Definition of Polypropylene staple fiber

Polypropylene staple fiber is a single fiber, which can improve crack resistance, impermeability, anti-wearing ability, anti-freezing ability, anti-explosion ability and improve the workability of concrete.

Short polypropylene staple fibers are evenly distributed in mortar and concrete, which keeps the integrity of the structure well and prevents the structure from being scattered into many fragments when it is damaged by impact. The corrosion of the steel bars in the structure can greatly extend the service life of the project and reduce the maintenance cost of the project.

Polypropylene staple fiber is used in anti-cracking putty powder, thermal insulation mortar, concrete, construction engineering level, wall, floor, pool, basement, and access bridge engineering. It has anti-cracking, anti-wear, wear resistance, toughness, and impact. , explosion-proof, also has resistance to tearing, improve the bonding of old and new interfaces.

Polypropylene staple fiber has superior moisture permeability and quick-drying property, good combability and spinning performance, and can produce soft and tough fabrics. The fabric is light in weight, warm in warmth, delicate in hand, and comfortable to take. , acid and alkali resistant. At the same time, it has the ability to dissolve quickly, good filling and insulation.

Polypropylene fiber is a synthetic fiber spun from isotactic polypropylene obtained by polymerization of propylene as a raw material, and its trade name is polypropylene fiber in my country.

Polypropylene fibers can be divided into long fibers, short fibers, spunbonded non-woven fabrics, melt-blown non-woven fabrics, and so on. Polypropylene long fibers can be divided into ordinary long fibers and fine denier long fibers (monofilament size ≤2.2 dtex, which can be used to produce clothing and decoration and some industrial filament products. Polypropylene fine denier long fibers have good luster, soft feel, and drape Good properties, low density, suitable for the knitting industry, when interwoven with cotton, viscose silk, real silk, spandex, etc., into cotton cover acrylic, silk cover acrylic and other products, it is an ideal material for making high-end sportswear, T-shirts, etc.

Most of the production process of polypropylene staple fiber adopts a porous, low-speed, continuous process, that is, a short spinning process. Polypropylene staple fiber blended with cotton can be made into polypropylene cotton muslin and bed sheets, that is, fiber and viscose blend can be used as blankets, polypropylene pure spinning and blended yarns, polypropylene blankets, carpets, polypropylene cotton wool filter nozzles. The thickness of the fiber for sanitary products is 1.5-2.5, and the thickness of the fiber for ground fabrics is 5-10. The fiber length is 1.5-200.0 mm, depending on the purpose of the fiber. The length of short fibers used as concrete is 1.5-200.0 mm, the length used as diapers is generally 40.0 mm, and the length used as above-ground fabrics is 60.0 mm.

Polypropylene staple fibers can be divided into cotton type, wool type, carpet type and medium and long type short fibers according to the specifications of natural fibers. They can be spun purely or blended with natural or other fibers in varying proportions to make sliver, fabric and felt.

Polypropylene staple fibers are mainly used in needle-punched carpets, automotive interiors, non-woven fabrics, ropes, decorative materials, medical and sanitary products, etc. short fiber is also called cut fiber. Chemical fiber long fiber bundles are cut or broken into fibers corresponding to various natural fiber lengths. Natural fibers such as whiskers and asbestos can also be used. Short fiber limit, the length is generally 35 ~ 150mm. According to the specifications of natural fibers, it can be divided into short fibers such as cotton type, wool type, carpet type and medium and long type. They can be spun purely or blended with natural or other fibers in varying proportions to make sliver, fabric and felt.

Characteristics of polypropylene staple fibers

Polypropylene staple fibers have low density, light weight, and can float on the water; polypropylene colored yarns have high strength and strong tensile strength; polypropylene staple fibers have certain acid and alkali resistance.

Corrosion resistance, even if soaked

Don’t worry about it in sea water; polypropylene staple fiber has low hygroscopicity and almost no moisture absorption; polypropylene staple fiber is an environmentally friendly and pollution-free product.

Polypropylene products are able to give good bulk and cover, are abrasion resistant, colorfast, and quick drying.

Polypropylene has low static, is resistant to deterioration from chemicals, mildew, perspiration, rot and weather, is stain and soil resistant, and sunlight resistant.

Polypropylene garments wick body moisture from the skin, are very comfortable, and very lightweight.

How is Virgin Polypropylene Staple Fiber (PPSF) made?

Polypropylene fiber is manufactured from isotactic polypropylene chips by melt spinning process to form filaments. These filaments/fibers are then solidified by air/water quenching and after application of spin, the finish is collected in cans. The fiber is stretched several times in a chemical hot bath, relaxed, and crimped to be made suitable for various spinning systems.

Polypropylene staple fiber is used to manufacture Air Filter, Water Filters, and other industrial fabrics, It is also used for woven carpets, non-woven carpets, upholstery, carpet backing, etc.

Polypropylene staple fibers offer superior features due to their lowest specific gravity resulting in better relative coverage, high dimensional stability, excellent recovery properties namely elasticity and resiliency, low thermal conductivity, lowest static charge, and inertness to chemicals.

The denier range of PP Fiber is 1.5D to 70Denier.

Geotextile made of Polypropylene Staple Fiber (PPSF)

Geotextiles are permeable fabrics that, when used in association with soil, have the ability to separate, filter, reinforce, protect, or drain. Typically made from polypropylene or polyester, geotextile fabrics come in three basic forms: woven (resembling mail bag sacking), needle punched (resembling felt), or heat bonded (resembling ironed felt).

Higher Breaking Tenacity and higher Breaking Elongation are the pre-requisites for a Good Quality Geotextile.

The UV stabilization is done by using a high-quality HALS-based UV Stabiliser in desirable proportions to meet Indian as well as global standards.

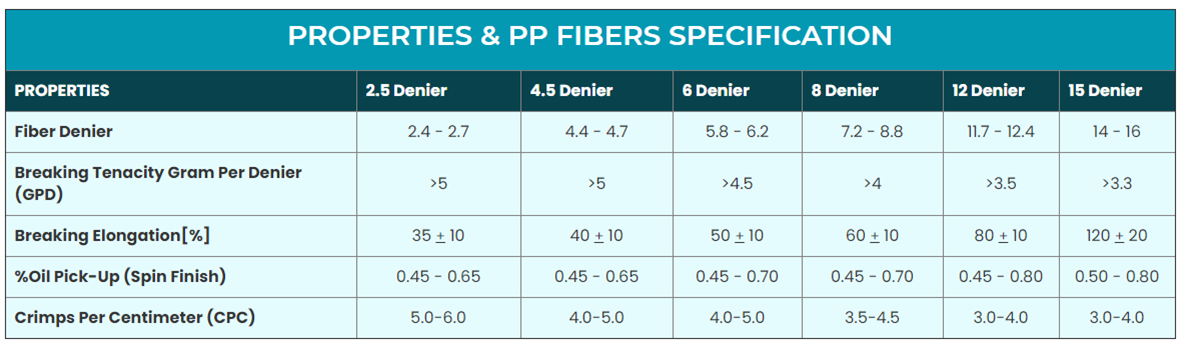

Specifications of Virgin Polypropylene Staple Fiber

Deniers:- 1.5D to 70 Denier

Cut length:- 25,32,51,64,76,102 and 124 mm (as per customer requirement)

Tensile strength:- >3.5gm/Denier

Elongation:- >70%

Crimps:- 3 to 5 per cm

Shades:- All shades available

UV Stabilization:- Yes, the level of UV Stabilisation can be tailor-made to customer’s requirements.

Applications of Virgin Polypropylene Staple Fiber (PPSF)

Spinning Yarns, Filer Fabrics, GeoTextile, Auto-mobiles floor carpet, thermal bonded fabrics, insulations, carpet, filter fabrics, felts and non-woven carpet, building construction, RCC

Polypropylene staple fiber (PPSF) is also available in short cut lengths for RCC building construction and making cement sheets, tiles, and home pipes. This enhances the strength of the cement/RCC.

Fiber Reinforced Concrete (FRC) is Portland Cement concrete reinforced with thousands of small fibers more or less randomly distributed during mixing and thus improve concrete properties in all directions.

Polypropylene fibers of 0.5% to 1% are normally used in concrete. Natural white polypropylene fibers of 3 and 6 Deniers and in lengths of 6, 12, and 20mm respectively are commonly used in various applications.

Polypropylene is used in apparel (Activewear and sportswear, socks, thermal underwear, lining fabrics).

Spunbond non-woven fabrics, also known as filament non-woven fabrics, are made by extrusion spinning, stretching, meshing, and bonding after melting polypropylene raw materials. It has the characteristics of short process, low cost, high productivity, excellent product performance, and wide range of uses. Polypropylene non-woven fabrics are widely used in various fields of production and life (such as disposable medical and sanitary products, disposable anti-fouling clothing, agricultural cloth, furniture cloth, shoe industry lining, etc.)

What Is The Difference Between Polyester And Polypropylene?

The first thing to be analyzed is the elongation at break. In the production practice, the suspension method is used from time to time in the measurement, but it is calculated by the strong force. The concept is that the weight of a single fiber suspension is equal to its breaking strength (km). Research and experiments show that the elongation at break of polyester is 30-40%, polypropylene is greater than that of polyester, nylon is 18-45%, and vinylon is 12%-25%. From the data point of view, it is difficult to rank high and low. See the specifications of the centrifuge manufacturer.

The second point is to analyze the recovery. In this performance, the recovery rate of nylon at 10% elongation is above 90%. This is a characteristic of nylon. The level of other materials is that polypropylene is better than polyester, and vinylon is relatively poor. Of the class.

Next, analyze the wear resistance, which is also one of the key performances of the centrifuge screen. It is necessary to pay attention to it, because good maintenance is helpful to the centrifuge, but the wrong choice was chosen from the beginning. The non-wearing screen is pale and weak for maintenance, so this performance is very important. From the surface of a large number of data, polyester and nylon have good wear resistance, followed by polypropylene, and finally It’s Vinylon.