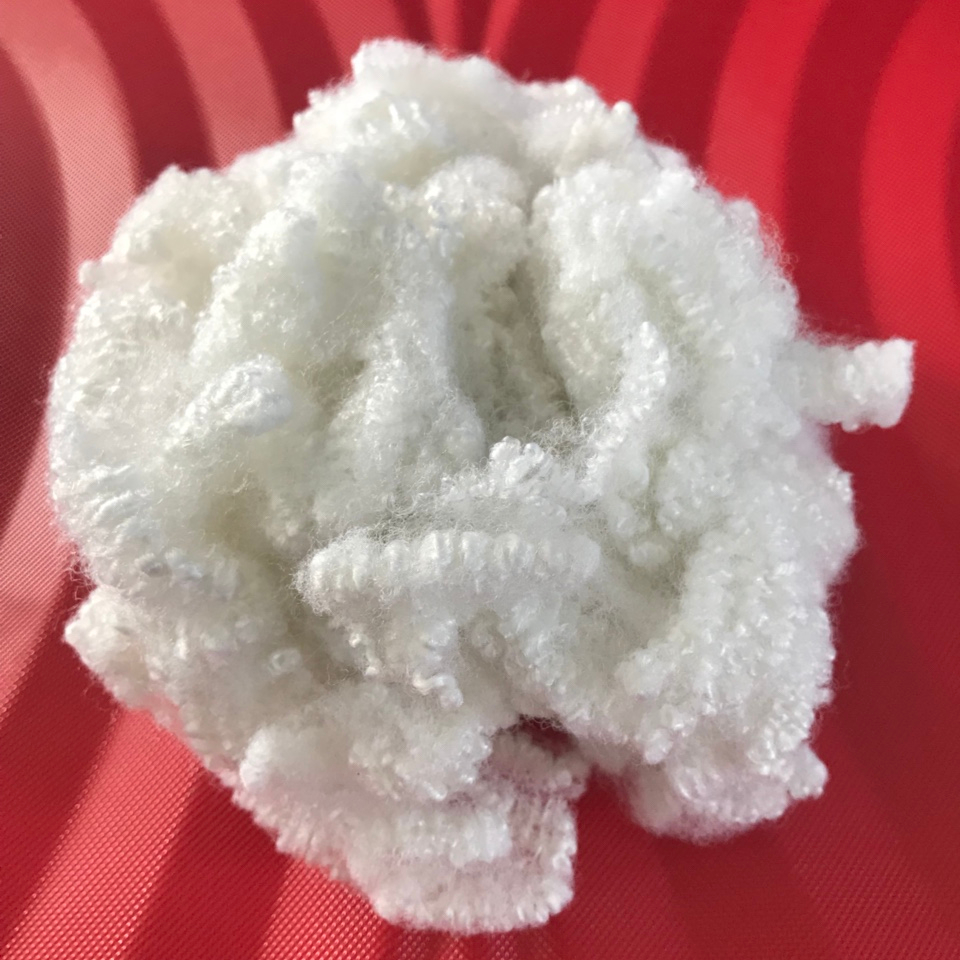

Hollowfibre with Mechanical Crimp for Duvets and Pillows

- Hollow Staple Fibers have the advantages of the lightness and heat-retention whereas the fibers are hollow,

and they are greatly known for their bulkiness with less weight. - They are generally used for padding, pillow, cushion and furniture filler

PRODUCT DETAIL

What is HollowFibre?

Hollowfibre is a synthetic polyester material characterized by its unique structure—fibers with hollow spaces running through their length. This hollow core traps air, contributing to the material’s insulating properties and loft. Commonly used as filling in duvets and pillows, hollow fiber offers a full, springy feel, resulting in lightweight and puffy bedding products. Its synthetic nature makes it durable, long-lasting, and fully machine washable, enhancing its practicality for everyday use.

Hollowfibre is a synthetic material that makes your bedding super comfortable. Hollowfibre stands apart from other synthetic materials because its polyester strands have a special structure that gives it unique features and its name.

Advantages of HollowFibre

- Affordability: Hollow fiber is cost-effective, providing quality bedding options at accessible prices.

- Low Maintenance: Products filled with hollow fiber are typically machine washable and quick-drying, simplifying care routines.

- Lightweight and Airy: The hollow structure contributes to a lightweight feel, offering comfort without excessive weight.

- Breathability: The spaces within the fibers allow for air circulation, enhancing breathability and reducing the likelihood of overheating during sleep.

- Hypoallergenic Properties: Being synthetic, hollow fiber is less likely to harbor allergens, making it suitable for individuals with allergies.

The structure of hollowfibre filling

The name hollowfibre comes from its unique design – each polyester strand has a hollow center running through it. These strands look like tiny tubes instead of solid threads. You’ll find these hollow fibers are thicker and more wire-like compared to other synthetics like microfibre. This creates a filling that stays light but firm, and your duvets get excellent loft and structure.

Hollowfibre’s physical properties make it perfect for bedding. The fibers are quite wiry and keep their shape well, so your duvet stays springy and structured. Your duvet will stay plump and hold its shape over time, but it won’t last as long as natural alternatives.

How hollowfibre traps heat

The clever design of hollowfibre serves one main purpose – it keeps you warm. Each fiber’s hollow center creates an extra air pocket that traps warm air. This design copies the way natural down fillings work to keep you cozy.

Your hollowfibre duvet creates a warm cocoon by capturing body heat in these hollow cores. Some advanced hollowfibre fillings are even better at trapping heat because they’re shaped like spiral springs, which create extra air pockets.

This special construction means your hollowfibre duvet can keep you warm without weighing you down. You can get really warm bedding that doesn’t need to be thick or heavy.

Common misconceptions about synthetic fillings

People often think synthetic fillings can’t match natural ones for comfort. But modern hollowfibre has come a long way over the last several years. Many brands now make synthetic duvets that feel almost like premium natural fillings.

Temperature regulation is another misunderstood aspect. Some people think synthetic fillings make them too hot, but hollowfibre breathes quite well. Notwithstanding that, it doesn’t breathe as well as natural fibers, so it might not work for people who get night sweats.

Durability concerns are common too. Hollowfibre duvets might not last as long as natural ones, but they’re great value for their price. They work perfectly if you like to change your bedding regularly.

Natural Duvet Fillings: Types and Properties

Natural fillings have ruled the bedding market for centuries. They bring unique qualities that synthetic alternatives try to copy. Each material adds something special to your sleep experience.

Down and feather: the traditional choice

Down consists of soft, fluffy clusters found under birds’ outer feathers. Ducks and geese provide most of these clusters. Down has no stiff quill, which makes it light and fluffy. This creates thousands of tiny air pockets that trap heat really well but still let your skin breathe.

Hungarian goose down leads the premium market. It gives you better insulation and softness than other options. Down-filled duvets are incredibly warm for their weight. They’re about three times warmer than synthetic materials. Most down duvets mix down with feathers – you’ll usually find 85% feathers and 15% down. The more down you have, the lighter and warmer your duvet gets.

A good down duvet can last 20 years if you take care of it. Feather-mix options should give you at least 10 years of good use.

Wool: a sustainable alternative

Wool stands out as an eco-conscious choice among natural fillings. Its thick structure traps air really well. This gives you great insulation that lets your skin breathe.

Wool’s best feature is how it handles temperature. It pulls moisture away from your body to keep you warm in winter and cool in summer. What’s more, wool naturally fights off allergens and dust mites. This makes it perfect if you have allergies.

Wool proves itself as a renewable, biodegradable option. Most of it comes from carefully monitored farms. Despite these good points, wool duvets weigh more than down ones and don’t drape as nicely.

Cotton and silk options

Cotton and silk duvets work great for people who want natural, allergy-friendly bedding. These materials create flat, smooth duvets that feel nice against your body.

Silk does an amazing job managing temperature. It helps you sleep comfortably all year round. People with eczema or asthma find silk especially helpful. Cotton duvets breathe really well too. They’re perfect for warm weather or summer nights.

Both materials last a long time. Just remember that silk might lose some of its natural properties if you wash it too much.

Comparing Comfort and Sleep Quality

Your choice between hollowfibre and natural fillings will shape your sleep experience. Each option comes with unique comfort features that affect how well you sleep.

Weight and breathability factors

The duvet’s weight plays a big role in how comfortable you feel while sleeping. Hollowfibre duvets give you more warmth for their weight compared to natural options. You’ll stay warm without feeling weighed down. People who don’t like heavy bedding find these duvets really appealing.

Natural and synthetic materials handle air flow differently. Natural fillings let air move through much better than synthetic ones. Goose down allows three to four times better air circulation than hollowfibre filling. The air moves freely through natural duvets, and you won’t get that stuffy feeling common with synthetic options.

Temperature regulation differences

Sleep quality depends a lot on temperature control. Experts say your bedroom should stay between 16-18°C for the best rest. Natural fillings are great at managing temperature. Down works really well to trap air when it’s cold while staying breathable in warmer weather.

Hollowfibre filling insulates well but tends to keep more heat in. These duvets work best when temperatures stay steady but might not adapt as well when temperatures change. Natural fillings adapt better throughout the year.

Moisture-wicking capabilities

Moisture control matters a lot to hot sleepers and people who get night sweats. Natural fillings handle moisture better than synthetics. Wool can soak up 30% of its weight in moisture, while down lets body moisture evaporate quickly.

Hollowfibre duvets handle moisture okay but can’t match what natural materials can do. Microfibre options work better than regular hollowfibre at controlling moisture. New synthetic fillings now come with special moisture-wicking technology.

Hot sleepers should pick natural fibers. These materials keep you warm while letting moisture escape, which helps you stay dry all night long.

Practical Considerations for Your Decision

Comfort and warmth are great, but practical factors usually determine the choice between hollowfibre and natural fillings. Let’s get into these significant factors that affect your satisfaction in the long run.

Original cost vs. long-term value

The price difference between synthetic and natural options remains substantial. Hollowfibre duvets start at about £20, which makes them nowhere near as expensive as natural alternatives. Premium down duvets can set you back £700 or more, which is quite an investment upfront.

The price doesn’t tell the whole story though. Natural filled bedding lasts three times longer than synthetic options. A quality down duvet that’s well cared for can last up to 30 years. Even the best synthetic duvets usually need replacement after 5-10 years.

Maintenance and cleaning requirements

Each filling type has its own cleaning needs. Hollowfibre duvets shine here because you can just toss them in your home washing machine without any special care. This makes them perfect for homes with kids or pets where you just need to wash them often.

Natural duvets just need more care:

- Down/feather duvets usually call for professional cleaning or special washing steps

- Wool duvets work best with gentle washing at low temperatures

- Silk duvets usually belong at the dry cleaners

It’s worth noting that dust mites’ attention is drawn less to synthetic fillings than natural ones. A good wash at 60°C kills dust mites and cleans out allergens well.

Durability and replacement timelines

The Sleep Council says you should replace duvets every 2-5 years, but this changes based on what they’re filled with. Natural fillings last longer – a good down duvet can serve you well for 10-20 years if you take care of it. Synthetic options usually last about 5 years before they need replacement.

Allergy and sensitivity concerns

Hollowfibre filling works better for people with allergies. Synthetic materials are naturally hypoallergenic, which helps if you react badly to natural materials. You can also wash them at high temperatures to get rid of dust mites.

Recent studies show synthetic bedding might actually trap more allergens because their outer fabric often has a looser weave. Duvet protectors are a great way to get more life out of your duvet and block allergens, whatever filling you choose.

Conclusion

Your choice between hollowfibre and natural duvets ended up depending on what you need and your situation. Hollowfibre duvets are great value for money-conscious buyers and people with allergies. Natural fillings breathe better and last longer.

We’ve found that hollowfibre works best for people whose priorities include easy care and regular washing. These synthetic options might need replacing every 5-10 years, but their budget-friendly price makes this less of an issue. Natural fillings like down and wool cost more up front but give you exceptional durability and better temperature control.

New buyers might find hollowfibre duvets a good place to start, especially with their hypoallergenic features and simple care needs. People looking for long-term value and premium comfort should think over natural alternatives. The higher price tag and special care requirements are worth considering.

Both options have clear advantages, and your pick should line up with your budget, lifestyle, and sleep priorities. The right care and maintenance will extend your duvet’s life by a lot and keep your nights cozy for years to come.

Polyester Staple Fiber used in Non-woven Industry

| Luster | Denier | Cross Section | End-Use |

| SD | 1.5, 1.7, 2, 3, 4, 6 & 15 | Solid | Nonwoven Interlining, Sanitary Material, Microfiber and Thermal Bonding |

| FBR (Black) | 1.5, 1.7 & 3 | Solid | Needlepunch, Resin Bonding & Fiberfill |

| SD | 1.5 & 4.5 | Solid | Dyeable Fabric & High-Pile |

| SD | 6, 8 & 15 | Hollow and Hollow-Siliconized | Resin Bonding, Needlepunch, Fiberfill, Flame Retardant Fabric, Anti Bacteria & Platinum Photon Fiber |

| SD, BR,OBBR | 0.7, 1.1, 1.2, 1.4, 2.0, 6, 8, 12, 15 & 20 | Solid | Low Pilling, Knitting, Fiberfill, Thermal Bonding, Needlepunch, Infrared Fiber & Resin Bonding |

| SD | 2, 3, 4.5, 7, 12 & 15 | Hollow Conjugate | Resin Bonding, Needlepunch & Fiberfill |

| SD | 7 | Hollow Conjugate | Anti-Bacteria |

Polyester Staple Fiber as per Direct End Use

| Type | Denier | Section | End Use |

| Anti Pilling | 1.4, 1.5, 2, 2.5 & 3 | Solid & Hollow | Sportswear, Underwear, Casual wear |

| Bamboo Charcoal | 1.5, 1.7 & 6 | Hollow | Bedding, Shoe pad, Cushion, Thermal Sock |

| Spinning Use | 1.3, 1.4, 1.5 & 1.7 1.5 | Solid Hollow | Sportwear, Casual Wear, Underwear |

| Dopedyed Black | 1.5, 2 & 3 | Solid | Nonwoven, Casual wear, Sport wear, Underwear |

| Flame Retardant | 1.4 | Solid | Home, Comfort & Clothing textiles |

| Micro Fiber | 0.8 – 1.0 | Solid | Cloth & Fleece |

| High Tenacity | 1.2 | Solid | Yarn, Cloth & Water transport |

| High Void Conjugate | 3, 7, 12 & 15 | Hollow | Toy Padding, Badding, Furniture Cushion, etc |

| Regular Fiber | 2, 2.5, 3, 6 & 15 | Solid | Nonwoven, Filter medics, Padding, etc. |

Other keywords:

Fibras discontinuas de poliéster 15d * 64mm hueca siliconada

Blanco barato relleno de fibra de poliéster lavable hsc Guata de poliéster de fibra

Discontinuas de poliéster de fibra de poliéster de residuos-La sra.

Technical Parameter

Specification

- Denier: 6D-15D

- Type: Hollow Mechanical crimp

- Grade: Recycle, First quality

- Color: white, optical white,

- Cut Length: 32mm-76mm

- Finish: silicon, slick, dry, FR, antibacterial, low shrinkage

- Application: Filling, Wadding, fiberfill, insulation, filtration etc.

| Division | Color | Fineness(De) | Fiber Length(mm) | Touch | Grade |

| Hollow fiber | White | 6~15 | 32~76 | Dry, Silicone, Slick,Snow | Recycled |

| Product type | Recycled Polyester Staple Fiber |

| Fineness | 7D / 15D |

| Cut length | 32mm / 51mm / 64mm |

| Luster | semi dull |

| COLOR | Raw white |

| Pattern | Hollow Siliconized & Hollow Non-Siliconized |

| Raw Material | 100% PET flakes |

| Grade | Recycled, AAA grade |

| Packing details | 250kg-350kg/PP woven bag/bale |

| Delivery time | 5-20days after 30% deposit |

| Payment Term | TT30/70; L/C at sight |

| MOQ | 1x40HQ; 22 – 23 tons/container |

| Quality | First quality |

Specifications of Polyester Staple Fiber Viet Nam

Denier Size: 3D, 6D, 7D, 10D, 15D

Cut length: 32mm, 51mm, 64mm, 76mm,

Feel: siliconised or non siliconised soft as well as harsh feel

Tensile strength: 3.5 to 4.5 gm/Denier

Elongation: 40 to 60%

Oil Pickup: minimum 0.20% to 0.35%

Crimps: 3 to 5 per cm

Shades: All shades available

Color Fastness: 4+

Quality: Hollow Conjugate Siliconised Fiber, Hollow Non-Conjugate Siliconised Fiber, Solid Fiber Siliconised/non Siliconised

Application: Cushions – Pillows – Quilts – Toys – Jacket – Mattress – Non woven carpet – Automotive felts, speaker felts, geo textiles, polyfill wadding, filter fabrics and other acoustics as well.

FAQ

1. What do you offer?

We produce recycled hollow conjugated siliconized and non-siliconized polyester staple fiber mainly, we can make hollow fiber (HS/ HD) and virgin polyester staple fiber HCS as well.

2. What is it used for?

Our fiber is widely used in filling, non-woven fabric

3. Are you a factory or a trading company?

We are a factory specialized in polyester staple fiber for many years but now we also have our own professional trading company. We will source many types of textile products such as yarn, PP fibers from others to supply our own customers as well. We also provide our own customers with other related products such as: Foam, Pillows, Cushions, Toys, Down/ Feather,…

4. Where is your factory location?

Our factory locates in the north and the south of Vietnam. You can visit us from Ho Chi Minh City and Hanoi City, Vietnam. You could contact our salesman to fetch you if visiting.

5. Can you accept free sample?

Yes, the hand sample is free when not exceed 1 kilograms. Upon price confirmation, we will provide a sample within 2-3 days; the freight cost will be charged to client.

6. Can you provide ODM service?

Yes, we work on ODM orders. Which means size, material, quantity, design, packing solution, etc, will depend on your requests, and your logo will be customized on our products.

7. How about your quality? What’s the minimum order Quantity (MOQ)?

Please try a trial order, you will know it. The MOQ is 23,000 Kilograms/order, but the price will be lower if you order bulk volume.

8. Can I mix different items in one order?

Sure, you can mix any products we can provide.

9. How can you guarantee the product quality?

We have experienced QC team. We control not only productive process but also raw material. In addition, we have different kinds of testing instrument to help us guarantee the product quality.

10. What’s the payment terms?

L/C at sight, 30% TT in advance are mostly accepted; other terms shall be negotiable by both sides

For more information, please feel free to contact :

Mr. Tony Tan

Mobile number: +84 90 466 5251 (Whatsapp/Wechat/Viber/Signal)