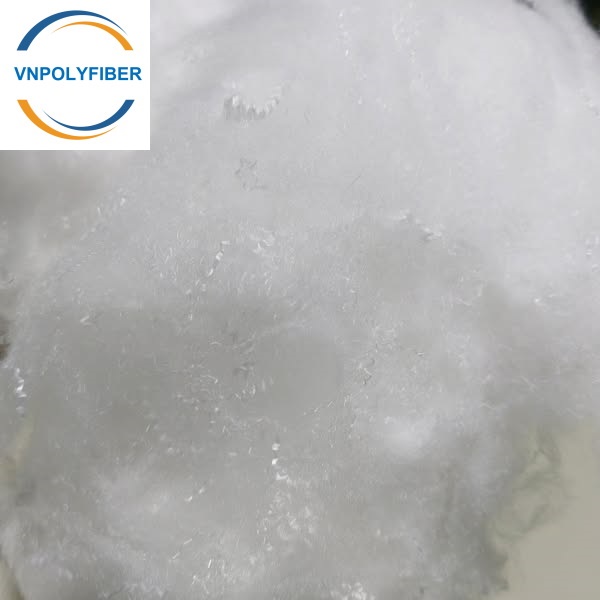

Virgin Low Melting Fiber White 4D x 51MM

Low melting fibers, also known as fusible fibers, are a type of synthetic fiber engineered to melt at significantly lower temperatures than conventional fibers like standard polyester. This unique property makes them invaluable in various industries, acting as a thermal bonding agent without the need for traditional adhesives. This eliminates the use of chemical binders, promoting a more environmentally friendly and sustainable manufacturing process.

PRODUCT DETAIL

What is Low Melting Fiber?

Low melting fibers, also known as fusible fibers, are a type of synthetic fiber engineered to melt at significantly lower temperatures than conventional fibers like standard polyester. This unique property makes them invaluable in various industries, acting as a thermal bonding agent without the need for traditional adhesives. This eliminates the use of chemical binders, promoting a more environmentally friendly and sustainable manufacturing process.

The Science Behind Low Melting Fibers

Typically, low melting fibers are bicomponent fibers, meaning they consist of two different polymers extruded together. One polymer has a lower melting point, forming the sheath, while the other has a higher melting point, forming the core. When heated, the sheath melts and bonds with adjacent fibers, creating a strong, cohesive structure. The core maintains the structural integrity of the fiber, preventing complete melting.

Common polymer combinations include:

- Co-polyester/Polyester (CoPET/PET): This is a prevalent combination, offering excellent bonding strength and durability.

- Polypropylene/Polyethylene (PP/PE): Used in applications where flexibility and moisture resistance are crucial.

The precise melting point of the sheath polymer is carefully controlled during manufacturing, allowing for tailored bonding properties.

Applications in Car Interiors

The automotive industry has embraced low melting fibers for their ability to create lightweight, durable, and aesthetically pleasing interior components.

- Headliners: Low melting fibers are used to bond the fabric facing to the foam backing of headliners. This eliminates the need for adhesives, reducing VOC emissions and improving air quality inside the vehicle. The resulting headliner is also more resistant to delamination and sagging.

- Door Panels: Similar to headliners, low melting fibers bond the fabric or leather covering to the molded substrate of door panels. This creates a smooth, seamless finish and enhances the overall durability of the panel.

- Carpets and Floor Mats: Low melting fibers are used to bond the carpet pile to the backing, creating a strong, wear-resistant floor covering. They can also be used in molded carpets, allowing for complex shapes and designs.

- Seat Covers: Low melting fibers can be incorporated into nonwoven fabrics used as seat cover backings, providing added stability and durability.

- Acoustic Insulation: Due to the ability to create bulky and stable nonwoven structures, low melting fibers are used for sound dampening in various areas of the vehicles.

Advantages in Car Interiors:

- Lightweighting: Reducing the weight of interior components improves fuel efficiency and reduces emissions.

- Improved Durability: Thermal bonding creates a strong, long-lasting bond, enhancing the lifespan of interior components.

- Enhanced Aesthetics: Low melting fibers allow for smooth, seamless finishes and complex designs.

- Reduced VOC Emissions: Eliminating adhesives minimizes the release of volatile organic compounds, improving air quality inside the vehicle.

- Recyclability: Using a singular polymer type, or compatible polymer combinations, improves the ability to recycle the interior parts.

Applications in Furniture

Low melting fibers play a crucial role in furniture manufacturing, offering a sustainable and efficient alternative to traditional bonding methods.

- Upholstery: Low melting fibers are used to bond fabric to foam or other padding materials, creating a smooth, wrinkle-free finish. They also enhance the durability and longevity of upholstery.

- Mattress Ticking: Low melting fibers are used to bond the ticking fabric to the quilting, creating a stable and comfortable sleep surface.

- Furniture Padding: Low melting fiber blended nonwovens are used to create padding that provides shape and support to furniture pieces.

- Nonwoven interlinings: Low melting fibers bond interlinings to the outer fabric, giving furniture added stability and structure.

Advantages in Furniture:

- Improved Comfort: Thermal bonding creates a smooth, even surface, enhancing comfort.

- Increased Durability: Strong, durable bonds extend the lifespan of furniture.

- Reduced Production Costs: Eliminating adhesives reduces material costs and simplifies the manufacturing process.

- Environmental Friendliness: Reduced VOC emissions and the potential for recycling contribute to a more sustainable furniture industry.

Applications in Nonwoven Fabrics

Low melting fibers are essential in the production of various nonwoven fabrics, offering a versatile bonding solution.

- Filtration Media: Low melting fibers create highly efficient filtration media for air and liquid filtration.

- Geotextiles: They are used in geotextiles for soil stabilization, erosion control, and drainage applications.

- Hygiene Products: Low melting fibers are used in diapers, feminine hygiene products, and other absorbent products.

- Medical Textiles: They are used in medical textiles for wound dressings, surgical gowns, and other applications.

- Automotive Interiors: As previously detailed.

- Construction: They are used in roof underlayments, and insulation.

Advantages in Nonwoven Fabrics:

- Versatility: Low melting fibers can be used to create a wide range of nonwoven fabrics with tailored properties.

- Cost-Effectiveness: Thermal bonding eliminates the need for expensive adhesives

- Enhanced Strength and Durability: Thermal bonds create strong, durable nonwoven fabrics.

- Improved Filtration Efficiency: Low melting fibers can create highly efficient filtration media.

- Customizable Properties: The properties of nonwoven fabrics can be tailored by adjusting the type and amount of low melting fiber used.

Environmental Considerations

The use of low melting fibers offers several environmental advantages:

- Reduced VOC Emissions: Eliminating adhesives minimizes the release of harmful VOCs.

- Energy Efficiency: Thermal bonding requires less energy than traditional bonding methods.

- Recyclability: Using compatible polymers improves the recyclability of finished products.

- Sustainable Materials: The availability of bio-based low melting fibers further enhances sustainability.

In conclusion, low melting fibers are a versatile and sustainable material that is transforming the automotive, furniture, and nonwoven fabric industries. Their unique bonding properties offer numerous advantages, including improved durability, enhanced aesthetics, reduced production costs, and environmental friendliness. As technology advances, the applications of low melting fibers are expected to expand further, contributing to a more sustainable and efficient future.

Technical Parameter

PET/COPET Low Melt Fiber

- Before Heating

- After Heating

- ES fiber is a bi-component fiber composed of low melt PE and hydrophobic PP which has excellent adhesion through core-sheath spinnerets.

- The fibers are widely applied for non-woven applied to mask, protective clothing, sanitary pad, diapers.

Video

FAQ

1. What do you offer?

We supply a comprehensive range of fibers, including recycled hollow conjugated (both siliconized and non-siliconized) polyester staple fiber, hollow fiber, microfiber, virgin polyester staple fiber, and low-melt fiber.

2. What is it used for?

Our fibers are versatile and widely utilized across both the filling and non-woven industries, providing essential loft, durability, and texture for various consumer and industrial applications.

3. Are you a factory or a trading company?

We are primarily a manufacturer specializing in polyester staple fiber with years of industry expertise. To better serve our clients, we also operate a dedicated trading division that allows us to act as a one-stop solution provider.

In addition to our own fiber production, we source high-quality textile components (such as yarn and low-melt fibers) and finished goods (including foam, pillows, cushions, toys, and down/feather products) to ensure our customers have access to a comprehensive supply chain.

4. Where is your factory location?

To maintain a robust and flexible global supply chain, our manufacturing facilities are strategically located throughout Asia, specifically in Vietnam, China, Malaysia, Thailand, and Indonesia. If you would like to visit one of our sites, please contact your sales representative, and we will be happy to arrange transportation for you.

5. Can you accept free sample?

Yes, we provide free hand samples for quantities under 1 kilogram. Once a price is confirmed, we can prepare and dispatch your sample within 2–3 business days. Please note that while the sample is free, the freight costs are the responsibility of the client.

6. Can you provide ODM service?

Absolutely. We specialize in ODM (Original Design Manufacturing). This means we can customize the material composition, dimensions, quantity, packaging, and branding to meet your specific requirements. Your logo and unique specifications will be integrated into the final product.

7. How about your quality? What’s the minimum order Quantity (MOQ)?

We invite you to place a trial order to experience our quality firsthand. Our standard MOQ is 23,000 kilograms per order.

Regarding pricing, we maintain a no-bargain policy. We believe in transparency and efficiency, so we provide our most competitive offer upfront to save you time and ensure a straightforward procurement process.

8. Can I mix different items in one order?

Yes, for your convenience, we allow for a maximum of two different items to be mixed within a single container.

9. How can you guarantee the product quality?

Quality is the cornerstone of our business. We employ an experienced QC team that monitors every stage of production, from raw material inspection to the final manufacturing process. We utilize a range of advanced testing instruments to ensure our fibers meet strict industry standards.

Our business philosophy is simple: We aim to serve one customer 1,000 times, rather than 1,000 customers once. We prioritize long-term partnerships built on consistent excellence.

10. What’s the payment terms?

L/C at sight, 30% TT in advance are mostly accepted; other terms shall be negotiable by both sides

For more information, please feel free to contact :

Tony Tan

Mobile number: +84 90 466 5251 (Whatsapp/Wechat/Viber/Signal)