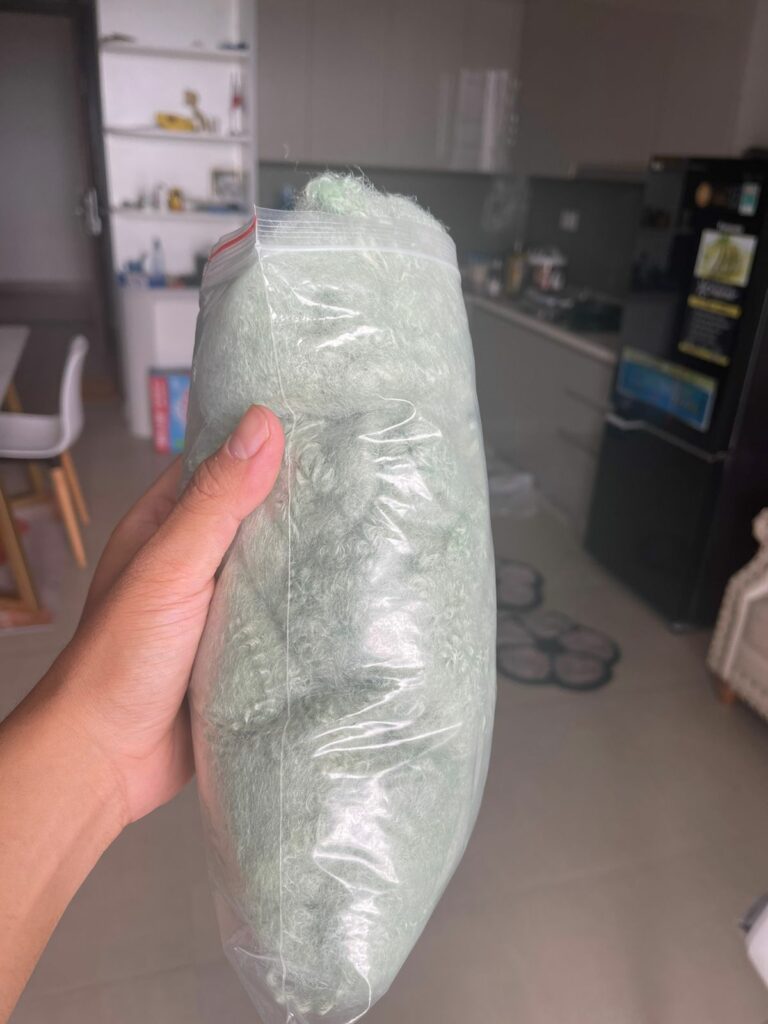

Green Hollowfibre

- Superior Quality & Benefits

- 100% Siliconized Fiber – Ensures long-lasting shape and volume retention.

- Soft & Lightweight – Provides a plush, cloud-like feel.

- Shape Memory – Adapts to any form yet always restores its original shape.

- Hypoallergenic & Non-Toxic – Safe for all users, including those with sensitivities.

- Moisture-Resistant & Odor-Free – Does not absorb surrounding smells.

- Durable & Easy to Maintain – Machine washable at all temperatures.

- Static-Free & Excellent Insulation – Keeps warmth effectively without static buildup.

PRODUCT DETAIL

What is Green Hollowfibre?

Green Hollowfibre is a specialized variety of siliconized synthetic fluff, distinguished by its unique structure. Unlike standard fibrous materials, it consists of mechanically twisted fiber balls, enhancing resilience and loft.

Green Hollowfibre is a premium synthetic material that stands out for its softness, durability, and exceptional insulation properties. It is a specialized variety of siliconized synthetic fluff, distinguished by its unique structure of mechanically twisted fiber balls rather than continuous strands. This innovation makes it an ideal choice for bedding, upholstery, apparel, and toy manufacturing, offering superior comfort, longevity, and eco-friendly benefits.

In this comprehensive guide, we will explore everything you need to know about Green Hollowfibre , including its composition, properties, advantages, production process, applications, and market demand.

This type of fiber is known for being:

- Lightweight and breathable

- Hypoallergenic and non-toxic

- Resistant to moisture and odors

- Highly durable and easy to maintain

- A sustainable alternative to traditional synthetic fillers

Its unique composition makes it an exceptional filling material for a wide range of consumer and industrial products.

2. Production Process of Green Hollowfibre

The production of Green Hollowfibre involves advanced manufacturing techniques to ensure high quality and consistency. The key steps include:

Step 1: Raw Material Selection

The fiber is made from high-quality polyester or recycled PET (polyethylene terephthalate) bottles, which undergo thorough cleaning and processing before conversion into fiber.

Step 2: Siliconization

The fiber is coated with a silicone layer, enhancing its softness, reducing friction, and preventing clumping. This process allows the fiber to maintain its loft and flexibility for an extended period.

Step 3: Mechanical Twisting

Unlike conventional polyester fiberfill, Green Hollowfibre is formed into small, spring-like balls through a mechanical twisting process. This step provides extra resilience and bounce, ensuring that the fiber retains its shape and volume over time.

Step 4: Heat Treatment & Bonding

The fiber undergoes heat treatment, ensuring proper bonding and structural integrity. This process enhances its durability and performance in various application

3. Key Properties & Benefits of Green Hollowfibre

A. Superior Comfort and Softness

Green Hollowfibre is incredibly soft, making it an excellent choice for pillows, bedding, and upholstery. The fiber adapts to different shapes while retaining its plush feel.

B. Hypoallergenic & Safe

The fiber is non-toxic and free from allergens, making it ideal for people with sensitive skin or allergies. It does not attract dust mites or other allergens, ensuring a healthier sleeping environment.

C. Moisture and Odor Resistance

Unlike natural fillers, Green Hollowfibre does not absorb moisture or retain odors. This makes it perfect for humid environments where traditional fillers may develop mold or bacteria.

D. Easy Maintenance

The fiber is machine washable at all temperatures, dries quickly, and retains its shape after multiple washes, making it a low-maintenance and long-lasting choice.

E. Excellent Insulation & Temperature Regulation

Thanks to its hollow structure, the fiber traps air, providing superior thermal insulation. This property makes it ideal for cold-weather clothing, blankets, and sleeping bags.

F. Environmentally Friendly

Many manufacturers are now producing Green Hollowfibre from recycled PET bottles, reducing plastic waste and promoting sustainability.

4 Applications of Green Hollowfibre

Due to its versatility, Green Hollowfibre is widely used in various industries. Some of the most common applications include:

A. Bedding & Home Textiles

- Pillows

- Duvets & comforters

- Mattress toppers

- Cushion fillings

B. Furniture & Upholstery

- Sofa and chair cushions

- Decorative pillows

- Padding for upholstered furniture

C. Apparel & Fashion Industry

- Insulated winter jackets

- Sleeping bags

- Padded coats

D. Toy Manufacturing

- Soft stuffed toys

- Plush animals

- Baby cushions and comfort items

E. Automotive Industry

- Car seat padding

- Headrests

- Interior upholstery

F. Medical & Healthcare Sector

- Hypoallergenic pillows

- Medical cushions and support pillows

- Hospital bedding

5. Market Demand & Future Trends

A. Rising Demand for Sustainable Materials

With growing environmental concerns, consumers and businesses are shifting toward eco-friendly materials. Green Hollowfibre , especially when made from recycled PET, aligns perfectly with this demand.

B. Growth in Bedding & Upholstery Industry

As home decor and luxury bedding markets expand, the demand for premium fiberfill solutions like Green Hollowfibre is rising significantly.

C. Increasing Use in the Fashion Industry

More clothing brands are choosing synthetic insulation materials over traditional down feathers, boosting the popularity of Green Hollowfibre in outerwear and winter clothing.

D. Expansion in the Medical Sector

The healthcare industry’s focus on hypoallergenic and washable materials is further fueling the demand for high-performance synthetic fibers.

6. Why Choose Green Hollowfibre Over Other Fillers?

| Feature | Green Hollowfibre | Traditional Polyester Fiber | Natural Down |

|---|---|---|---|

| Softness | ✅ Excellent | ✅ Good | ✅ Excellent |

| Hypoallergenic | ✅ Yes | ❌ No | ❌ No |

| Moisture Resistance | ✅ Yes | ❌ No | ❌ No |

| Shape Retention | ✅ Excellent | ❌ Poor | ❌ Poor |

| Machine Washable | ✅ Yes | ✅ Yes | ❌ No |

| Eco-Friendly Options | ✅ Available | ✅ Available | ❌ No |

From the table above, it is evident that Green Hollowfibre outperforms traditional polyester and down in several aspects, making it a superior choice for various applications.

7. Conclusion

Green Hollowfibre is revolutionizing the textile, bedding, furniture, and apparel industries with its unmatched softness, durability, and eco-friendly advantages. Whether used in pillows, blankets, jackets, or plush toys, it offers outstanding comfort, insulation, and longevity.

As sustainability becomes a key priority for manufacturers and consumers alike, Green Hollowfibre is emerging as one of the best synthetic alternatives to traditional fillers. Its hypoallergenic nature, moisture resistance, and ability to retain its shape make it a highly desirable material for modern applications.

If you are looking for a premium-quality, versatile, and sustainable fiber solution, Green Hollowfibre is undoubtedly the best choice.

Technical Parameter

| Product type | Green Hollowfibre |

| Fineness | 7D / 15D |

| Cut length | 32mm / 51mm / 64mm |

| Luster | semi dull |

| COLOR | Raw white |

| Pattern | Hollow Siliconized & Hollow Non-Siliconized |

| Raw Material | 100% PET flakes |

| Grade | Recycled, AAA grade |

| Packing details | 250kg-350kg/PP woven bag/bale |

| Delivery time | 5-20days after 30% deposit |

| Payment Term | TT30/70; L/C at sight |

| MOQ | 1x40HQ; 22 – 23 tons/container |

| Quality | First quality |

Ideal Applications

✔ Bedding – Perfect for blankets and decorative pillows.

✔ Soft Toys – Ensures safety and durability.

✔ Clothing – Used as a premium insulation material.

FAQ

1. What do you offer?

We produce recycled hollow conjugated siliconized and non-siliconized polyester staple fiber mainly, we can make Hollowfibre (HS/ HD) and virgin polyester staple fiber HCS as well.

2. What is it used for?

Our fiber is widely used in filling, non-woven fabric

3. Are you a factory or a trading company?

We are a factory specialized in polyester staple fiber for many years but now we also have our own professional trading company. We will source many types of textile products such as yarn, PP fibers from others to supply our own customers as well. We also provide our own customers with other related products such as: Foam, Pillows, Cushions, Toys, Down/ Feather,…

4. Where is your factory location?

Our factory locates in the north and the south of Vietnam. You can visit us from Ho Chi Minh City and Hanoi City, Vietnam. You could contact our salesman to fetch you if visiting.

5. Can you accept free sample?

Yes, the hand sample is free when not exceed 1 kilograms. Upon price confirmation, we will provide a sample within 2-3 days; the freight cost will be charged to client.

6. Can you provide ODM service?

Yes, we work on ODM orders. Which means size, material, quantity, design, packing solution, etc, will depend on your requests, and your logo will be customized on our products.

7. How about your quality? What’s the minimum order Quantity (MOQ)?

Please try a trial order, you will know it. The MOQ is 23,000 Kilograms/order, but the price will be lower if you order bulk volume.

8. Can I mix different items in one order?

Sure, you can mix any products we can provide.

9. How can you guarantee the product quality?

We have experienced QC team. We control not only productive process but also raw material. In addition, we have different kinds of testing instrument to help us guarantee the product quality.

10. What’s the payment terms?

L/C at sight, 30% TT in advance are mostly accepted; other terms shall be negotiable by both sides

For more information, please feel free to contact :

Mr. Tony Tan

Mobile number: +84 90 466 5251 (Whatsapp/Wechat/Viber/Signal)