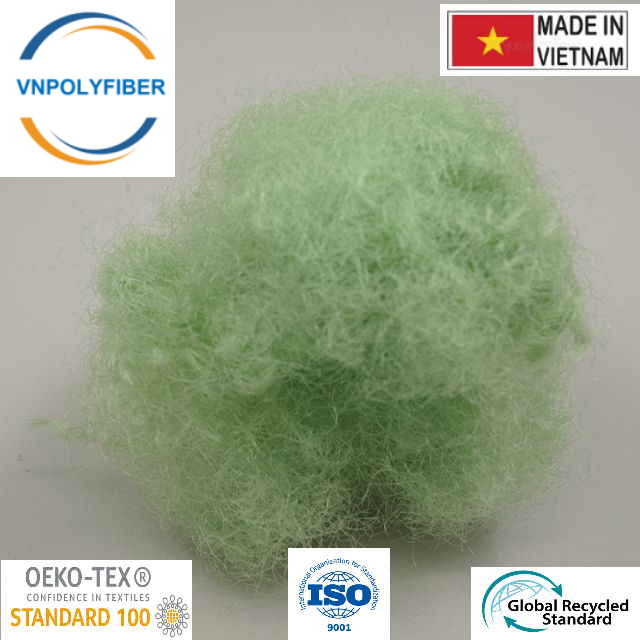

Green Hollow Fiber

Eco-Color: Deep green tones built directly into the fiber—no chemicals needed and zero fading from washing or UV light.

Built to Last: Tough, wrinkle-resistant material that outlasts cotton or silk with easy “wash-and-wear” care.

Stay Dry: Hollow-fiber technology provides superior breathability and quick-drying performance.

High Performance: Naturally hydrophobic—ideal for activewear, uniforms, and outdoor gear.

PRODUCT DETAIL

In the pursuit of a circular economy, Green Hollow Fiber has emerged as a revolutionary material within the synthetic textile industry. Unlike traditional colored fibers that rely on heavy chemical dyeing or synthetic masterbatches, this recycled polyester staple fiber derives its unique coloration directly from the raw material itself: post-consumer PET bottles. This natural pigment process ensures a vibrant, durable finish while significantly reducing the environmental footprint of the manufacturing cycle.

Produced across the advanced recycling hubs of South East Asia and China, Green Hollow Fiber is manufactured directly from PTA and MEG, high-grade PET chips, or repurposed polyester waste. This versatility allows manufacturers to produce a fiber that is as functional as it is aesthetic, serving vital roles in spinning yarns, creating high-tenacity geotextiles, and providing high-loft filling for cushions, toys, and pillows.

Understanding the Specifications and Structural Types

The utility of green polyester fiber is defined by its diverse range of deniers and structural engineering. For manufacturers, selecting the correct type is essential for the performance of the final product:

Solid Fibers Available in a broad spectrum of deniers ranging from 1.3 to 30 dtex, green solid fibers are the backbone of high-durability textiles. These fibers are prized for their consistent color density and high-tensile strength, making them the preferred choice for industrial uniforms and heavy-duty upholstery.

Hollow Fibers Offered in deniers from 6.7 to 13 dtex, green hollow fibers are engineered with a central void that traps air. This structure provides lightweight volume and enhanced thermal insulation. These fibers are available in both siliconized finishes for a “slick” hand-feel and non-siliconized finishes for applications requiring higher friction and bonding.

Hollow Conjugated Siliconized (HCS) Fibers Commonly used for applications requiring maximum loft and warmth retention, HCS fibers feature a three-dimensional spiral crimp. This makes them the ultimate choice for high-end filling materials where “bounce-back” resilience and a soft, feather-like touch are non-negotiable requirements.

Characteristics of Recycled Green Hollow Fiber

Green polyester fibers are renowned for a set of unique properties that distinguish them from natural fibers and traditional synthetics:

Vibrant and Chemical-Free Coloration The most significant characteristic of this fiber is its ability to retain deep green tones—ranging from forest green and olive to emerald—without the use of coloring chemicals or masterbatches. Because the pigment is inherent to the bottle source, the color does not fade after repeated washing or prolonged exposure to UV light.

Industrial Durability and Maintenance Polyester fibers are inherently resistant to wear and tear. This durability ensures a long-term service life, even in high-use environments. Furthermore, these fibers offer exceptional wrinkle resistance and a “wash-and-wear” convenience that requires minimal maintenance compared to silk or cotton.

Moisture-Wicking and Breathability The engineering of hollow fiber allows for superior breathability. The material is quick-drying and hydrophobic, making it an ideal candidate for activewear, uniforms, and outdoor gear that must perform under moisture-heavy conditions.

Strategic Applications Across Industries

The aesthetic appeal and practical durability of green hollow fiber allow it to transcend the boundaries of traditional textile use:

Fashion, Apparel, and Costume Design In the world of fashion, green polyester fibers provide designers with a palette of vibrant, durable hues. From the luxurious drape of green satin and crepe used in eveningwear to the flexibility of stretch polyester used in casual leggings and jumpsuits, the material offers endless creative flexibility. Furthermore, the theatrical industry relies on the vibrant neon and sage tones of green polyester for costumes that require both visual impact and the ability to withstand the rigors of performance.

Premium Home Décor and Upholstery Green polyester velvet and twill are extensively used in home décor. The fade-resistant nature of the fiber makes it ideal for curtains and drapery that are constantly exposed to sunlight. In upholstery, green polyester provides a luxurious touch to furniture while ensuring that cushion covers remain vibrant and durable over years of use.

Industrial and Composite Reinforcements Beyond aesthetics, green polyester fibers serve functional roles in industrial settings. In some advanced manufacturing sectors, green-dyed fibers are combined with carbon fiber to reinforce composite structures. These hybrids are used in automotive parts and sporting goods where weight reduction and structural integrity are paramount.

The Benefits of Sourcing Green Polyester Fiber

Manufacturers who transition to green hollow fiber enjoy several strategic advantages:

Creative Flexibility and Aesthetic Appeal The wide range of naturally occurring green shades provides designers with a unique palette that suggests a “natural” and “earthy” brand identity without the use of toxic dyes.

Low Maintenance and Easy Care Polyester is significantly easier to clean than natural fabrics. It resists staining and does not require specialized dry cleaning, which lowers the total cost of ownership for the end consumer.

Eco-Friendly and Sustainable Solutions By using recycled PET materials, manufacturers contribute to environmental conservation. The reduction in chemical usage during the coloring process further enhances the “Green” credentials of the final product, allowing brands to meet the strict GRS (Global Recycled Standard) requirements.

Innovations in Green Fiber Technology

Recent advancements in South East Asia and China have introduced groundbreaking methods for enhancing the performance of green-colored fabrics. Innovations such as nanotechnology-based dyeing using green silver nanoparticles (G-AgNPs) synthesized with chitosan have been explored to provide antibacterial properties while enhancing color fastness. Furthermore, ongoing improvements in sustainable production techniques continue to reduce the environmental impact of manufacturing, ensuring that green hollow fiber remains at the forefront of the eco-conscious textile revolution.

Conclusion: The Future of Sustainable Textiles

Green hollow fiber represents a perfect fusion of functionality and aesthetic versatility. Whether utilized in high-fashion couture, luxury home décor, or heavy-duty industrial applications, these fibers offer a combination of durability, vibrant color retention, and ease of maintenance that natural fibers cannot match. By choosing high-quality recycled green PSF, manufacturers are investing in a material that supports both creative excellence and a healthier planet.

Technical Parameter

Polyester Staple Fiber used in Non-woven Industry

| Luster | Denier | Cross Section | End-Use |

| SD | 1.5, 1.7, 2, 3, 4, 6 & 15 | Solid | Nonwoven Interlining, Sanitary Material, Microfiber and Thermal Bonding |

| FBR (Black) | 1.5, 1.7 & 3 | Solid | Needlepunch, Resin Bonding & Fiberfill |

| SD | 1.5 & 4.5 | Solid | Dyeable Fabric & High-Pile |

| SD | 6, 8 & 15 | Hollow and Hollow-Siliconized | Resin Bonding, Needlepunch, Fiberfill, Flame Retardant Fabric, Anti Bacteria & Platinum Photon Fiber |

| SD, BR,OBBR | 0.7, 1.1, 1.2, 1.4, 2.0, 6, 8, 12, 15 & 20 | Solid | Low Pilling, Knitting, Fiberfill, Thermal Bonding, Needlepunch, Infrared Fiber & Resin Bonding |

| SD | 2, 3, 4.5, 7, 12 & 15 | Hollow Conjugate | Resin Bonding, Needlepunch & Fiberfill |

| SD | 7 | Hollow Conjugate | Anti-Bacteria |

Polyester Staple Fiber as per Direct End Use

| Type | Denier | Section | End Use |

| Anti Pilling | 1.4, 1.5, 2, 2.5 & 3 | Solid & Hollow | Sportswear, Underwear, Casual wear |

| Bamboo Charcoal | 1.5, 1.7 & 6 | Hollow | Bedding, Shoe pad, Cushion, Thermal Sock |

| Spinning Use | 1.3, 1.4, 1.5 & 1.7 1.5 | Solid Hollow | Sportwear, Casual Wear, Underwear |

| Dopedyed Black | 1.5, 2 & 3 | Solid | Nonwoven, Casual wear, Sport wear, Underwear |

| Flame Retardant | 1.4 | Solid | Home, Comfort & Clothing textiles |

| Micro Fiber | 0.8 – 1.0 | Solid | Cloth & Fleece |

| High Tenacity | 1.2 | Solid | Yarn, Cloth & Water transport |

| High Void Conjugate | 3, 7, 12 & 15 | Hollow | Toy Padding, Badding, Furniture Cushion, etc |

| Regular Fiber | 2, 2.5, 3, 6 & 15 | Solid | Nonwoven, Filter medics, Padding, etc. |

FAQ

1. What do you offer?

We supply a comprehensive range of fibers, including recycled hollow conjugated (both siliconized and non-siliconized) polyester staple fiber, hollow fiber, microfiber, virgin polyester staple fiber, and low-melt fiber.

2. What is it used for?

Our fibers are versatile and widely utilized across both the filling and non-woven industries, providing essential loft, durability, and texture for various consumer and industrial applications.

3. Are you a factory or a trading company?

We are primarily a manufacturer specializing in polyester staple fiber with years of industry expertise. To better serve our clients, we also operate a dedicated trading division that allows us to act as a one-stop solution provider.

In addition to our own fiber production, we source high-quality textile components (such as yarn and low-melt fibers) and finished goods (including foam, pillows, cushions, toys, and down/feather products) to ensure our customers have access to a comprehensive supply chain.

4. Where is your factory location?

To maintain a robust and flexible global supply chain, our manufacturing facilities are strategically located throughout Asia, specifically in Vietnam, China, Malaysia, Thailand, and Indonesia. If you would like to visit one of our sites, please contact your sales representative, and we will be happy to arrange transportation for you.

5. Can you accept free sample?

Yes, we provide free hand samples for quantities under 1 kilogram. Once a price is confirmed, we can prepare and dispatch your sample within 2–3 business days. Please note that while the sample is free, the freight costs are the responsibility of the client.

6. Can you provide ODM service?

Absolutely. We specialize in ODM (Original Design Manufacturing). This means we can customize the material composition, dimensions, quantity, packaging, and branding to meet your specific requirements. Your logo and unique specifications will be integrated into the final product.

7. How about your quality? What’s the minimum order Quantity (MOQ)?

We invite you to place a trial order to experience our quality firsthand. Our standard MOQ is 23,000 kilograms per order.

Regarding pricing, we maintain a no-bargain policy. We believe in transparency and efficiency, so we provide our most competitive offer upfront to save you time and ensure a straightforward procurement process.

8. Can I mix different items in one order?

Yes, for your convenience, we allow for a maximum of two different items to be mixed within a single container.

9. How can you guarantee the product quality?

Quality is the cornerstone of our business. We employ an experienced QC team that monitors every stage of production, from raw material inspection to the final manufacturing process. We utilize a range of advanced testing instruments to ensure our fibers meet strict industry standards.

Our business philosophy is simple: We aim to serve one customer 1,000 times, rather than 1,000 customers once. We prioritize long-term partnerships built on consistent excellence.

10. What’s the payment terms?

L/C at sight, 30% TT in advance are mostly accepted; other terms shall be negotiable by both sides

For more information, please feel free to contact :

Tony Tan

Mobile number: +84 90 466 5251 (Whatsapp/Wechat/Viber/Signal)