Hollow Conjugate Polyester Staple Fiber for Stuffing, Filling Pillows and Nonwoven

Highly elastic with good raw white

Super soft hand feeling with silicon

Less flaw and better warmth character

Mainly used for filling material, non-woven fabric, polyester wadding ,polyester cotton, silk-like cotton,needle-punched cotton and so on.

PRODUCT DETAIL

Hollow Conjugate Siliconized Polyester

| Model NO. | Hollow Conjugate Siliconized Polyester |

| Width | 51mm/64mm /32mm /38mm /76mm |

| Grade | Virgin/ Recycled |

| Shape | Hollow Conjugated |

| Transport Package | by Ocean |

| Specification | 3d /2.8d/ 6d /7d/ 10d/12d /15d/ 20d/24d/27d/30d et |

| Trademark | VNPOLYFIBER |

| Origin | Viet Nam, China |

| HS Code | 55032000 |

| Production Capacity | 50000 tons |

Product Description

Product Description

| Fineness | 0.9D ~ 25D |

| Fiber length | 25/32/28/38/51/64/76/108MM |

| material | Chips or Pet Flakes |

| pattern | Silicon or Non-silicon |

| color | OB or RW |

| delivery time | 3 days after getting original lc or T/T advanced prepayment |

| payment | L/C OR T/T |

| loading port | Any port in Viet Nam or China |

| package | Non-woven Bags |

| MOQ | 1 x40ft HC |

| Specification sheet for 1.2D | |||||||

| No. | Inspection Item | Unit | Standard | Measure Value | Result | ||

| 1 | fineness | dtex | 1.21 | Passed | |||

| 2 | Tolerance | % | ±30 | 10 | Passed | ||

| 3 | Length | mm | 52.5 | Passed | |||

| 4 | Length Tolerance | % | ±10 | +3 | Passed | ||

| 5 | Crimp | pcs/25mm | 8±3.0 | 8.2 | Passed | ||

| 6 | Doubles long fiber content | mg/100g | ≤200 | 0 | Passed | ||

| 7 | Flaw content | mg/100g | ≤1000 | 362.7 | Passed | ||

| Specification sheet for 1.4D | |||||||

| No. | Inspection Item | Unit | Standard | Measure Value | Result | ||

| 1 | fineness | dtex | 1.52 | Passed | |||

| 2 | Tolerance | % | ±30 | -14 | Passed | ||

| 3 | Length | mm | 51.5 | Passed | |||

| 4 | Length Tolerance | % | ±10 | +1 | Passed | ||

| 5 | Crimp | pcs/25mm | 8±3.0 | 7.8 | Passed | ||

| 6 | Doubles long fiber content | mg/100g | ≤200 | 0 | Passed | ||

| 7 | Flaw content | mg/100g | ≤1000 | 352.4 | Passed | ||

| Specification sheet for 3D | |||||||

| No. | Inspection Item | Unit | Standard | Measure Value | Result | ||

| 1 | fineness | dtex | 3.15 | Passed | |||

| 2 | Tolerance | % | ±30 | -5.4 | Passed | ||

| 3 | Length | mm | 50.8 | Passed | |||

| 4 | Length Tolerance | % | ±10 | 0.4 | Passed | ||

| 5 | Crimp | pcs/25mm | 8±3.0 | 8.6 | Passed | ||

| 6 | Doubles long fiber content | mg/100g | ≤200 | 0 | Passed | ||

| 7 | Flaw content | mg/100g | ≤1000 | 169 | Passed | ||

| Specification sheet for 6D | |||||||

| No. | Inspection Item | Unit | Standard | Measure Value | Result | ||

| 1 | fineness | dtex | 7.71 | Passed | |||

| 2 | Tolerance | % | ±30 | 28.5 | Passed | ||

| 3 | Length | mm | 56.1 | Passed | |||

| 4 | Length Tolerance | % | ±10 | +10 | Passed | ||

| 5 | Crimp | pcs/25mm | 8±3.0 | 10.1 | Passed | ||

| 6 | Multiple Length Fiber | mg/100g | ≤200 | 1 | Passed | ||

| 7 | Defect Content | mg/100g | ≤1000 | 344 | Passed | ||

| 8 | bulking intensity V1 | cm3/g | ≥140 | 172 | Passed | ||

| 9 | bulking intensity V2 | cm3/g | ≥35 | 62 | Passed | ||

| 10 | bulking intensity V3 | cm3/g | ≥140 | 150 | Passed | ||

| 11 | rebound degree | % | ≥70 | 72 | Passed | ||

| 12 | Hollow rate | % | ≥12 | 12 | Passed | ||

| Specification sheet for 7D | ||||||||

| No. | Inspection Item | Unit | Standard | Measure Value | Result | |||

| 1 | fineness | dtex | 8.82 | Passed | ||||

| 2 | Tolerance | % | ±30 | 26.0 | Passed | |||

| 3 | Length | mm | 55.8 | Passed | ||||

| 4 | Length Tolerance | % | ±10 | +9 | Passed | |||

| 5 | Crimp | pcs/25mm | 8±3.0 | 8.1 | Passed | |||

| 6 | Multiple Length Fiber | mg/100g | ≤200 | 29 | Passed | |||

| 7 | Defect Content | mg/100g | ≤1000 | 480 | Passed | |||

| 8 | bulking intensity V1 | cm3/g | ≥140 | 190 | Passed | |||

| 9 | bulking intensity V2 | cm3/g | ≥35 | 76 | Passed | |||

| 10 | bulking intensity V3 | cm3/g | ≥140 | 156 | Passed | |||

| 11 | rebound degree | % | ≥70 | 76 | Passed | |||

| 12 | Hollow rate | % | ≥12 | 14 | Passed | |||

Technical Parameter

Usually used as padding/filling material of cushions, bedding, sofas, etc.

Specification:

size(denier):3D 7D 15D 30D

length(mm):28mm -152mm

Category: Chemical Fiber

Usage: Garment, Industrial, Home Textile, Army, Bag, Shoes, Tent and Awning

Grade: Recycled

Transport Package: PP Bales

Fiber Type: Staple

Material: Pet

Feature: Heat-Resistant, Anti-Static, Anti-Distortion, Flame Retardant, Abrasion-Resistant, Anti-Pilling

Shape: Rayon

About Us:

We are a leading supplier of polyester staple fiber based in Viet Nam. With a strong presence in both the domestic and international markets, we can supply various types of PSF, both recycled and virgin grades.

Our product offerings include a range of hollow conjugated polyester staple fiber (white, brown, green), as well as solid, conjugate, and siliconized fibers ranging from 3D to 15D. We also have microfiber, with sizes ranging from 0.9D to 1.4D and cut lengths from 25mm to 32mm. Our fibers are primarily utilized in the production of non-woven fabrics and spinning yarns, and are in high demand in European and South American markets.

We adhere to international quality standards and pride ourselves on delivering products that are well-received across various global markets. Our state-of-the-art facilities and stringent quality control measures ensure that we consistently meet and exceed customer expectations.

If you are interested in knowing more about our products, please do not hesitate to reach out to us. We welcome the opportunity to establish mutually beneficial partnerships with new clients worldwide. Thank you for considering us.

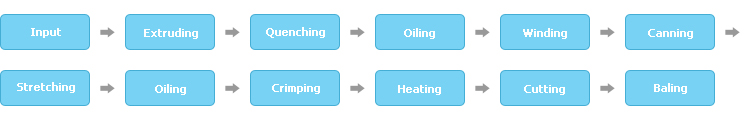

Staple fiber production process

The base material, which comes in chips, is melted in an extruder before being quantified in a gear pump and transferred to a nozzle. Polymers that pass through the nozzle are cooled and solidified in a spinning tank, and end up in a fiber form (semi-finished product). Fiber released from multiple spinning tanks is lubricated and gathered before being wound by a gear wheel and placed in cans. Fiber placed in cans is given various properties through a stretching process, in which fiber is stretched at various roller speeds designed to endow different degrees of rigidity and elasticity.

The fiber is again lubricated for enhanced quality and to facilitate the processes that follow. A crimping process takes place to give the fiber various properties, including bulk and mixability. Moisture and lubricant on the fiber is dried off in a heat dryer. The fiber is then cut into required lengths and end up in a bale form. The fiber is then compressed, packaged, and stored for factory release when ordered.

PRODUCTION PROCESS OF POLYESTER STAPLE FIBER

Video

FAQ

1. What do you offer?

We produce recycled hollow conjugated siliconized and non-siliconized polyester staple fiber mainly, we can make hollow fiber (HS/ HD) and virgin polyester staple fiber HCS as well.

2. What is it used for?

Our fiber is widely used in filling, non-woven fabric

3. Are you a factory or a trading company?

We are a factory specialized in polyester staple fiber for many years but now we also have our own professional trading company. We will source many types of textile products such as yarn, PP fibers from others to supply our own customers as well. We also provide our own customers with other related products such as: Foam, Pillows, Cushions, Toys, Down/ Feather,…

4. Where is your factory location?

Our factory locates in the north and the south of Vietnam. You can visit us from Ho Chi Minh City and Hanoi City, Vietnam. You could contact our salesman to fetch you if visiting.

5. Can you accept free sample?

Yes, the hand sample is free when not exceed 1 kilograms. Upon price confirmation, we will provide a sample within 2-3 days; the freight cost will be charged to client.

6. Can you provide ODM service?

Yes, we work on ODM orders. Which means size, material, quantity, design, packing solution, etc, will depend on your requests, and your logo will be customized on our products.

7. How about your quality? What’s the minimum order Quantity (MOQ)?

Please try a trial order, you will know it. The MOQ is 23,000 Kilograms/order, but the price will be lower if you order bulk volume.

8. Can I mix different items in one order?

Sure, you can mix any products we can provide.

9. How can you guarantee the product quality?

We have experienced QC team. We control not only productive process but also raw material. In addition, we have different kinds of testing instrument to help us guarantee the product quality.

10. What’s the payment terms?

L/C at sight, 30% TT in advance are mostly accepted; other terms shall be negotiable by both sides