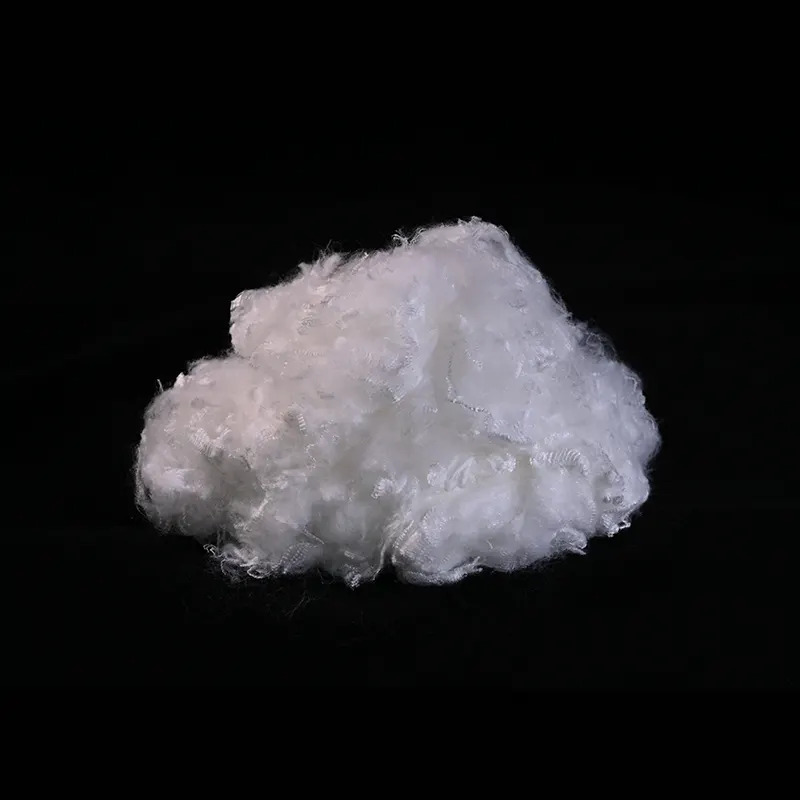

What is biodegradable fiber?

Biodegradable means that it can be biodegraded using micro-degradable materials. It is often connected with biodegradable materials.

Biodegradable materials refer to materials that can be completely decomposed into low-molecular compounds by microorganisms (such as bacteria, fungi, and algae, etc.) under appropriate and definite natural environmental conditions.

Fully biodegradable materials can be completely decomposed by microorganisms and have a positive effect on the environment.

While human beings create modern civilization, it also brings negative impacts—white pollution. Disposable tableware, disposable plastic products, and agricultural mulch are difficult to recycle, and their treatment methods are mainly incineration and landfill. Incineration will produce a large amount of The harmful gases pollute the environment; if buried, the polymers in it cannot be decomposed by microorganisms in a short time, and also pollute the environment. Residual plastic films exist in the soil, hindering the development of crop root systems and the absorption of water and nutrients, making the soil The air permeability is reduced, resulting in crop yield reduction; after eating the discarded plastic film, it will cause intestinal obstruction and death; synthetic fiber fishing nets and fishing lines lost in the ocean or discarded in the ocean have caused considerable damage to marine life.

Therefore, it is imperative to promote green consumption and strengthen environmental protection.

What are the factors for degradation of Biodegradable fiber

Biodegradable fiber does not mean that it is completely environmentally friendly and can be completely degraded. First, it must choose an appropriate environment to degrade. If it is stored in an improper environment, it may cause environmental pollution and threaten groundwater. Then there are many factors that affect the degradation. If these factors change, it will also affect the degradation.

Effect of pH value on biodegradable fiber

Mader et al. believe that the change of pH value has a great influence on the hydrolysis rate of the copolymer chain, but the degradation rate is not very different in different parts of the organism. The degradation of the copolymer can form an acidic microenvironment, which promotes the self-catalysis of the copolymer, which leads to the acceleration of its degradation.

Effect of temperature on biodegradable fibers

In experiments, it is rare to see the relationship between the degradation of materials and temperature, because in vitro experiments are often carried out by simulating body temperature, and the body temperature does not change much. However, in the process of in vitro experiments, sometimes for the needs of the experiment, the temperature can be raised appropriately to shorten the experiment period. However, during the accelerated degradation process, the temperature should not be too high or too low, because the polymer will have side reactions when the temperature is too high; when the temperature is too low, the purpose of accelerated degradation cannot be achieved. Therefore, in order to avoid the influence of temperature and air flow on biodegradable fibers, biodegradable fibers are stored in a low-temperature sealed environment.

Effect of molecular weight on biodegradable fibers

Wu et al. believed that the hydrolysis rate of the material was significantly affected by the molecular weight and distribution of the copolymer. This is mainly because each ester bond may be hydrolyzed, and the ester bond hydrolysis on the molecular chain is irregular. When the polymer molecular chain is longer, the more sites it can undergo hydrolysis, the faster the degradation. .

Effect of material structure on biodegradable fibers

Anhydrides and orthoesters are easily hydrolyzed. Li et al. believed that the quality and molecular weight of the comb copolymer decreased rapidly due to the polarity of the skeleton, which was conducive to the cleavage of the ester bond. Therefore, the degradation rate of the comb molecular copolymer is larger than that of the linear molecule.

The effect of monomer composition ratio on biodegradable fibers

The degradation behavior of materials is related to the physical and chemical properties of materials. The polarity, molecular weight and distribution of polymers all affect the degradation performance of materials. After research, Wu et al. believed that the degradation of the copolymer had a great relationship with the molecular weight and crystallinity of the copolymer. For example, the crystallinity of glycolide and lactide copolymers is lower than that of the homopolymers of the two monomers. Glycolic acid is more hydrophilic than lactic acid. Therefore, the hydrophilicity of PGLA copolymer containing more glycolide is better than that of PGLA copolymer rich in lactide, so the degradation rate is faster. The hydrophilic polymer has a large water absorption capacity, and the internal molecules of the material can fully contact with the water molecules, and the degradation rate is fast. On the contrary, the internal molecules of hydrophobic polymer materials have less contact with water molecules, and the degradation rate is slow.

Effect of enzymatic hydrolysis on biodegradable fibers

Many reactions in living organisms lead to the degradation of polymers, including oxidation, chemical hydrolysis, and enzymatic reactions in body fluids. Hollald et al. believe that in the early glass state, enzymes are difficult to participate in the degradation, but enzymatic hydrolysis is the main factor affecting the copolymer in the rubber state.

Effect of polymer affinity/hydrophobicity on biodegradable fibers

Hydrophilic polymers can absorb a large amount of water, and the degradation rate is accelerated; hydrophobic polymers absorb less water, and the degradation rate is slow. Especially polymers containing hydroxyl and carboxyl groups are relatively easy to degrade