Bicomponent Fiber

- Bicomponent fibers are extensively used in nonwovens for products like baby diapers, medical textiles, wipes, and filters due to their softness, strength, and bonding abilities.

- Material: PET/PE

- Fiber Type: Bicomponent ES

- Color: Raw white

- Fineness: 1.4D-20D

PRODUCT DETAIL

In the rapidly evolving world of synthetic textiles, bicomponent fiber has emerged as a revolutionary material. Unlike traditional monocomponent fibers, which are extruded from a single polymer, bicomponent fibers are engineered “miracle fibers” that combine the best properties of two different materials into a single filament.

For industries ranging from hygiene and medical textiles to high-performance filtration, understanding the mechanics of bicomponent technology is essential for product innovation. In this guide, we will explore the structures, polymer combinations (like PET/PE), and the massive industrial advantages of these specialized fibers.

What is Bicomponent Fiber?

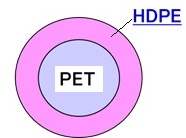

At its core, a bicomponent fiber is a synthetic filament consisting of two distinct polymers extruded simultaneously through the same spinneret. Instead of mixing the polymers into a chemical blend, they remain physically separate but bonded together within the cross-section of the fiber.

This “two-in-one” approach allows manufacturers to solve the age-old trade-off in textile engineering: the struggle between strength and softness, or durability and bondability. By strategically placing one polymer in the center (core) and another on the outside (sheath), we create a fiber that performs tasks a single polymer never could.

Technical Configurations: The Geometry of Performance

The way the two polymers are arranged determines the fiber’s “personality.” There are four primary configurations used in modern manufacturing:

1. Core-Sheath (C/S) – The “Bonding” Specialist

This is the most common configuration, especially for ES (Easy Soft) fibers.

The Core: Usually a high-melting-point polymer like PET (Polyester), providing the tensile strength and structural “skeleton.”

The Sheath: A lower-melting-point polymer like PE (Polyethylene) or Co-PET.

The Result: When heat is applied, the sheath melts to act as a glue, while the core stays solid. This is the secret behind glue-free thermal bonding in nonwovens.

2. Side-by-Side (S/S) – The “Natural Crimp”

In this setup, two polymers are extruded next to each other. Because different polymers shrink at different rates when cooled or heated, the fiber naturally curls. This creates a permanent, 3D helical crimp that provides incredible loft, bulk, and springiness—perfect for high-end upholstery and insulation.

3. Segmented Pie (Splittable)

Imagine a pie cut into 8 or 16 wedges of alternating polymers (like Nylon and PET). After the fiber is woven or laid, high-pressure water jets “split” these wedges into individual micro-filaments. This is how high-performance microfiber cleaning cloths achieve their massive surface area.

4. Island-in-the-Sea

This is the “ultra-fine” technology. Many “islands” of one polymer are surrounded by a “sea” of another. Once the “sea” is dissolved away in a chemical bath, you are left with a bundle of ultra-fine nanofibers, often used in synthetic suedes (like Alcantara) and advanced filtration.

Deep Dive: The PET/PE Bicomponent Advantage

For many in the sales and marketing of nonwovens, the PET/PE (Polyester/Polyethylene) combination is the industry gold standard. Let’s look at why this specific pairing is so dominant in the 1.4D to 20D range.

Thermal Bonding Excellence: The PE sheath melts at roughly 130°C, while the PET core remains stable up to 250°C. This allows for high-speed “Through-Air Bonding,” creating a fabric that is strong but remains incredibly soft to the touch.

Chemical Stability: Both PET and PE are resistant to most chemicals, making them ideal for medical environments and industrial filters.

Skin-Friendliness: PE is naturally smoother and less irritating than PET, which is why Bicomponent ES fiber is the preferred choice for the top-sheet of baby diapers and feminine hygiene products.

Key Properties and Why They Matter

1. Superior Thermo-bonding

One of the biggest advantages of bicomponent fiber is the elimination of chemical binders. Traditional nonwovens often required “latex glue” to hold fibers together. Bicomponent fibers allow for thermal bonding, which is cleaner, more eco-friendly, and results in a more breathable product.

In the hygiene market, “hand-feel” is everything. By using a PE sheath, manufacturers can achieve a silk-like texture. This is why bicomponent fibers are ubiquitous in:

Face masks (inner layer)

Sanitary napkins

Adult incontinence products

3. Structural Integrity and Durability

Because the PET core provides a high modulus of elasticity, products made from these fibers don’t lose their shape easily. This is vital for filtration media, where the fiber must withstand high air or liquid pressure without collapsing.

4. High Loft and Insulation

Using side-by-side configurations or specific crimping techniques, bicomponent fibers can trap a massive amount of air. This makes them superior to natural down or standard polyester in winter jackets, sleeping bags, and mattress paddings.

Global Applications: Where Do We See Bicomponent Fibers?

Nonwoven Fabrics (The Powerhouse)

The largest consumer of bicomponent technology is the nonwoven sector. From Spunbond to Meltblown and Carded webs, these fibers provide the “glue” that holds the modern world together.

Hygiene: Diapers and wipes.

Medical: Surgical gowns and drapes.

Geotextiles: Road stabilization fabrics that need to last decades.

Advanced Filtration

In air purification (HEPA filters) and liquid filtration, the ability to control the fiber diameter (down to 1.4D and lower) allows for precise “pore size” control, trapping microscopic particles while maintaining high flow rates.

Automotive Industry

Modern cars use bicomponent fibers for sound insulation, headliners, and trunk liners. The PET/PE or PET/Co-PET fibers allow for molded parts that are lightweight yet rigid.

The Future: Sustainability and Innovation

As the global market shifts toward a circular economy, the bicomponent industry is adapting. We are seeing a rise in:

Biodegradable Bicomponents: Using PLA (Polylactic Acid) cores.

Mono-material Bicomponents: (PET/Co-PET) to ensure the entire product can be melted down and recycled without separating different plastics.

Conclusion

Bicomponent fiber is more than just a textile; it is a specialized tool for engineers to create the next generation of high-performance products. Whether you are looking for the extreme softness required for baby care or the rugged durability needed for industrial filtration, bicomponent technology offers a customizable solution that standard fibers simply cannot match.

Technical Parameter

Product Specifications for Sourcing

When sourcing high-quality Bicomponent ES Fiber, it is important to look for the following standard specifications to ensure compatibility with high-speed carding machines:

Material: PET/PE (Core/Sheath)

Fiber Type: Bicomponent ES

Color: Raw White (High brightness)

Fineness Range: 1.4D (for soft hygiene) up to 20D (for industrial padding)

Cut Length: Custom lengths (typically 38mm to 64mm) for various nonwoven processes.

Video

FAQ

1. What do you offer?

We supply a comprehensive range of fibers, including recycled hollow conjugated (both siliconized and non-siliconized) polyester staple fiber, hollow fiber, microfiber, virgin polyester staple fiber, and low-melt fiber.

2. What is it used for?

Our fibers are versatile and widely utilized across both the filling and non-woven industries, providing essential loft, durability, and texture for various consumer and industrial applications.

3. Are you a factory or a trading company?

We are primarily a manufacturer specializing in polyester staple fiber with years of industry expertise. To better serve our clients, we also operate a dedicated trading division that allows us to act as a one-stop solution provider.

In addition to our own fiber production, we source high-quality textile components (such as yarn and low-melt fibers) and finished goods (including foam, pillows, cushions, toys, and down/feather products) to ensure our customers have access to a comprehensive supply chain.

4. Where is your factory location?

To maintain a robust and flexible global supply chain, our manufacturing facilities are strategically located throughout Asia, specifically in Vietnam, China, Malaysia, Thailand, and Indonesia. If you would like to visit one of our sites, please contact your sales representative, and we will be happy to arrange transportation for you.

5. Can you accept free sample?

Yes, we provide free hand samples for quantities under 1 kilogram. Once a price is confirmed, we can prepare and dispatch your sample within 2–3 business days. Please note that while the sample is free, the freight costs are the responsibility of the client.

6. Can you provide ODM service?

Absolutely. We specialize in ODM (Original Design Manufacturing). This means we can customize the material composition, dimensions, quantity, packaging, and branding to meet your specific requirements. Your logo and unique specifications will be integrated into the final product.

7. How about your quality? What’s the minimum order Quantity (MOQ)?

We invite you to place a trial order to experience our quality firsthand. Our standard MOQ is 23,000 kilograms per order.

Regarding pricing, we maintain a no-bargain policy. We believe in transparency and efficiency, so we provide our most competitive offer upfront to save you time and ensure a straightforward procurement process.

8. Can I mix different items in one order?

Yes, for your convenience, we allow for a maximum of two different items to be mixed within a single container.

9. How can you guarantee the product quality?

Quality is the cornerstone of our business. We employ an experienced QC team that monitors every stage of production, from raw material inspection to the final manufacturing process. We utilize a range of advanced testing instruments to ensure our fibers meet strict industry standards.

Our business philosophy is simple: We aim to serve one customer 1,000 times, rather than 1,000 customers once. We prioritize long-term partnerships built on consistent excellence.

10. What’s the payment terms?

L/C at sight, 30% TT in advance are mostly accepted; other terms shall be negotiable by both sides

For more information, please feel free to contact :

Tony Tan

Mobile number: +84 90 466 5251 (Whatsapp/Wechat/Viber/Signal)