What is hollow fiber or hollowfibre?

Hollow fiber duvets get their name since they’re made from fibers that have space between their knotting. The ‘hollow’ space between the fibers helps to ensure that the duvet is breathable and also means it’s higher than many other comparable duvets filled with alternative synthetic fillings.

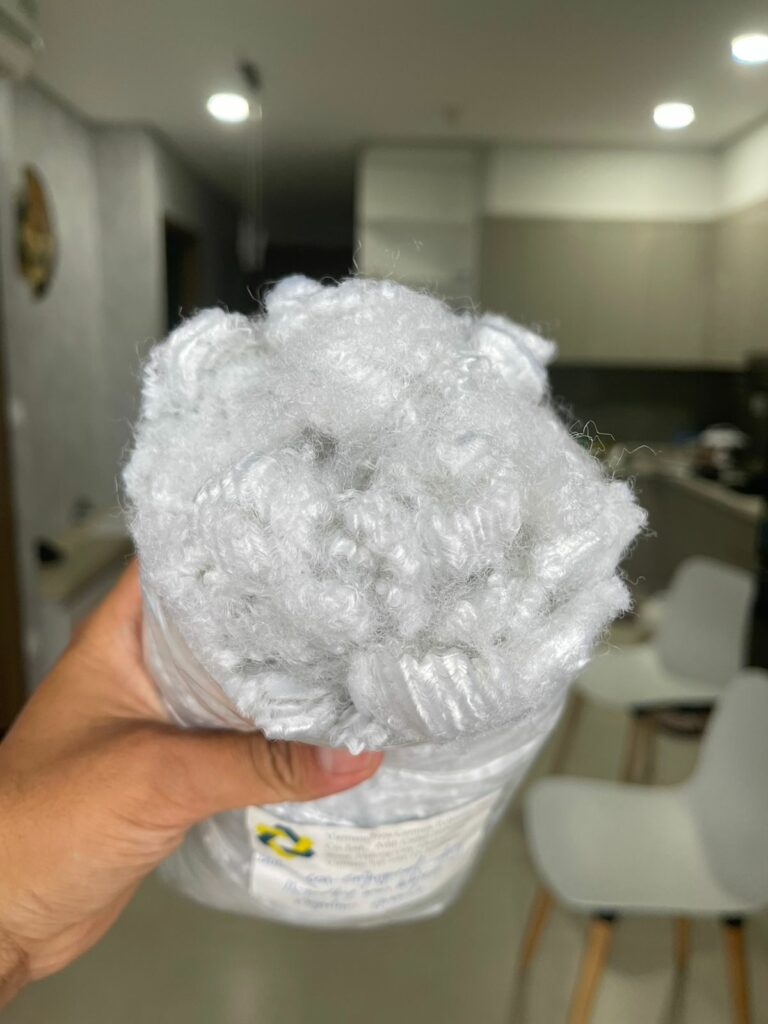

Hollow Fiber is a synthetic polyester material used for the filling in duvets and pillows (amongst other things). With a dense structure, Hollow Fiber has a full, springy feeling that creates lightweight puffy duvets and pillows.

Hollow Fiber is a synthetic, or ‘man-made’ material similar in appearance to candy floss. The fibre is soft and bouncy, making it a perfect filling for pillows and duvets. It is durable, long-lasting and fully machine washable, the most popular filling choice for most duvets.

It is also ideal for allergy sufferers. Synthetic, or ‘non-allergenic’ duvets are hypoallergenic – the only real option for those who suffer from allergies to feathers or down, but also those allergic to dust mites. Hollow Fiber duvets and pillows can be machine washed at 60 degrees, killing dust mites and bacteria. The hollow, synthetic fibres also take away any sweat and can be washed much more regularly than natural fillings.

What are the benefits of hollow fiber?

There are many benefits to using hollow fiber. Here are the top reasons for it being so popular for bedding:

- Value for money – hollow fiber is a very affordable material and its high quality makes it fantastic value for money.

- Maintenance – This material requires low maintenance as it is usually machine washable and easy to dry. It also doesn’t require as much fluffing and re-arranging as some feather and down products do.

- Lightweight – This is a lightweight material that is airy and won’t weigh you down.

- Breathable – The hollow spaces allow the fabric to breathe and won’t stifle you in the night.

What is Microfiber?

Microfibers are finer than any fiber in nature.

First used in functional sportswear, it was not long before they became fashionable as well.

Microfibers are well suited for blending with other man-made and natural fibers.

Around the world at two kilos.

Silk, the finest natural thread we know, sets the benchmark for measuring fibers: it is 1 dtex (decitex), meaning that one gram of fiber is 10,000 meters long.

The man-made fiber industry has now succeeded in producing even finer ones.

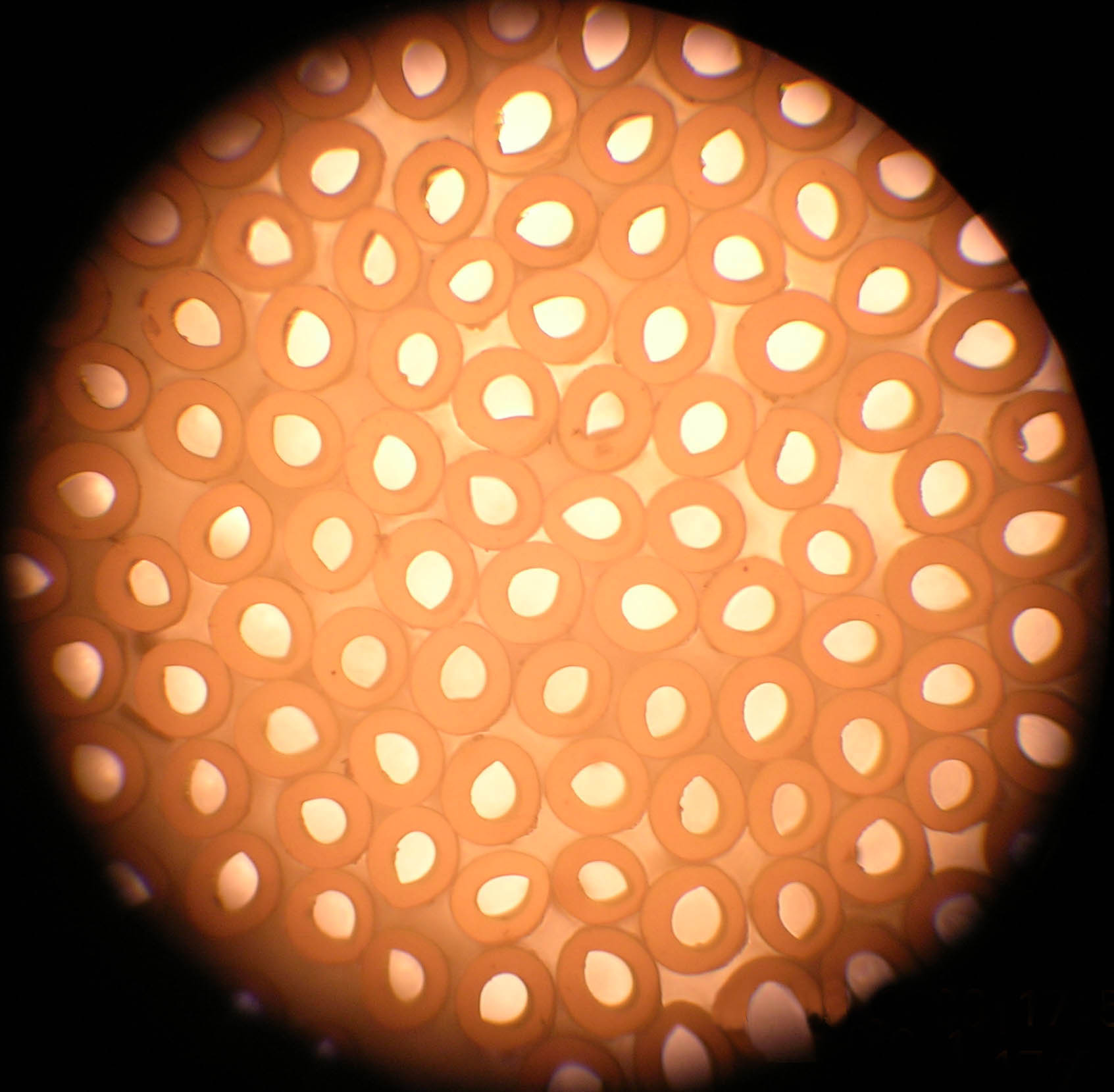

Microfibers are usually made of polyester, polyamide, or acrylic – with titers in the range of 0.5 to 1.2 dtex.

Just under three kilos of this thread would be enough to go round the globe at the equator.

Microfibers can be twice as fine as silk, three times finer than cotton, some six times finer than wool, and sixty times finer than a human hair.

These very fine threads are “bundled” into filament yarns or cut to a certain staple length, before being spun into yarn.

The use of Microfibers gives a much higher volume for the same weight. This explains the particular advantages of Microfibers : Textiles made from them have very high thread density.

This means they have a much higher number of air chambers and tiny pores, allowing the skin to breathe and the body to regulate temperature more easily.

Microfibers is made up of fine fibers which are tightly woven together, allowing no space between them.

This material is also synthetic and made up of 100% polyester.

Whereas traditional hollow fiber duvets are made from a filling that has fibers with hollow space between them, microfiber duvets have very fine fibers which are tightly woven and without the hollow space. Microfiber duvets offer the ultimate warmth due to their tightly packed fibers and you’ll find that most come treated with an anti-allergy coating which will ensure they’re the perfect choice for those suffering from allergies. Of course, microfiber duvets are also lightweight compared to natural filled duvets and are one of the most popular synthetic fillings currently on the market. Microfiber provides warmth without the weight and as such, duvets with a Microfibers filling can be very light yet warm.

Characteristics of microfiber

Microfibers are made solely from man-made fibers. They are the finest of all the fibers.

Sportswear from Microfibers functions particularly well. It is breathable and at the same time provides reliable protection against wind and rain.

Fashionable apparels in Microfibers have a graceful flow, silk-like feel, and are extremely comfortable.

Microfiber clothing is not sensitive, retaining its positive qualities after washing or cleaning.

@tonytan91 #polyesterstaplefibberpillow #psf #polyesterfiber #polyester

What are the benefits of microfiber?

Microfiber has some similar benefits to hollow fiber. Here is why it’s such a great option for your bedding:

- Affordability – Although it is not typically as inexpensive as hollow fiber, it is still fantastic value for money.

- Maintenance – This is also a low-maintenance product. All of our microfiber products are machine washable and easy to dry.

- Warmth – Because the fibers are so tightly woven together it will keep you nice and warm all through the night.

- Soft as down – The fine fibers of microfiber give a soft and silky feel. This makes it a great substitute for feather and down products.

What is the difference between hollow fiber and microfiber?

Hollow Fiber and Down Duvets fillings vs Microfiber Duvets

Hollow Fiber Filling Duvets

The first thing to mention about Hollow Fiber and other synthetic duvet fillings is the price. They’re cheaper. Quite considerably. This this value for money, however, can often comes with a shorter lifespan for your duvet, but that isn’t always a bad thing. It means you can afford to replace your Hollow Fiber duvet more often and, if we’re being honest, there’s nothing quite a nice as brand new bedding! Also, a good quality synthetic duvet, properly cared for, can easily last up to 10 years.

If you’re unlucky enough to suffer from allergies, eczema, asthma, rhinitis or are sensitive to dust, then hypoallergenic Hollow Fiber is should be your first choice.

Hollow Fiber duvets are very light, compared to feather and down duvets. Sometimes, natural filling duvets can feel very heavy, which certainly appeals to some, but not everyone.

Synthetic duvets are considerably easier to look after. They can be washed at higher temperatures (up to 60°) and quickly dried outside on the washing line or in your tumble dryer (assuming it’s big enough!). You don’t need to wash Hollow Fiber duvets before use, either, something that’s frequently recommended for feather and down filling duvets.

Down Duvet Filling Duvets

Feather and down filled duvets tends to be more commonly found in the ‘higher-end’ establishments, like five-star hotels. Whether this is any indication of being ‘better’ is a debatable point, but if you’re running a guest house or B&B, your guests might have an experience they consider more ‘luxurious’. This however, means that natural filling duvets tend to be considerably more expensive than Hollow Fiber.

Feather and down duvets are more ‘breathable’, meaning they will absorb more of the moisture in the bed. This moisture, of course, can’t just stay there and natural duvets will need airing regularly to release this moisture. Regular airing is precisely the same for synthetic fillings, however the duvet will not absorb as well as feather. Natural filling duvets are a little more difficult to clean and dry, requiring much lower temperatures and long drying times.

Natural filled bedding is a lot more durable than synthetic. It will accept considerably more ‘wear and tear’ and in some cases, can last up to three times longer than a synthetic filled duvet. A premium quality feather/down filled duvet could last as long as 30 years.

Feathers are biodegradable, so better for the environment (although the birds contributing their feathers may disagree). Synthetic filling duvets are not biodegradable and need to be disposed of in a responsible manner, like any other synthetic materials.

A feather/down will need a thorough wash before used, as the feathers can be quite dirty and greasy, until washed properly. Hollow Fiber filling duvets can be used straight out of the box (bag/wrapper/etc.). Washing is an all-round pain, compared to synthetic filled duvets.

Microfiber Filing Duvets

The most popular type of duvet fill is made of synthetic fibres. There are so many on the market and they can be found for sale at all major retailers. Whatever your preference, we have all slept under a synthetic duvet at some point. Synthetic duvets are often categorised as those with polyester Hollow Fiber or Microfiber fillings.

Many people find them a great alternative to duvets with natural fillings such as feather or down – they are cheaper, easier to care for and often have better hypo-allergenic properties. They don’t last as long though, can make you hot and sweaty, or a little bit chilly as they don’t have such good breathable or insulating properties. However they’re an easy, affordable lightweight duvet solution, particularly for families.

Microfiber duvets are better than Hollow Fiber duvets – they are less sweaty and they drape better over the bed. You will tend to pay a bit more for them though – but often it’s negligible – these are still some of the cheapest duvets in stores.

Technically, the key difference is that micro fibres are much finer than hollow fibres giving a lighter, more luxurious feel. Whereas the hollow fibres are thick and wiry strands of polymer (with a hollow centre) which are more hard wearing and are often treated with anti-allergy chemicals. These differences in practice mean that Microfiber duvets tend to be softer and give a bit more of a ‘down’ type of feel, whereas Hollow Fiber duvets are more springy and hold their shape. Micro fibres also wick moisture from the body, keeping you dryer at night – we tend to get a little sweatier at night under a synthetic duvet compared to down or feather.

Read more :

https://vnpolyfiber.com/hollow-polyester-fiber-vs-down-and-feather/

https://vnpolyfiber.com/pillow-types-and-classifications-all-you-need-to-know/

https://www.barnhardtcotton.net/blog/know-fibers-wovens-vs-nonwovens-knit-fabrics/

https://sleepypeople.com/the-difference-between-microfibre-and-hollowfibre-duvets/

Source from: Industrievereinigung Chemiefaser e.V.