What is PLA? What is Polylactic Acid?

PLA (Polylactic Acid) is a recyclable and excellent biodegradable new polymers materials, which is extracted from natural plants, such as sugar cane, cassava, corn and so on.We would like to represent our partner who is the only enterprise that employs melt direct spinning method to produce PLA fiber. Our featured nonwoven pro- ducts,made of PLA bi-component staple fiber, can provide unique comfort and a close experience to nature. CTEXIC and Changjiang biological co.,ltd are brother units under HI-TECH Group and we are working hand in hand to provide green products and an available idea to the market.

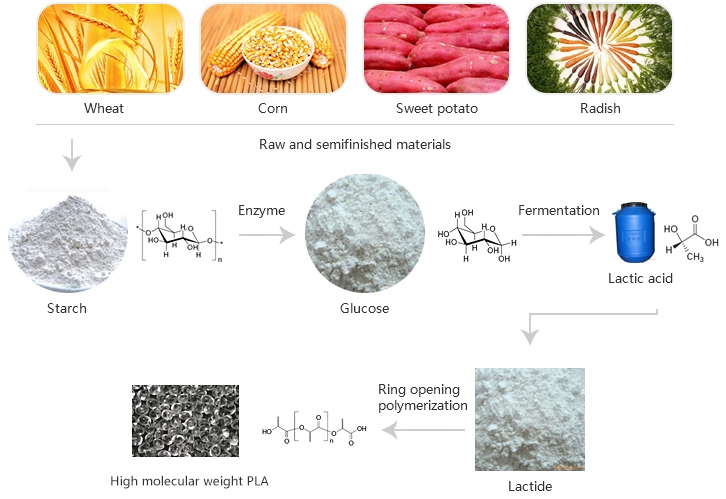

PLA(Poly Lactic Acid) is a renewable and 100% biodegradable new polymer material, which is extracted from natural plants,such as sugar cane,cassava, corn and so on.Sugar is extrated from starch plants and transfered into Lactic Acid after microbial fermentation. Through the process of polymerization of Lactic Acid, PLA comes into being.

PLA is mainly used to produce fiber, film, plastic and so on.PLA fiber, because of its excellent bio-compatibility, breathability,anti UV comfort and insulation properties, is used to produce textile garments, upholstery fabrics and personal care products.

Comparaed with other biodegradable natural fiber, PLA fiber is melt- processable, and it shares many similarities with some synthetic fibers. For example, PLA fiber has good resilence, smooth surface and good mechanical properties.

PLA is becoming a potential replacement of petroleum-based polymers because of its 100% biodegradability and bio-based properties. Especia-lly after the Copenhagen meeting, PLA, as a low carbon emission product draws international attention. Therefore, PLA fiber is alsohonoerd as “21st Century Green Fiber”

Features of PLA Fiber

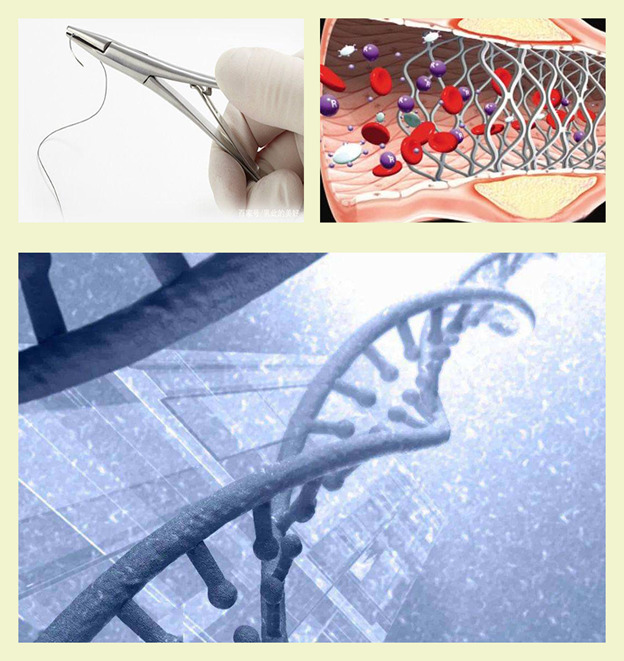

1. Non-toxic: PLA fiber is green and comes from starch of non-staple crops, e.g. corn etc., it is also called Corn Fiber. It is naturally biocompatible and antibacterial. PLA fiber can decompose easily inside the human body and the decomposition products are confirmed highly safe to human beings. Surgical products such as heart stent and surgical sewing threads made of PLA fiber have been approved by FDA and come into the market.

2. Eco-friendly: Nowadays, plastic pollution is a big threat to the Earth. More and more countries issued laws preventing the usage of non-degradable plastics. Large quantities of the wasted facial masks and medical protective clothing caused by COVID-19 epidemic increased the heavy burden of the environment. PLA fiber which is fully biodegradable and compostable becomes one of the few excellent substitute fiber materials

Applications of PLA Fiber (Polylactic Acid Fibers)

- Hygienic and disposable materials

- Textiles and apparel

- Composite materials (jube fiber and kenaf fiber)

- Cigarette filter

- PLA modified materials

PLA is fully biodegradable and biocompatible which makes this fiber attractive for medical applications like wound dressing. The fiber is also useful as an eco- and people-friendly alternative to existing textile fibers for industrial and consumer apparel applications.

PLA fabric is suitable for bedding, which is effective against bacteria, skin-friendly and harmless.

Major applications for PLA fibers and non-wovens include clothing and furnishings such as drapes, upholstery, and covers. Some exciting potential applications include household and industrial wipes, diapers, feminine hygiene products, disposable garments, and UV-resistant fabrics for exterior use (awnings, ground cover, etc.) among others.

- Denier: 4.5 D | 6.0 D | 9.0 D | 15 D

- Conventional color: Raw white | green | blue.

- PLA fiber are more hydrophilic than PET

- Low flammability and smoke generation characteristics.

- 100% biodegradable and compostable. PLA Fiber is made from PLA (PolyLactic Acid), also PLA is made from corn. the fiber products look and feel just like regular fiber, but they are 100% biodegradable and compostable. Corn is a renewable resource which makes corn fiber much more sustainable than regular fiber. Did you know that regular fiber is made from petroleum? PLA Fiber is however biologically degradable when subjected to the right conditions. It is therefore very well suited for waste treatment through composting. It will also improve the compost quality by increasing the C/N ratio in organic waste. Because lactic acid is made out of natural sugar resources, which are in turn made by photosynthesis out of CO 2 in plants, the material can be regarded as “CO2-neutral” and therefore renewable.

PLA fiber uses natural and renewable plant resources as raw materials, which reduces the dependence on traditional petroleum resources and meets the requirements of sustainable development in the international community. It has the advantages of both synthetic fibers and natural fibers, and at the same time has complete natural circulation and biodegradation Compared with conventional fiber materials, PLA fiber has many excellent properties, such as good drapability, comfort and hand feeling, good resilience, good crimp and crimp durability, etc., which makesPLA fiber in There are broad application prospects in the clothing market, household and decoration market, non-woven fabric market, medical and health protection and other fields.

Clothing fabrics

PLA fiber has good shape retention. When blended with cotton, it has properties similar to polyester-cotton blended fabrics. It has good gloss, but does not produce metallic glare. Good hand feeling; when it is blended with wool, it has good shape stability, crease resistance and brightness; so it is suitable for dynamic clothing, children’s clothing, underwear and sweatshirts, etc.

Home textiles

PLA fiber has the characteristics of cashmere-like feel, silk-like soft luster, warmth retention of wool, and moisture absorption and moisture conductivity of cotton fiber. Its application in bedding (interweaving/blending) can give full play to its advantages of good skin affinity, non-irritating skin, and non-allergic effects, and overcomes the shortcomings of polyester-cotton/wool-polyester fabrics and is better than cotton/wool fabrics. Excellent dimensional stability and skin-friendliness, easy to wash, dry and care.

Industrial textiles

Automotive interior

Medical supplies

Another characteristic of PLA fiber is its good biocompatibility. In this respect, it has some incomparable advantages of traditional medical devices. For example, in the past, stainless steel bone nails were used in the treatment of fractures and other orthopedic diseases, and the patient had to undergo a second operation to be cured; however, the use of polylactic acid bone nails only requires one surgical implantation. To a great extent alleviate the suffering of patients. In addition, PLA fibers have been successfully applied in some specific fields, such as the production of disposable infusion sets, non-removable surgical sutures, orthopedic fixtures and surgical devices, medical stents, biological catheters, etc. The pressure of medical waste on the environment.

Protective Equipment

PLA is a thermoplastic polymer with good toughness, good biocompatibility, skin-friendly and breathable advantages. It can be used to make products such as sanitary napkins, panty liners, diapers, medical gauze, bandages, bed sheets, high-grade antibacterial wipes, etc.

Daily necessities

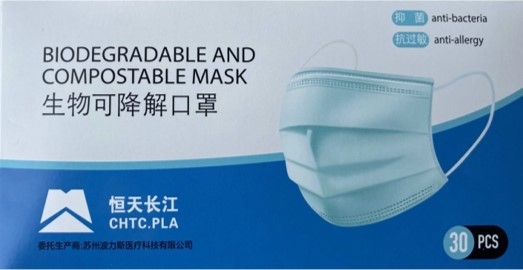

At present, there are mainly two kinds of cigarette filter materials used in the market, one is cellulose diacetate fiber and the other is polypropylene fiber. Compared with these two traditional materials, the cigarette filter made of PLA fiber not only has a wide range of sources, but also is biodegradable, and its polar molecular structure determines its ability to absorb and remove harmful components in smoke. Therefore, the use of PLA fiber filters will bring about major changes to the cigarette filter industry. In addition, masks are another key application field of PLA fiber.

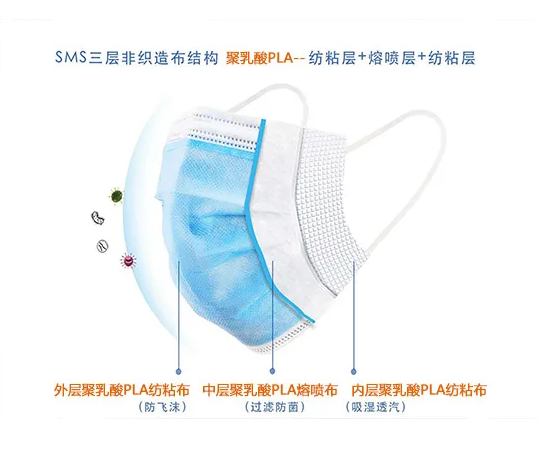

Features of PLA Facial Mask:

1. All components (from BM nonwoven fabric to mask accessories) are made of PLA material, can break down into CO2 and H2O, thus fully biodegradable.

2. Naturally anti-bacterial, always keeping fresh breath.

3. Naturally slightly acidic, similar to human skin, no skin allergy after long-time wearing.

4. PLA mask is stiff and smooth, can speak freely when wearing it.

Filter efficiency higher than 95% under the condition of 85g/l flow.

Packing: individually packed per piece, 30pcs per box, 40 boxes per case.

PLA Foaming Materials

The technical process of continuous extrusion foaming and thermoforming of high temperature resistant PLA products developed by the company has passed national scientific certification, and has reached advanced international standard. The company now has production capacity of 2000t/y of PLY foaming sheet, and 1000t/y thermoforming PLA forming products. More than 20 new forming products are developed and produced, and are widely used in the fields of food and beverage, packaging, construction and automobile etc..

Specification of PLA foam sheet:

foaming rate: 5 ~ 25 times. thickness: 1 ~ 5 mm. width: 1040 mm. color can be customized.

Product features:

Compared with ordinary PLA thermo-forming products, PLA foamed products are light, heat-resisting and shock proof.

Compared with pulp products, it is water and oil resistant, and can be used for refrigerated packaging.

The product can be used in a wide temperature range from -20 ℃ to 130 ℃.

Certification:

DIN CERTCO certification based on EU EN13432 standard.

BPI certification based on ASTM6400.

Passed the food contact safety test according to FDA and LFGB.

The production management passed BRC certification.

Is PLA fiber more expensive than PET fiber?

The price of PLA fiber and PET fiber may vary depending on the quality, source, and supplier of the materials. However, based on some online sources, PLA fiber tends to be slightly more expensive than PET fiber, as it is produced from renewable resources and has higher processing costs. PLA fiber also has lower availability and demand compared to PET fiber, which is widely used for various applications. The average price of PLA fiber is 25% more expensive than PET fiber. However, these prices may change over time due to market fluctuations, environmental factors, and technological developments.

How to recycle PLA fiber

There are different ways to recycle PLA fiber, depending on the availability of facilities and equipment. Here are some possible methods:

- PLA composting: PLA is a biodegradable material, which means it can be broken down by microorganisms over time. You can compost PLA filaments on your own, but it may take several months or years, depending on the temperature, humidity, and oxygen levels. You can speed up the process by shredding the filaments into smaller pieces and adding them to a compost bin with other organic materials.

- Filament re-extrusion: You can also reuse PLA filaments by melting and extruding them into new filaments. This requires a filament extruder, which is a device that can heat, mix, and shape plastic materials into thin strands. Filament re-extrusion involves two steps: first, shredding the PLA filaments into small pieces using a blender or a meat grinder. Second, feeding the pieces into the filament extruder and adjusting the temperature and speed settings to produce new filaments. You can also add colorants or additives to modify the properties of the recycled filaments.

- Optimise 3D printing settings: Another way to reduce PLA waste is to optimise your 3D printing settings to minimise the amount of material used and the number of failed prints. You can do this by adjusting the infill density, layer height, print speed, and support structures of your 3D models. You can also use software tools to slice, repair, and optimise your 3D models before printing them

These are some of the methods to recycle PLA fiber. However, you should also check the local regulations and guidelines for recycling bioplastics in your area, as they may vary depending on the country or region. Recycling PLA fiber can help reduce the environmental impact of 3D printing and promote a circular economy.

Read more: https://vnpolyfiber.com/what-is-pla-fiber-polylactic-acid-fibers/