What is recycled polyester?

By 2020, the tide had turned towards recycled polyester, with a staggering 52% of all fibers produced being this eco-friendly material. And considering the ever-growing focus on sustainability and environmental consciousness, it’s safe to say that this trend has only accelerated in the years since.

The reasons for this shift are clear:

- Environmental Impact: Traditional polyester, derived from petroleum, has a hefty environmental footprint. Its production releases greenhouse gases and depletes non-renewable resources. Recycled polyester, on the other hand, breathes new life into plastic waste, reducing landfill burden and saving precious resources.

- Performance: Recycled polyester doesn’t compromise on quality. It retains the same desirable properties as virgin polyester, such as durability, wrinkle resistance, and moisture wicking. Plus, advancements in technology have resulted in even softer and more luxurious recycled polyester options.

- Consumer Demand: Eco-conscious consumers are increasingly seeking sustainable options, and brands are taking notice. By offering recycled polyester products, they cater to this growing demand while aligning themselves with responsible practices.

The shift towards recycled polyester is a testament to our collective desire for a more sustainable future. It’s a win-win for the environment, consumers, and the fashion industry as a whole. As technology continues to improve and awareness grows, we can expect to see recycled polyester become the new standard, not just a trend.

Here are some additional points to consider:

- The rise of closed-loop recycling systems, where textile waste is collected and transformed back into new polyester fibers, holds immense potential for further reducing environmental impact.

- Innovations in dyeing and finishing processes are making recycled polyester even more versatile and appealing for a wider range of applications.

- Collaborations between brands, manufacturers, and recycling organizations are crucial for creating a robust and efficient infrastructure for recycled polyester production and consumption.

By embracing recycled polyester and supporting sustainable practices, we can all contribute to a more responsible and planet-friendly fashion industry. Let’s keep the momentum going!

How to make RPET

Recycled polyester (rPET) has become a major player in the textile industry, offering a more sustainable alternative to virgin polyester. Factories source rPET from a variety of discarded materials, giving new life to plastic waste and reducing its environmental impact. Here’s a closer look at the sources of rPET:

Household Waste:

- Plastic bottles: The most common source of rPET, plastic bottles discarded after consuming beverages or household products are collected and recycled into new fibers.

- Straws and containers: Plastic straws, food containers, and other single-use items often end up in landfills. rPET production diverts this waste, giving it a second life as useful textiles.

Industrial Waste:

- Textile scraps: Clothing, carpets, and other discarded textiles made from polyester can be recycled into rPET fibers, creating a closed-loop system that minimizes reliance on virgin materials.

- Factory offcuts: Manufacturers and factories often generate waste in the form of fabric scraps and offcuts. This waste can also be used to produce rPET, reducing overall environmental impact.

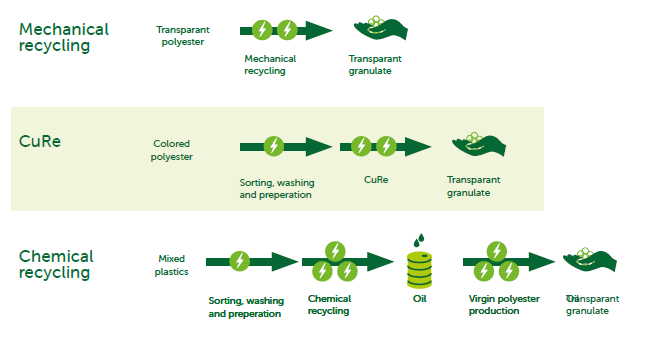

Different types of recycling: Mechanics and Chemicals

There are 2 ways to recycle polyester: For mechanical recycling, plastic is melted to make new yarn. This process can only be done a few times before the fiber loses its quality. Chemical recycling involves breaking down the plastic molecules and reforming them into yarn. This process maintains the quality of the original fiber and allows the material to be recycled infinitely, but it is more expensive.

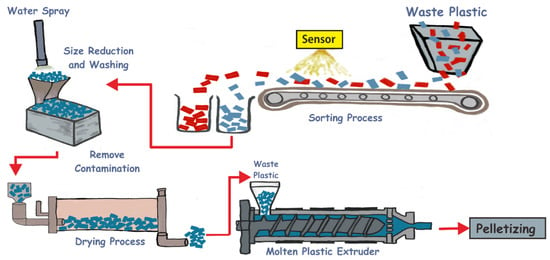

Mechanical Recycling: The Melting Pot Approach

Think of mechanical recycling like a giant melting pot. This method involves shredding and melting down polyester waste, such as used bottles or discarded clothing, into plastic pellets. These pellets can then be spun into new polyester fibers and woven into fresh textiles.

Pros:

- Simple and cost-effective: Mechanical recycling is the more established and affordable method, making it widely accessible.

- Energy-efficient: Compared to chemical recycling, mechanical processes require less energy, reducing its environmental footprint.

- Wide range of input materials: Various polyester waste, including textiles, bottles, and containers, can be used for mechanical recycling.

Cons:

- Fiber degradation: Each mechanical recycling cycle shortens the polyester fibers, eventually reducing their quality and suitability for further recycling.

- Limited applications: The recycled fibers may not possess the same strength and performance as virgin polyester, limiting their use in certain applications.

- Downcycling: Lower-quality fibers might be relegated to less demanding products after each recycling cycle.

Chemical Recycling: The Molecular Remix

Chemical recycling takes a more sophisticated approach, breaking down the very building blocks of polyester. This method involves using chemicals to deconstruct the polymer chains of the material, essentially separating the molecules. These molecules can then be rearranged and reassembled into new, high-quality polyester fibers.

Pros:

- Infinite recycling: Chemically recycled polyester can be recycled repeatedly without any significant loss of quality, unlike mechanically recycled fibers.

- Maintains quality: The resulting fibers are nearly identical to virgin polyester in terms of strength, performance, and versatility.

- Wider application range: The high-quality fibers enable use in demanding applications like sportswear and high-end textiles.

Cons:

- Higher cost: Chemical recycling is a more complex and expensive process compared to mechanical methods.

- Energy-intensive: The chemical processes involved tend to require more energy than mechanical recycling, impacting its environmental footprint.

- Limited feedstock: Currently, chemical recycling technology focuses primarily on clean polyester waste streams, restricting the range of input materials.

The Future of Polyester Recycling:

Both mechanical and chemical recycling play crucial roles in achieving a more sustainable future for polyester. Mechanical recycling remains the dominant method due to its affordability and simplicity, but continued advancements in chemical recycling technology promise greater efficiency and wider applicability. The ideal scenario involves a combination of both approaches, optimizing resource utilization and minimizing environmental impact throughout the polyester lifecycle.

By understanding the advantages and limitations of each method, we can make informed choices as consumers and support the development of more sustainable technologies for polyester recycling. Let’s move towards a future where every used polyester bottle or discarded garment gets a second life, reducing our reliance on virgin materials and minimizing our environmental footprint.

What are Differences between virgin polyester and the more sustainable recycled polyester?

This synthetic man-made material was first produced in the 1930s. Factories create it out of fossil fuels. They also produce it using the most common form of plastic on earth, rPET. (This is the short form of the technical term ‘polyethylene terephthalate’.) We use this fibre to make all sorts of products, everything from sustainable fashion garments to upholstery and packaging.

This particular textile has always been a popular choice, as it doesn’t stretch or shrink after washing. It’s durable and easy to clean, dries fast and doesn’t crease, too.

Factories make this synthetic textile from petroleum, which, as we know, is not practical. The process of transforming crude oil into petroleum involves using plenty of energy, which is not environmentally friendly. It also releases a number of toxins into the atmosphere. This is harmful to humans, the environment and the world’s fragile eco-system.

The original synthetic material is extremely popular and still widely produced. This is despite many sustainable fabrics on the market like reprocessed polyester.

Certification standards for recycling

For this reprocessed to be high quality and sustainable, it has to meet certain certification regulations. These include the GRS (Global Recycled Standard) that ensures the fibre meets certain criteria, and the Oeko-Tex 100 Standard.

The Global Recycled Standard involves following strict chemical order in the manufacturing process of recycled polyester. The manufacturer also needs to follow best practices when it comes to social and environmental responsibility.

Under the Oeko-Tex100 Standard, manufacturing recycled polyester fibres requires using materials free of chemicals. Also, the textile produced cannot include substances that will harm the environment and the health of human beings.

Sustainable polyester will benefit your business

Recycled polyester (rPET) is an excellent sustainable choice compared to virgin polyester. Here’s a breakdown of why:

Environmentally Friendly:

- Reduces reliance on fossil fuels: Virgin polyester is made from petroleum, a non-renewable resource. rPET, on the other hand, gives new life to plastic waste, reducing our dependence on fossil fuels and their associated environmental damage. Unlike virgin polyester derived from petroleum, recycled polyester gives new life to plastic waste, lowering our dependence on non-renewable resources.

- Lessens landfill burden: Plastic waste, especially single-use items like bottles and straws, often ends up in landfills. rPET production diverts this waste from landfills, reducing pollution and conserving space. Diverting plastic waste from landfills not only reduces pollution but also conserves valuable space.

- Lower carbon footprint: Compared to virgin polyester, rPET production has a significantly lower carbon footprint. This is because the energy needed to melt and reprocess plastic is much less than that required to extract and refine petroleum.

Performance and Versatility:

- Maintains desirable qualities: rPET retains the same positive qualities as virgin polyester, such as durability, wrinkle resistance, moisture wicking, and quick drying. This makes it suitable for a wide range of clothing, sportswear, and even home textiles.

- Softness and comfort: Advancements in technology have resulted in rPET that is even softer and more comfortable than traditional polyester. This makes it ideal for garments and accessories that come into direct contact with the skin.

- Dyeing and finishing: rPET takes dyes and finishes well, allowing for a variety of colors, patterns, and textures. This opens up endless possibilities for designers and manufacturers.

- Durable and versatile: It retains the desirable qualities of traditional polyester, making it suitable for various applications while offering comfort and style.

Recycled polyester offers a multitude of benefits for children’s and infants’ clothing, making it a popular and responsible choice for parents and manufacturers alike. Here’s a breakdown of the key points you mentioned:

Benefits for Children and Infants:

- Soft and Gentle: The softness and gentle nature of recycled polyester makes it ideal for delicate skin, ensuring comfort and minimizing irritation for your little ones.

- Lightweight and Breathable: Lightweight fabrics made from this material allow for easy movement and comfort, especially during playtime or warm weather.

- Swimsuit Suitability: The UV resistance of recycled polyester makes it a great choice for swimwear, protecting children from harmful sun rays while they enjoy the water.

Additional advantages:

- Durability and Performance: Beyond children’s wear, recycled polyester excels in industrial applications due to its high durability and resistance to fire and insects, making it a long-lasting and practical choice.

- Sustainability Champion: Recycled polyester offers a second life to non-toxic plastics, diverting them from landfills and oceans. This not only reduces plastic pollution but also conserves valuable resources.

- Energy-Efficient Production: Compared to virgin polyester, the production of recycled polyester requires less energy, further minimizing its environmental impact.

- Eco-Friendly Printing: The water-free heat transfer process used for printing on recycled textiles is another win for the environment, eliminating the need for water-intensive dyeing processes.

Overall, recycled polyester offers a compelling alternative to traditional fabrics for children’s and infants’ clothing, contributing to both style and sustainability. Its comfort, performance, and eco-friendly credentials make it a responsible choice for parents and a positive step towards a greener future.

Application of recycled polyester

Recycled polyester has become a major player in the textile industry, offering a more sustainable alternative to virgin polyester for a wide range of clothing and homeware items. Here’s a closer look at its versatility:

Clothing:

- For all ages and styles: From playful patterns for children’s clothes to sophisticated garments for high-fashion brands, recycled polyester caters to diverse tastes and needs.

- Leisure and workwear: Its durability and practicality make it ideal for activewear, sportswear, and even workwear.

Homeware

- Cozy and functional: From comfy cushions and soft blankets to stylish curtains and practical aprons, recycled polyester brings comfort and sustainability to our homes.

- Elevating home décor: Even luxurious items like tablecloths, bedspreads, and comforters can be crafted from recycled polyester, adding a touch of eco-conscious elegance to your living space.