Wet Wipe Nonwoven Fabric: Innovation, Sustainability, and Market Prospects

Wet wipes have become an indispensable part of modern life, serving in personal hygiene, baby care, household cleaning, healthcare, and industrial applications. At the heart of every high-quality wipe lies its nonwoven fabric—a material that determines softness, absorbency, strength, and environmental performance. As hygiene standards rise and sustainability becomes a global priority, wet wipe nonwoven fabric is undergoing rapid innovation in both materials and manufacturing.

Comfort and Softness: Gentle Care for Sensitive Skin

One of the primary factors driving demand is comfort. Nonwoven fabrics made from fibers such as cotton, viscose, or polyester provide a smooth, soft texture that is non-abrasive, making wipes safe even for delicate areas like the face or baby skin. Advanced processes such as spunlace nonwoven technology, which uses high-pressure water jets to entangle fibers, enhance softness and drape, delivering wipes that feel natural against the skin while remaining durable.

Absorbency and Strength: Functional Performance

Effective wet wipes must combine high absorbency with strength. The porous fiber network of nonwoven fabrics quickly absorbs liquids, dirt, and oils while retaining moisture for longer use. Blends of natural cellulose and synthetic fibers provide the best balance—cotton or viscose adds softness and water retention, while polyester or polypropylene ensures tensile strength. This prevents tearing or disintegration during cleaning, whether for household spills, medical use, or personal care.

Hygiene and Safety in a Health-Conscious World

Post-pandemic, hygiene and microbial resistance have become crucial selling points. Nonwoven fabrics for wipes are manufactured under strict quality control, often incorporating antibacterial, antiviral, or antifungal properties. Advanced treatments such as silver ion layers or quaternary ammonium compounds neutralize pathogens, while natural extracts like tea tree oil or aloe vera are being introduced for skin-friendly antibacterial effects. These features make wipes a reliable alternative to traditional cloths, reducing the risk of contamination and cross-infection.

Versatility and Convenience

Wet wipe nonwoven fabrics are highly versatile, available in different weights, textures, and sizes. They can be engineered into small, portable wipes for on-the-go use or large sheets for industrial cleaning. Pattern variations—mesh for scrubbing, pearl for softness—enhance function while adding visual appeal. This adaptability has fueled demand across personal care, household, healthcare, automotive, and food service industries.

Sustainability and Eco-Friendly Alternatives

With growing environmental awareness, biodegradable wet wipes are a key focus. Traditional synthetic fibers such as polyester and polypropylene are durable but not easily degradable, contributing to landfill and microplastic pollution. In response, manufacturers are adopting:

Natural fibers: Cotton, bamboo, and hemp offer biodegradability and comfort, though cost and durability vary.

Bio-based polymers: PLA (polylactic acid) and PHA (polyhydroxyalkanoate) are renewable, biodegradable plastics gaining attention for wet wipes.

Recycled fibers: rPET (recycled polyester) reduces reliance on virgin petroleum resources while lowering environmental impact.

Some brands are achieving carbon-neutral or compostable product lines, appealing to eco-conscious consumers and aligning with regulatory pressures.

Production Technologies: From Spunlace to Electrospinning

Spunlace Nonwoven: The Industry Standard

Most wet wipes today are made with spunlace nonwoven fabric, where water jets entangle fibers into strong yet soft webs. This method ensures high absorbency, softness, and durability without adhesives or binders, making it ideal for baby wipes, facial wipes, and medical products.

Wet-Laid Nonwoven: High Absorbency and Smoothness

In wet-laid nonwoven production, fibers are suspended in water and deposited into sheets, producing fabrics with uniform density and excellent absorbency. Natural fibers like rayon and cotton are commonly used, delivering wipes that remain moist and effective longer.

Electrospinning: Next-Generation Technology

Electrospinning technology is a breakthrough that produces nanofibers with extremely fine diameters and high porosity. The resulting fabrics offer superior absorbency, breathability, bacterial filtration, and softness. Electrospun nonwovens also allow incorporation of functional additives—such as silver or zinc ions—for antibacterial effects, or moisturizers for skincare wipes. With higher customization potential and lower energy use, electrospinning is expected to redefine premium wet wipes.

Addressing Microplastic Pollution

A major environmental concern with wet wipes is microfiber shedding during use and disposal. Studies show that wet-spunlace nonwovens with cellulose-polyester blends shed fewer microplastics than meltblown nonwovens. Innovations in fiber bonding, surface treatments, and sustainable blends are helping manufacturers reduce microfiber release. Educating consumers on proper disposal further minimizes pollution risks.

Applications Across Industries

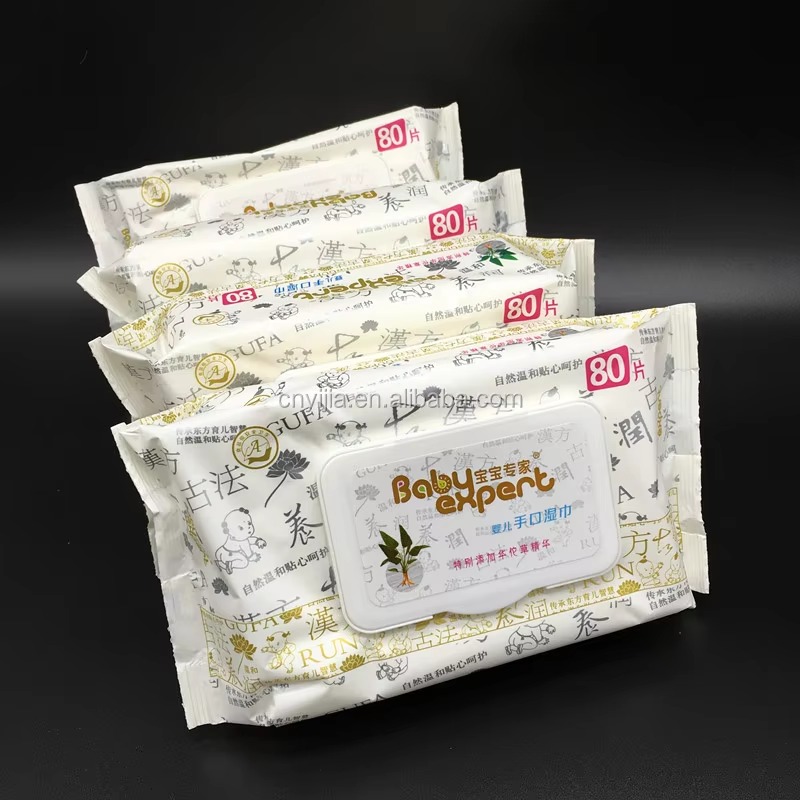

Personal Care and Baby Care

Soft, skin-safe wipes are a staple in baby care and cosmetics. Alcohol-free, fragrance-free formulations combined with gentle spunlace fabrics provide safe cleansing without irritation.

Medical and Healthcare

Hospitals use disinfectant wipes and surgical-grade wipes made from low-lint, antimicrobial fabrics to maintain sterile environments and prevent hospital-acquired infections.

Household and Industrial Cleaning

Durable wet wipes are replacing cloth rags and paper towels for cleaning kitchens, bathrooms, machinery, and vehicles. Their ability to handle grease, oil, and solvents while remaining lint-free makes them indispensable.

Automotive and Decoration

Nonwoven fabrics are also expanding into automotive interiors and home décor. They are used for seat covers, carpets, wall coverings, and curtains, offering sound insulation, heat resistance, and recyclability.

Innovation in Antibacterial and Antiviral Fabrics

Manufacturers are advancing beyond conventional chemicals toward safe, multifunctional nonwoven fabrics. Examples include:

Nanotechnology-enhanced silver ions for stronger, longer-lasting antibacterial protection.

Plant-derived extracts encapsulated into fibers for natural antimicrobial action.

Covalently bonded antiviral textiles, developed through advanced modification technologies, for durable pathogen resistance.

These innovations enhance both consumer safety and product value, especially in baby care, healthcare, and sensitive skin products.

Market Trends and Consumer Preferences

The wet wipes market is one of the fastest-growing segments of the nonwoven industry. Growth is driven by rising health awareness, busy lifestyles, and the demand for sustainable, multifunctional products. Consumers increasingly prefer wipes made with natural or biodegradable materials, and multifunctional wipes with skincare, deodorizing, or disinfecting benefits.

E-commerce has accelerated market expansion, making diverse products accessible and boosting competition among brands. Market segmentation—baby care, sensitive skin, pet care, industrial use—continues to broaden consumer adoption.

Future Outlook

The future of wet wipe nonwoven fabric lies in balancing performance, comfort, and sustainability. Innovations in fiber science, intelligent manufacturing, and eco-friendly materials are expected to dominate. Manufacturers are likely to focus on:

Expanding use of biodegradable and compostable fibers.

Reducing microfiber pollution through improved bonding and coatings.

Integrating smart manufacturing for real-time quality control.

Creating multifunctional wipes with skincare, antibacterial, or deodorizing properties.

As environmental regulations tighten and consumer expectations evolve, wet wipes with sustainable nonwoven fabrics will increasingly define market success. From healthcare to household cleaning, they will remain a trusted, convenient, and safe solution in modern living.