Antibacterial fiber

Bacteria Inhibition: Advanced technology stops germs from growing on the fiber surface.

Hygiene & Safety: Reduces the risk of infection and transmission for a cleaner experience.

Ideal Applications: Perfect for high-touch textiles and hygienic filling materials.

PRODUCT DETAIL

What is Antibacterial Polyester Fiber?

Antibacterial polyester staple fiber material is a specialized polyester product endowed with powerful antibacterial capabilities. In the modern market, this fiber presents ample application potential and high demand, offering healthier and cleaner alternatives across various sectors. As a modern functional fiber, it is produced by incorporating an antibacterial masterbatch and employing a distinctive procedure to ensure long-lasting protection.

Whether used in medical environments, home textiles, or outdoor gear, antibacterial fiber plays a crucial role in minimizing the transmission of germs and bacteria.

Antibacterial fiber is a high-tech functional material produced by incorporating an antibacterial masterbatch into the polyester polymer. This unique manufacturing process ensures that the fiber exhibits strong resistance to methicillin, Staphylococcus aureus, and other common pathogens.

It possesses both antibacterial and bactericidal properties, meaning it does not just inhibit the growth of bacteria but actively works to kill them, effectively preventing infections.

Core Product Characteristics:

Broad-Spectrum Protection: Our fibers offer a comprehensive range of silver ions, zinc oxide, and elemental copper antibacterial properties.

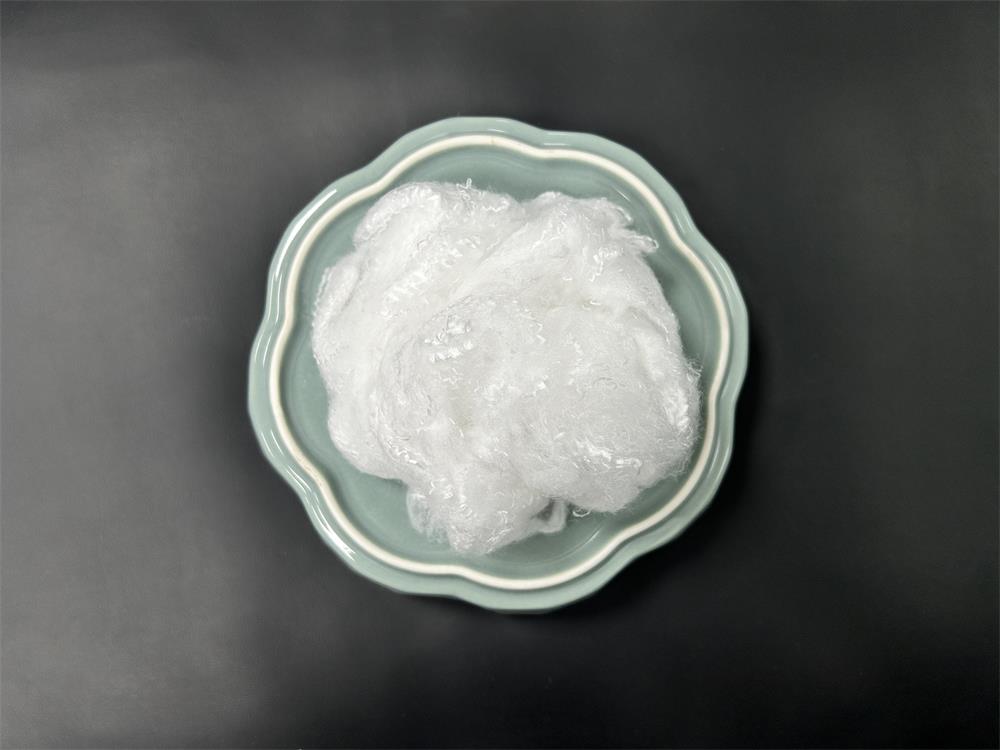

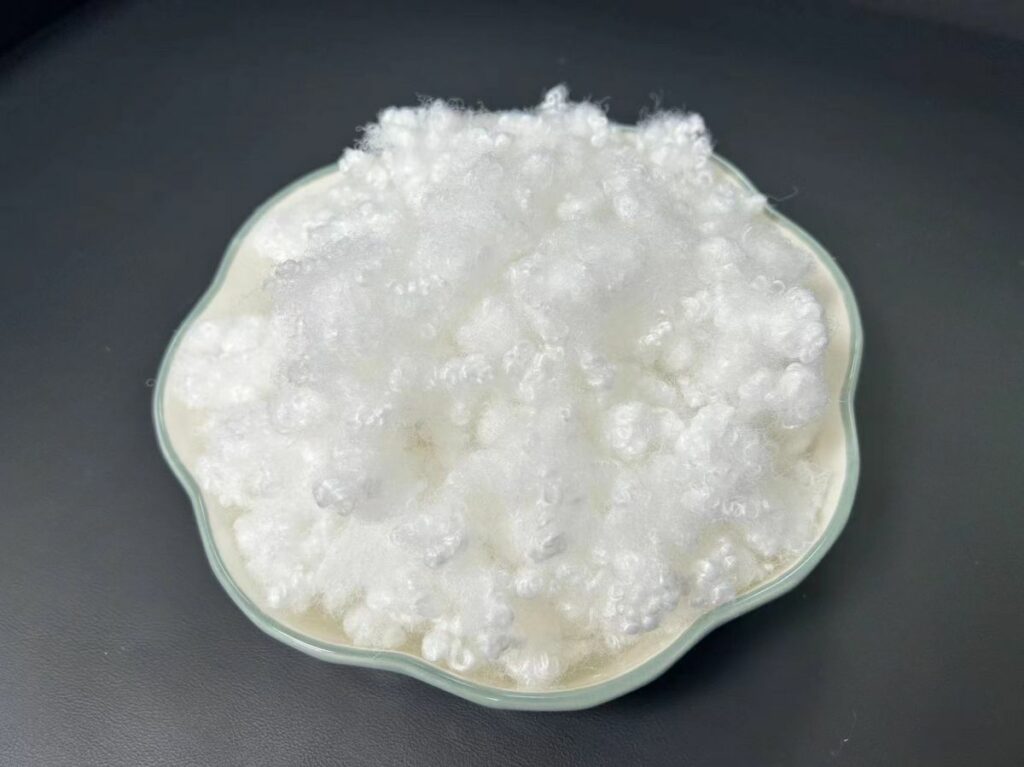

Aesthetic Flexibility: The fiber is white in color and can be easily dyed to meet specific fashion or industrial requirements.

Permanent Performance: Unlike surface-treated fabrics, this fiber endures multiple wash cycles without compromising its permanent antibacterial attributes.

The Role of Polyester Short Fiber

The base of this product is polyester short fiber. Comprising high-quality polyester raw materials, this short fiber boasts outstanding wear resistance, corrosion resistance, and elasticity. These traits make it ideal for manufacturing various textiles and filling materials.

Because it delivers excellent softness and elasticity, it is perfectly suited for creating diverse textiles like bedding, apparel, and household items. Additionally, it serves as an optimal filling material for mattresses, cushions, and sofa cushions, catering to the diverse requirements of the global textile sector.

Technical Achievement: How the Antibacterial Function Works

The antibacterial function of this fiber is achieved through specialized technology that inhibits bacterial growth directly on the fiber surface. This function effectively restricts bacterial proliferation, thereby:

Reducing Transmission: Lowering the risk of bacterial spread and infection.

Hygienic Experience: Offering users a cleaner, fresher, and more hygienic experience throughout the product’s life.

Methods of Preparation

There are two primary methods of obtaining antibacterial fiber:

Mixed Type Preparation (In-Melt): This involves blending heat-resistant inorganic antibacterial agents, such as ceramic powder containing silver, copper, and zinc ions, into the polyester melt before spinning. This ensures the antibacterial agent is “locked” inside the fiber.

Post-Treatment Type: This entails adding antibacterial agents to the surface of the polyester fibers after they have been formed. This type of fiber finds wide applications in underwear, medical supplies, and home textiles.

5 Key Benefits of Antibacterial Fiber

Minimizing Germ Transmission: It plays a vital role in high-traffic areas like hospitals, schools, and public spaces where bacterial loads are high.

Infection Risk Reduction: The effectiveness in eradicating bacteria helps significantly reduce the risk of healthcare-associated infections.

Odor Control: It effectively diminishes the presence of odor-causing bacteria, ensuring fabrics maintain a fresh and clean scent even after heavy use.

Environmental Integrity: While being a high-tech synthetic, these fibers can be engineered to be environmentally friendly. (Note: While standard polyester is not biodegradable, it can be recycled; natural alternatives like bamboo are often cited for their biodegradability).

Durability and Longevity: The fiber demonstrates extreme durability, retaining its antibacterial properties even after multiple industrial washes.

Diverse Applications and Domains

Home Textiles

In the home, antibacterial fiber is fashioned into bedding, towels, and bathrobes. These products cultivate a clean and cozy living environment, protecting families from the microscopic growth often found in damp or warm household areas.

Medical and Sanitary Products

In the realm of medical and health products, this fiber is indispensable. It is crafted into:

Medical Masks and Apparel

Surgical Towels and Drapes

Gauze and Bandages These applications are critical in thwarting the spread of bacteria in sterile environments.

Outdoor and Performance Gear

For outdoor products, the fiber is utilized in tents, sleeping bags, and backpacks. It offers a healthy and comfortable experience during outdoor endeavors by preventing the fiber decay and odors caused by moisture and bacterial reproduction.

Classification of Antibacterial Fibers

1. Natural Antibacterial Fiber

Some materials have inherent antibacterial properties and can be directly processed into fibers. Examples include:

Chitin and Chitosan fiber

Hemp fiber

Bamboo fiber

2. Artificial (Synthetic) Antibacterial Fiber

Antibacterial agents are added to ordinary fibers (like polyester, acrylic, polypropylene, or nylon) that do not naturally possess these functions.

Inorganic Agents: Ag (Silver), Cu (Copper), Zn (Zinc) ions and metal oxides.

Organic Agents: Organometallic compounds, halides, isothiazoles, and quaternary ammonium salts.

Technical Parameter

The Antibacterial Mechanism: Under the Microscope

Antibacterial effects are usually achieved by interfering with the bacteria at a cellular level. This includes:

Interfering with DNA and protein synthesis.

Disrupting the activity of enzymes involved in bacterial cell metabolism.

Contact Killing: Cationic polymers or metal ions express a charge that ruptures the bacterial cell membrane upon contact.

Leading Research: The Power of Zinc Oxide (ZnO)

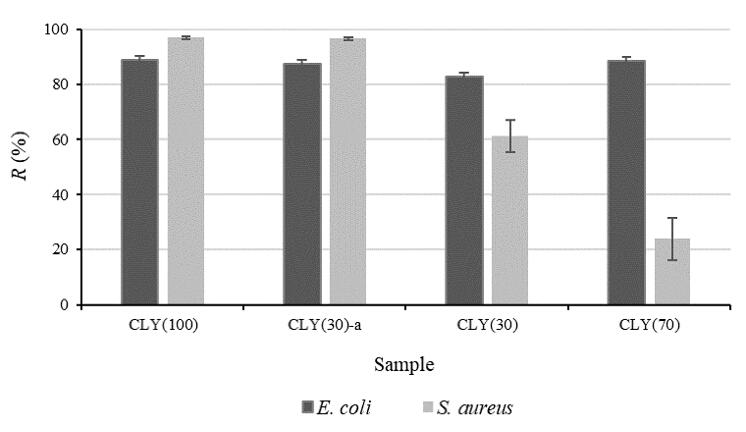

Innovative research continues to enhance the performance of these fibers. For example, studies by Domen Malis et al. investigated the effect of ZnO (Zinc Oxide) on the antibacterial activity of cellulose fibers. By testing against Gram-negative Escherichia coli and Gram-positive Staphylococcus aureus, researchers proved that the composition of the fiber blend (such as CLY fibers blended with CV) has a significant influence on its ability to kill bacteria, showcasing the future of functional composite fibers.

Reduction, R, of E. coli and S. aureus for different CLY fiber samples.

Conclusion: A Healthier Alternative

Whether used as gauze, bandages, or air conditioning filtration, antibacterial polyester staple fiber is a cornerstone of modern health-conscious manufacturing. It slows the rate of fiber decay, eliminates odor, and prevents the spread of disease, making it the preferred choice for the medical, food, and pharmaceutical industries.

Video

FAQ

1. What do you offer?

We supply a comprehensive range of fibers, including recycled hollow conjugated (both siliconized and non-siliconized) polyester staple fiber, hollow fiber, microfiber, virgin polyester staple fiber, and low-melt fiber.

2. What is it used for?

Our fibers are versatile and widely utilized across both the filling and non-woven industries, providing essential loft, durability, and texture for various consumer and industrial applications.

3. Are you a factory or a trading company?

We are primarily a manufacturer specializing in polyester staple fiber with years of industry expertise. To better serve our clients, we also operate a dedicated trading division that allows us to act as a one-stop solution provider.

In addition to our own fiber production, we source high-quality textile components (such as yarn and low-melt fibers) and finished goods (including foam, pillows, cushions, toys, and down/feather products) to ensure our customers have access to a comprehensive supply chain.

4. Where is your factory location?

To maintain a robust and flexible global supply chain, our manufacturing facilities are strategically located throughout Asia, specifically in Vietnam, China, Malaysia, Thailand, and Indonesia. If you would like to visit one of our sites, please contact your sales representative, and we will be happy to arrange transportation for you.

5. Can you accept free sample?

Yes, we provide free hand samples for quantities under 1 kilogram. Once a price is confirmed, we can prepare and dispatch your sample within 2–3 business days. Please note that while the sample is free, the freight costs are the responsibility of the client.

6. Can you provide ODM service?

Absolutely. We specialize in ODM (Original Design Manufacturing). This means we can customize the material composition, dimensions, quantity, packaging, and branding to meet your specific requirements. Your logo and unique specifications will be integrated into the final product.

7. How about your quality? What’s the minimum order Quantity (MOQ)?

We invite you to place a trial order to experience our quality firsthand. Our standard MOQ is 23,000 kilograms per order.

Regarding pricing, we maintain a no-bargain policy. We believe in transparency and efficiency, so we provide our most competitive offer upfront to save you time and ensure a straightforward procurement process.

8. Can I mix different items in one order?

Yes, for your convenience, we allow for a maximum of two different items to be mixed within a single container.

9. How can you guarantee the product quality?

Quality is the cornerstone of our business. We employ an experienced QC team that monitors every stage of production, from raw material inspection to the final manufacturing process. We utilize a range of advanced testing instruments to ensure our fibers meet strict industry standards.

Our business philosophy is simple: We aim to serve one customer 1,000 times, rather than 1,000 customers once. We prioritize long-term partnerships built on consistent excellence.

10. What’s the payment terms?

L/C at sight, 30% TT in advance are mostly accepted; other terms shall be negotiable by both sides

For more information, please feel free to contact :

Tony Tan

Mobile number: +84 90 466 5251 (Whatsapp/Wechat/Viber/Signal)