Polyester Fiberfill 7 Denier 15 Denier – Hollow Slick Conjugate Fiber Fill

- Hollow PSF has better loft, recovery and warmth retention property than solid PSF, because there is a hole in single fiber, it can save some air.

- Our hollow PSF is easy to be carded and good at bonding with low melting fiber.

- It’s mainly used for fiberfill, filtration, padding, wadding, insulation etc

PRODUCT DETAIL

What is Polyester Fiberfill?

Polyester fiberfill, that fluffy, resilient material nestled within our pillows, cushions, and stuffed toys, is a ubiquitous yet often underappreciated component of modern life. Its versatility, affordability, and comfort-enhancing properties have made it a staple in numerous industries. This post delves into the world of polyester fiberfill, exploring its properties, manufacturing, applications, and the reasons behind its enduring popularity.

Polyester fiberfill is a synthetic filling material composed of fine, crimped polyester fibers. These fibers are engineered to create a lightweight, lofty, and resilient fill that provides cushioning, support, and warmth. Unlike natural fills like down or feathers, polyester fiberfill is hypoallergenic, resistant to mold and mildew, and easy to care for.

Polyester fiberfill was originally developed by Imperial Chemical Industries (ICI) in partnership with DuPont. Over time, it has become a widely accepted material for various applications due to its affordability and versatility.

How to make polyester fiberfill

The journey of polyester fiberfill begins with the same raw materials as other polyester fibers: PTA and MEG. These are polymerized into PET chips, which are then melted and extruded through spinnerets. However, the extrusion process for fiberfill is specifically designed to create crimped fibers. Crimping involves creating a wave-like or spiral shape in the fibers, which significantly increases their bulk and resilience.

After extrusion, the fibers are often siliconized, a process that involves coating them with a silicone finish. This treatment enhances the fiber’s softness, smoothness, and loft. The fibers are then processed into a loose, fluffy fill, ready for use in various applications.

Key Properties of Polyester Fiberfill

- Loft and Resilience: The crimped fibers create a high degree of loft, providing excellent cushioning and support. The fibers’ resilience allows them to spring back into shape after compression, maintaining their bulk over time.

- Softness and Smoothness: Siliconization contributes to a soft, smooth texture, enhancing comfort.

- Hypoallergenic: Polyester fiberfill is inherently hypoallergenic, making it an ideal choice for individuals with allergies or sensitivities.

- Resistance to Mold and Mildew: Polyester’s hydrophobic nature prevents moisture absorption, inhibiting the growth of mold and mildew.

- Warmth and Insulation: The trapped air within the fiberfill provides excellent thermal insulation, keeping users warm and comfortable.

- Lightweightness: Polyester fiberfill is lightweight, making it easy to handle and transport.

- Durability and Longevity: Polyester fibers are strong and durable, ensuring that the fill maintains its properties over time.

- Easy Care: Polyester fiberfill is machine washable and dryable, simplifying cleaning and maintenance.

- Affordability: Compared to natural fills, polyester fiberfill is relatively inexpensive, making it a cost-effective option.

Applications of Polyester Fiberfill

Polyester fiberfill’s versatility has led to its widespread use in numerous applications:

- Bedding: Pillows, comforters, mattress toppers, and quilts rely on polyester fiberfill for its comfort, support, and warmth.

- Furniture: Upholstery cushions, sofa pillows, and furniture padding utilize polyester fiberfill for its cushioning and resilience.

- Toys and Stuffed Animals: Polyester fiberfill is the primary filling material for toys and stuffed animals, providing a soft, safe, and durable fill.

- Crafts and Sewing: Polyester fiberfill is used in various craft projects, including quilting, sewing, and toy making.

- Automotive Interiors: Seat cushions, headrests, and other automotive interior components utilize polyester fiberfill for its comfort and support.

- Outdoor Gear: Sleeping bags, camping pillows, and other outdoor gear benefit from polyester fiberfill’s warmth, lightweightness, and moisture resistance.

- Filtration: Some coarser grades of polyester fiberfill are used in filtration applications.

Advantages of Polyester Fiberfill

- Consistent Quality: The manufacturing process ensures consistent quality and performance.

- Versatility: Polyester fiberfill can be engineered to meet specific requirements, offering a range of loft, softness, and resilience.

- Easy Maintenance: Machine washability and dryability simplify cleaning.

- Cost-Effectiveness: Polyester fiberfill is an affordable filling material.

- Hypoallergenic and Safe: Free from allergens and resistant to mold and mildew.

Considerations and Variations

- Hollow Conjugated Siliconized (HCS) Fiberfill: This type of fiberfill features a hollow core and a conjugate structure, further enhancing loft and resilience.

- Microfiber Fill: Finer polyester fibers are used to create a softer, more luxurious fill.

- Recycled Polyester Fill: Increasingly, recycled polyester is used to produce fiberfill, reducing the environmental impact.

The Future of Polyester Fiberfill

Polyester fiberfill will continue to be a vital material in numerous industries. Ongoing research and development focus on improving its sustainability, exploring bio-based alternatives, and enhancing its performance characteristics. As consumers seek comfortable, affordable, and easy-care products, polyester fiberfill will remain a staple in our daily lives. Recent advancements in polyester fiberfill include the development of blends that combine polyester staple fibers with binder fibers, allowing for thermally bonded products with improved durability and resilience. These advancements aim to enhance the performance of polyester fiberfill while maintaining its softness and aesthetic appeal.

Read more:

Technical Parameter

Specification

- Denier: 3D-15D

- Type: Hollow Conjugate Slick

- Grade: Recycle, First quality

- Color: white, optical white,

- Cut Length: 32mm-76mm

- Finish: silicon, slick, dry, FR, antibacterial, low shrinkage

- Application.Filling Material: filling toys pillows (51/64)Spinning quilt/spinning cotton/cloth lining/slippers lining/(51/64)Needle-punched nonwoven/ polyester wadding/nonglue cotton/Filtering material/Hard mattress(51/64)

Staple fiber production process

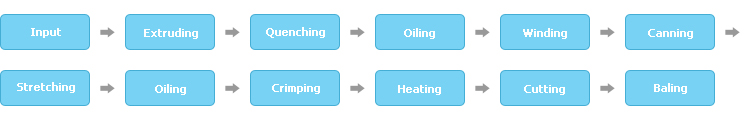

The base material, which comes in chips, is melted in an extruder before being quantified in a gear pump and transferred to a nozzle. Polymers that pass through the nozzle are cooled and solidified in a spinning tank, and end up in a fiber form (semi-finished product). Fiber released from multiple spinning tanks is lubricated and gathered before being wound by a gear wheel and placed in cans. Fiber placed in cans is given various properties through a stretching process, in which fiber is stretched at various roller speeds designed to endow different degrees of rigidity and elasticity.

The fiber is again lubricated for enhanced quality and to facilitate the processes that follow. A crimping process takes place to give the fiber various properties, including bulk and mixability. Moisture and lubricant on the fiber is dried off in a heat dryer. The fiber is then cut into required lengths and end up in a bale form. The fiber is then compressed, packaged, and stored for factory release when ordered.

PRODUCTION PROCESS OF POLYESTER STAPLE FIBER

FAQ

1. What do you offer?

We supply a comprehensive range of fibers, including recycled hollow conjugated (both siliconized and non-siliconized) polyester staple fiber, hollow fiber, microfiber, virgin polyester staple fiber, and low-melt fiber.

2. What is it used for?

Our fibers are versatile and widely utilized across both the filling and non-woven industries, providing essential loft, durability, and texture for various consumer and industrial applications.

3. Are you a factory or a trading company?

We are primarily a manufacturer specializing in polyester staple fiber with years of industry expertise. To better serve our clients, we also operate a dedicated trading division that allows us to act as a one-stop solution provider.

In addition to our own fiber production, we source high-quality textile components (such as yarn and low-melt fibers) and finished goods (including foam, pillows, cushions, toys, and down/feather products) to ensure our customers have access to a comprehensive supply chain.

4. Where is your factory location?

To maintain a robust and flexible global supply chain, our manufacturing facilities are strategically located throughout Asia, specifically in Vietnam, China, Malaysia, Thailand, and Indonesia. If you would like to visit one of our sites, please contact your sales representative, and we will be happy to arrange transportation for you.

5. Can you accept free sample?

Yes, we provide free hand samples for quantities under 1 kilogram. Once a price is confirmed, we can prepare and dispatch your sample within 2–3 business days. Please note that while the sample is free, the freight costs are the responsibility of the client.

6. Can you provide ODM service?

Absolutely. We specialize in ODM (Original Design Manufacturing). This means we can customize the material composition, dimensions, quantity, packaging, and branding to meet your specific requirements. Your logo and unique specifications will be integrated into the final product.

7. How about your quality? What’s the minimum order Quantity (MOQ)?

We invite you to place a trial order to experience our quality firsthand. Our standard MOQ is 23,000 kilograms per order.

Regarding pricing, we maintain a no-bargain policy. We believe in transparency and efficiency, so we provide our most competitive offer upfront to save you time and ensure a straightforward procurement process.

8. Can I mix different items in one order?

Yes, for your convenience, we allow for a maximum of two different items to be mixed within a single container.

9. How can you guarantee the product quality?

Quality is the cornerstone of our business. We employ an experienced QC team that monitors every stage of production, from raw material inspection to the final manufacturing process. We utilize a range of advanced testing instruments to ensure our fibers meet strict industry standards.

Our business philosophy is simple: We aim to serve one customer 1,000 times, rather than 1,000 customers once. We prioritize long-term partnerships built on consistent excellence.

10. What’s the payment terms?

L/C at sight, 30% TT in advance are mostly accepted; other terms shall be negotiable by both sides

For more information, please feel free to contact :

Tony Tan

Mobile number: +84 90 466 5251 (Whatsapp/Wechat/Viber/Signal)