Flame Retardant Polyester staple Fiber

Superior Safety: High-performance polyester with permanent flame-retardant properties.

Versatile Use: Ideal for home textiles, apparel, and automotive interiors.

Dual Benefit: Combines the durability of polyester with essential fire protection.

PRODUCT DETAIL

In industries where fire safety is paramount—ranging from automotive interiors and public transportation to home furnishings and protective apparel—the raw materials used can mean the difference between a minor incident and a catastrophe. Flame Retardant (FR) Polyester Staple Fiber has emerged as a high-tech, environmentally friendly solution designed to delay combustion, prevent the spread of flames, and minimize toxic smoke emissions.

Unlike standard polyester, which can act as a fuel source, FR Polyester is engineered at the molecular level to act as a fire-stopping barrier.

What is Flame Retardant Polyester Fiber?

Flame Retardant Polyester is a modified synthetic fiber that incorporates advanced chemical technology to inhibit the combustion process. While regular fibers ignite and burn rapidly, FR fibers are designed to melt rather than burn.

The “Self-Extinguishing” Property

One of the most critical features of this fiber is its ability to self-extinguish. When the material is exposed to an open flame, it will char and melt; however, the moment the external heat source is removed, the fiber ceases to burn. This characteristic is vital for preventing “after-flame” spread in household and industrial settings.

Advanced Chemical Engineering: Non-Halogen Technology

Modern safety standards now demand environmentally friendly flame retardants. Older technologies often relied on halogens (like bromine or chlorine), which release highly toxic gases when heated.

Our FR Polyester utilizes Non-Halogen Phosphorus-based technology:

Copolymerization: Phosphorus-based reactive flame retardants and inorganic polymers are added directly during the fiber aggregation (polymerization) process.

Intrinsic Stability: Because the flame retardant is “built-in” to the polymer chain rather than just coated on the surface, the fire resistance does not wash out or wear off over time.

Low Toxicity: In the event of extreme heat, these fibers release significantly less toxic smoke and no halogenated gases, meeting strict international environmental regulations.

Major Applications Across Industries

Home Textiles & Upholstery

For mattresses, curtains, and carpets, FR fiber is a legal requirement in many regions. It delays the spread of fire in residential settings, providing occupants with critical extra minutes to escape.

Automotive & Transportation

FR Polyester is extensively used in seat materials and automotive interiors. It meets the rigorous safety standards required for public buses, trains, and aircraft, where fire containment is a matter of national safety.

Protective Apparel

While firefighters wear specialized aramid fibers, FR Polyester is frequently used in secondary protective layers and workwear for industrial workers exposed to high-heat environments.

Building Insulation & Nonwovens

In construction, FR nonwoven felts prevent fires from traveling through walls or ventilation systems, protecting the structural integrity of the building.

Classification of FR Fibers

Intrinsic FR Fibers: Naturally fire-resistant materials like Basalt, Glass, or Aramid fibers.

Modified FR Fibers: Synthetic fibers (Polyester, Nylon, Cellulose) that gain fire resistance through chemical modification during spinning or blending. This is the most cost-effective and versatile category for consumer goods.

Future Trends: Research & Innovation

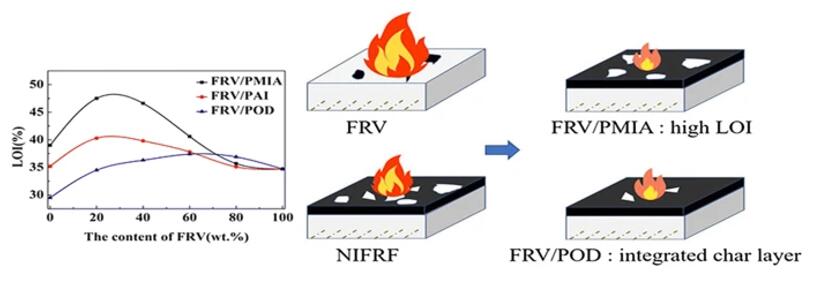

The industry is moving toward Functional Composites. Recent research by experts like Shuheng Liang has demonstrated that blending FR Viscose with nitrogen-containing intrinsic fibers can achieve an LOI as high as 47.5%. The future of Vnpolyfiber lies in these green, long-term environmental protection types that combine high safety with low ecological impact.

Conclusion: Why Invest in FR Polyester?

Choosing Flame Retardant Polyester Staple Fiber is an investment in safety and liability reduction. With an LOI of 32%+, non-halogen toxicity levels, and high durability, it provides a high-tech shield for your products.

Whether you are designing a new line of home textiles or sourcing materials for automotive seating, our FR fibers offer the performance and peace of mind that modern consumers and regulators demand.

Technical Parameter

Understanding the Limiting Oxygen Index (LOI)

To quantify how “fireproof” a fiber is, the industry uses the Limiting Oxygen Index (LOI). This measures the minimum percentage of oxygen required in the air to support the combustion of the material.

Flammable Materials: LOI < 22% (burns easily in normal air).

Combustible Materials: LOI between 22% and 27%.

Flame Retardant Materials: LOI > 27%.

Our high-quality FR Polyester Staple Fiber boasts an LOI ≥ 32%, placing it firmly in the superior protection category.

LOI Comparison Table: Common vs. FR Fibers

| Fiber Type | LOI Value (Standard) | Fiber Type (FR Modified) | LOI Value (FR) |

| Cotton | 18.0 | FR Polyester (PET) | 28.0 – 32.0+ |

| Acetate | 17.0 | FR PAN (Acrylic) | 27.0 |

| Regular Polyester | 23.5 | PVC Fiber | 35.0 |

| Nylon | 22.0 | PSA Fiber | 33.0 |

| Wool | 24.0 | Phenolic Fiber | 50.0 |

The Flame Retardant Mechanism: How it Works

The goal of FR technology is to disrupt the “Fire Triangle” (Fuel, Heat, Oxygen). The mechanism of our polyester involves:

Endothermic Effect: The fiber absorbs heat during decomposition, cooling the surrounding environment.

Covering Protection: As it melts, it forms a char layer that acts as a physical barrier, isolating the polymer from oxygen and heat.

Gas Dilution: The decomposition releases non-combustible gases that dilute the flammable gases near the fire source.

Droplet Effect: Modified PET is engineered so that if droplets form, they do not carry flames to other surfaces (Non-flaming droplets).

Video

FAQ

1. What do you offer?

We supply a comprehensive range of fibers, including recycled hollow conjugated (both siliconized and non-siliconized) polyester staple fiber, hollow fiber, microfiber, virgin polyester staple fiber, and low-melt fiber.

2. What is it used for?

Our fibers are versatile and widely utilized across both the filling and non-woven industries, providing essential loft, durability, and texture for various consumer and industrial applications.

3. Are you a factory or a trading company?

We are primarily a manufacturer specializing in polyester staple fiber with years of industry expertise. To better serve our clients, we also operate a dedicated trading division that allows us to act as a one-stop solution provider.

In addition to our own fiber production, we source high-quality textile components (such as yarn and low-melt fibers) and finished goods (including foam, pillows, cushions, toys, and down/feather products) to ensure our customers have access to a comprehensive supply chain.

4. Where is your factory location?

To maintain a robust and flexible global supply chain, our manufacturing facilities are strategically located throughout Asia, specifically in Vietnam, China, Malaysia, Thailand, and Indonesia. If you would like to visit one of our sites, please contact your sales representative, and we will be happy to arrange transportation for you.

5. Can you accept free sample?

Yes, we provide free hand samples for quantities under 1 kilogram. Once a price is confirmed, we can prepare and dispatch your sample within 2–3 business days. Please note that while the sample is free, the freight costs are the responsibility of the client.

6. Can you provide ODM service?

Absolutely. We specialize in ODM (Original Design Manufacturing). This means we can customize the material composition, dimensions, quantity, packaging, and branding to meet your specific requirements. Your logo and unique specifications will be integrated into the final product.

7. How about your quality? What’s the minimum order Quantity (MOQ)?

We invite you to place a trial order to experience our quality firsthand. Our standard MOQ is 23,000 kilograms per order.

Regarding pricing, we maintain a no-bargain policy. We believe in transparency and efficiency, so we provide our most competitive offer upfront to save you time and ensure a straightforward procurement process.

8. Can I mix different items in one order?

Yes, for your convenience, we allow for a maximum of two different items to be mixed within a single container.

9. How can you guarantee the product quality?

Quality is the cornerstone of our business. We employ an experienced QC team that monitors every stage of production, from raw material inspection to the final manufacturing process. We utilize a range of advanced testing instruments to ensure our fibers meet strict industry standards.

Our business philosophy is simple: We aim to serve one customer 1,000 times, rather than 1,000 customers once. We prioritize long-term partnerships built on consistent excellence.

10. What’s the payment terms?

L/C at sight, 30% TT in advance are mostly accepted; other terms shall be negotiable by both sides

For more information, please feel free to contact :

Tony Tan

Mobile number: +84 90 466 5251 (Whatsapp/Wechat/Viber/Signal)