allows more penetration of the tanning agents.

6. Tanning

Using vegetable or chrome tannins, the raw-hide is put into drums again to go through the tanning process and transform into stable material. Tanning to transform the skin into leather thanks to tannins which are plant, mineral or combined substances used to transform putrescible skins into a rot-proof material, leather.

7, Drying/ Wrought Ironing

The hide is then stretched, smooth and dried to remove water content. Drying is achieved by various methods such as hanging, drying tunnels and drying machines.

8.Grading

After being buffed, brushed and finished, the leather is graded on colour uniformity, softness, thickness and natural defects before being sent out.