What is hemp?

Hemp derives from the fibers of the cannabis plant. It is grown from a different – although very similar-looking – cultivar to the plant that produces the well-known narcotic. Modern techniques can now produce hemp fiber and yarn that are soft and strong, and that dye well. The long fibers can be woven or knitted, and blend well with other fibers. Cotton–hemp blends produce a soft, elastic fabric, while silk blends have a smooth, drapey quality.

Hemp is said to be six times as strong as cotton, far more weather-resistant, and more lustrous and absorbent. Until recently, hemp has not been used in apparel as much as cotton or linen – although some claim that the first jeans were made of hemp. A scrap of hemp fabric dating back to around 8,000 BC is thought to be one of the oldest relics of human activity. One of the most common uses of hemp was in rope-making – England’s King Henry VIII made it obligatory to grow hemp in the 16th century, such as the need for it in ropes for ships.

From rope-making to dress-making, hemp is now being used in a variety of clothing from basics to couture.

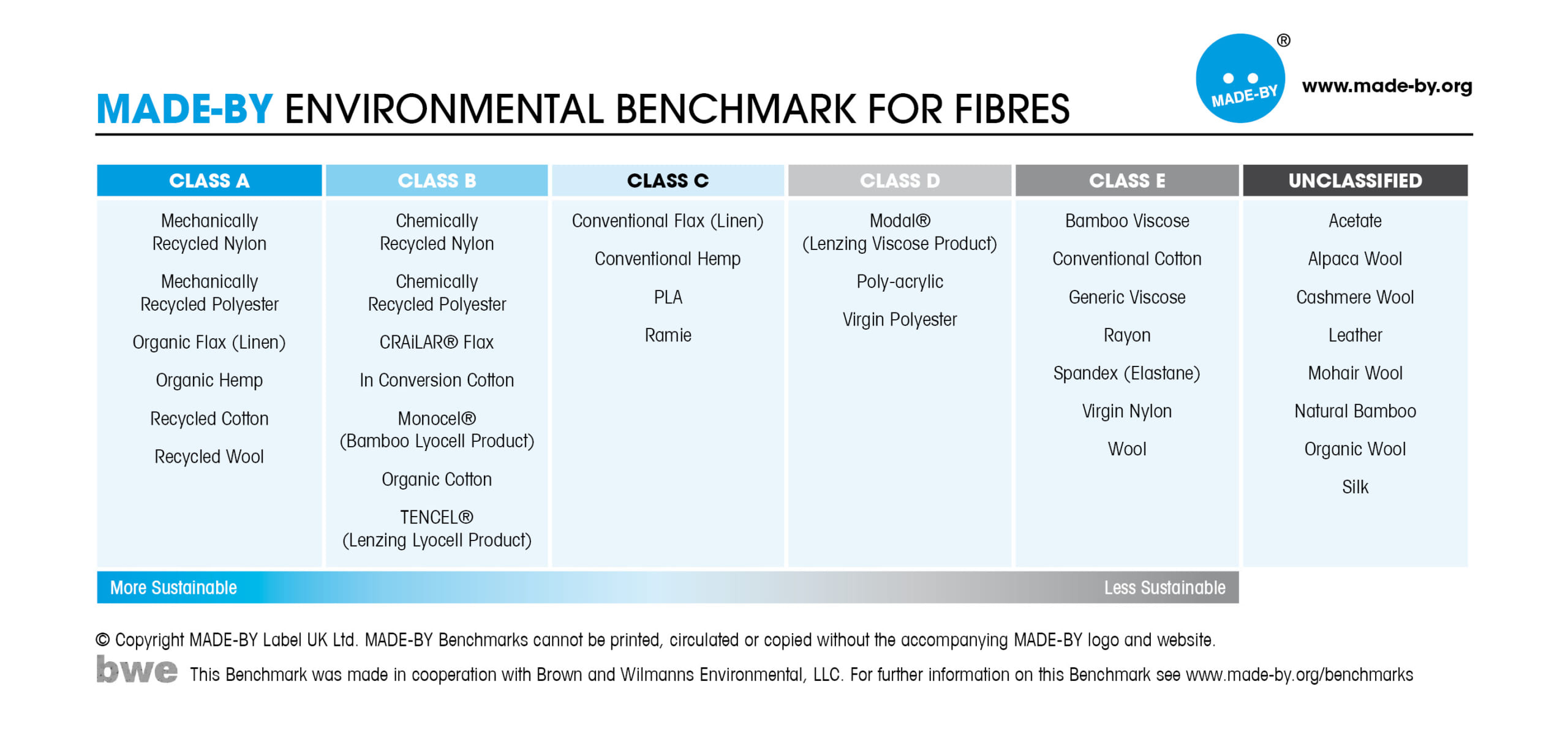

Thanks to its fast-growing, adaptable, and environmentally friendly characteristics, hemp is now being explored as a potential key crop. Hemp grows easily with little water, usually requires no chemical fertilizers and pesticides, and has a high yield. It also blocks out weeds as it grows and can improve the soil, making it a good break crop’ for farmers. The Made-By Environmental Benchmark for Fibres ranks organic hemp (which all hemp almost invariably is) as a Class A fiber. About a fifth of all hemp grown globally comes from China, currently the world’s major producer of both textile-grade hemp fiber and hemp yarn and textiles. The European Union and Canada also grow hemp commercially.

However, hemp is not a major fiber for the global textile industry. For this to change it would need to overcome a series of legal technical constraints across the whole production chain. Because it is hard to distinguish this cultivar from the one used to produce the psychotropic drug, there are also legal and political obstacles preventing hemp from becoming a more widely grown crop, especially in the US.

The technology involved in processing hemp has been described as being “at the same technological level it was at fifty years ago and consequently, it is only viable in countries where labor costs are low”. As a bast fiber (like jute and flax), hemp is traditionally soaked in dew to soften it – known as “retting”. The fibers are then “scutched” – scraped off in the same way that flax is turned into linen.

Processing pros and cons

Current processing techniques for hemp are also undermining the crop’s environmentally friendly credentials. Turning hemp into yarn and fabric requires “degumming”, which uses chemicals (primarily caustic soda). Further, hemp is usually spun and milled in older factories in China on old, less energy-efficient machines.

“Currently produced hemp textiles do not have an overall lower environmental impact than regular cotton textiles.”

In 2015 a study compared hemp from China’s Heilongjiang province with cotton from the Yellow River Region. It concluded that hemp cultivation has “significantly less environmental impact compared to cotton …[and] also uses only half of the land”. However, when it came to processing, the report warned that “currently produced hemp textiles do not have an overall lower environmental impact than regular cotton textiles” due to inefficient techniques. Manufacturers in Europe may offer a more sustainable way forward for hemp processing. According to the European Confederation of Linen and Hemp (CELC), its hemp producers use high-performance industrial equipment and technical expertise resulting in mechanical defibering that uses less energy and no chemical treatments.

Source of Hemp Fiber

China is the first country in the world to cultivate and use hemp. As the earliest natural fiber used by human beings for fabrics, hemp is a high-value biomass resource with outstanding “low carbon quality“.

Hemp is an eco-friendly, renewable and multi-purpose plant. It does not require the use of pesticides and herbicides during the entire growth process, and does not pollute the environment. After degumming, spinning and other processes, it becomes the raw material for hemp fiber textiles.

What is hemp fabric?

Hemp fabric comes from a plant with the same name. It is one of the fastest-growing plants and it doesn’t need much water, energy, pesticide, or fertilizers. The plant is very good for the soil, it can be grown for many years in the same place without exhausting it. This is why hemp is considered to be eco-friendly.

Hemp has very similar properties to linen. They are often difficult to differentiate.

However, as hemp belongs to the same family as cannabis (although it does not have the same psychoactive effects), growing hemp is heavily regulated or prohibited in many countries.

Hemp is much more resistant than cotton. It is hypoallergenic and non-irritating to the skin. In fact, hemp is one of the most environmentally friendly fabrics currently available. The plant is very naturally resistant to pests and growth requires little water. Hemp fabric is known for aging well; the more you wear it, the softer it becomes.

Pros:

- Mechanically processed.

- Grows like a weed (very resistant to insects and diseases) and does not require the use of any insecticide or pesticide.

- Very strong fiber. Clothes last longer.

- Only takes 11 weeks to mature.

- Grows in Canada & USA … and everywhere.

- Hemp regenerates soils.

- It removes contaminating metals from the soil.

- Perfect crop rotation for soybean and corn.

- The whole hemp industry (building material, food, and many more) has infinite potential.

- Hemp seeds are the perfect balance of omega 3 and 6.

- Growing hemp is carbon negative.

- Biodegradable

Cons:

- The expertise to scutch, degum, spin and knit hemp remain to be developed in Canada (some start-up companies are starting to offer Canadian grown hemp textiles. Check out eko-terre.com)(soon to be a pro?)

- Often needs to be blended with other fibers to reduce the price.

- For now, hemp fabric comes from either China or Romania.

- Hemp fabric is higher maintenance (wrinkles easily).

- There’s still this stupid confusion between hemp and marijuana.

- The fiber may need to be degummed using sodium hydroxide and sulfuric acid. I still need to find more info on that.

Advantages of Hemp Fabric

Moisture absorption and breathability: There is a cavity in the center of the fiber, and there are many cracks and holes connected with it in the longitudinal direction, which can guide sweat or moisture to the surface of the fabric in time and lose it to the air.

Natural antibacterial: Hemp plants contain a variety of active phenolic substances, organic acids and inorganic salts, which have obvious killing and inhibitory effects on a variety of bacteria.

Anti-UV: The cross section of hemp fiber is irregular in shape, and the molecular structure is helical, polygonal, and loose. After light or sound waves are injected, it is destroyed and absorbed, so that hemp fabric has a good function of anti-ultraviolet.

Absorb odor: Due to the porous structure of hemp fiber, its specific surface area is increased, and the adsorption performance is greatly improved.

Anti-static: The molecular structure of hemp fiber is stable, the orientation degree of molecular arrangement is good, and the ability to generate static electricity is extremely low.

Application of Hemp Fabric

Source: https://respecterre.com/blogs/news/the-best-eco-friendly-fibres

Source: https://www.commonobjective.co/