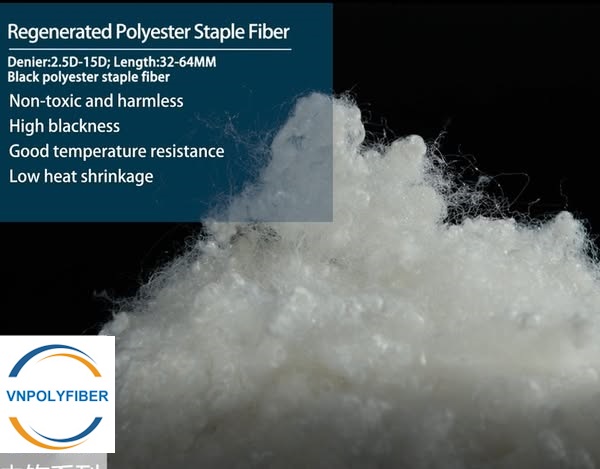

Virgin Micro Denier Fiber

- Hollow PSF has better loft, recovery and warmth retention property than solid PSF, because there is a hole in single fiber, it can save some air.

- Our hollow PSF is easy to be carded and good at bonding with low melting fiber.

- It’s mainly used for fiberfill, filtration, padding, wadding, insulation etc.

Specification

- Denier: 6D-15D

- Type: Hollow Mechanical crimp

- Grade: Recycle, First quality

- Color: white, optical white,

- Cut Length: 32mm-76mm

- Finish: silicon, slick, dry, FR, antibacterial, low shrinkage

- Application: Filling, Wadding, fiberfill, insulation, filtration etc.

PRODUCT DETAIL

What is Micro Denier Fiber

Micro denier fibers are defined by their exceptionally fine diameter, typically less than 1 denier per filament. Denier, as a reminder, is a unit of linear density, indicating the weight of a fiber in grams per 9,000 meters.

Key characteristics of Micro Fibers

- Softness and Silkiness: The small diameter of micro denier fibers creates a remarkably soft and silky texture, mimicking the feel of natural fibers like silk or cashmere.

- High Surface Area: The increased surface area-to-volume ratio enhances the fiber’s ability to trap air, providing excellent thermal insulation and breathability.

- Drape and Conformability: Micro denier fabrics exhibit excellent drape and conformability, allowing them to mold to the body’s contours for a comfortable fit.

- Enhanced Wicking Properties: The fine fibers create a capillary effect, efficiently wicking moisture away from the skin, promoting dryness and comfort.

- Lightweightness: Due to their small diameter, micro denier fibers contribute to lightweight fabrics, making them ideal for apparel and other applications where weight is a concern.

Applications of Micro Denier Fibers

- High-End Apparel: Micro denier fabrics are used in luxury clothing, including sportswear, outerwear, and intimate apparel, where softness, drape, and performance are paramount.

- Home Textiles: They are incorporated into bedding, upholstery, and cleaning cloths, providing a soft, luxurious feel and enhanced cleaning performance.

- Technical Textiles: Micro denier fibers are used in specialized applications, such as filtration media, medical textiles, and industrial wipes, where their high surface area and wicking properties are advantageous.

- Nonwoven Fabrics: They are used to make high quality nonwovens for applications such as filtration, or high end wipes

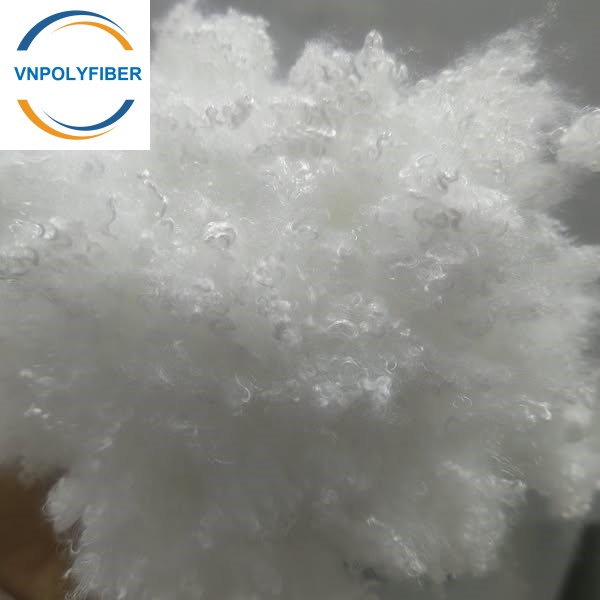

What is HCS Fiber

HCS fibers, or Hollow Conjugate Siliconized fibers, are engineered fibers characterized by their hollow core and conjugate structure. The hollow core traps air, providing excellent thermal insulation, while the conjugate structure enhances bulk and resilience. Siliconization, a surface treatment with silicone, further improves the fiber’s softness and smoothness.

Key characteristics of HCS fibers

- High Bulk and Resilience: The hollow core and conjugate structure create a lofty, voluminous fiber that resists compression, providing excellent cushioning and support.

- Excellent Thermal Insulation: The trapped air in the hollow core acts as a thermal barrier, providing superior warmth and comfort.

- Softness and Smoothness: Siliconization enhances the fiber’s softness and smoothness, improving its hand feel and comfort.

- Lightweightness: The hollow core reduces the fiber’s weight, contributing to lightweight products.

- Durability and Longevity: HCS fibers are highly durable and resistant to compression, maintaining their bulk and resilience over time.

Applications of HCS Fibers

- Bedding: HCS fibers are widely used in pillows, comforters, and mattress toppers, providing exceptional comfort, support, and warmth.

- Furniture: They are incorporated into upholstery and furniture padding, offering excellent cushioning and resilience.

- Stuffing and Filling: HCS fibers are used as stuffing for toys, cushions, and other filled products, providing a soft, lofty, and durable fill

- Filtration: Due to the high surface area, and the ability to create bulky non wovens, it is also used in some filtration applications.

Difference between Micro Denier and HCS Fiber

While both micro denier and HCS fibers contribute to enhanced comfort and performance, they differ significantly in their structure and properties:

- Diameter: Micro denier fibers are exceptionally fine, while HCS fibers have a larger diameter with a hollow core.

- Structure: Micro denier fibers are solid, while HCS fibers have a hollow core and conjugate structure.

- Properties: Micro denier fibers excel in softness, drape, and wicking, while HCS fibers excel in bulk, resilience, and thermal insulation.

- Applications: Micro denier fibers are primarily used in apparel and technical textiles, while HCS fibers are predominantly used in bedding, furniture, and stuffing.

The choice between micro denier and HCS fibers depends on the specific requirements of the application. If softness, drape, and wicking are paramount, micro denier fibers are the ideal choice. If bulk, resilience, and thermal insulation are crucial, HCS fibers are the preferred option.

Both micro denier and HCS fibers represent advancements in fiber technology, offering unique properties and benefits. Understanding their distinct characteristics and applications allows manufacturers to create products that meet the evolving demands of consumers and industries.

Technical Parameter

| Product type | Recycled Polyester Staple Fiber |

| Fineness | 7D / 15D |

| Cut length | 32mm / 51mm / 64mm |

| Luster | semi dull |

| COLOR | Raw white |

| Pattern | Hollow Siliconized & Hollow Non-Siliconized |

| Raw Material | 100% PET flakes |

| Grade | Recycled, AAA grade |

| Packing details | 250kg-350kg/PP woven bag/bale |

| Delivery time | 5-20days after 30% deposit |

| Payment Term | TT30/70; L/C at sight |

| MOQ | 1x40HQ; 22 – 23 tons/container |

| Quality | First quality |

Specifications of Polyester Staple Fiber Viet Nam

Denier Size: 3D, 6D, 7D, 10D, 15D

Cut length: 32mm, 51mm, 64mm, 76mm,

Feel: siliconised or non siliconised soft as well as harsh feel

Tensile strength: 3.5 to 4.5 gm/Denier

Elongation: 40 to 60%

Oil Pickup: minimum 0.20% to 0.35%

Crimps: 3 to 5 per cm

Shades: All shades available

Color Fastness: 4+

Quality: Hollow Conjugate Siliconised Fiber, Hollow Non-Conjugate Siliconised Fiber, Solid Fiber Siliconised/non Siliconised

Application: Cushions – Pillows – Quilts – Toys – Jacket – Mattress – Non woven carpet – Automotive felts, speaker felts, geo textiles, polyfill wadding, filter fabrics and other acoustics as well.

FAQ

1. What do you offer?

We produce recycled hollow conjugated siliconized and non-siliconized polyester staple fiber mainly, we can make hollow fiber (HS/ HD) and virgin polyester staple fiber HCS as well.

2. What is it used for?

Our fiber is widely used in filling, non-woven fabric

3. Are you a factory or a trading company?

We are a factory specialized in polyester staple fiber for many years but now we also have our own professional trading company. We will source many types of textile products such as yarn, PP fibers from others to supply our own customers as well. We also provide our own customers with other related products such as: Foam, Pillows, Cushions, Toys, Down/ Feather,…

4. Where is your factory location?

Our factory locates in the north and the south of Vietnam. You can visit us from Ho Chi Minh City and Hanoi City, Vietnam. You could contact our salesman to fetch you if visiting.

5. Can you accept free sample?

Yes, the hand sample is free when not exceed 1 kilograms. Upon price confirmation, we will provide a sample within 2-3 days; the freight cost will be charged to client.

6. Can you provide ODM service?

Yes, we work on ODM orders. Which means size, material, quantity, design, packing solution, etc, will depend on your requests, and your logo will be customized on our products.

7. How about your quality? What’s the minimum order Quantity (MOQ)?

Please try a trial order, you will know it. The MOQ is 23,000 Kilograms/order, but the price will be lower if you order bulk volume.

8. Can I mix different items in one order?

Sure, you can mix any products we can provide.

9. How can you guarantee the product quality?

We have experienced QC team. We control not only productive process but also raw material. In addition, we have different kinds of testing instrument to help us guarantee the product quality.

10. What’s the payment terms?

L/C at sight, 30% TT in advance are mostly accepted; other terms shall be negotiable by both sides

For more information, please feel free to contact :

Mr. Tony Tan

Mobile number: +84 90 466 5251 (Whatsapp/Wechat/Viber/Signal)