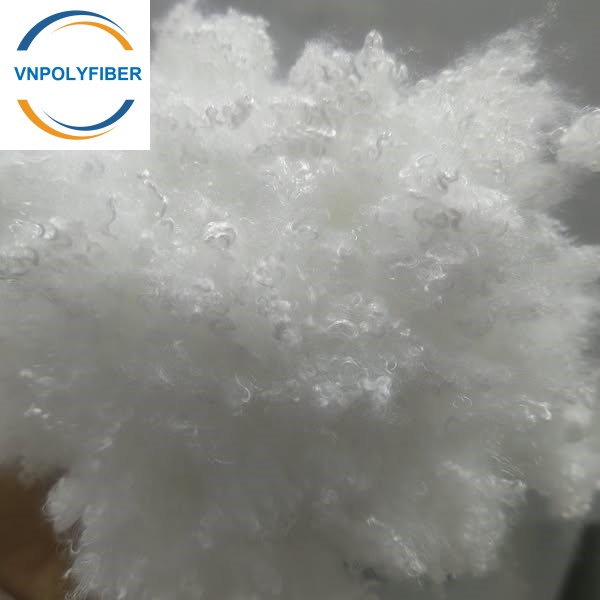

Virgin HCS 7D 64mm, Virgin HCS 15D 64mm

- Hollow PSF has better loft, recovery and warmth retention property than solid PSF, because there is a hole in single fiber, it can save some air.

- Our hollow PSF is easy to be carded and good at bonding with low melting fiber.

- It’s mainly used for fiberfill, filtration, padding, wadding, insulation etc.

Specification

- Denier: 6D-15D

- Type: Hollow Mechanical crimp

- Grade: Recycle, First quality

- Color: white, optical white,

- Cut Length: 32mm-76mm

- Finish: silicon, slick, dry, FR, antibacterial, low shrinkage

- Application: Filling, Wadding, fiberfill, insulation, filtration etc.

PRODUCT DETAIL

Virgin HCS Fiber 7D x 64mm and 15D x 64mm

Application:

Features: high bulkiness and easy open, excellent tenacity, high resilience and durability, feather touch, light and soft;Environmentally friendly, excellent filling power, anti-static, durable

Application: Pillows, blankets, comforter, toys, filling material for bedding, furniture, spray-bonded cotton, polyester wadding, padding, non-woven, filling quilt, cushion, home textile, etc.

Advantage of PSF HCS Hollow Conjugate Fiber Siliconized :

– Warm keeping :The hollow polyester staple fiber is lighter by 20% than ordinary fiber with its hollow Construction. It makes no air convection in fiber to keep warm. It can keep body warm by wrapping warm air and isolating cold air. The fiber is light and good in warm keeping.

– Good hygroscopicity :Hollow polyester staple fiber can discharge the moisture quickly in the body skin and keep dry and warm, reduce the un comfortable sticky feeling with its advantages of special wicking effect and large surface.

– Soft feeling in hand, good fall :It bright soft and comfortable feeling in hand to touch the hollow polyester staple fiber fabric. Compared with the daily heavy thermal fabric, it is more easily wet, dry and comfortable. It is very soft and excellent in pendency.

– Wide application: Hollow polyester staple fiber is a high quality material for the high-grade fabric. Blended with cotton, wool and viscose fiber, it is widely used to make thin thermal underwear, warm winter casual wear and sportswear with good warm keeping, soft feeling and soft luster. It is also used to make soft and thermal socks and gloves with wear resistance. It is also used to make light and soft tweeds.

Polyester Staple Fiber used in Non-woven Industry

| Luster | Denier | Cross Section | End-Use |

| SD | 1.5, 1.7, 2, 3, 4, 6 & 15 | Solid | Nonwoven Interlining, Sanitary Material, Microfiber and Thermal Bonding |

| FBR (Black) | 1.5, 1.7 & 3 | Solid | Needlepunch, Resin Bonding & Fiberfill |

| SD | 1.5 & 4.5 | Solid | Dyeable Fabric & High-Pile |

| SD | 6, 8 & 15 | Hollow and Hollow-Siliconized | Resin Bonding, Needlepunch, Fiberfill, Flame Retardant Fabric, Anti Bacteria & Platinum Photon Fiber |

| SD, BR,OBBR | 0.7, 1.1, 1.2, 1.4, 2.0, 6, 8, 12, 15 & 20 | Solid | Low Pilling, Knitting, Fiberfill, Thermal Bonding, Needlepunch, Infrared Fiber & Resin Bonding |

| SD | 2, 3, 4.5, 7, 12 & 15 | Hollow Conjugate | Resin Bonding, Needlepunch & Fiberfill |

| SD | 7 | Hollow Conjugate | Anti-Bacteria |

Polyester Staple Fiber as per Direct End Use

| Type | Denier | Section | End Use |

| Anti Pilling | 1.4, 1.5, 2, 2.5 & 3 | Solid & Hollow | Sportswear, Underwear, Casual wear |

| Bamboo Charcoal | 1.5, 1.7 & 6 | Hollow | Bedding, Shoe pad, Cushion, Thermal Sock |

| Spinning Use | 1.3, 1.4, 1.5 & 1.7 1.5 | Solid Hollow | Sportwear, Casual Wear, Underwear |

| Dopedyed Black | 1.5, 2 & 3 | Solid | Nonwoven, Casual wear, Sport wear, Underwear |

| Flame Retardant | 1.4 | Solid | Home, Comfort & Clothing textiles |

| Micro Fiber | 0.8 – 1.0 | Solid | Cloth & Fleece |

| High Tenacity | 1.2 | Solid | Yarn, Cloth & Water transport |

| High Void Conjugate | 3, 7, 12 & 15 | Hollow | Toy Padding, Badding, Furniture Cushion, etc |

| Regular Fiber | 2, 2.5, 3, 6 & 15 | Solid | Nonwoven, Filter medics, Padding, etc. |

Other keywords:

Fibras discontinuas de poliéster 15d * 64mm hueca siliconada

Blanco barato relleno de fibra de poliéster lavable hsc Guata de poliéster de fibra

Discontinuas de poliéster de fibra de poliéster de residuos-La sra.

Technical Parameter

| Product type | Recycled Polyester Staple Fiber |

| Fineness | 7D / 15D |

| Cut length | 32mm / 51mm / 64mm |

| Luster | semi dull |

| COLOR | Raw white |

| Pattern | Hollow Siliconized & Hollow Non-Siliconized |

| Raw Material | 100% PET flakes |

| Grade | Recycled, AAA grade |

| Packing details | 250kg-350kg/PP woven bag/bale |

| Delivery time | 5-20days after 30% deposit |

| Payment Term | TT30/70; L/C at sight |

| MOQ | 1x40HQ; 22 – 23 tons/container |

| Quality | First quality |

Specifications of Polyester Staple Fiber Viet Nam

Denier Size: 3D, 6D, 7D, 10D, 15D

Cut length: 32mm, 51mm, 64mm, 76mm,

Feel: siliconised or non siliconised soft as well as harsh feel

Tensile strength: 3.5 to 4.5 gm/Denier

Elongation: 40 to 60%

Oil Pickup: minimum 0.20% to 0.35%

Crimps: 3 to 5 per cm

Shades: All shades available

Color Fastness: 4+

Quality: Hollow Conjugate Siliconised Fiber, Hollow Non-Conjugate Siliconised Fiber, Solid Fiber Siliconised/non Siliconised

Application: Cushions – Pillows – Quilts – Toys – Jacket – Mattress – Non woven carpet – Automotive felts, speaker felts, geo textiles, polyfill wadding, filter fabrics and other acoustics as well.

FAQ

1. What do you offer?

We supply a comprehensive range of fibers, including recycled hollow conjugated (both siliconized and non-siliconized) polyester staple fiber, hollow fiber, microfiber, virgin polyester staple fiber, and low-melt fiber.

2. What is it used for?

Our fibers are versatile and widely utilized across both the filling and non-woven industries, providing essential loft, durability, and texture for various consumer and industrial applications.

3. Are you a factory or a trading company?

We are primarily a manufacturer specializing in polyester staple fiber with years of industry expertise. To better serve our clients, we also operate a dedicated trading division that allows us to act as a one-stop solution provider.

In addition to our own fiber production, we source high-quality textile components (such as yarn and low-melt fibers) and finished goods (including foam, pillows, cushions, toys, and down/feather products) to ensure our customers have access to a comprehensive supply chain.

4. Where is your factory location?

To maintain a robust and flexible global supply chain, our manufacturing facilities are strategically located throughout Asia, specifically in Vietnam, China, Malaysia, Thailand, and Indonesia. If you would like to visit one of our sites, please contact your sales representative, and we will be happy to arrange transportation for you.

5. Can you accept free sample?

Yes, we provide free hand samples for quantities under 1 kilogram. Once a price is confirmed, we can prepare and dispatch your sample within 2–3 business days. Please note that while the sample is free, the freight costs are the responsibility of the client.

6. Can you provide ODM service?

Absolutely. We specialize in ODM (Original Design Manufacturing). This means we can customize the material composition, dimensions, quantity, packaging, and branding to meet your specific requirements. Your logo and unique specifications will be integrated into the final product.

7. How about your quality? What’s the minimum order Quantity (MOQ)?

We invite you to place a trial order to experience our quality firsthand. Our standard MOQ is 23,000 kilograms per order.

Regarding pricing, we maintain a no-bargain policy. We believe in transparency and efficiency, so we provide our most competitive offer upfront to save you time and ensure a straightforward procurement process.

8. Can I mix different items in one order?

Yes, for your convenience, we allow for a maximum of two different items to be mixed within a single container.

9. How can you guarantee the product quality?

Quality is the cornerstone of our business. We employ an experienced QC team that monitors every stage of production, from raw material inspection to the final manufacturing process. We utilize a range of advanced testing instruments to ensure our fibers meet strict industry standards.

Our business philosophy is simple: We aim to serve one customer 1,000 times, rather than 1,000 customers once. We prioritize long-term partnerships built on consistent excellence.

10. What’s the payment terms?

L/C at sight, 30% TT in advance are mostly accepted; other terms shall be negotiable by both sides

For more information, please feel free to contact :

Tony Tan

Mobile number: +84 90 466 5251 (Whatsapp/Wechat/Viber/Signal)