What are nonwovens?

Nonwovens are one of the fastest-growing segments of the textile industry.

The term “nonwoven” became popular more than half a century ago when nonwovens were regarded as low-price substitutes for traditional textiles. However, today, the nonwoven fabric technology is the most modern method used in the branch of textile industry. Nonwoven technology exists to approximate the appearance, texture, and strength of conventional woven and knitted fabrics due to their simple production stages, high efficiency of production, lower cost, and disposability. Multi-layer nonwoven composites, laminates, and three-dimensional nonwoven fabrics are commercially produced. Nonwovens combined with other materials have different chemical and physical properties. Therefore, nonwovens can be used a wide variety of industrial engineering, consumer, and health-care goods [1-7].

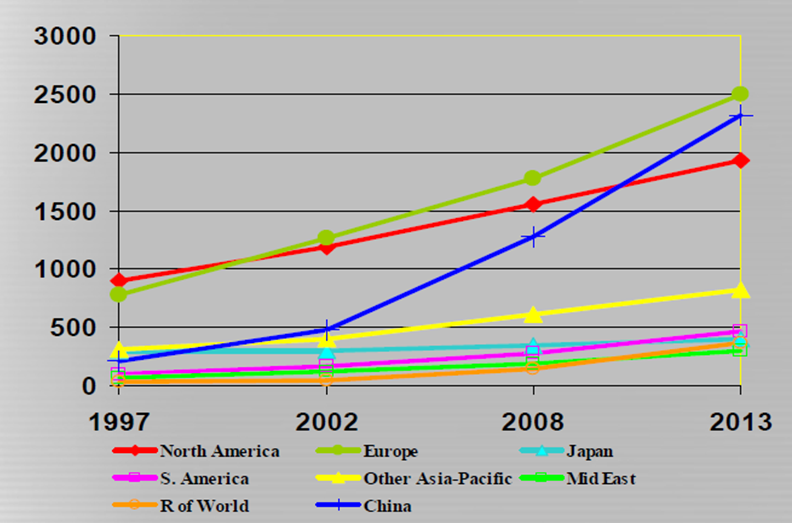

Among the textiles applications, nonwovens are one of the fastest-growing segments of the textile industry and constitute roughly one third of the fiber industry. The latest estimates, taking into account the official INDA (Association of Nonwoven Fabrics Industry) put the global nonwovens production at over 1,500,000 tons in North America, over 2,000,000 tons in China, and around 2,500,000 tons in Europe.

Meltblown

Nonwovens produced from the extrusion of polypropylene (PP) into microfilaments, forming a fabric with greater surface area. Optimized for superior adsorption or to form a barrier. Meltblown fabrics are known for their use as filters for face masks and respirators, but they can also be applied in oil sorbents and wipes, among others.

Carded

Nonwovens produced from the consolidation of a variety of fibers (such as PP, PE, PET, Rayon and Cotton) into a soft, lofty web through chemical, mechanical or thermal processes. We produce air-through bonded (ATB), resin bonded (RB), spunlaced, and thermobonded (TB) carded nonwovens.

Spunmelt

Nonwovens produced from the extrusion of one or more polymers (such as PP, PE or PLA) into filaments, that are consolidated into a web through a thermal process. Fitesa has the world’s largest spunmelt bicomponent capacity and offers multiple colors, bonding patterns and other properties.

Stitchbond Nonwoven Technology

The Ingenious Hybrid

As our company’s core competency, this technological capability lies at the heart of many market applications, and also answers the growing need for technically engineered material. Today, we are the world’s largest producer of Stitchbond fabrics. Our proprietary technology – bringing together combinations of materials — has already proven to have infinite possibilities.

The Origin

East German Textile Engineer Dr. Heinrich Mauersberger invented the original Stitchbond process in 1949, and produced the first “Maliwatt” stitchbond nonwoven machine in 1957.

The Successor

Arno Wildeman began producing a Stitchbond nonwoven in 1968 in the United Kingdom and the first to commercialize its use in the West. In the early 1970s, he pursued the dramatic redesign of the original Mauersberger concept to incorporate new capabilities into the Stitchbond process. This new technology platform became the foundation of unique process capabilities that continue to evolve to this day at Tietex.

The Process

Stitchbond Nonwoven technology is a process that pierces through flexible substrates in the form of nonwovens, films, papers and foams (or combinations thereof) with a series of pointed needles positioned adjacent to each other. These needles then stitch either a simple or complex network of textile yarns into the substrate(s) to form textile/nonwoven hybrids for a broad array of applications. The stitching either strengthens or reinforces substrates, or brings an extensive number of alternative properties to the resulting composites.

Figure 1. World Nonwoven Production by Region

- Nonwovens features:

The commonly used fibers include natural fibers (cotton, jute, flax, wool), synthetic fibers (polyester (PES), polypropylene (PP), polyamide, rayon), special fibers (glass, carbon, nanofibers, bicomponent, superabsorbent fibers), etc [1,6,8-10,12-15,16].

Two or more types of fibers are typically utilized. The fibers are usually blended or mixed in order to improve performance properties of nonwovens, such as strength and other properties. The fiber blend or mix can be natural/natural, synthetic/synthetic, or natural/synthetic [6,8-10].

Man-made fibers are the most widely used in the nonwoven industry. Owing to impurities and higher costs, natural fibers are of minor importance for the production of nonwovens.

Fiber characteristics influence not only nonwoven fabric properties but also processing performance. Web cohesion, fiber breakage, and web weight uniformity are the key quality parameters and are influenced by fiber diameter, fiber length, fiber tensile properties, fiber finish, and crimp. The properties of nonwoven fabrics are largely dependent on fiber properties and fabric structural geometry.

Nonwovens have three key features and are as follows:

The fabrics are composed of textile fibers.

The basic structural element of textile fabrics is fibers, rather than yarns or threads.

The fabrics are held together by means other than the interlacing or interloping characterizing traditional woven or knit fabrics [1].

While manufacturing nonwovens some conventional textile operations, such as carding, drawing, roving, spinning, weaving, or knitting, are partially or completely eliminated. For this reason, the choice of fiber is directly related to fabric quality [1-6, 8-11].

All kinds of fibers can be used to produce nonwoven fabrics. The selection of fibers is based on the following features[1,6]:

- the cost-effectiveness,

- the ease of processability, and

- the desired end-use properties of the web.

2.1. Natural fibers

2.1.1. Cotton

Cotton is the most important vegetable fiber used to produce nonwoven bonded fabrics. The oldest textiles made from cotton originated around 5800 B.C. At present, cotton is cultivated in about 75 countries on 79 million acres of land, which represents about 0.8 % of all agricultural areas worldwide. Cotton plants grow in shrub-or tree-like forms to heights o from 25 cm to 2 m, depending on origin, soil, climate, and cultivation conditions. It grows fruit the size of walnuts which contain seeds that burst open and the cotton swells out in thick white flocks. The process of sowing to harvesting takes 175-225 days. Hand picking is advantageous compared to machine picking, as only fibers from completely mature capsules are being collected. After the harvest, the seeded cotton is ginned. Among the plant-derived fibers, cotton has the highest percentage of cellulose and is free of wooden particulates [1-4,6].

Raw cotton contains the following substances:

- cellulose (80-90%),

- water (6-8%),

- hemicellulose and pectin (4-6%),

- ash (1-10%),

- waxes and fats (0.5-1.0%), and

- proteins (0-1.5%) [6].

- The quality of cotton depends on the following parameters:

- length of fiber (10-60 mm),

- fineness of fiber (1.0-4 dtex),

- linear density (1.50-1.54 g/cm3),

- color,

- maturity degree (75-85%),

- purity (trash and dust),

- tensile strength (25-50 cN/tex),

- elongation (7-10%),

- moisture absorption (7-8%), and

- moisture regain (7.1-8.5 %).

Cotton, as a natural cellulosic fiber, has many characteristics, such as:

- comfortable,

- good absorbency,

- good color retention,

- well printable,

- machine-washable,

- dry-cleanable,

- good strength,

- well drapeable and

- easy to handle and sew.

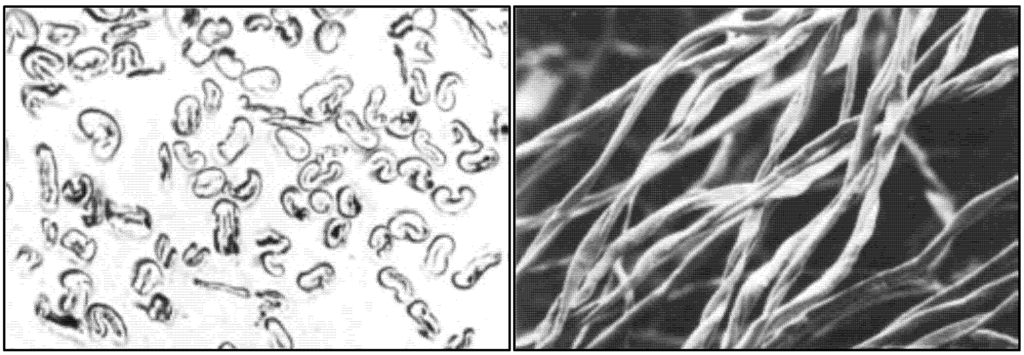

Figure 2. Microscopic View of Cotton Fiber [6]

Figure 2 shows a vertical view, revealing the convolutions typical for a cotton fiber and the cross section of cotton fibers. Cotton’s shape and structure make it suitable for the production of nonwoven bonded fabric: cotton has a ribbon-shaped cross-sectional form, spiral twist, a hollow structure, a high wet strength for a hollow structure, a high wet strength for a high module, and it is hygroscopic.

Cotton fiber was used extensively during the early development period of nonwoven business. Cotton mills in USA tried to find ways to upgrade the waste cotton fibers into saleable products. The first method was bonding the short cotton fibers with latex and resin. These products were used in industrial wipes. Over the past decade, bleached cotton fiber has been used for producing fabrics on conventional nonwoven equipment. These products were used in medical and health-care applications, wiping and wiper markets, and some apparel markets. At the same time, cotton fiber has physical properties like fiber length, strength, and resilience, which is important particularly to its process-ability. For example, long cotton fiber is suitable for producing nonwovens. The fiber has excellent absorbency and feels comfortable for the skin. The wet and dry strengths are good. Dimensional stability and resilience recovery are moderate. The spunlace process is usually utilized in producing medical and health-care fabrics, especially in Japan and the Asian region [14].

2.1.2. Jute

After cotton, jute is the natural fiber with the second highest production volume. Chemically, the jute is a highly lignified fiber, which consists of [6,9,11] the following:

- cellulose (60%),

- hemicellulose (26%),

- lignin (11%),

- proteins (1%),

- waxes and fats (1%), and

- ash (1%)

Producing of a compound with the substances cellulose and bastose is differ from bast fibers. Jute is a significant fiber for special applications of nonwoven bonded fabrics. It is mostly used because of its inexpensiveness and good physical properties:

- floor coverings in basic materials,

- base and intermediate layer of tufted floor coverings,

- upholstery filling pieces.

2.1.3. Flax

Flax is the one of the oldest cultivated plants with a cultural importance dating to prehistorical periods. Linseed was first found in the former Mesopotamia. Fragments, linseed, and capsules are estimated to be from the eighth millennium. Flax was discovered during the excavation of Ali Kosh in Iran. In old Egyptian graves and seaside settlements in Switzerland, linen fabrics and mummification bandages were found. They originated around 5000-3000 B.C. The oldest fabric fragment found to date is from a settlement in ancient Egypt [9,11,16].

Flax belongs to the family Linaceae, and the type considered here is from the genus Linum. There are wild-growing, small herbaceous perennials and cultivated annual flax plants. Flax is cultivated worldwide in tropical and cold climate zones. Fiber flax grows in humid, moderate climates, whereas oil flax grows in dry, warm areas. The harvest reaps approximately 4000 kg/ha. The fibers are embedded in the parenchyma of the stem in a high concentration and are freed by retting. Then the flax is washed, dried, and broken to loosen the brittle wood from the bast and to separate the fibers from each other. The wooden parts are removed by means of scotches [6]. Finally, the fibers are combed by means of hackles. The properties of technical fibers and single fibers have to be distinguished. The technical fiber is 200-800 mm in length and composed of a fiber bundle. It has a fineness of about 10-40 dtex. The single fiber has a length of 7-42 mm depending on its location in the stem, its diameter is about 15-37 µm, and the density lies between 1.43 (raw) and 1.52 g/cm3 (bleached). The maturity of the fiber is determined by harvesting time. Good fiber profit with good fiber quality may be obtained at the time of yellow maturity. The relative strength fluctuates between 30 and 55 cN/tex. For all these properties, flax fiber is used for nonwoven bonded fabrics, mostly for the fabrication of filling pieces [11,16].

2.1.4. Wool

Wool is the most important animal fiber used in manufacturing nonwoven bonded fabrics. It is used mainly as reclaimed wool or cuttings because of its high price. The variation in quality and the impurities in reclaimed wool as well as the chemical and physical properties determined by its provenance impose restrictions on its use [17].

Wool is a suitably stiff and permanently crimped bi-component fiber. The distinct variations in thickness are in most cases favorable to produce nonwovens [16]. Wool fiber is initially used to make felt. The wool fibers are then pressed into a flat sheet and subjected to moisture, heat, and agitation. The scaly structure of the wool fiber causes the fibers to interlock and mat. Weaving or knitting in the production of such felts and simple mechanical interlocking of fibers in the production of such felts and simple mechanical interlocking of fibers in a batt structure is capable of producing a dimensional stable fabrics with densities, up to 0.7 g/cm3. Animal felts have been used since ancient times. Traditional felting method is still used for producing clothing item such as hats, slippers, interlinings and handbags. In addition to traditional felting method, modern pressed felting techniques are used in a wide range of industrial applications. These products are used for polishing metals, optical surfaces plastics, and jewelry, and in manufacturing seals, gaskets, washers, felt nibs and markers, air and liquid filters, oil wicks, piano cushion felts, shoes, toys, pennants, table covers, notice boards, bookbinding, furniture components and orthopedic appliances. [11,18,19].

Wool is not only used for producing felts but also used for producing needle-punched, hydroentangled, thermally and chemically bonded fabrics. In recent years, the production of serviceable, lightweight wool fabrics of 70-150 g/m2 for apparel applications using a process known as hydroentanglement has been commercialized. Man-made fibers such as polyester, polypropylene, viscose rayon, and blends containing cotton, wood pulp, and other fibers can be used for producing hydroentangled bonded fabrics in the medical and hygiene industries. However, in recent years, wool is used hydroentanglement process [20].

For example, while producing hydroentangled fabrics, at firstly the web is transported by a porous belt or a drum is passed below a series of injector heads (typically 6-8 heads in total depending on requirements), which produce single or multiple rows of closely spaced, fine columnar water jets of about 60-140 µm diameter as required. Commercially, these jets operate at pressures of about 25-250 bar, although much higher pressures up to 1000 bar are now possible depending on the machine design. The jet pressures used depend on web weight line speed and fiber properties, and normally, the pressure is profiled so that it tends to increase as the web passed toward the machine exit. Usually, the web is treated face and back to achieve a homogeneously bonded structure, although single-sided treatments are possible using lightweight webs [20]. At each injector, suction is applied from below to remove excess water from the surface of the conveyor. The design and surface structure of the conveyor belt influence the resulting fabric structure. Bonded fabric is taken away from the belt and is dried, wound, and slit according to the required width. Chemical and thermal bonding can be done before and after drying. While producing nonwoven fabrics by the hydroentanglement method, a large volume of water is used. Water has to be recirculated and filtered to remove particulates before entering to the injectors. Recirculation and filtration account for a considerable part of the total cost of a hydroentanglement facility [20].

2.2. Man-made fibers

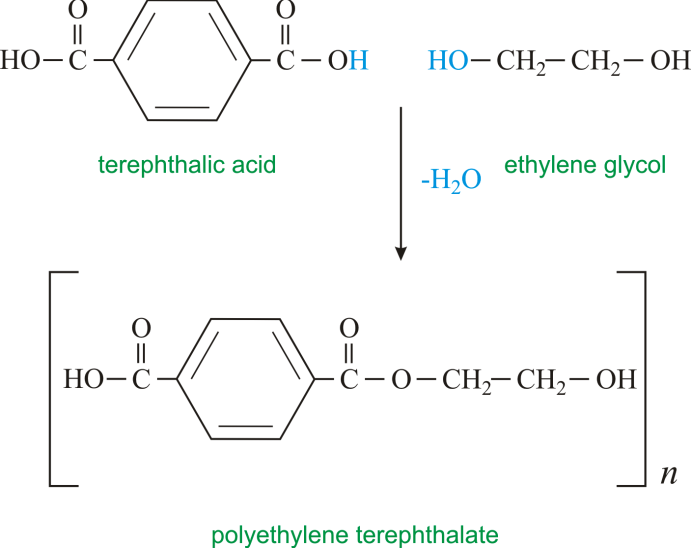

2.2.1. Polyester

As its name indicates, this type of fiber consists of macromolecules of esters which are chemicals made of acids and alcohol (Figure 3). If many of these basic molecules are combined, they will form polyesters [6].

Figure 3. Polyester Fibers [6]

The earliest study on polyester was conducted by W.H. Carothers at DuPont in the early 1930s, which is comparable to the present-day studies on condensation polymers. Even though a great number of polyesters have been evaluated by now, only a few of them are around that can create good fibers and are crystalline with a melting point between 220 and 280°C, and only three of them gained significance in fiber production [21,22].

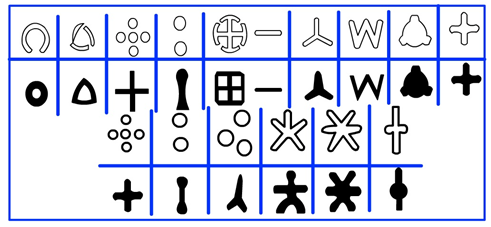

Physical properties of polyester fibers are important while producing nonwoven materials. For example, the lengths of cut are adapted to the respective manufacturing procedure. Fibers are also available in different of luster and cross-sectional forms (Figure 4).

Figure 4. Cross-sectional View of Polyester Fibers [23]

They are inexpensive, easily produced from petrochemical sources, and have a desirable range of physical properties. They are strong, lightweight, easily dyeable and wrinkle resistant, and have very good wash wear properties. Therefore, it is mostly used in nonwoven production. Cross-sectional polyester fibers are used in the following three major areas [14]:

- Apparel: Every form of clothing;

- Home Furnishings: Carpets, curtains, draperies, sheets and pillowcases, wall coverings, and upholstery; and

- Other Uses: Hoses, power belting, ropes and nets, threads, tire cords, auto upholstery, sails, floppy disk liners, and fiberfill for various products including pillows and furniture.

Surgeons’ gowns, for example, were once woven from linen but are now for the most part made from repellant-treated entangled polyester fiber pulp composites on spun-bond melt-blown laminates. These new gowns are far superior to the older material in providing a breathable barrier between the surgeon and the patient, which serves to significantly reduce hospital infections. Spun-lace mattress pad facing (100% polyester) continues to be the replacement for spun-bonded material because of the textile-like character of entangled fiber fabrics. Polyethlene terephthalate (PET) has become the most important polymer type of fibrous prostheses. It is reasonably inert, biocompatible, flexible, and resilient and has an appropriate level of tissue acceptance. However, polymerization initiators, antioxidants, titanium dioxide, and other impurities should be minimized to improve its biocompatibility [14].

Polyester is less flammable than cellulosic fibers because it melts while coming in contact with the flame. Crystar, a DuPont trade name, is used to produce as a polyester spunbonded fabrics [14].

Among the bi-component fibers, polyester is the most used fiber. Because of its increasing strength and soft hand of the nonwoven fabric, polyester is used in continuous bi-component filaments having a sheath component made of linear low-density polyethylene (PE) and a core component made of polyester. The tensile strength of the fabrics is improved remarkably by the bi-component filaments and depends on the linear low-density polyethylene /polyester ratio. The ultrasonically bonded polyester/polypropylene blend like Matarh’s Ultraskin, the protective clothing, is said to protect wearers from rain while offering the breathability needed to provide comfort [24].

Most of the insulation and industrial products are manufactured from synthetic and inorganic fibers by dry- and wet-laid methods. Nonwoven polyester fiber mats are used to produce electrical insulation laminates and electrical tape backing appliances. Polyester and high-temperature-resistant m-aramid nonwoven mats are used as a cost-efficient interchange for aramid paper for insulation composites [25].

Polyester fiber composites are widely used as filtration media. The layers of composite structure give excellent tear strength, a smooth, fiber-free surface, and edge stability. These products supply higher filtration efficiencies than calendared spun-bonded media [26].

Polyester fibers are used inside seat cushions, back pillows, mattresses and waterbeds, decorative and throw pillows, outdoors furniture, and even hand-stuffed custom upholstery in fiberfill applications [27].

2.2.2. Polypropylene

The fibers from polypropylene were introduced to the textile arena in the 1970’s and have become an important member of the rapidly growing family of synthetic fibers.

Polypropylene is generally available as chips or granules which are white in color and are semicrystalline. Polypropylene fibers are produced by a larger variety of processes than any other melt-spun fibers. The general physical properties of polypropylene fibers are shown in Table 1.

Polypropylene has established itself as a very useful industrial and household fiber. However, it has not made a very significant impact in the apparel sector mainly due to its hydrophobicity lock of dyeability and slightly waxy handle. Polypropylene nonwovens are increasingly being used as filter fabrics for wet filtration in the chemical and pharmaceutical industries. Industrial applications also include medical and surgical disposables [14,28].

| Moisture Regain (%) | <0.1 |

| Refractive Index | 1.49 |

| Thermal Conductivity (Btu-in/ft.hr.ºF) | 0.95 |

| Coefficient of Linear Thermal Expansion (ºF) | 4.0×10-5 |

| Heat of Fusion (cal/g) | 21 |

| Specific Heat (cal/g.c) | 0.46 |

| Heat of Combustion (Btu/Ib) | 19400 |

| Oxygen Index | 17.4 |

| Decomposition Temperature Range (ºC) | 328-410 |

| Dissipation Factor (0.1 MHz) | <0.0002 |

| Dielectric Constant (0.1 MHz) | 2.25 |

| Specific Volume Resistively (Ω Cm) | >1016 |

Table 1. Polypropylene physical properties [14]

Advantages of PP fibers for nonwoven fabrics are [12,14] as follows:

- surface smoothness and hardness,

- resistance to micro-organisms,

- chemical resistance,

- inherent hydrophobicity that can be modified using fiber finishes and other treatments,

- high tenacity,

- high shrinkage,

- low melting point leading to significant energy conservation,

- low density and specific gravity enabling lightweight fabrics to be produced,

- good abrasion resistance,

- good resilience,

- good bulk and cover, and

- good stain and soil release.

Disadvantages of polypropylene fibers [14] are as follows:

- difficult to dye after manufacturing,

- high crystallinity and poor thermal conductivity,

- poor UV and thermal stability (requires expensive UV stabilizers and antioxidants to overcome this problem,

- poor resilience compared to PET and nylon,

- poor adhesion to glues and latex, and

- Flammable and melts and burns like wax.

There are only half-dozen manufacturers of polyester spunbonded fabrics in the world, and the bulk of such fabrics are made from both isotactic polypropylene polymers. This is conduct by the cost and ease of procedure of polypropylene. Polypropylene spunbonded fabrics are used in a variety of end uses, which include absorbent product coverstock markets, home furnishing and automotive markets because of lowest cost, and in low polypropylene nonwoven fabric applications [29].

Polypropylene is also used extensively in sheath-core configuration to take advantage of the lower melting point of the former in thermally bonded spunbonds; the polypropylene core fiber retains its fibrous character and excellent physical properties. Even though there is only a very small window of temperature at which polypropylene will melt for bonding purposes, the fabrics made in this manner do not suffer any appreciable loss of fiber properties [29].

2.2.3. Polyamide

Synthetic man-made fibers account for the largest part of the raw material used in manufacturing nonwoven bonded fabrics. Polyamide fibers are the oldest ones that are used in production, and they also increase the serviceability of the product. This improved quality is of importance for various purposes (see Ref. [17]):

- where nonwoven bonded fabrics are subjected to frequent folding as in the case of paper reinforced with synthetic fibers, and

- where they are subjected to exceptional resistance to abrasion, as is the case with needled floor coverings.

The pioneering work of Wallace Carothers of the DuPont Company in the USA led to the discovery of nylon 66 in the 1930s. This polymer was melt-spun to give to the world the first synthetic fiber. The fiber was introduced commercially by DuPont in 1939 using a patent of W.H. Carothers granted in 1938. The success of nylon 66 led to the vigorous growth of the synthetic fiber industry. Subsequently, Paul Schlack in Germany discovered nylon 6, which was produced through another method, in 1939. Both these fibers now occupy an important place among the commodity fibers and have had a far-reaching impact on the international fiber front [30].

Only a few of the many known polyamides have reached large-scale significance for production. Only polyamide 6 (PA6) and polyamide 6.6 (PA66) came to large-scale production. Polyamide 6 is known as perlon and polyamide 6.6, which is generally called nylon to distinguish it from perlon. The numbers after the word “polyamide” indicate the number of carbon atoms in each molecule that make up the polyamide [17]. The structural units of a polyamide are combined by an amide (-NH-CO-) group. A polyamide manufactured from aliphatic monomer(s) is commonly designated as nylon. However, the US Federal Trade Commission has defined nylon as a manufactured fiber where the fiber-forming substance is a long-chain synthetic polyamide in which less than 85 % of a amide linkages are attached directly to two aromatic rings, while a polyamide in which at least 85 % of the amide links are attached to two aromatic groups is known as an aramid [30].

| Polyamide Fibers | Maximum Tensile Strength (cN/tex) | Maximum Elongation (%) | Relative Wet Strength (%) | Water Retention Value (WRV) (%) | Water Content at 20 ºC and 65 % Rel.Humidity (%) |

| 1.6 dtex/40 mm bright | 50-60 | 45-55 | 80-90 | 10-15 | 4 |

| 3.0 dtex/40 mm semi-dull | 45-55 | 50-60 | 80-90 | 10-15 | 4 |

| 17 dtex/ 80 mm semi-dull | 40-50 | 65-75 | 80-90 | 10-15 | 4 |

| 22 dtex/80 mm semi-dull | 40-50 | 55-65 | 80-90 | 10-15 | 4 |

| 35 dtex/100 mm bright prof | 30-40 | 70-80 | 80-90 | 10-15 | 4 |

Table 2. Typical values for normal polyamide fiber properties [6]

*Fibre does not have the usual round crosssection

The most important values for the physical properties of normal spun polyamide fibers are listed in Table 2, which covers various fiber thickness, degrees of luster and cross-sectional forms. The term “normal” is of great importance for nonwoven bonded fabrics, because:

- co-polyamide fibers can also be used;

- the filaments used in spun-laid methods are produced under different conditions than the textile or technical man-made methods with regard to their production conditions;

- very strong and excellent tear strength fibers are not used in nonwoven bonded fabrics, whereas they are used in tarpaulins, conveyor belts, and tires,

- fibers which react differently when dyed can be used together, for example, in needle floor coverings;

- nylon fibers are used as nonwovens separators in Ni/H and Ni/Cd batteries;

- these fibers find application in high-performance wipes, synthetic suede, heat insulators, battery separators and specialty papers [14];

- fibers have excellent physical properties like polyester fiber, and it has a high melting point, which conveys good high-temperature performance [14];

- these fibers are more water sensitive than polyester despite the fact that nylon is not considered a comfortable fiber in contact with the skin;

- its toughness makes it a major fiber of choice in carpets, including needle- punched floor covering products. Because it is more expensive than polyester, polypropylene, or rayon, nylon has somewhat limited use in nonwoven products; and

- the resiliency and wrinkle recovery performance of a nonwoven produced from nylon are not as good as that from PET fiber [14].

2.2.4. Rayon

Rayon, which is one of the oldest manufactured fibers, is a regenerated cellulose fiber with a wide spectrum of properties. Historically, rayon faced a strong challenge from synthetic fibers like nylon, polyester, and acrylics, which came much later, but in spite of this competition, it has retained its place as a major textile fiber. The important considerations in favor of rayon are that the essential raw material for its production, namely cellulose, is abundantly available and a renewable source. Moreover, its hydroscopicity and easy dyeability characteristics are additional assets. Furthermore, rayon fibers can be produced with a wide range of properties, particularly mechanical properties, so far unmatched by any other fiber, natural or manufactured [31].

Dissolved cellulose method was first explored at the end of the 19th century. The first fibers were produced by dissolved cellulose in cuprammonium hydroxide solvent and tiny orifices were dissolved into a bath containing reagents. Regenerated filaments form cellulose and break tiny orifices into a reagent bath to remove solvent [31].

Some of the advantages of rayon fibers based on their properties are as follows:

- It is bulky to handle and create bulky fabrics.

- A flame-retardant compound may be mixed with viscous solution prior to spinning or after producing web as coating.

- It has high absorbency and purity. These properties make rayon fiber to produce surgical dressing, sanitary protection, swabs, tampons, and disposable nonwovens [11]. Disposable nonwovens are designed to be discarded after a single use or, sometimes, after a few uses. Examples of disposable nonwovens include medical garments, filters, tea-bag, covers, and disposable diapers.

- It is highly absorbent; that is, it is being produced in order to obtain higher water capacity. These fibers are used in surgical nonwovens.

- It is easy to dye.

- It is a soft material and comfortable to wear and thus used in making bedspreads, blankets, curtains, tablecloths, blouses, dresses, jackets, etc.

2.3. Other fibers

2.3.1. Glass

Glass fiber is an inorganic nonmetallic man-made fiber. Generally, the glass is defined as the frozen state of a supercooled and thus solidified liquid. It results from the suppression of the crystallization of melt. Initial materials for producing glass are different mineral substances largely found in nature (quartz sand, chalk, dolomite, feldspar, and others).

Glass fibers are produced from different compositions (%) of glass (Table 3).

| Silica (SiO2) | 54.0–56.0 |

| Alumina (Al2O3) | 12.0–14.5 |

| Boron anhydride(B2O3) | 5.0–10.0 |

| Calcium oxide (CaO) | 15.5–16.5 |

| Magnesium oxide (MgO) | 4.0–4.2 |

| Sodium oxide (Na2O) | 0.7–1.0 |

| Iron oxide (Fe2O3) | Up to 0.3 |

Table 3. Glass fiber composition

Nonwovens of glass fibers are classified as follows:

- A-glass: close to window glass with regard to its composition.

- C-glass: shows better resistance to chemical impact.

- E-glass: combines the characteristics of C-glass with very good insulation to electricity.

- AE-glass: alkali resistant glass [6].

In general, textile glass fibers have a high tenacity at a low elongation combined with extremely low density. This results in favorable tenacity or modulus values relative to their weight. Glass fiber is brittle, but in drawing very thin fibers (with a diameter of several micron) from molten glass, a fibrous material is obtained, having a flexibility sufficient for textile processing and utilization as a finished product.

Glass fiber mats are excellent heat and noise insulation materials. They are capable of withstanding temperatures above 150°C. Textile glass as a mineral material is naturally inflammable and does not release steam or poisonous gases when subjected to heat.

Glass fabrics are highly efficacious for filtering various liquids; filters of glass fibers used for filtering corrosive chemical reagents have a life 10 or 15 times longer than those made of usual materials (cotton, metal web etc). Glass staple fibers are used for the reinforcement of plastics and building materials for insulation and so forth [32].

2.3.2. Carbon

Although first produced for electric lamp filaments from cupro-cellulose by Pauly, Fremery, Bromert and Urban at Oberbruch near Aachen, Germany, in 1898, carbon fibers only gained significance after 1963. In recent years, carbon fibers have found much attention. They are made by means of thermal degradation of viscose fibers or polyacrylonitrile fibers at temperatures up to 1000°C or even 1500°C. The fibers contain between 95 and 98 % carbon. Additional thermal treatment of the pyrolized polyacrylonitrile fibers at temperatures between 2000 and 3000°C converts them into graphite, which shows an excellent grid-like structure, where carbon contents amount to 99% [6].

Among the exceptional properties of carbon fibers are their high tenacity, high modulus of elasticity, high brittleness, low creeping tendency, chemically inert behavior, low heat-expansion, and good electrical conductivity. Using their unique properties, the application of carbon fiber is most pronounced in the superfiber category. The high modulus of carbon fibers makes them best suitable for application in composite materials used in high- performance functions. Carbon fiber is not used on its own, but mixed with resin as fiber reinforced materials. This is called a composite material and is now one of the most important structural and heat-resistant materials. The composite material made of glass fiber and plastic is distinguished as glass fiber-reinforced plastics (G-FRP) from that made of carbon fiber and plastic (carbon fiber-reinforced plastic, C-FRB) [14,33].

Such composites are mainly used in:

- aircraft cabin structural materials, such as floor, other internal sections and operations systems;

- aircraft: vertical tail, tail cone, main wing, floor beams, floor panels, composite material for cockpit, and body;

- wind power generations;

- ski-poles;

- natural gas storage tank;

- fishing rod;

- golf shafts; and

- tennis racket [15,21].

In recent years, some new applications of carbon fibers have been found, such as rehabilitation of a bridge in building and construction industry. Others include decoration in automotive, marine, general aviation interiors, general entertainment and musical instruments and after market transportation products. Conductivity in electronics technology provides additional new application [34].

2.3.3. Nanofiber

In fiber diameter, the range from 0.1 to 1 nm is of angstrom size, that from 1 to 10 nm is of nano size, that from 100 to 1000 nm is of sub-micron size, and that from 1000 to 10 000 nm is of micron size. Fibers with an angstrom size diameter are effectively the molecular chain. Nanometer size and sub-micron size fibers can be classed as nanofiber. A micron-size fiber is called a micro-fiber. Fibers with a diameter more than a few micrometers are the conventional fibers, including those with millimeter, centimeter, or meter-order diameter [35].

The nonwoven industry generally considers nanofibers as having a diameter of less than 1µm, although the National Science Foundation (NSF) defines nanofibers as having at least one dimension of 100 nm or less. The name derives from the nanometer, a scientific measurement unit representing a billionth of an ammeter, or there to four atoms wide.

Figure 5.Schematic Diagram of Electrospinning Process [14]

Generally, polymeric nanofibers are produced by an electrospinning process. A schematic diagram of electrospinning is shown in Figure 5. Electrospinning is a process that spins fibers of diameter ranging from 10 mm to several hundred nanometers. This method has been known since 1934 when the first patent on electrospinning was filed. The process makes use of electrostatic and mechanical forces to spin fibers from the tip of affine orifice or spinneret. The spinneret is maintained at positive or negative charge by a DC power supply. When electrostatic repelling force overcomes the surface tension force of the polymer solution, the liquid spills out of the spinneret and forms an extremely fine continuous filament. These filaments are collected onto a rotating or stationary collector with an electrode beneath the opposite charge to that of the spinneret where they accumulate and bond to form a nanofiber fabric [36].

In this method, polymer and solvents are used. Nanofibers in the range of 10-2000 nm diameter can be achieved by choosing the appropriate polymer solvent system. Table 4 gives a list of some of the polymer solvent systems used in electrospinning [14,37].

| Polymer | Solvent |

| Nylon 6 and nylon 66 | Formic acid |

| Polyacrylonitrile | Dimethyl formaldehyde |

| PET | Trifluoroacetic acid/dimethyl chloride |

| PVA | Water |

| Polystyrene | DMF/toluene |

| Nylon 6 co polyamide | Formic acid |

| Polybenzimidazole | Dimethyl acetamide |

| Polyramide | Sulfuric acid |

| Polyimides | Phenol |

Table 4. Polymer solvent systems for electrospinning [14]

Nanofibers exhibit special properties mainly due to extremely high surface to weight ratio compared to conventional nonwovens. Nonwoven products such as aerosol filters, facemasks, and protective clothing are used mostly in filtration applications because of low density, large surface area to mass, high pore volume, and tight pore size. At present, military fabrics under development designed for chemical and biological protection have been enhanced by laminating a layer of nanofiber between the body side layer and carbon fibers. Nanofibers are also used in medical applications, which include drug and gene delivery, artificial blood vessels, artificial organs, and medical face masks. For example, carbon fiber hollow nano-tubes, smaller than blood cells, have potential to carry drugs into blood cells [14].

2.3.4. Bicomponent

There has been a trend in the polymer industry since the midsixties to apply polymer blends and mixtures for the modification of material properties. In the man-made fiber industry, this trend is realized in the manufacture of fibers consisting of two or more components [38].

Bicomponent fibers can be defined as “extruding two polymers from the same spinneret with both polymers contained within the same filament.” A close relative is “co-spun fiber,” which is a group of filaments of different polymers, but a single component per filament, spun from the same spinneret [39]. Bicomponent fibers are commonly classified by the structure of their cross-section as side-by-side (S/S), sheath core, island in the sea, or segmented pie. Of these, the side-by-side and sheath core arrangements are relevant for thermal bonding applications [40].

2.3.4.1. Side-by-side

Two components are arranged side by side and are divided along their length into two or more distinct regions (Figure 6). The geometrical configuration of side-by-side bi component fibers, particularly asymmetry, makes it possible to achieve an additional three-dimensional crimp during thermal bonding by differential thermal shrinkage of the two components, for example. This latent crimp gives rise to increased bulk stability and a softer fabric handle [40].

Figure 6. Cross Sections of Side-by-Side Bicomponent Fibers

2.3.4.2. Sheath core fibers

In sheath core bicomponent fibers (Figure 7), one of the components (the core) is fully surrounded by another component (the sheath). The arrangement of the core is either eccentric or concentric depending on the fabric properties required. If high fabric strength is required, the concentric form is selected, whereas if bulk is required, the eccentric type is used. One advantage of sheath core fibers is the ability to produce a surface with the required luster, dyeability, and handle characteristics while having a core that dominates the tensile properties. The core sheath structure also provides a means of minimizing the cost by engineering the relative proportions of the two polymer components. Commercially, the ratio of the polymer components is typically 50:50 or 30:70, but in some cases, a ratio of 10:90 is used [40].

Figure 7. Cross Sections of Sheath Core Bicomponent Fibers

The first industrial exploitation fiber involved the use of Co-PET/PET or PE/PP fibers for hygiene applications as well as high-loft batting, wiping cloths, medical wipes, and filters. The difference in the sheath core melting temperature in PE/PP is about 40°C. In Co-PET/PET bicomponents, the sheath melts at 100-110°C while the core melts at 250-265°C [40]. Bicomponent fibers are generally used in blend ratios of 10-50% depending on the application and process parameters. A useful experimental guide is given in Table 5.

| Parameter | Nonwoven Fabric Handle | ||

| Soft | Medium | Harsh | |

| Bicomponent Fiber Content (%) | 10-20 | 15-30 | “/>30 |

| Bonding Temperature (ºC) | 140-150 | 150-160 | 160-180 |

| Fiber Fineness (dtex) | 1.7-3.3 | 3.3-6.7 | >6.7 |

Table 5 A practical guide for producing nonwoven fabrics with different handle characteristics from Co-PET/PET bicomponent fibers

2.3.4.3. Island in the sea or segmented pie

Island in the sea is one type of bicomponent fiber whereby many fibrils of one polymer are dispersed in the matrix of another polymer. The fibrils are known as islands and the matrix is the sea. The island in the sea fibers have excellent tensile properties, and provide good feel, softness, and bursting and tearing strength for the nonwoven fabrics.

Bicomponent filaments can be used to produce a bonded fabric, with one of the components being thermoplastic to facilitate heat bonding and the other component having properties that will enhance the quality of the final fabric [4]. Bicomponent fibers are also used for spunlaced nonwoven products like medical disposable textiles, filtration products and air-laid nonwoven structures as absorbent cores in wet wipes [14].

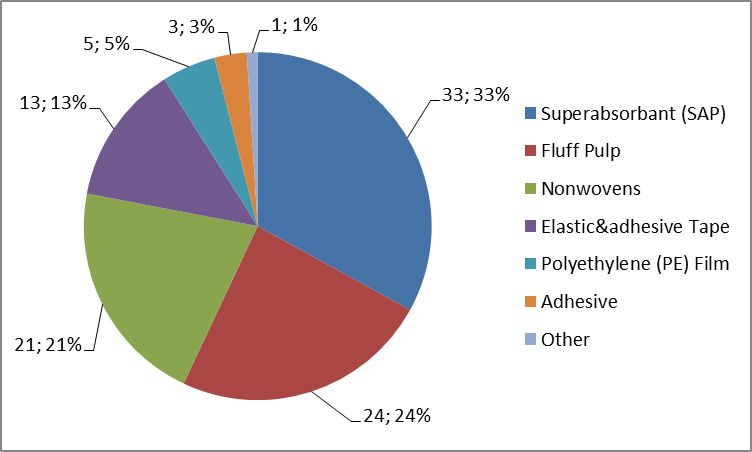

2.3.5. Superabsorbent fibers

Superabsorbent (also known as superabsorbent polymers or SAP) consists of a material which can absorb many times its own weight in aqueous fluids. Superabsorbent fibers absorb 50-150 times their own weight while the diameter increases. The small diameter of the fiber, which is about 30 µm, gives a very high surface area for contact with the liquid. Viscose rayon or cotton without load only absorbs about 30 times, wool 17 times, and polyester 3 times their own weight [14]. The advantage that fibers offer compared to powders is due their physical form, or dimensions, rather than their chemical nature [18]. Also, the fiber surface is not smooth. It has a crenulated structure with longitudinal grooves. These are beneficial in transporting moisture to the surface. The lubricant has also been selected to enhance this wetting effect and results in a very high rate of moisture absorption. Typically, the fiber will absorb 95% of its ultimate capacity in 15 seconds [35].They are therefore an ideal material for use in products which are designed to contain fluids such as baby diapers/nappies, incontinence products, and feminine hygiene pads and liners [21,22,38] (Figure 8).

Figure 8 Composition of Baby Diaper

Superabsorbent material was first produced in the early 1970s in Japan and USA. It was introduced into baby diapers in the early 1980s and later that decade into adult incontinence pads. By the early 1990s, superabsorbent material had become widely used in disposable baby diapers/nappies and incontinence products [41]. The use of superabsorbent materials in fiber form has now become a commercial reality. The majority of superabsorbent material available for today’s absorbent hygiene products market is sold in granular form; some superabsorbent material is also available as a fiber. The granular material is a polymer made up of millions of identical units of sodium acrylate formed into a chain fence like structure. These are then linked to make the material into a three dimensional network. In their dry state, the long polymer chains are coiled. When they absorb liquid, they uncoil and the network expands. The liquid is then stored in the spaces in the molecular network and the material forms a gel which locks the liquid in [41].

The advantages of super absorbent fibers [41] are as follows:

They help keep the skin dry. This is done by drawing the liquid away from the skin and absorbing and retaining it in the core of the product. This creates greater comfort for the user.

They help protect against skin irritation in diaper users by reducing skin wetness. If skin becomes too wet, it is more vulnerable to irritation because the natural balance of the skin, which helps protect against harmful bacteria, can be compromised.

They help prevent the spread of infections. The containment of fluid in the superabsorbent core reduces leakage. It also reduces the risk of urine mixing with other material and becoming contaminated with microorganisms which can cause the spread of diseases such as gastroenteritis.

They offer improved quality of life and personal dignity. Many people suffer from a lack of bladder or bowel control as a result of illness, disability, or age. Disposable products with superabsorbents help many of these individuals, and their care givers maintain a quality of life with greater mobility and independence.

- Experimental

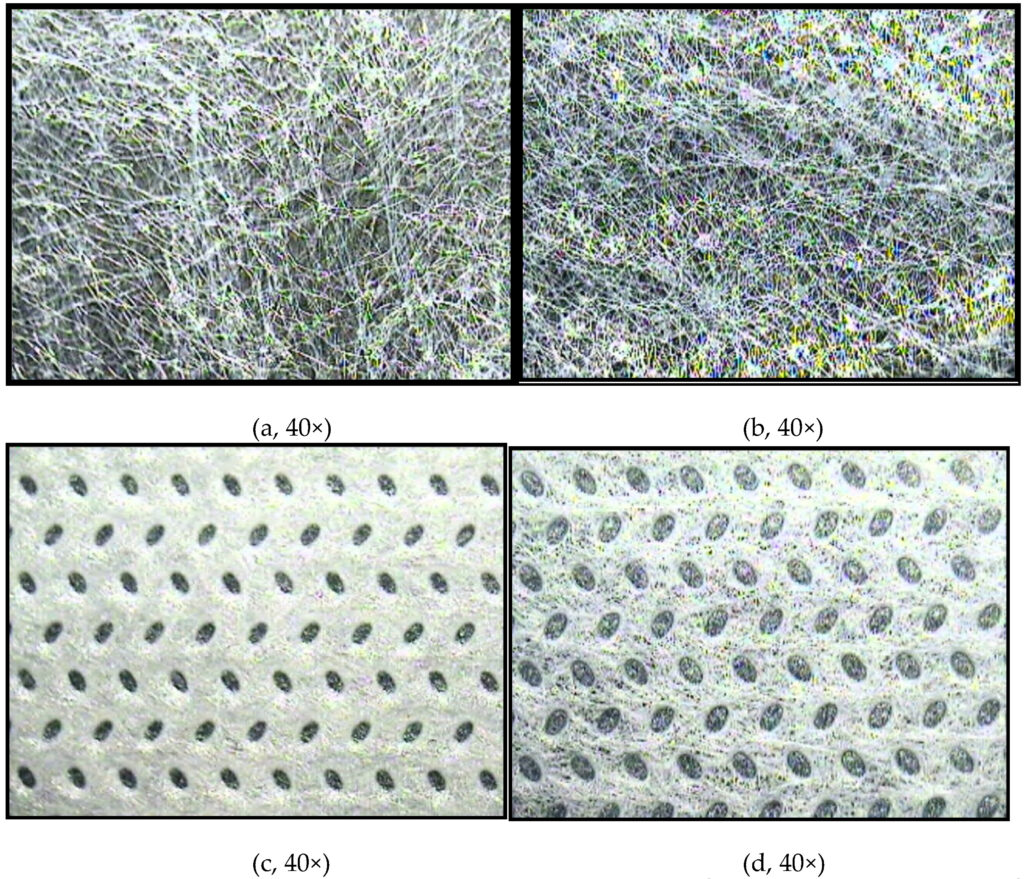

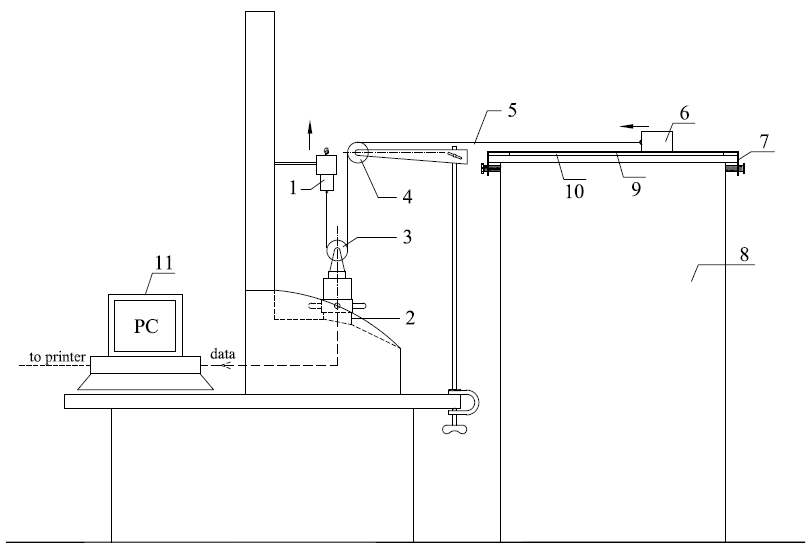

This chapter focuses on the effects of fiber type, applied force, mass per unit area, contact surface, and fabric direction on the friction behavior of % PP and PES spunbond nonwoven fabrics. These samples have been used in medical packages, aprons, cleaning cloths, make up cleaning pads, protective cloths, wet towels, and home textiles. Therefore, it is important to evaluate friction behavior of nonwoven fabrics. Spunbonded nonwoven fabric samples (100 % polypropylene (PP) and polyester (PES)) were tested. While evaluating samples, Textile-Test Methods For Nonwoven-Part 3: Determination of Tensile Strength and Elongation and Textile-Test Methods For Nonwoven-Part 2: Determination of Fabric Thickness, ISO 9073-2, 1995 standards are used under standard test conditions. Some of the physical characteristics of nonwoven fabrics are given in Table 6. Before friction tests, a digital stereo microscope connected to computer (Figure 9) is used to examine surface view of samples [42].

| Weight (g/m2) | Raw Material | Thickness (mm) | Tensile Strength (N/5 cm) | Elongation (%) | ||

| MD | CD | MD | CD | |||

| 12 | Polypropylene (PP) | 0.10 | 23.0 | 11.0 | 40.0 | 40.0 |

| Polyester (PES) | 0.07 | 20.0 | 10.0 | 15.0 | 19.0 | |

| 17 | Polypropylene (PP) | 0.11 | 45.0 | 40.0 | 65.0 | 65.0 |

| Polyester (PES) | 0.09 | 30.0 | 14.0 | 18.0 | 21.0 | |

| 100 | Polypropylene (PP) | 0.49 | 200.0 | 163.0 | 70.0 | 71.0 |

| Polyester (PES) | 0.75 | 114.0 | 150.5 | 45.3 | 21.4 | |

Table 6 Physical properties of nonwoven fabrics

Figure 9. Microscope Views of Nonwoven Fabrics: (a) 12 g/m2 Polypropylene, (b) 12 g/m2 Polyester, (c) 100 g/m2 Polypropylene, (d) 100 g/m2 Polyester

Frictional properties of nonwoven fabrics have been tested by using horizontal working principle device. This device is named as “horizontal platform experiment device.” The mechanism is developed which is shown in Figure 10 by designing and extra changes upon conventional universal tensile tester in order to perform friction experiments. The designed and manufactured device consists of anti friction rollers (3,4), non-stretch yarn (5), a sled (6), and a sled bed (7). A non-stretch yarn (5) is passed through rollers (3,4) to upper carrier claw (1) of tensile tester. Fastening the sample to the circular sled (6) made of circular 50mm diameter Delrin material is ensured by using a clip in proper dimensions. Nonwoven fabric (10) sample which is covered on sled (6) is lay out in the same direction (MD and CD) with horizontal platform [42].

Figure 10. Horizontal Platform Experiment Device [42,43]

Sled bed (7) is designed with the aim of stretching the fabric (10) on experiment table (8) so as to hold it stable and to prevent slipping, curling, twisting, or folding during the experiment. While the upper carrier claw (1) of developed device is moving at a specific speed, it also pulls Delrin sled (6), and as a result, a friction occurs between two surfaces. At the same time, the load changes stemming from fabric surface structure created during the movement are perceived by load cell (2) and created in graphical and numerical values by the computer (42).

All nonwoven samples were conditioned according to ISO139 before tests, and tests were performed in the standard atmosphere of 20±2°C temperature, and 65±5% relative humidity.

Design Expert 6.01 statistical package program is used to analyze data obtained by experimental works according to variance analysis at α = 0.05 significance. Obtained analysis of variance (ANOVA) table is summarized in the following section, where p value less than 0.05 means that mentioned assessed factor has significant impact. Regression models were formed to define the relationship between independent variables (mass per unit area, fiber type, applied force, contact surface, and fabric direction), and response variables (static and kinetic friction coefficient).

While conducting statistical analysis, fiber type, contact surface, and fabric direction were accepted as categorical, whereas fabric mass per unit area and applied force were accepted as numerical factors. The frictional behavior of samples was used to analyze the general factorial design. The analysis of variance, lack of fit tests, and residual analysis were performed to select the proper model for the friction behavior.

3.1. Results and discussion

Friction tests were conducted under five loads (7.4, 10.2, 14.5, 17.3, and 20.2 N) and from three points of the fabric for machine direction (MD) and cross direction (CD) of samples and under three friction environment (fabric-abrasive wool fabric, wood, and metal). At the end of friction tests, the highest value for the movement at its start was accepted as static friction resistance, whereas the average of values read thereafter were accepted as kinetic friction resistance. Attention was paid to ensure that the sample attached to Delrin part which was placed on horizontal platform was slightly strained and rubbed to different parts of the fabric. Figures obtained using the test results of friction behavior of nonwoven fabric obtained in the tests are given Figures 11-14 [42].

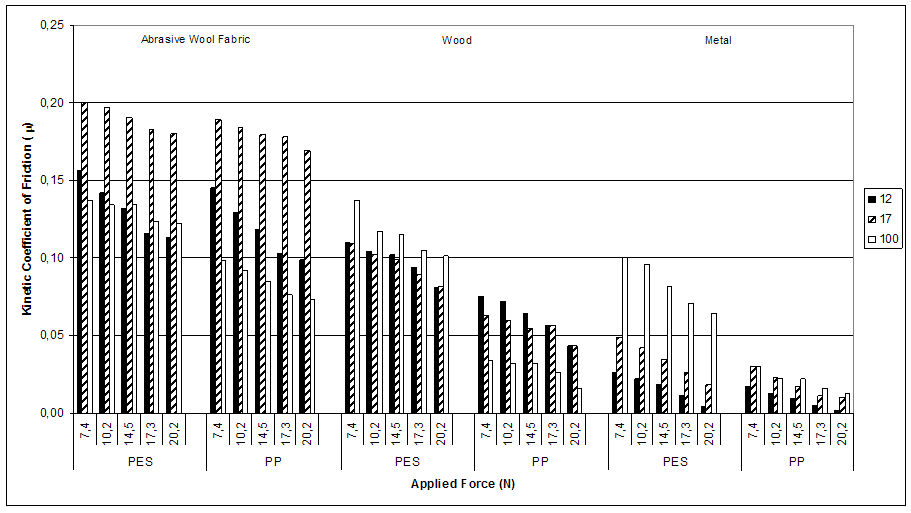

In Figures 11 and 12, the change against applied force (load) of static friction forces obtained as a result of friction tests conducted at machine direction (MD) and cross direction (CD) under three friction platforms of 100% PP- and PES-based nonwoven surfaces of three weights is shown [42].

When these figures are examined, it can be observed that when the force in normal direction (vertical direction) applied on the sample increased, static friction coefficient values tended to decrease. The result for this effect is interpreted to be the more uniform fabric surface created by fabric friction interaction as load increased, as a result of which friction coefficient tended to decrease [42].

When the impact of fiber type on friction coefficient is viewed, it can be seen that friction coefficient values of polypropylene (PP)-based nonwoven fabrics had much lower values than those of polyester (PES)-based samples. This is believed to have been caused by the fact that polypropylene-based samples had a tougher surface. As the surface is smoother, less force is required for sliding action so as to move when compared to polyester-based nonwoven fabrics, in which case friction coefficient values were measured much lower [42].

In addition, we can see that fabric mass per unit area has a significant impact on friction values. As the fiber orientation of nonwoven fabrics with low weight is not smooth, they showed fluctuations in behaviors, and it has been seen that they had higher friction coefficient. However, it has been found out that as weight increases, friction coefficient values started to decrease as fiber orientation on nonwoven fabric surface was more stabile. When one looks at microscope views in Figure 9a and 9b belonging to fabric samples, it can be seen that fiber orientation distributed irregularly, and that as fabric weight increased (Figure 9c and 9d), surface smoothness deteriorated. This structure of the used samples helps us in understanding the obtained findings [42].

Figure 11. MD Static Friction Coefficient

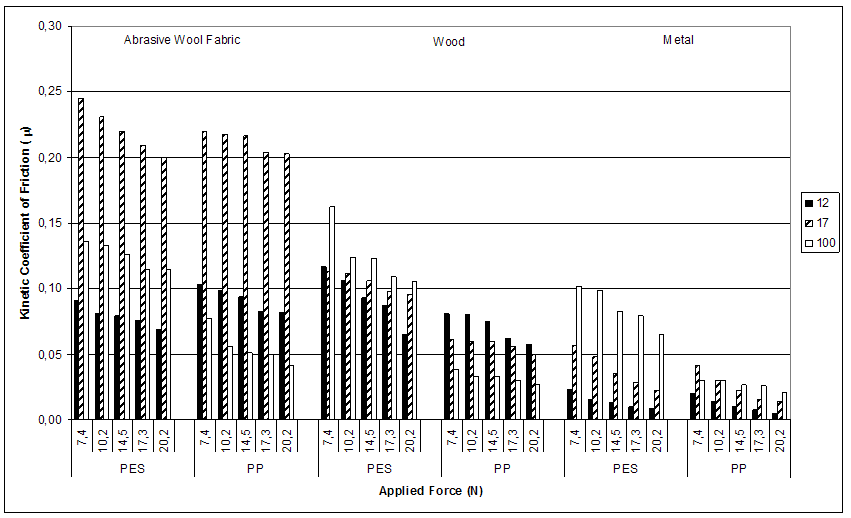

Figure 12. CD Static Friction Coefficient In Figures 13 and 14, the change against applied force (load) of kinetic friction forces obtained as a result of friction tests conducted at machine direction (MD) and cross direction (CD) under three friction platforms of 100% PP- and PES-based nonwoven surfaces of three weights is shown [42].

When these figures are examined, it can be observed that kinetic friction coefficient values in CD direction of samples at different friction surfaces (abrasive wool fabric, wood and metal) are slightly higher when compared to MD direction. The reason for this result can be the fact that fiber orientation in CD direction is more preventive for friction movement in the formation of samples [42].

When each load group of same type of sample is examined in itself, it can be observed that as the force in applied normal direction (vertical direction) increases, kinetic friction coefficient values tend to decrease. The result for this effect is interpreted to be the more uniform fabric surface created by fabric friction interaction as load increased, as a result of which friction coefficient tended to decrease [42].

When we look at the impact of different friction environments on friction behavior, the lowest friction coefficient values were witnessed in fabric-metal friction environment, and the highest friction coefficient values were obtained in abrasive wool fabric friction environment. As metal surface is more smooth and slippery compared to wooden and abrasive wool fabric, it is observed that metal showed smaller resistance to friction, hence lower values for friction of metal in this interaction. In addition, in fabric-abrasive fabric friction environment, as a result of the tests applied in both machine and cross directions, higher kinetic friction coefficient values were measured, especially in 17 g/m2 mass per unit area nonwoven fabric sample, compared to other samples. This is interpreted to have been caused by irregular distribution of fiber orientation in samples with low weight [42].

As a result of friction tests realized under fabric wooden friction environment, kinetic friction coefficient values were higher for polyester-based samples (especially 100 g/m2) as weight of surface structure in both machine and cross directions increased and gained a softer structure. As for polypropylene-based samples, on the other hand, as mass per unit area increased, surface structure became smoother and therefore friction coefficient tended to decrease [42].

In fabric-metal friction environment, as mass per unit area increased, friction coefficient values for both samples tended to increase as well, which is interpreted to have been caused by the softening of surface [42].

Figure 13. MD Kinetic Friction Coefficient

The statistical analyses show that the best fitting model is the quadratic model for spunbond nonwoven fabrics (Tables 7 and 8).

Figure 14. CD Kinetic Friction Coefficient

| Source | P Value | Adjusted R2 | Predicted R2 |

| Linear | <0.0001 | 0.6361 | 0.6214 |

| 2FI | <0.0001 | 0.7905 | 0.7680 |

| Quadratic | ≤≤ 0.0001 | 0.8586 | 0.8485 |

| Cubics | <0.0001 | 0.7719 | 0.7605 |

Table 7. Model summary statistics (static)

ANOVA results for friction coefficient of nonwoven fabric samples are given in Table 9. When ANOVA table is examined, it can be seen that weight, fiber type, applied force, and contact surface of nonwoven fabrics have significant impact on friction coefficient values, whereas fabric direction showed no significant impact. In addition, according to the table, the R2 value of the model turned out to be some 0.86. In this case, terms in the model can explain the model at 86% ratio. This case shows that the model created for friction coefficient can express with rather high accuracy the relation between independent variables and dependent variable and that experimental work results were acceptable as accurate .

| Source | P Value | Adjusted R2 | Predicted R2 |

| Linear | <0.0001 | 0.6451 | 0.6290 |

| 2FI | <0.0001 | 0.7765 | 0.7536 |

| Quadratic | ≤≤ 0.0001 | 0.8554 | 0.8456 |

| Cubics | <0.0001 | 0.7726 | 0.7611 |

Table 8. Model summary statistics (kinetic)

| Factor | Static | Kinetic | ||

| F Value | Prob>F | F Value | Prob>F | |

| Model | 91.58 | <0.0001 | 89.28 | <0.0001 |

| Mass Per Unit Area | 5.40 | 0.0213 | 4.22 | 0.0415 |

| Fiber Type | 138.62 | <0.0001 | 111.04 | <0.0001 |

| Applied Force | 38.32 | <0.0001 | 31.58 | <0.0001 |

| Contact Surface | 318.75 | <0.0001 | 333.38 | <0.0001 |

| Fabric Direction | 3.32 | 0.0701 | 7.395E-004 | 0.9783 |

| Weight2 | 72.95 | <0.0001 | 83.57 | <0.0001 |

| Weight × Applied Force | 86.79 | <0.0001 | 57.47 | <0.0001 |

| Weight × Contact Surface | 50.17 | <0.0001 | 48.94 | <0.0001 |

| Fiber Type × Contact Surface | 7.83 | 0.0006 | 9.40 | 0.0001 |

| R2 | 0.8681 | 0.8651 | ||

| Adjusted R2d | 0.8586 | 0.8554 | ||

| Predicted R2pre | 0.8485 | 0.8456 | ||

Table 9. ANOVA table

The regression equation of the quadratic model for spunbond nonwoven sample is as follows;

Static Friction Coefficient = 0.24 + 0.00364×A – 0.019×B-0.015×C + 0.045×D + 0.003×E – 0.001931×AC – 0.023×AD + 0.005×BD – 0.16×A2

Kinetic Friction Coefficient = 0.24 + 0.004678×A – 0.017×B – 0.013×C + 0.047×D – 0.004×E + 0.00012×AC – 0.022×AD + 0.0060×BD – 0.17×A2

According to model performance values, the correlation coefficient between predicted and observed air permeability values is 0.85, indicating a strong predictive capacity of the regression model for spunbond nonwoven samples.

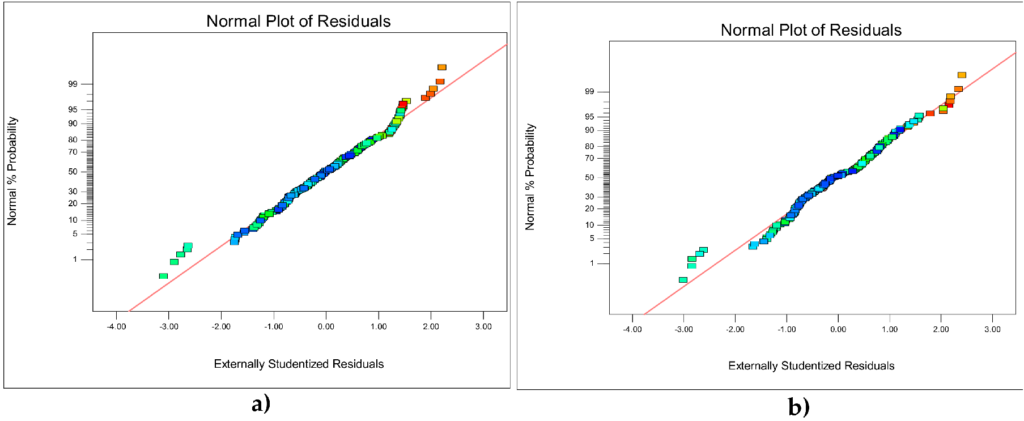

Figure 15. Normal Plot of Residual Coefficient of Friction Values: (a) Static and (b) Kinetic

Figure 15 gives normal distribution graph of residuals for quadratic model. As can be seen from the figure, no problems are observed in normal distribution in the chosen model. This analysis also supports the conformity of chosen model.

- Conclusion

Nonwoven industry brings a wealth of advantages to people throughout the world by providing the superior products. For example, modern disposable baby diapers have made an important contribution to the quality of life of millions of people. Since their introduction, modern single-use diaper products have improved steadily through scientific advances in design and basic raw materials, becoming lighter, more compact, more absorbent, and easier to use. For this reason, selection of raw material is very important for nonwoven manufacturers. Raw materials have not only delivered significant product improvements but also benefited people people using these products byproviding hygiene and comfort.