PLA Fiber – Biodegradable Polylactic Acid Fiber

- PLA fiber, also known as polylactic acid fiber, is a type of synthetic fiber derived from renewable resources such as corn starch or sugarcane.

- It is a biodegradable and compostable material, making it an environmentally friendly alternative to traditional petroleum-based synthetic fibers.

PRODUCT DETAIL

The customized biodegradable Polylactic Acid Fiber from manufacturers in China is an environmentally sustainable fiber option that is increasingly popular in the textile industry. Derived from renewable resources such as corn starch or sugarcane, PLA fiber provides a more eco-friendly alternative to traditional synthetic fibers.

In addition to being biodegradable, PLA fiber boasts excellent properties including a soft and lightweight texture, breathability, and moisture-wicking capabilities that contribute to comfort when worn. These qualities make it well-suited for activewear, sportswear, and intimate apparel. Moreover, PLA fiber is hypoallergenic, gentle on sensitive skin, and naturally resistant to bacteria, which reduces the risk of odor formation and promotes freshness and hygiene in apparel.

Overall, the highest quality customized biodegradable Polylactic Acid fiber offers a blend of eco-friendliness, comfort, and performance, making it a favorable choice for consumers and brands looking for sustainable textile options.

Through technological innovation in utilizing natural materials, biodegradable material brands enhance the performance and environmental properties of sustainable recycled materials. The best Biodegradable PLA Fiber, derived from crops such as corn and cassava, is a 100% biological base material. Lactic acid is extracted through microbial fermentation, followed by refining, oligomerization, high-temperature lysis, and polymerization to create Polylactic Acid (PLA) with excellent biodegradability.

PLA can be fully degraded by soil microorganisms within a year of disposal, generating only CO2 and water without environmental pollution. With favorable physical properties such as a high melting point, good processing performance, hardness, and mechanical properties akin to resin, biodegradable PLA Fiber material is cost-effective. It also offers moisture absorption, high elastic recovery rate, low flammability and smoke emission, UV stability, pleasing texture, and drape, particularly suitable for light-colored fabrics.

Technical Parameter

PLA fiber offers several advantages:

1. Sustainability: PLA fiber is made from renewable resources, reducing reliance on fossil fuels. It is biodegradable and compostable under appropriate conditions, making it an eco-friendly choice for various applications.

2. Biodegradability: Unlike traditional synthetic fibers like polyester, which can persist in the environment for hundreds of years, PLA fiber breaks down into harmless byproducts when exposed to certain conditions, such as high temperatures and microbial activity.

3. Versatility: PLA fiber can be processed into various forms, including staple fibers for textiles, filaments for 3D printing, and packaging materials. It can be blended with other fibers to enhance performance and tailor specific properties.

4. Performance: PLA fiber exhibits properties similar to other synthetic fibers, including strength, durability, and moisture-wicking capabilities. It can be engineered to meet specific performance requirements for different applications.

PLA fiber is commonly used in a variety of applications, including textiles (such as apparel, bedding, and nonwoven fabrics), packaging, biomedical materials, and 3D printing filaments. Its sustainable and biodegradable nature makes it a preferred choice for environmentally conscious consumers and industries seeking to reduce their environmental impact.

Biodegradable fibers refer to fibers that can be degraded by microorganisms in a certain period of time and under appropriate natural conditions. According to the source of fiber materials, biodegradable fibers mainly include natural polymer fibers and synthetic polymer fibers.

Classification

- Natural Biodegradable Polymer Fiber

In general, natural polymer fibers exhibit good biodegradability due to their natural cellulose sources. Common natural fibers are cotton fiber, animal hair fiber, silk fiber, etc. In addition, current research focuses more on cellulose fibers, protein fibers, chitin fibers, starch fibers, etc. If you are interested in these natural fiber products, please click to view the list of natural fiber products. - Synthetic Biodegradable Polymer Fiber

The most popular chemical synthetic polymers mainly include biodegradable polyester fibers and water-soluble polymer fibers. Currently developed polyester fibers include polyglycolic acid ester (PGA) fiber, polylactic acid (PLA) fiber, poly-ε-caprolactone (PCL) fiber, polyvalerolactone (PVL) fiber, etc.

Water-soluble polymers are hydrophilic polymer materials that can dissolve or swell in water to form solution or dispersion. Their molecular chains generally contain a certain number of strong hydrophilic groups, such as carboxyl, hydroxyl, amino, ether and amide groups. Common such biodegradable fibers include polyvinyl alcohol (PVA) fibers, polypropylene glycol (PPG) fibers, and polyethylene glycol (PEG) fibers.

Fibers made of polyhydroxyalkanoates (PHA) are another important type of biosynthetic biodegradable polymer fibers. PHA is an aliphatic copolyester with different structures synthesized by microorganisms through the fermentation of various carbon sources. Its basic structure is shown in the figure below. PHAs have different monomer structures, so there is a wide variety. Among them, the most common ones are poly-3-hydroxybutyrate (PHB), polyhydroxyvalerate (PHV) and the copolymer of PHB and PHV (PHBV).

General structure of polyhydroxyalkanoates with some modifications as reported, Where if n = 1, R = methyl: poly (-3-hydroxybutyrate); R = hydrogen: poly (-3-hydroxypropionate); R = propyl: poly (-3-hydroxyhexanoate); R = nonyl: poly (-3-hydroxydodecanoate); R = ethyl: poly (-3-hydroxyvalerate); R = pentyl: poly (-3-hydroxyoctanoate); If n = 2, R = hydrogen: poly(-3-hydroxybutyrate); If n = 3, R = hydrogen: poly (-5-hydroxyvalerate). [1]

Application and Research

Due to their biocompatibility and biodegradability, these biodegradable polyester fibers are mainly used in surgical sutures, drug release systems, tissue engineering, and implants.

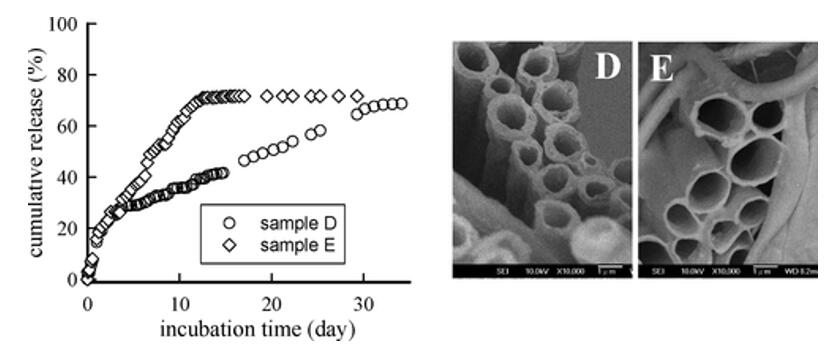

For example, combined with coaxial electrospinning technology, Chi Wang et al. prepared a core-shell fiber using two biodegradable polymer solutions of PLA and PHB. The PDLLA/PHB fibers can be used for sustained release of dimethyloxalylglycine (DMOG) drugs. In this work, the DMOG release was about 25% within 60 h. After the burst release, the linear release of DMOG is up to 70%, and it is feasible that the release rate is controlled by the thickness of the PHB shell. [2]

Video

FAQ

1. What do you offer?

We produce recycled hollow conjugated siliconized and non-siliconized polyester staple fiber mainly.

We also supply home textile machineries and products at factory origin and its price.

2. What is it used for?

Our fiber is widely used in filling, non-woven fabric, spinning, bedding stuff, home textile, automotive interiors…

3. Are you a factory or a trading company?

We are a factory specialized in polyester staple fiber for many years but now we also have our own professional trading company. We will source many types of textile products such as yarn, PP fibers from others to supply our own customers as well. We also provide our own customers with other related products such as: Foam, Pillows, Cushions, Toys, Down/ Feather,…

4. Where is your factory location?

Our factory locates in the north and the south of Vietnam. You can visit us from Ho Chi Minh City and Hanoi City, Vietnam. You could contact our salesman to fetch you if visiting.

5. Can you accept free sample?

Yes, the hand sample is free when not exceed 1 kilograms. Upon price confirmation, we will provide a sample within 2-3 days; the freight cost will be charged to client.

6. Can you provide ODM service?

Yes, we work on ODM orders. Which means size, material, quantity, design, packing solution, etc, will depend on your requests, and your logo will be customized on our products.

7. How about your quality? What’s the minimum order Quantity (MOQ)?

Please try a trial order, you will know it. The MOQ is 23,000 Kilograms/order, but the price will be lower if you order bulk volume.

8. Can I mix different items in one order?

Sure, you can mix any products we can provide.

9. How can you guarantee the product quality?

We have experienced QC team. We control not only productive process but also raw material. In addition, we have different kinds of testing instrument to help us guarantee the product quality.

10. What’s the payment terms?

L/C at sight, 30% TT in advance are mostly accepted; other terms shall be negotiable by both sides

For more information, please feel free to contact :

Mr. Tony Tan

Mobile number: +84 90 466 5251 (Whatsapp/Wechat/Viber/Signal)