What is Fully drawn yarns (FDY) ?

FDY also know as FOY is a type of highly drawn polyester filament yarns that can be used to produce high-strength fabrics and textiles. The fabrics and textiles made from bright FDY have a bright luster. FDY is typically used to produce fabrics and textiles for high-end undergarments, high-end sportswear and sports shoes, and home furnishings. FOY/ FDY is produced by a process similar to POY manufacturing except that the yarn is produced at even higher spinning speeds coupled with intermediate drawing integrated in the process itself FDY can be used directly in weaving and knitting, especially for warp weaving.

Polyester Partially oriented yarns (Polyester POY)

POY is a type of partially drawn polyester filament yarns, which is the primary form of polyester filament yarns directly made through polymerizing and spinning processes. It is primarily used as a main raw material for DTY.

Our POY is primarily used by us as raw materials for the production of DTY through twisting and partially used directly in weaving and knitting. . To the extent our POY was not consumed by our DTY production capacity, it had been sold separately as end products.

Draw textured yarns (DTY)

DTY is a type of polyester filament yarns produced by processing POY through a texturing process. This process disperses, curls, and entangles the filaments composing the POY yarn, which gives DTY a fluffy appearance and gives it the properties of both natural fiber and synthetic fiber. DTY is typically used to produce fabrics and textiles for high-end apparel, high-end sportswear, high-end sports shoes, high-end sports bags, home furnishings, and zipper tapes.

DTY is a finished product from POY, simultaneously twisted & drawn. It is widely used in knitting and weaving.

Draw Texturised Yarn (DTY) is manufactured by texturizing partially oriented yarn using texturizing machines. Polyester DTY yarn is a continuous filament yarn that has been processed to introduce durable crimps twists, interlaces, loops. Yarns made from thermoplastic materials can be textured by heat setting in a twisted condition, which results in polyester DTY yarn of greater bulk, higher stretch, and more pleasing aesthetics. DTY is available in semi-dull, Full Dull, and bright DTY finishes.

- From 30D To 600D

- Recycle

- PTT

- Flame-retardant

- Anti-bacteria

- UV-cut

- Sea-island

- Low Melt Yarn

- Hollow

- Cationic & CD and SD

- RW – RAW WHITE

- DDB – DOPE DYED BLACK

- SD – SEMI DULL

- TBR – TRILOBAL BRIGHT

- FD – Full Dull

Polyester staple fiber (PSF)

PSF is a material formed by continuous or discontinuous threads, and it plays an important role in maintaining the tissue of animals or plants. Fiber is widely used as it can be weaved into threads, thrums, and or into the fibrous layer for paper or felt; and meanwhile, it is also used to produce other materials or formed into composite materials with other materials.

Polyester staple fiber is a short curly fiber suitable for mixing with cotton or other fibers such as rayon, acrylic, nylon, wool, ramie, etc. in spinning yarns for weaving and knitting. It is also an essential component for non-woven products and filling. Through spinning, weaving, knitting, and various non-woven processes, staple fiber can be transformed into the varietal textile and non-textile products commonly used in our daily life.

PTA

PTA has the form of a white, crystalline powder and looks like powdered sugar. It is quite inert, which means that, for example, it is difficult to dissolve in water or other liquids. PTA is an aromatic acid, primarily applied in the production of polyester. The main raw material for PTA is paraxylene (PX).

PTA is the down-stream product of petroleum. Light gasoline (also known as “petroleum naphtha”) can be produced from the petroleum through a certain process, MX (Mixed Xylene) can be extracted from petroleum naphtha, and then PX (paraxylene) is extracted. With PX (accounting for 65%-67% in the formula) as raw material and acetic acid as solvent, PTA produces crude terephthalic acid by air oxidation (with 35%-33% oxygen) under the action of the catalyst. Then, crude terephthalic acid is hydroformed to remove the impurities, then crystallized, separated, and dried to form pure terephthalic acid products, namely finished PTA products. Synthetic Resin.

Polyester chips (PET chips)

Polyester chip is the raw material used in the production of polyester fiber, filament yarn, and other polyester products.

PET (polyethylene terephthalate) chips are produced by granulating polyester formed in a polycondensation reaction of pure terephthalic acid and mono ethylene glycol. They are manufactured for textile applications and are supplied to the yarn-producing industry in semi-dull and super-bright.

The balancing stream of the polymer melt from the polycondensation section is discharged through metering pumps to the casting head. The molten ribbons coming out of the casting head are taken on the cooling chambers of the chips cutter where the molten ribbons are cooled by a chilled DM water system. The solidified polymer ribbons are then cut in a chips cutter and dried in the dryer. The dried chips are then passed through the classifier. The properly cut chips are stored in a chips silo. The chips are conveyed to the bagging silo for bagging.

What is Polyester Chip?

Polyester chips are made by mixing TEREPHTHALIC ACID and ETHYLENE GLYCOL, which are the main materials, at a certain ratio.

Polyester chips are made by melting the above two materials to make POLYMER, then drying and cutting them again.

When polyester chips are melted, Polyester filament yarns and short fibers are made.

For Textile Grade

PET Chips used in Textile Industry are also known as Fibre grade PET chips, filament-grade PET chips, or textile-grade PET chips. Textile grade PET Chips are used for making Polyester Filament yarn like POY, FDY, and Staple fiber used widely in the Textile industry.

The Yarn grade or Textile grade chips are available in Super Bright (BR Chips), Semi Dull (SD Chips), Cationic Semi Dull, and Cationic Super Bright PET Chips (CD Chips). The process of making PET Chips consists of mixing a thermoplastic polyester-resin material with an alumina tri-hydrate (ATH) filler and with a pigment, if desired, in a heated extruder to produce a continuous stream of the thermoplastic agglomerate. This product is allowed to cool, then it is cut, ground, and screened to a predetermined size, as required to meet the size characteristics of the desired resin-chip product.

PET Chips used in Textile Industry are also known as Fibre grade PET chips, filament-grade PET chips, or textile-grade PET chips. Textile grade PET Chips are used for making Polyester Filament yarn like POY, FDY, and Staple fiber used widely in the Textile industry.

They have the following characteristics :

- High Reaction Speed – low thermal degradation, bright whiteness, resistance to yellowing and deterioration.

- High Degree of Polymerization – high crystalline regions, concentrated molecular weight distribution.

- Diversified Packaging – Can be packaged and shipped according to customers’ specific requirements.

For Bottle Grade

The end use of Bottle grade chips mainly depends on the Intrinsic Viscosity (IV). PET Chips with IV 0.80 is mainly used for drinking water bottles & mineral water bottles. PET Chips with IV 0.82 is mainly used in making bottles for carbonated drinks, small bottles for edible oil, liquor, medicines & pet sheets as they need better strength & a high finished product rate. PET Chips with an IV of 0.85 are mainly used for making big packing bottles for carbonated drinks & 3-5 gallons water bottles as these bottles should have good strength & resistance against high pressure.

Features of bottle-grade PET Chips are low processing temperature, wide scope in processing, excellent transparency, and high finished product rate. We can supply the best quality Bottle grade polyester chips from manufacturers & suppliers in China, Taiwan, & Korea.

For Film Grade

PET Chips, also known as Polyester Chips or Polyethylene Terephthalate Chips is the base of any type of plastics & polymer. Depending on the processing, PET may exist both as an amorphous (transparent) commonly known as Bright or Super Bright Chips and as a semi-crystalline material commonly known as PET Semi-Dull Chips.PET Chips are also used to make PET films. High-quality chips without Silica & CiO2 contents are used to make PET films.

The Film grade polyester chips are commonly available in Super Bright and Additive (Silica) varieties. The feature of film grade PET chips is excellent clarity as the film is made in very thin specification & even the slightest mistake in raw material can be harmful to the film quality. The film is available in two types, Viz.,1. Plain (both side untreated (UT) 2. One side Corona treated film (CT), Applications of film grade pet chips are Printing & Lamination, Metallization, Embossing, Holograms, thermal lamination.

We can supply you best quality Film grade Polyester chips from manufacturers & suppliers in China, Taiwan, Malaysia & Korea.

PET CHIP FOR TEXTILE FIBER

Properties

– Heat-resistant, high-IV

– Clear and transparent

– Excellent resistance to shock

APPLICATION

– Heat-resistant containers for juice, tea, and sports drinks

– Packaging sheet

TECHNICAL SPECS:

| Property | Units | Specification |

| Intrinsic Viscosity | dl / g | 0.80 ± 0.02 |

| Color Value | L | 81.5 ± 5.0 |

| Color Value | b | Max 0.0 |

| -COOH | eq/ton | Max 40 |

| D-EG | wt% | Max 1.5 |

| Melting Point | ℃ | 252.0 ± 2.0 |

| Density | kg / ㎥ | 1.400 ± 0.003 |

Bright CHIP / Semi Dull CHIP

FEATURES

– Good mechanical properties and consistent quality

– Uniform properties

APPLICATION

– Polyester filament

– Polyester staple fiber

– PET Sheet, film

SPEC – SD

| Property | Units | Specification |

| Intrinsic Viscosity | dl / g | 0.650 ± 0.007 |

| Color Value | L | 75.0 ± 3.0 |

| Color Value | b | 6.0 ± 1.5 |

| -COOH | eq/ton | Max 55 |

| D-EG | wt% | Max 1.2 |

| Melting Point | ℃ | 254.0 ± 2.0 |

SPEC – SBR

| Property | Units | Specification |

| Intrinsic Viscosity | dl / g | 0.660 ± 0.015 |

| Color Value | L | 57.5 ± 5.0 |

| Color Value | b | -5.0 ~ 0.0 |

| -COOH | eq/ton | Max 55 |

| D-EG | wt% | Max 1.2 |

| Melting Point | ℃ | 254.0 ± 2.0 |

RECYCLE CHIP

FEATURES

– Competitive cost and various application

APPLICATION

– Regenerated Polyester staple fiber

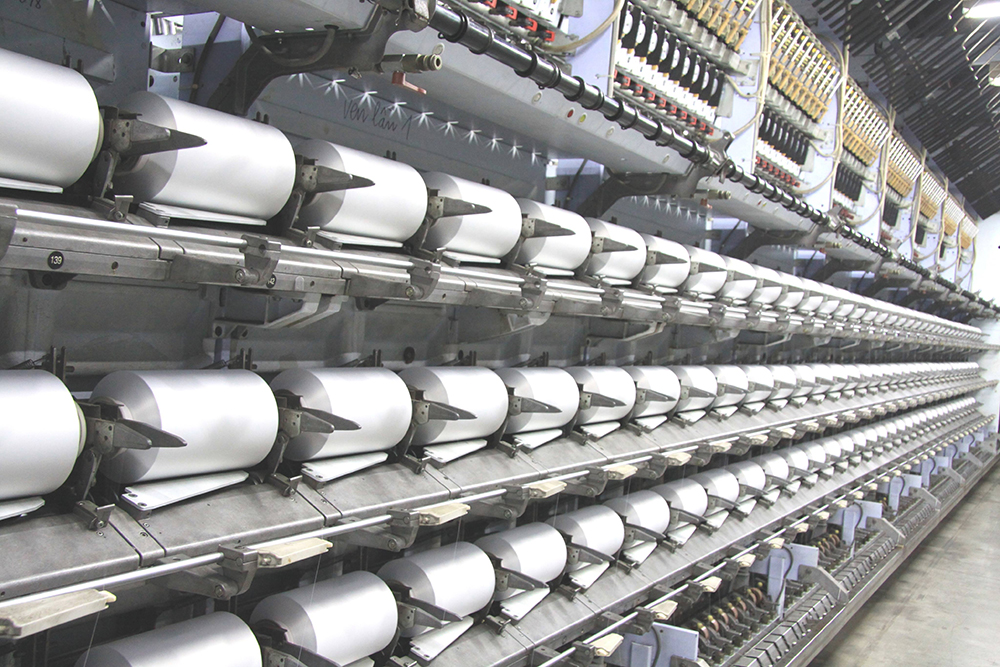

What is Polyester filament yarn

Polyester filament yarn is a thin yarn produced by spinning a liquid polymer through a fine nozzle.

Polyester is the most used artificial fiber as clothing material with excellent elasticity, resilience, and heat processability and is easy to manage.

It is also processed into fibers that have similar or better performance than natural fibers such as cotton, wool, and linen. It is also being developed into quick drying, cold-feeling, and antibacterial yarn.

As the demand for sustainable textile increases, we at VNPOLYFIBER have decided to contribute to the endeavour by producing polyester fibers from PET flakes and PET chips which are made from waste recycled bottles. We endeavour to contribute to the new world’s efforts toward Reducing, Reusing and Recycling sustainable fabrics.

Our Process Revolves Around Using Recyclable Waste PET Bottles To Produce Fiber That Can Be Used Into Bedding Stuff and Nonwoven Industry.

Waste PET bottles are thoroughly cleaned, sorted, de-capped and processed into flakes

Polyester chips are turned into high-grade flakes and are further made into fiber filament polyester yarn

The resulting fiber is ready to be made into fiberfilling or OE yarn or Ring Spun yarn.

All of our products are certified by Global Recycle Standard (GRS).

Recycling one plastic bottle saves energy to power a light bulb for an hour

We can reduce PET bottles in oceans to make clothes, shoes, bags instead of just throwing them away.

By recycling waste PET bottles to make polyester fibers , We use 90% less water, 66% less energy and emit 26% fewer greenhouse gases.

All of our fiber product ranges meet the international recycle standard norms and are certified by Global Recycle Standard (GRS).

Strict quality checks meet the necessary quality requirements of the sportswear and knit industry.

Due to consistency in raw material and production hardware, we ensure uniformity in quality within the batch and from batch to batch.

We will reply to your inquiry within 24 working hours. Thank you for your cooperation!

Our business partner is one of the biggest and the best manufacturer in China’s polyester industry, specialized in PTA with annual capacity of 5 million MTS, polyester staple fiber (PSF) with annual capacity of 1.2 million MTS and polyester filament yarns including partially oriented yarn (POY), fully drawn yarn (FDY) and drawn texturized yarn (DTY) with annual capacity of 6.3 million MTS. The total annual capacity is 12.5 million MTS.

It is equipped with the world’s state-of-the art technology and machines including Dupont and TMT and Neumag and Barmag,

It has been exporting to more than 90 countries and regions since the year of 2004 with excellent qualtiy and customer service.