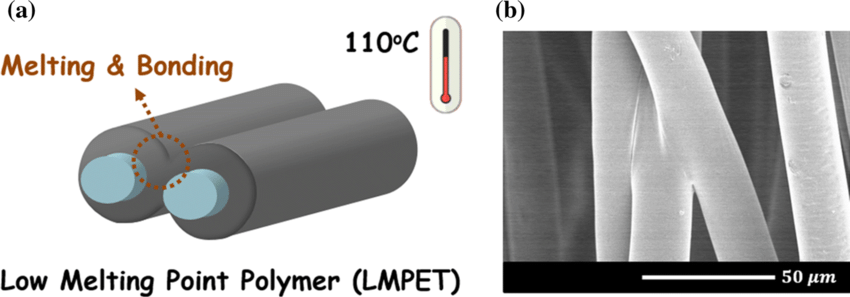

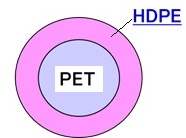

By blending two kinds of polymers, new fibers are made which own every characteristic of each polymer.

Bi-Component binder fibers with high-performance ability.

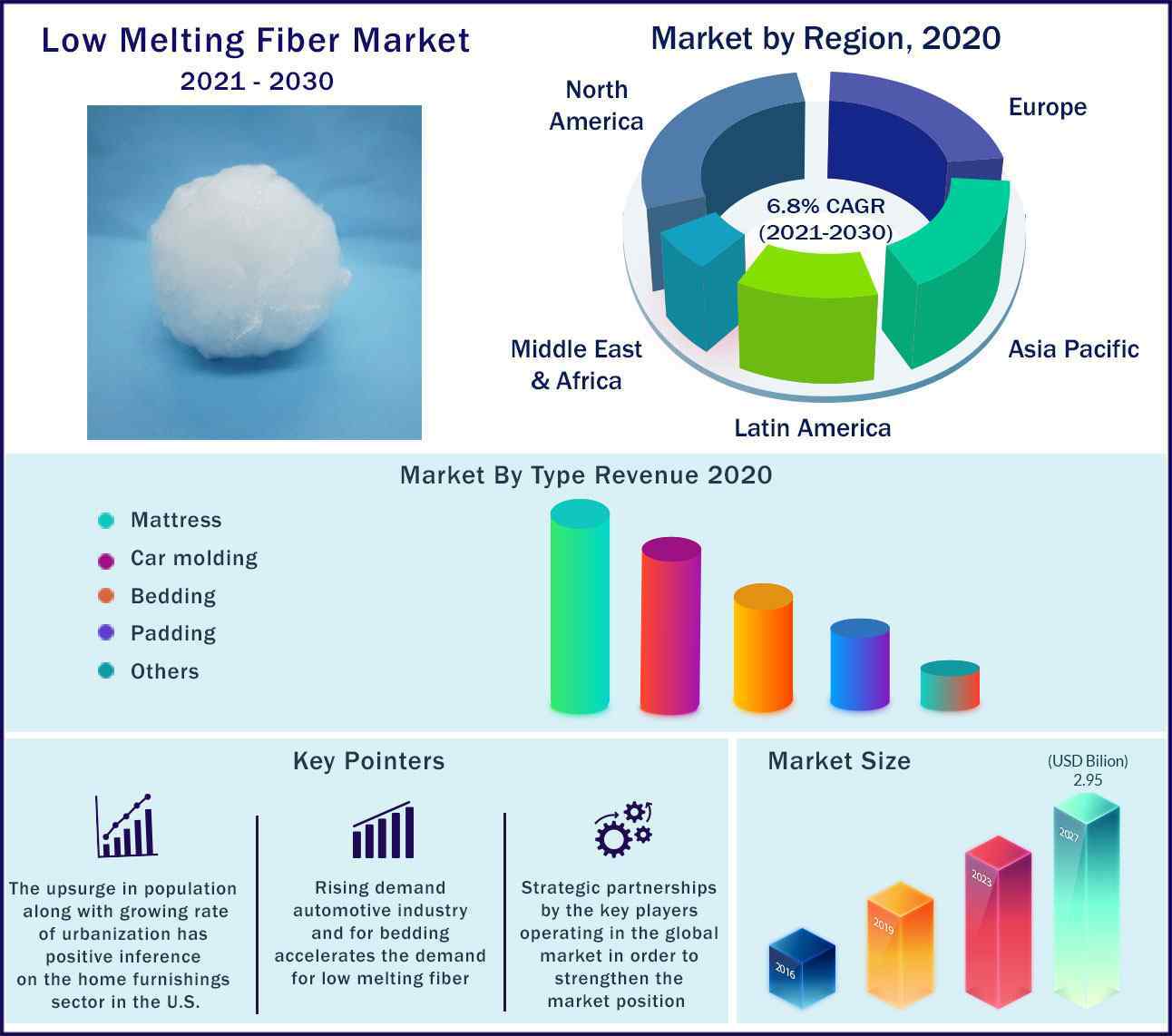

Bicomponent fibers have various types that suitable for heat-bonded nonwoven fabrics, dependent on their purpose and application (carding, wetlaid, airlaid).

Among other advantages such as soft touch, durable performance, process stability, and high speed, the bicomponent fibers have different melting points depending on the raw material used and make it possible to achieve a significantly higher material strength.

The first specific characteristic of Bi-Component fibers is the difference between the melting point of two polymers that causes one of these polymers to play as glue for sticking two fibers.

What is biodegradable fiber?

Biodegradable means that it can be biodegraded using micro-degradable materials. It is often connected with biodegradable materials.

Biodegradable materials refer to materials that can be completely decomposed into low-molecular compounds by microorganisms (such as bacteria, fungi, and algae, etc.) under appropriate and definite natural environmental conditions.

Fully biodegradable materials can be completely decomposed by microorganisms and have a positive effect on the environment.

While human beings create modern civilization, it also brings negative impacts—white pollution. Disposable tableware, disposable plastic products, and agricultural mulch are difficult to recycle, and their treatment methods are mainly incineration and landfill. Incineration will produce a large amount of The harmful gases pollute the environment; if buried, the polymers in it cannot be decomposed by microorganisms in a short time, and also pollute the environment. Residual plastic films exist in the soil, hindering the development of crop root systems and the absorption of water and nutrients, making the soil The air permeability is reduced, resulting in crop yield reduction; after eating the discarded plastic film, it will cause intestinal obstruction and death; synthetic fiber fishing nets and fishing lines lost in the ocean or discarded in the ocean have caused considerable damage to marine life.

Therefore, it is imperative to promote green consumption and strengthen environmental protection.