One year ago, Textile Exchange challenged over 50 textile, apparel, and retail companies, including Adidas, H&M, Gap, and Ikea, to increase their use of recycled polyester by 25 percent by 2020. The challenge was successful, and last month, the organization issued a statement celebrating that signatories have not only met the goal two years before the deadline, but they have actually exceeded it by upping their use of recycled polyester by 36 percent . In addition, twelve more companies have pledged to join the challenge this year . The organization forecasts that 20 percent of all polyester will be recycled by 2030 .

It’s encouraging to see companies taking steps to reduce their environmental impact and embrace more sustainable practices. By increasing the use of recycled polyester, we can help to reduce plastic waste and protect our planet’s oceans. It’s important to be mindful of the environmental impact of our clothing choices and consider more sustainable options when possible.

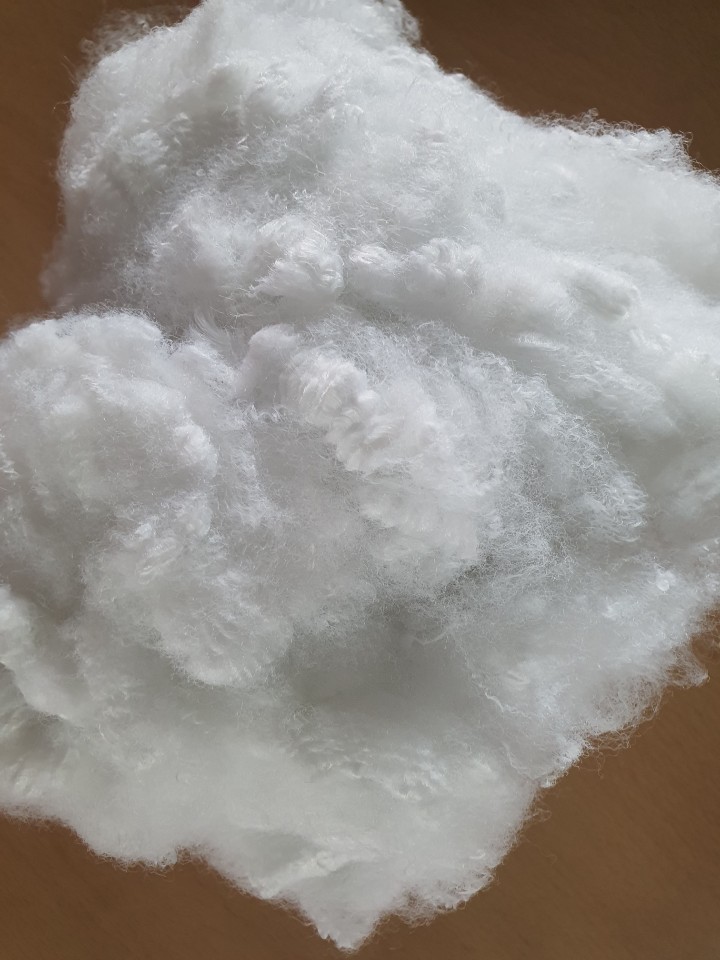

Recycled polyester, commonly referred to as rPET, is produced by melting down pre-existing plastic and transforming it into fresh polyester fiber. While there is often a focus on rPET derived from plastic bottles and containers discarded by consumers, it is important to note that polyethylene terephthalate can be recycled from both industrial and consumer sources. For instance, five soda bottles can provide enough fiber for a single extra large T-shirt.

Advantages of recycled polyester

Addressing the issue of plastic waste

Recycled polyester provides a sustainable solution for diverting non-biodegradable materials away from landfills and the ocean. Research from the NGO Ocean Conservancy highlights the alarming amount of plastic entering marine environments annually, with projections indicating a potential imbalance between plastic debris and marine life by 2050. The impact of plastic pollution is evident in the detrimental effects on seabirds and sea turtles, as they often mistake plastic for food.

Furthermore, statistics from the United States Environmental Protection Agency and the European Union underscore the significant volume of plastic waste generated and disposed of in landfills each year. The fashion industry contributes to this problem, with reports estimating a substantial amount of clothing ending up in landfills annually. Karla Magruder, a Board Member of Textile Exchange, emphasizes the importance of repurposing plastic waste into valuable materials for the benefit of both humans and the environment.

rPET, or recycled polyester, is a sustainable alternative to virgin polyester, offering similar quality with significant environmental benefits.

A study by the Swiss Federal Office for the Environment found that rPET production uses 59 percent less energy compared to virgin polyester. Additionally, WRAP estimates that rPET production reduces CO2 emissions by 32 percent in comparison to regular polyester.

Not only does using recycled polyester help to conserve resources and reduce energy consumption, but it also minimizes our reliance on petroleum-based raw materials. Brands like Patagonia emphasize the positive impact of using recycled polyester in terms of waste reduction, landfill preservation, and promoting new recycling practices for old polyester clothing.

With polyester accounting for a large portion of global PET production, transitioning to a non-virgin supply chain for polyester fiber, as advocated by brands like Nau, has the potential to significantly reduce energy and resource demands on a global scale.

Disadvantages of recycled polyester

Recycling in the textile industry faces challenges due to the composition of garments, as many are made from blends of polyester and other materials, making recycling more difficult or even impossible. Certain finishes and laminations on fabrics can further complicate the recycling process.

Even garments made from 100 percent polyester have limitations in terms of recyclability. The process of recycling PET (polyethylene terephthalate) can be done mechanically or chemically, with mechanical recycling being the more common and cost-effective method. However, mechanical recycling can result in a loss of strength in the fiber, necessitating a blend with virgin fiber.

There is a misconception that plastics, including polyester, can be infinitely recycled without degradation. However, each recycling process degrades the polymer, leading to the production of lower quality products over time. Despite claims from organizations like Textile Exchange that recycled polyester garments can be continuously recycled without a loss of quality, there are concerns about the overall sustainability of polyester production and recycling.

Some experts argue for a reduction in the use of plastic in general, urging for a shift towards natural fibers like cotton, hemp, and wool, which have lower environmental impacts compared to polyester. While recycled polyester (rPET) does have a lower energy footprint than virgin polyester, it still requires more energy than natural fibers.

In light of these considerations, there is a growing call for fashion brands and consumers to prioritize sustainable materials and production methods, moving away from an over-reliance on polyester and disposable plastic goods. Despite the potential for recycled polyester to play a role in a circular economy, the broader impact of polyester production and recycling processes should be carefully evaluated.

The environmental impact of the recycling process for PET materials is a topic of concern.

It has been noted that the chips produced through mechanical recycling can vary in color, leading to challenges in achieving consistent coloration. This inconsistency may result in dyers resorting to chlorine-based bleaches to whiten the material, increasing water, energy, and chemical usage in the process.

Additionally, there have been studies indicating that PET bottles may release antimony, a substance with potential carcinogenic properties. While health agencies assert that the quantities are too minimal to pose a threat (500 mg/kg PET), finding alternatives to antimony remains a key challenge in the recycling of PET materials.

Furthermore, there is ongoing discussion in the academic community regarding the calculation of CO2 emissions when comparing virgin polyester with recycled PET. The current assessment methods do not account for the environmental impact of the fiber’s initial production, which could potentially alter the results. This issue has been highlighted in a report by the Swiss Federal Office for the Environment.

Potential Environmental Impact of Recycled Polyester

Additionally, it is important to consider the potential impact of recycled polyester on the environment. Some argue that recycled polyester may not completely prevent plastic waste from entering the ocean, as man-made fabrics have the potential to release microscopic plastic fibers known as microplastics. Research conducted by Plymouth University in the UK has shown that a single cycle of a washing machine can release over 700,000 plastic fibers into the environment. Furthermore, a study published in the journal Environmental Science Technology in 2011 revealed that microfibers account for 85 percent of human-made debris found on shorelines worldwide. Whether garments are made from virgin or recycled polyester, both types of fabrics have the potential to contribute to the issue of microplastic pollution.