What is polyester staple fiber?

In the present day, polyester staple fiber is one of the most used fiber types globally for the textile industry. Due to its advantageous characteristics, the global demand for polyester staple fiber has been increasing for decades as an alternative and sustainable option to cotton and natural fibers. Flexibility, durability, high toughness, heat-resistance, stain-resistance, wrinkle resistance, versatility, and economical price are the main reasons for boosting polyester staple fiber in the global market. Polyester staple fiber is safe not for just humans in textile use, but polyester staple fiber can also be produced as recycled polyester staple fiber which is environmentally friendly. Global warming and pollution concerns have been the center of the world’s attention nowadays, so it would be great if we started using recyclable products, reusing and reducing them. Polyester recycled production starts from collecting plastic bottles and waste, which is then cleaned. Subsequently, the PET bottles are then cut into small pieces called PET flakes. Then, the flakes are melted into pellets, re-melted using high temperatures, and finally, those pellets are spun into the polyester recycled polymer.

POLYESTER FIBERS & POLY BLENDS

Polyester fibers are extremely strong and durable – resistant to most chemicals, stretching and shrinking, and wrinkle resistant. Polyester is hydrophobic in nature and quick drying. It can be used for insulation by manufacturing hollow fibers. Polyester retains its shape and hence is good for making outdoor clothing for harsh climates. It is also easily washed and dried.

Polyester Staple Fiber (PSF) is a synthetic man-made fiber created directly via a polymerization process of polyester material such as PTA (Purified Terephthalic Acid) and MEG (Mono Ethylene Glycol) under high temperature and pressure. After the spinning and drawing process, the polymer becomes staple fibers and is cut to a specific cut length. Polyester staple fiber plays an essential role in the textile industry due to several advantages of its characteristics. Polyester staple fiber is more durable than cotton or wool. Additionally, polyester staple fiber also has high heat, wrinkle and abrasion resistance, low absorbency, a stretching and shrinking resistance and quick-dry after washing.

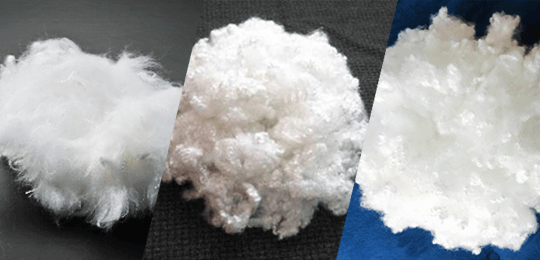

PSF luster Refers to the degree of light reflected from surfaces of fibers or the degree of gloss or sheen that the fiber possesses.

1.Full dull

Full dull yarns are manufactured from raw materials modified chemically and physically to reduce their normal luster. A few of the qualities of full dull yarns are that they have high tenacity and strength and look like cotton fiber. In addition, these yarns are of good pendent, soft visual appeal and a strong covering. Full dull yarns have various applications in manufacturing apparel, home textiles, etc.

2.Semi-dull

Semi-dull yarn is manufactured from raw materials with low luster compared to partially oriented bright yarns used to manufacture semi-dull polyester textured yarn.

How is polyester staple fiber made?

Polyester Staple Fiber is a synthetic man-made fiber made directly from Purified Terephthalic Acid (PTA) and Mono Ethylene Glycol (MEG) or Polyethylene Terephthalate (PET Chips), while recycled polyester staple fiber is made from recycled PET Chips, polyester waste, or post-consumer PET bottle flakes. The production of polyester staple fiber starts from the polymerization process where PTA is fed into hot MEG under a high temperature and pressure setting. Next is the melt spinning process. The bundle of continuous filaments obtained from the melt spinning technique (called tow) is subjected to the application of more processes such as drawing and crimping and is then cut into fixed lengths. After the cutting process, these cut fibers are called polyester staple fibers.

What are polyester staple fibers used for?

These are some of the industries that we are currently involved in.

AUTOMOTIVE

Our durable, high-performance shoddy, both natural and synthetic, are a key ingredient in the production of cost-effective acoustical parts and insulation for many automotive manufacturers.

High expectations are placed on components manufactured in or for the automotive industry in terms of quality and safety. In order to meet these expectations, standardized production processes that are subject to comprehensive quality assurance in accordance with standards are indispensable. All raw materials that we supply to our customers in the automotive industry meet these requirements and also guarantee a high level of safety within the production processes of our customers.

examples of applications:

upholstery, safety belts, airbags, seat seams, tire fabric, turbo hoses, nets, sound insulation, interior components, brake pads, clutch disks

BEDDING

Our recycled polyester fibers are often used for mattresses, pillows and quilts.

FURNITURE

Our re-processed fibers are used for batting, waddings, and needled and bonded felts used in many furniture items. Our products provide a lower cost alternative than a virgin polyester fiber. Our customers have used our re-processed fiber in demanding furniture applications while meeting their customers’ expectations for performance.

FILTRATION & ABSORPTION

To meet current needs of the filtration and absorption material market, we offer polyester fiber which can be mixed with cotton, polypropylene and acrylic blend fibers for yarn-wound, canister (string) and pleat media filters.

ACOUSTIC INSULATION

Our fibers are bought by manufacturers of acoustic insulation materials used in automobile parts, office partitions, ceiling tile, industry machinery and even household appliances. For damping sound resonance, especially in air cavities, the open design of cellulose, cotton, and polyester makes these fibers a proven and preferred acoustical solution. These manufacturers rely on our precisely modified natural and synthetic fibers for the high acoustical density.

High-quality sound insulation means above all better working conditions, a more pleasant living environment or more comfortable travelling. The enjoyment of music depends to a large extent on the right textile sound insulators. At the same time, however, the correct use of acoustic materials is also the basis for the targeted influencing of any background noise. The materials used also vary depending on the requirements. Our fibers offer the right basis for every desired solution.

examples of use:

Insulation materials, such as fleece for vehicle interiors, loudspeaker boxes, recording studios, concert halls, machines in general

SPINNING

Polyester staple fiber is mainly used in spinning production in the textile industry. Wherein, the resulting yarns, spun yarns, are used for apparel manufacturing, including sportswear, activewear, and intimate wear. As well as, shirts, socks, dresses, lingerie, gloves, suits, and sewing threads etc. In spinning production, polyester staple fiber can be individually produced for 100% Polyester spun yarn or combined with cotton, viscose or wool for blended yarn such as CVC 70/30 consisting of 70% cotton fiber and 30% polyester staple fiber. Compared to the cotton fiber, polyester staple fiber has major benefits in terms of cost, thinness, strength, abrasion resistance, water absorption, and multiple designs and colors. Thus, polyester staple fiber can be considered the main cotton fiber alternative for the garment industry.

Characteristics of polyester staple fiber

Polyester staple fiber feels like cotton. In the past, people were more likely to wear apparel made from natural fibers due to their familiarity, softness, and comfortable in wear nature. However, synthetic man-made fiber production has continued to develop properties like natural fiber. The end product of polyester staple fiber after the spinning process is called Polyester spun yarn. The properties and appearances are very close to cotton yarn. Polyester spun also has the same denier count as cotton, while the price is lower. Polyester staple fiber also has the alternative option to be environmentally friendly by using recycled polyester staple fiber, which is sustainable and eco-friendly. And the production of recycled polyester requires far fewer resources than new fibers and generates fewer Co2 emissions. Using recycled polyester staple fiber is a major value add to a company and it also creates a significant impact on brand images compared to others.

The differences in denier and cut length also affect the difference in hand-feel and product size. The smaller denier and shorter cut length bring a softer and smoother feeling. According to our product, our newly developed item is polyester staple fiber 1.0 D, which is used in spinning spun yarn. Spun yarn made from polyester staple fiber 1.0 D will have a soft feeling to the touch and is very close to spun cotton.