What are bicomponent fiber?

Two component fibers are highly praised for their unique characteristics that cannot be achieved by single component fibers. By selecting the correct combination of polymers and structural configurations, we can customize the performance of fibers to adapt to specific applications, including but not limited to absorption, strength, softness, heat resistance, and barrier performance. These innovative technologies are widely used in the processing of non-woven fabrics such as baby diapers, women’s sanitary napkins, adult diapers, and masks. The unique structure of dual component fibers can improve liquid management, breathability, and filtration efficiency in these applications.

What is low melting fiber?

Low melting fiber can be melted at temperature such as 100~200°C that bonds with other fibers deprived of any injurious adhesives than normal polyester fiber which can be melted at higher temperature of above 280°C. This property subsidizes to environmental preservation by producing low heat and carbon dioxide. It finds application in several areas such as door trims, automotive car interiors, ceiling materials, head liners, construction, furniture, industrial sector.

Low melting fiber is referred as a bi-component fiber which has strong bonding properties. The low melting fiber is used in the spinning of durable yarns. Moreover, this fiber is used as excellent insulating material in automotive and construction industry, due to its intricate structure. Furthermore, this fiber is blended with solid recycled material or solid polyester fibers, which is further used for the car molding. The low melting fiber provides easy bonding and high elasticity, and thus is used for the production of interior parts of car, mattress, medical goods, among others.

Low Melting Fiber refers to a bi-component fiber used as a thermal bonding fiber and its structure is typically a sheath/core type. It is composed of a sheath polymer and a core polymer. The melting point of the sheath polymer is lower than that of the core polymer.

The low melting fiber offers various benefits such as low melting point, durability, and high bonding strength. Moreover, it is blended with other types of fibers and is used to manufacture padding, interlining, and high quality mattress. Furthermore, it is used to manufacture sanitary and medical products. Thus, different benefits of low melting fiber is likely to boost the product demand across the globe.

COVID-19 Impact on Global Low Melting Fiber Market

Occurrence of novel coronavirus disease has obstructed the globe economy. Leading countries across the globe announced the lockdown situations most of the key players in the global low melting fiber market forced to the shutdown their production plants and sales as well as production of the automotive, construction components has been stopped which has directly affected on the target market industry. Major industries affected due to the distribution in the supply chain as well as lockdowns across the globe. However, the key supplies are resuming to the work, in order to accomplish their previous order by following government norms. COVID-19 situation is resolving gradually and most of the industries are starting their facilities at full capacity. The global low melting fiber industry is expected to grow post COVID world at significant growth rate.

The outbreak of COVID-19 significantly disrupted the Bicomponent Fiber market, leading to extensive disturbances in global supply chains and a notable decline in demand for products and services across various industries, including the Bicomponent Fiber market. Particularly in the first half of 2020, consumer spending was significantly impacted due to lockdowns and social distancing measures in numerous countries, resulting in reduced non-essential purchases and subsequently affecting market demand.

Moreover, COVID-19 severely disrupted manufacturing and supply chain operations, leading to production shutdowns and delays for many manufacturers due to workforce shortages, transportation constraints, and raw material scarcities. Consequently, the supply of Bicomponent Fiber products significantly decreased, exacerbating the market’s challenges.

However, with the implementation of vaccination programs and the gradual relaxation of restrictions in many countries, positive signs of recovery are emerging for the Bicomponent Fiber market. In response to the evolving market landscape, numerous businesses are adopting digital transformation strategies to enhance adaptability and improve competitiveness, which is expected to contribute to the gradual recovery of the Bicomponent Fiber market.

“In conclusion, while COVID-19 had a significant impact on the Bicomponent Fiber market, businesses are adapting to the changing market conditions and implementing measures to recover and thrive in the post-pandemic world.”

Global Low Melting Fiber Market 2024 by Manufacturers, Regions, Type and Application, Forecast to 2030

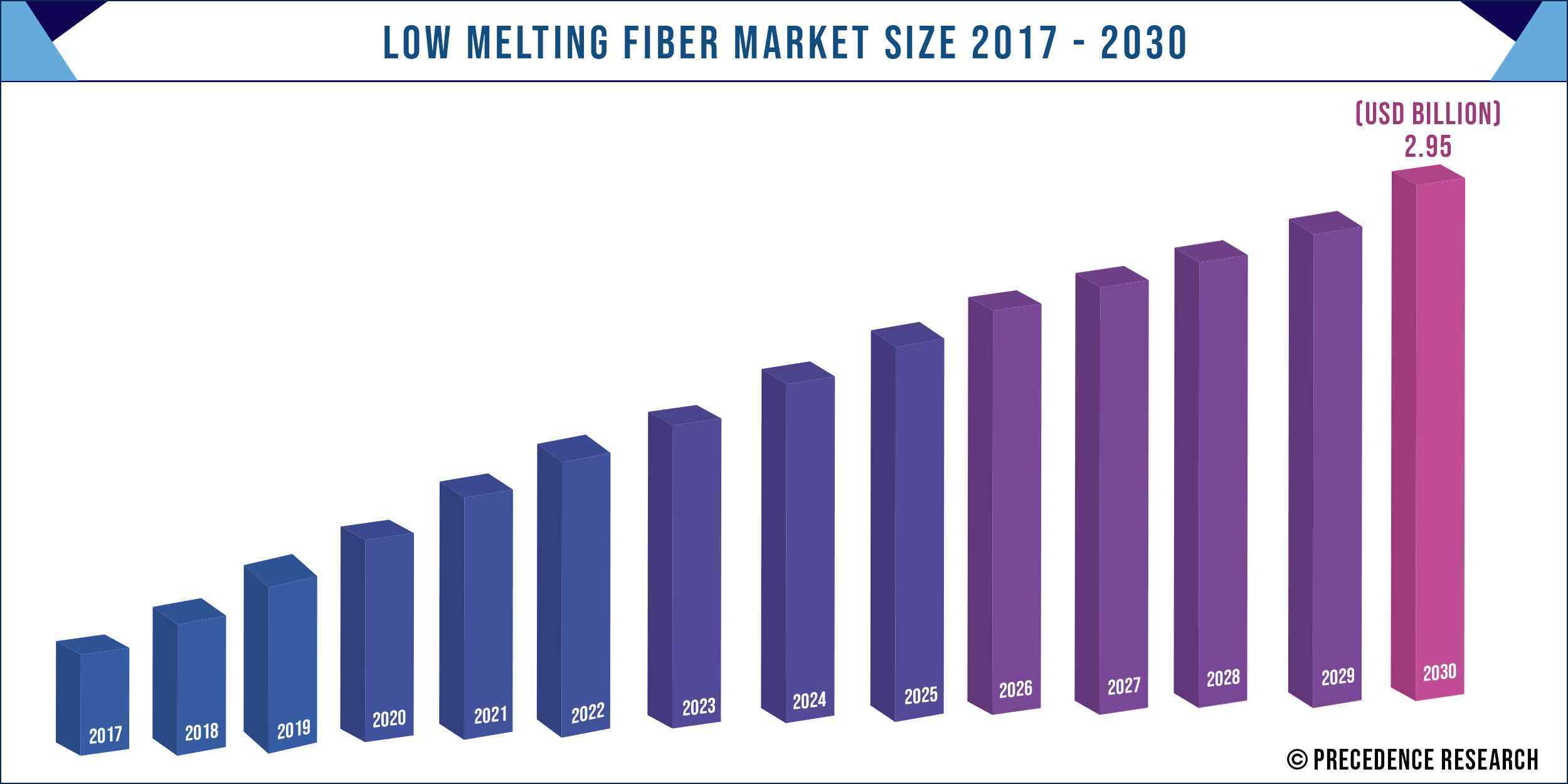

According to our (Global Info Research) latest study, the global Low Melting Fiber market size was valued at USD 1975.6 million in 2023 and is forecast to a readjusted size of USD 3373.3 million by 2030 with a CAGR of 7.9% during review period. Global Low Melting Fiber key players include Huvis, Toray Advanced Materials Korea, Far Eastern New Century, Nan Ya Plastics, etc. Global top four manufacturers hold a share about 70%. China is the largest market, with a share over 45%, followed by Korea and North America, both have a share over 45 percent. In terms of application, the largest application is Bedding Industry, followed by Automotive Industry, Construction, etc.

North America and Europe are experiencing steady growth, driven by government initiatives and increasing consumer awareness. Asia-Pacific, particularly China, leads the global Low Melting Fiber market, with robust domestic demand, supportive policies, and a strong manufacturing base.

Future of Global Low Melting Fiber Market

Increasing focus on the manufacturing of the vehicles is expected to fuel growth global low melting fiber industry in the near future. Heavy investment from the global EV’s as well as automakers, are expected to drive growth of the automotive and in turn growth of the global low melting fiber industry in the near future. In the manufacturing of automotive components including celling material, engine hoof, truck among others, low melting fiber plays vital role. Emergence of COVID has increased usage of the heightened hygienic products and low melting fiber is used in the production of such a various hygiene products including sanitary pads and dippers which is expected to fuel the target market industry in the near future. Further, post COVID world the bedding & furniture industry is anticipated to register significant growth rate owing to increasing adoption of the end use products like sofa and mattresses. This trend can have positive impact on the target industry growth over the forecast period of time.

Melting point ≤130 Segment Reported Major Market Share in 2020

On the basis of types, low melting fiber market is classified into melting point>130 and melting Point ≤130. Among these types, melting point ≤130 segment is projected to garner considerable market share during the forecast period. This product is ecological and obeys to low temperature. It further has outstanding bonding, improved mixing characteristics, and high resiliency which drive its demand across various application sectors.

Rising demand for low melting fiber in the automotive industry

Low melting fiber is used in the automotive materials including ceiling material, engine hoof, and others. Moreover, low melting fiber has an improved mixing properties, high resiliency, and outstanding bonding, which further proliferates the product demand. Furthermore, low melting fiber has a wide range of applications such as in car door trims, headliners, and others, and this is expected to offer lucrative growth opportunities across the global market players.

Fluctuating raw material prices hampering the market growth

The volatile prices of petroleum is likely to vary the raw material prices, this is further limiting the global low melting fiber market growth. Moreover, low melting fiber is not biodegradable as compared to natural fibers such as cotton, silk, hemp, and wool, among others. Furthermore, the lifespan of fibers has reduced, resulting in discarding non-woven low melting fiber, as litters, in the landfills. Owing to this, there are several environmental issues occurred which are hindering the product demand. Nevertheless, the growing demand for recyclable low melting fiber is projected to accelerate the market growth during the forecast period.

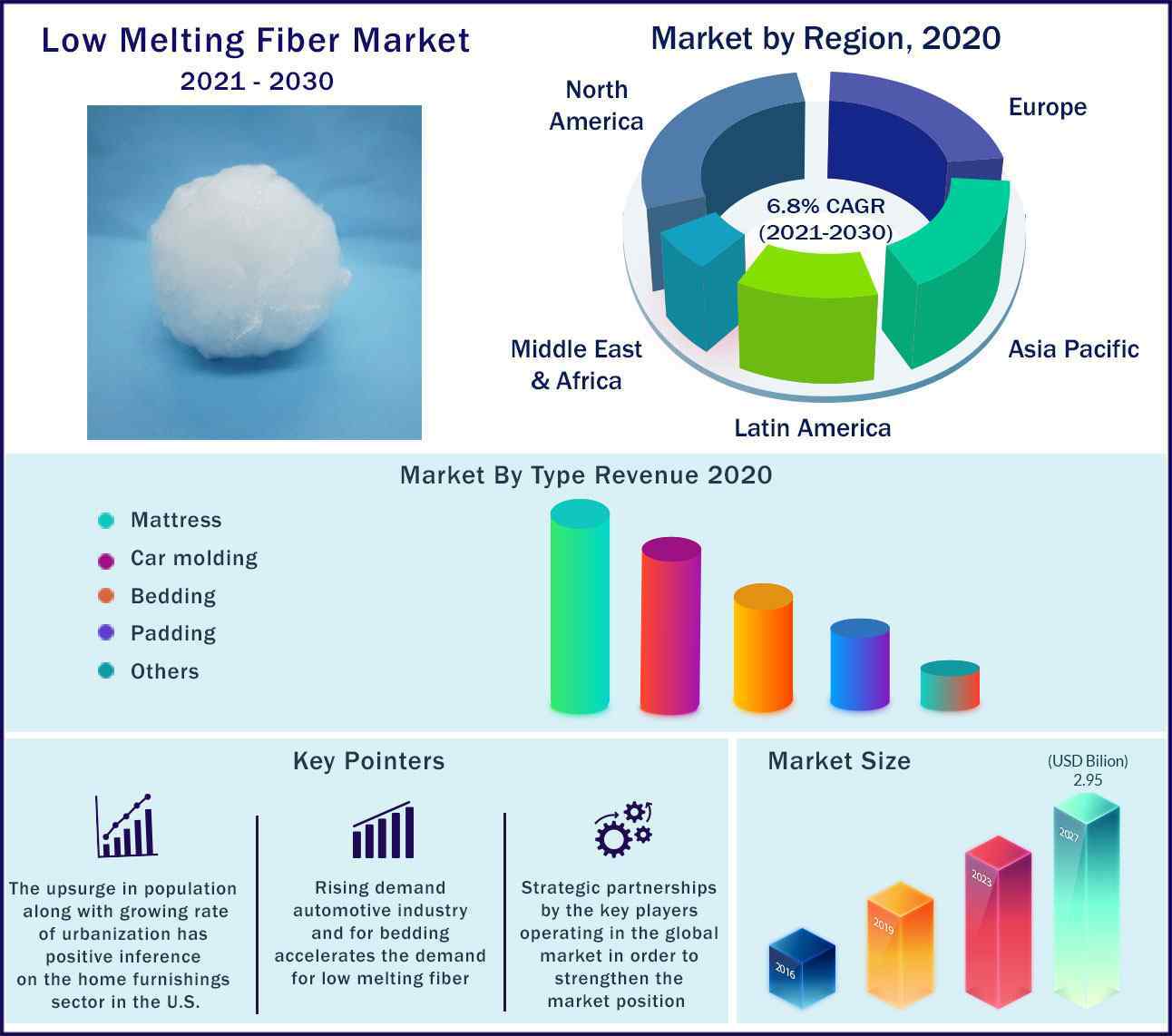

Mattress is Projected to Govern the Low Melting Fiber Market Revenue

Among various applications of low melting fiber, mattress segment dominated the market in terms of both volume and value in 2020. This high growth of the segment is credited to snowballing requirement from households and institutional, commercial sectors such as education, hospital and corporate segment. The development of the hospitality segment is helping to lift the advancement of mattress market. There is an augmented requirement for mattresses that offer outstanding coziness and sound sleep. Non-woven low melt fibers avert bed bug infestations hence widely employed in mattresses.

North America is Estimated to be the Largest Market for Low Melting Fiber

Low melting fiber market research report covers crucial trends and predictions of low melting fiber products across diverse geographical regions such as North America, Asia-Pacific, Europe, Latin America, and Middle East and Africa. China is the fastest advancing segment for low melting fiber across the globe. China accounted for considerable share for the global low melting fiber production in 2020. Also, in 2016, it was the significant importer of low melting fiber due to growing textile, carpet sector, and intensifying construction activities. China produced over 20 million tons of low melting fiber in 2010. China is the 2nd largest user of petroleum and derivative of petroleum distillation that is the feeder material for low melting fiber is likewise accessible in huge quantities.

North America market also offers noteworthy growth due to speedy growth of home furnishing industries and automotive sector. Further, rising bedding sector which is among the foremost sectors that employs low metal fiber drives the market demand in this region.

Some of the companies that are Top Players contending in the Market:

- FiberVisions Corporation

- Kolon

- Huvis

- Hyosung

- Far Eastern New Century

- Dupont

- Toray Advanced Materials Korea

- RadiciGroup

- Mitsubishi Chemical

- Jiangnan High Polymer Fiber

- FiberVisions Corporation

- Nan Ya Plastics

- XiangLu Chemical Fibers

- Yangzhou Tianfulong

- Ningbo Dafa

- ECER

- Beaulieu

- VNPOLYFIBER

Currently, Huvis is the global leader, and grasps over 30% market share in terms of production. Huvis, is the largest polyester company in Korea and was formed in 2000 when Samyang Corporation and SK Chemical divided their fabric divisions. Currently, the world’s largest low melt fiber company manufactures around 40% low melting fiber across the globe and exports to nearly 80 countries such as North America, Europe. The global low melting fiber sector has high concentration. The main manufacturers are concentrated in China, and Korea including Toray Chemical Korea, Huvis, Far Eastern New Century, XiangLu Chemical Fibers and Nan Ya Plastics.

Huvis a leading key player in the global low melting fiber industry established its joint venture in the United States along with the Indorama Ventures, in the year 2018. This joint venture is attributed to achieve leading position in the low melting fiber industry in the near future.

VNPOLYFIBER plays a role as a new player who can carter small and medium customers’ needs as we take our pride in our excellent customer service.

Photo of our low melting fiber is below:

Major Market Segments Covered:

By Type

- Melting Point ≤130

- Melting Point >130

By Application

- Mattress

- Automotive

- Construction

- Bedding

- Others

By Geography

- North America

- U.S.

- Canada

- Europe

- Germany

- France

- United Kingdom

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Rest of Latin America

- Middle East & Africa (MEA)

- GCC

- North Africa

- South Africa

- Rest of Middle East & Africa

Global Bicomponent Fiber Market Report Segments:

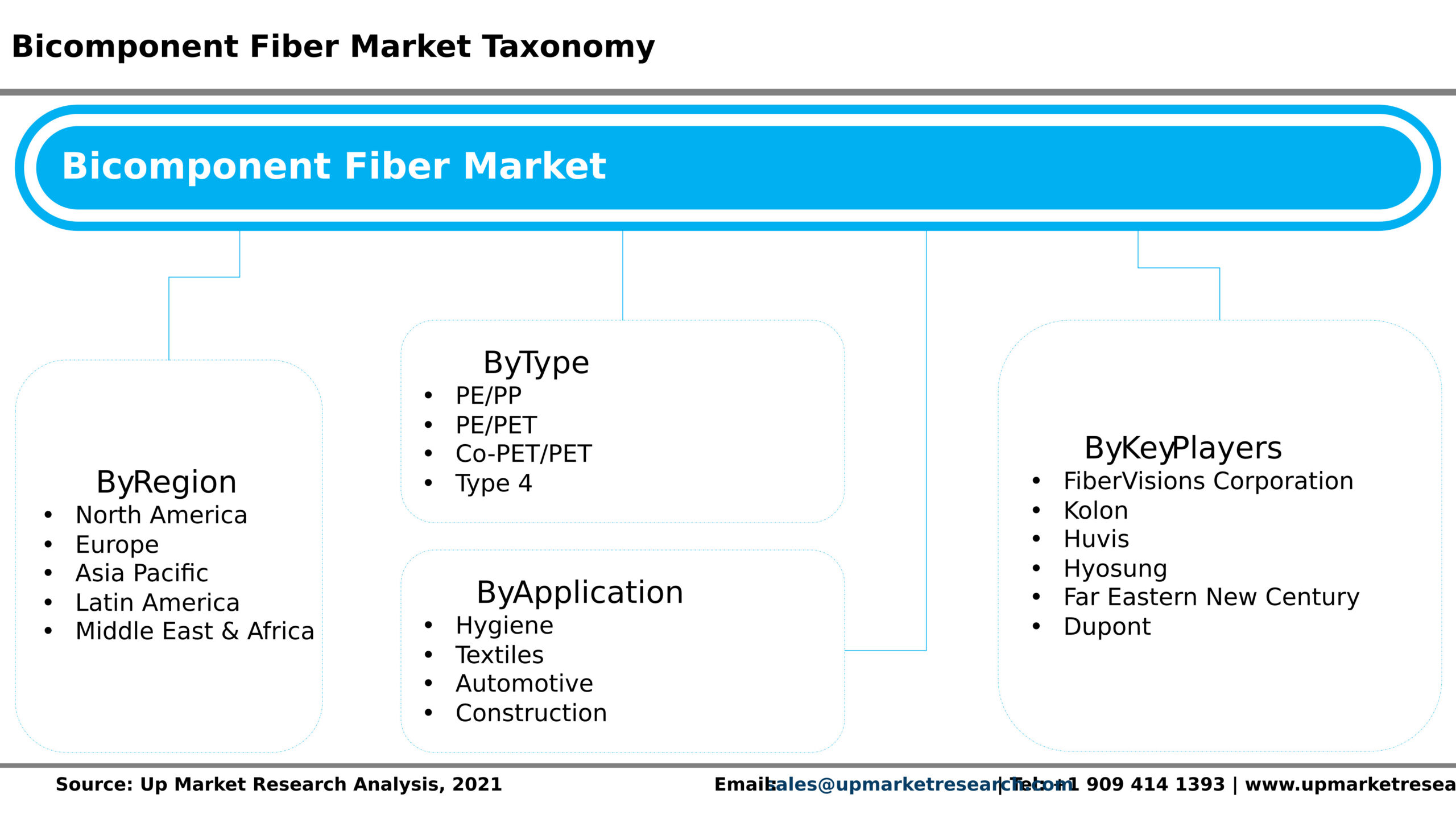

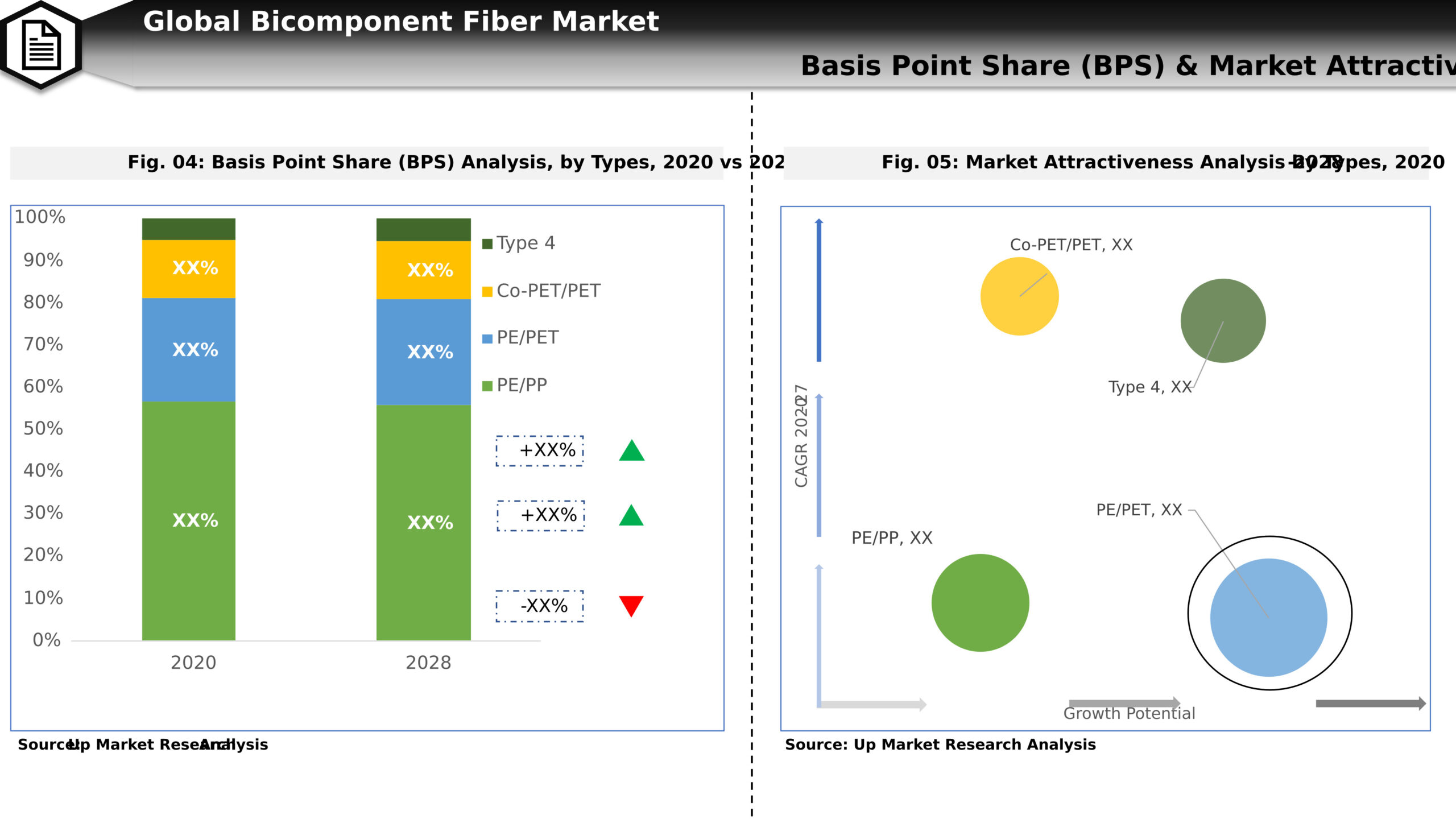

The market is segmented by Type PE/PP, PE/PET, Co-PET/PET and By Application Hygiene, Textiles, Automotive, Construction.

Bicomponent Fiber Market research report delivers a close watch on leading competitors with strategic analysis, micro and macro market trend and scenarios, pricing analysis and a holistic overview of the market situations in the forecast period. It is a professional and a detailed report focusing on primary and secondary drivers, market share, leading segments and geographical analysis. Further, key players, major collaborations, merger & acquisitions along with trending innovation and business policies are reviewed in the report.

Key Benefits for Industry Participants & Stakeholders:

- Industry drivers, restraints, and opportunities covered in the study

- Neutral perspective on the market performance

- Recent industry trends and developments

- Competitive landscape & strategies of key players

- Potential & niche segments and regions exhibiting promising growth covered

- Historical, current, and projected market size, in terms of value

- In-depth analysis of the Bicomponent Fiber Market

Overview of the regional outlook of the Bicomponent Fiber Market:

Bicomponent fibers, also known as conjugate fibers, are composed of two different fiber-forming polymers or similar fiber-forming polymers of different properties. Since the two components contained in the fiber complement each other, the performance of the composite fiber is generally superior to that of the conventional synthetic fiber, and has various uses.

According to our latest study, the global Bicomponent Fiber market size was valued at USD 3956 million in 2022 and is forecast to a readjusted size of USD 6073.7 million by 2029 with a CAGR of 6.3(Percent) during review period. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes.

The major manufacturers are concentrated in Korea, and China, such as FiberVisions Corporation, Kolon, Huvis, Hyosung, Toray Chemical Korea, etc. At present, Huvis is the world leader, holding about 19(Percent) production market share in 2019. VNPOLYFIBER can offer alternative options of bicomponent fiber which cost cheaper price and still maintain very good quality level.

In 2019, the global Bicomponent Fiber consumption market is led by China and China is the largest region consumption market, accounting for about 38(Percent) of global consumption of Bicomponent Fiber.

Based on region, the market is segmented into North America, Europe, Asia Pacific, Latin America and Middle East & Africa (MEA). North America region is further bifurcated into countries such as U.S., and Canada. The Europe region is further categorized into U.K., France, Germany, Italy, Spain, Russia, and Rest of Europe. Asia Pacific is further segmented into China, Japan, South Korea, India, Australia, South East Asia, and Rest of Asia Pacific. Latin America region is further segmented into Brazil, Mexico, and Rest of Latin America, and the MEA region is further divided into GCC, Turkey, South Africa, and Rest of MEA.

Highlights of The Bicomponent Fiber Market Report:

- The market structure and projections for the coming years.

- Drivers, restraints, opportunities, and current trends of Bicomponent Fiber Market.

- Historical data and forecast.

- Estimations for the forecast period 2028.

- Developments and trends in the market.

What are the types of Bicomponent Fiber available in the Market?

- Co-PET/PET

- PE/PP

- PE/PET

What are the factors driving applications of the Bicomponent Fiber Market?

- Hygiene

- Textiles

- Automotive

- Construction

Market scenario by region, sub-region, and country.

Market share of the market players, company profiles, product specifications, SWOT analysis, and competitive landscape.

Analysis regarding upstream raw materials, downstream demand, and current market dynamics.

Government Policies, Macro & Micro economic factors are also included in the report.

We have studied the Bicomponent Fiber Market in 360 degrees via. both primary & secondary research methodologies. This helped us in building an understanding of the current market dynamics, supply-demand gap, pricing trends, product preferences, consumer patterns & so on. The findings were further validated through primary research with industry experts & opinion leaders across countries. The data is further compiled & validated through various market estimation & data validation methodologies. Further, we also have our in-house data forecasting model to predict market growth up to 2028.

Which regions are leading the Bicomponent Fiber Market?

North America

Europe

Asia-Pacific

Middle East and Africa

South America

If you want to buy low melting fiber and bicomponent fiber, please free feel to contact us via email or Whatsapp. Our people will reply within 24 hours.