What is the difference between virgin and regenerated Polyester Staple Fiber?

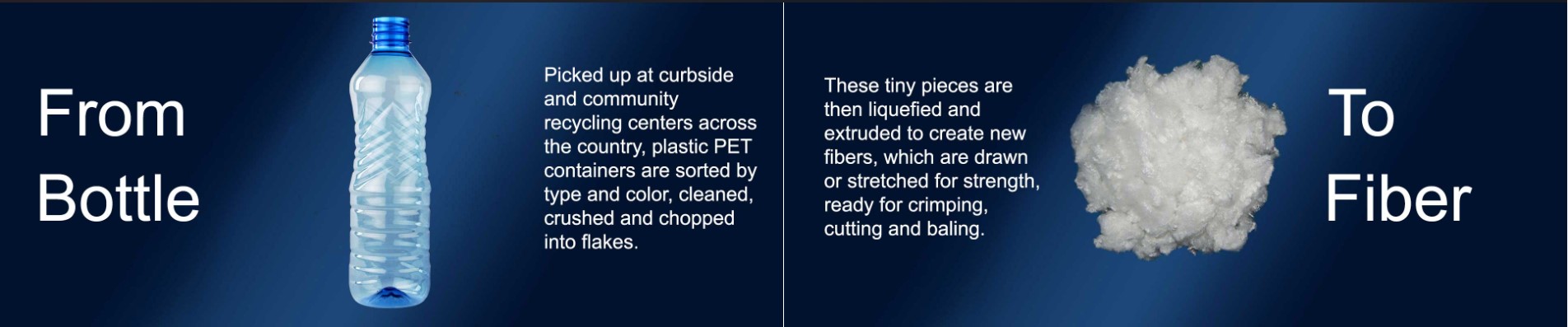

VNPOLYFiber uses regenerated polyester fiber fills for many of its products. Environmentally friendly, cost-effective, and safe, the regenerated polyester fiber is made from recycled plastic water bottles and performs equally as well as 100% virgin polyester for fills.

There is no difference in quality, the recycled fibers are the same as the virgin polyester but they are made out of post-consumer plastic bottles.

You may ask: Is it synthetic or is it down? Thanks to today’s cutting-edge technologies, it may be tough to tell the difference. Commonly known as “down alternatives”, Vnpolyfiber polyester fills are less expensive than down, but share similar performance benefits. From polyester batting to fluffy cluster fibers, these fills are ideal for creating easy-to-care-for, allergy-free bedding solutions.

- THE ENERGY NEEDED TO MAKE THE RPET IS LESS THAN WHAT IS NEEDED TO MAKE THE VIRGIN POLYESTER

- RECYCLING PET TO CREATE THE FABRICS PREVENTS IT FROM GOING TO LANDFILL

- USING MORE RECYCLED POLYESTER REDUCES OUR DEPENDENCE ON PETROLEUM AS THE RAW MATERIAL FOR OUR FABRIC NEEDS

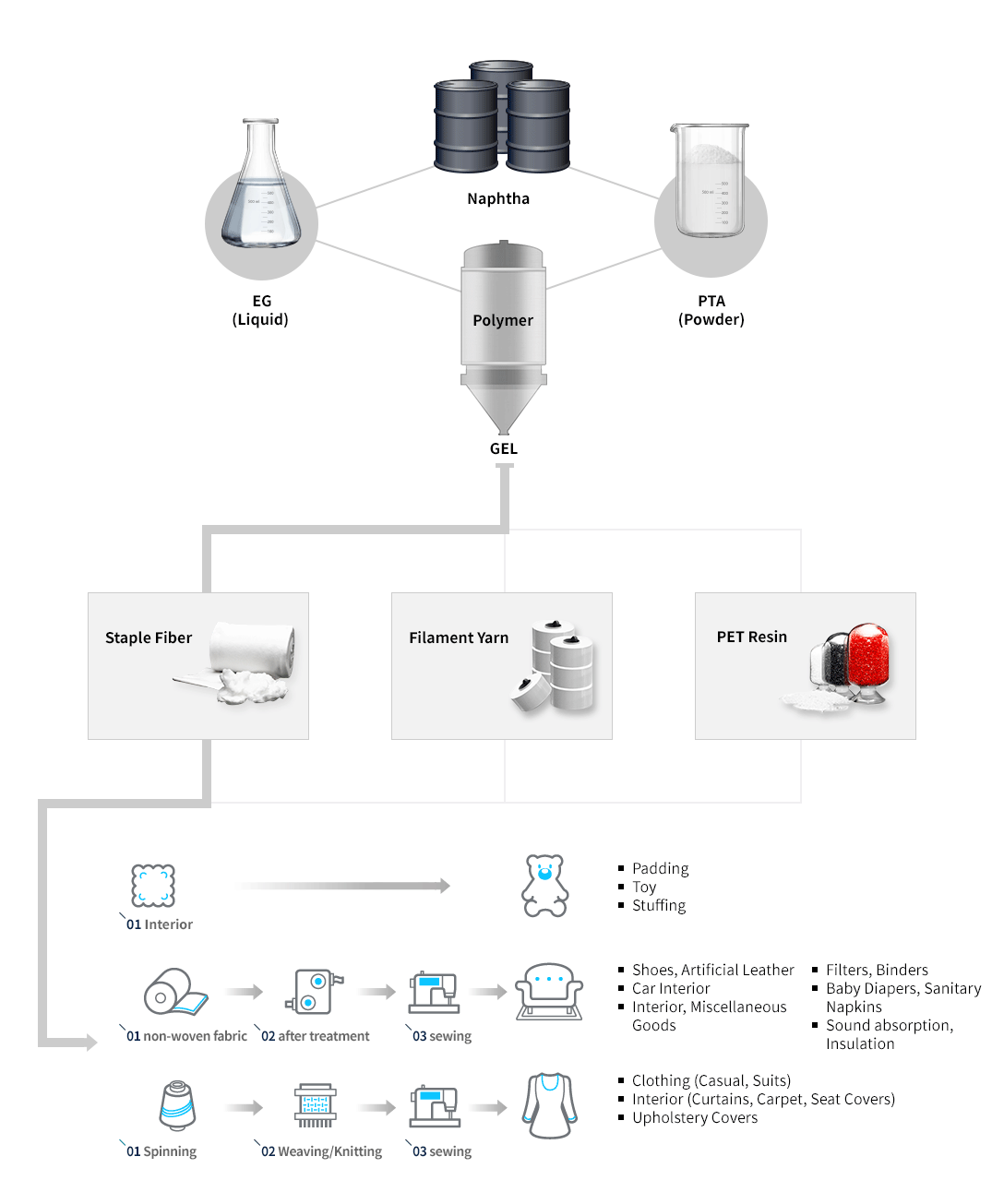

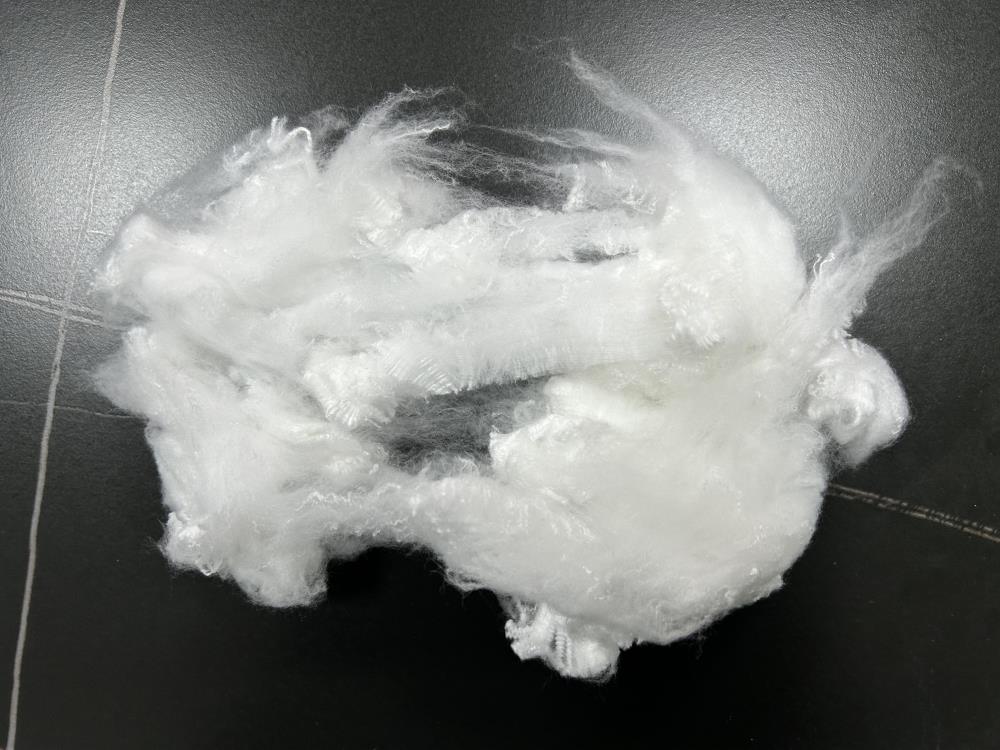

Virgin Polyester Staple Fiber (Virgin PSF)

Virgin Polyester Staple Fiber a synthetic man-made fiber that is manufactured from PTA & MEG through polymerization performed at a high temperature and pressure

After the spinning and drawing process, the polymer becomes staple fibers when cut short into the form of cotton or filament yarns when made into the form of yarn.

Staple fibers are widely used for industrial use as well as for clothing.

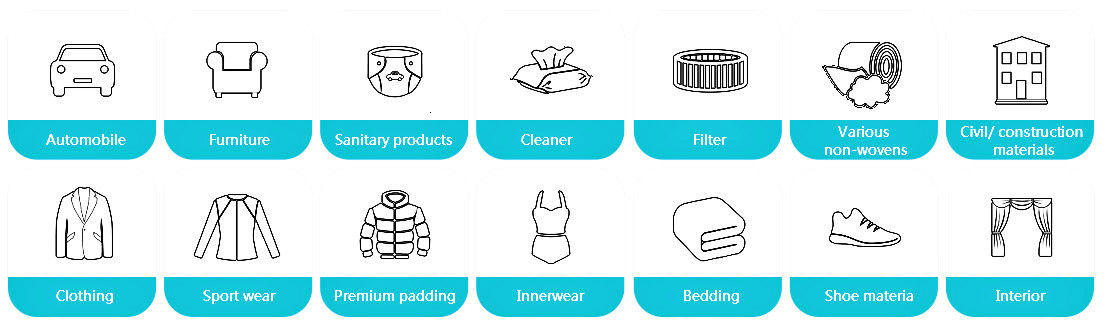

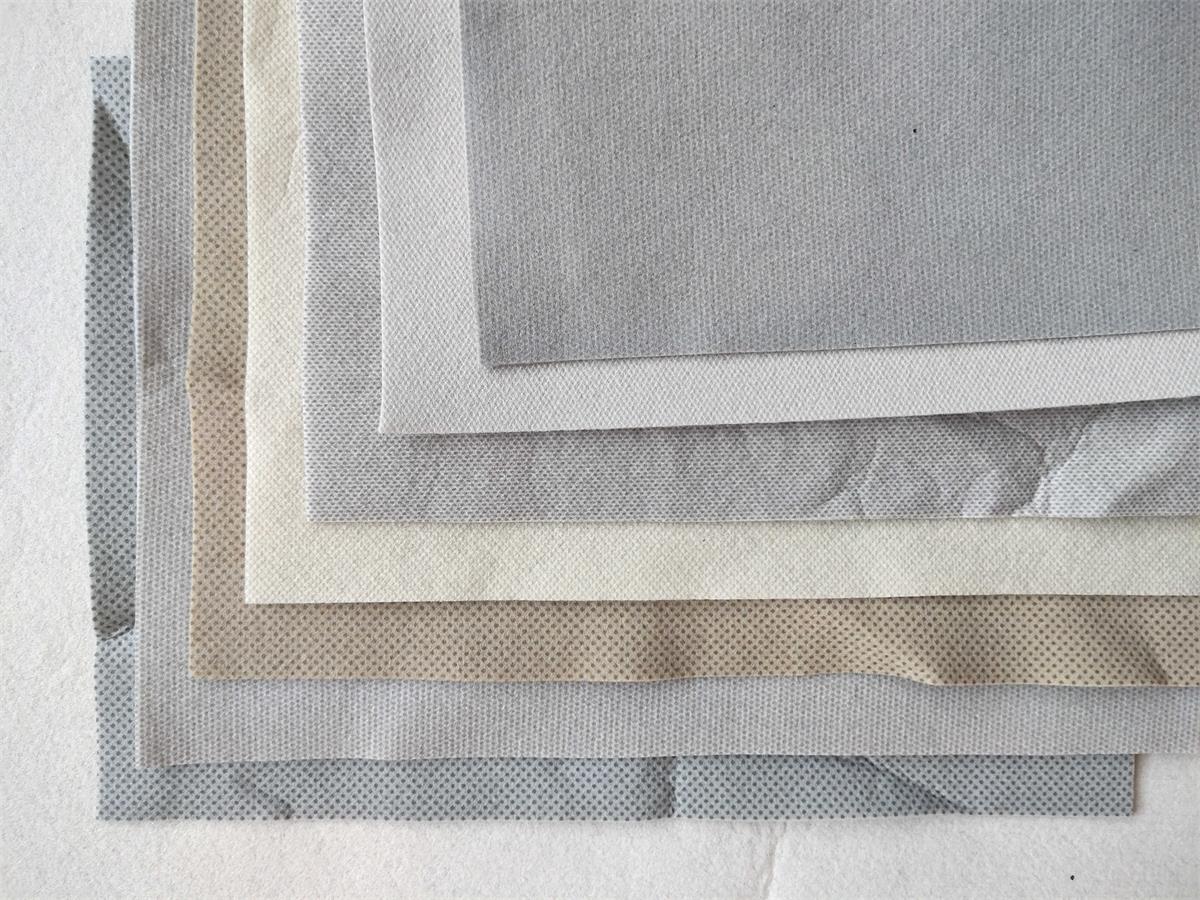

They are not only used for filling clothing, bedding, and furniture in the form of cotton or spinning after twisting cotton into yarn but they are also fabricated into non-woven fabrics through compression and used for a wide range of applications, including automobile, construction, furniture, sanitary materials, and agriculture, gradually expanding their scope of application.

Virgin polyester fiber is produced from 100% pure raw materials that have not been previously used. Unlike recycled polyester, which is made from post-consumer waste, virgin polyester undergoes a manufacturing process of melting and extruding raw materials into long strands that are then cut into fibers of varying lengths.

The benefits of virgin polyester fiber include high quality, durability, and wear-resistance, making it a suitable choice for products like clothing, upholstery, and automotive components. Its versatility allows for easy dyeing and shaping, making it a preferred material in the textile and automotive sectors.

Despite not being made from recycled materials, virgin polyester is still considered sustainable as it can be recycled and biodegraded without harming the environment. Using virgin polyester ensures high-quality products, enhances reputation, increases customer loyalty, and helps companies achieve sustainability goals through the use of recycled and reusable materials.

In summary, virgin polyester fiber is a high-quality, versatile, and sustainable material that is increasingly favored in various industries. As businesses prioritize sustainability and quality, the popularity of virgin polyester is expected to endure in the foreseeable future.

Virgin Polyester Staple Fiber Production Process

Application:

Automobile, Furniture, Sanitary products, Cleaner Filter, Various non-woven fabrics, Civil/construction materials, Clothing Sport wear, Premium padding, Innerwear, Bedding Accessory Interior

Polyester benefits

- Polyester fills are typically less expensive to produce than down and feather or microfiber fills making them practical and cost-efficient

- Polyester fills are hypoallergenic and are ideal for products designed for allergy-sensitive sleepers

- When it comes to easy maintenance, polyester fills are tough to beat and easy-to-care-for

- Adding a silicon finish to polyester fills provides a slick hand similar to down and feather fills

Virgin Polyester Staple fiber for Spunlace Nonwovens

Virgin spunlace polyester is a non-woven fabric composed of continuous filament polyester fibers in their original state. This material has not been recycled or pre-processed, resulting in a high-quality and pure product. Through the spunlace process, the fabric is further improved to enhance its softness and breathability, making it suitable for a wide range of uses.

Benefits of Virgin Spunlace Polyester Staple fiber

1. Environmental Sustainability:

Virgin spunlace polyester provides a sustainable alternative to traditional textiles by reducing environmental impact. Its production process requires less energy and water compared to traditional textile manufacturing, making it a more environmentally friendly option.

2. Biodegradable Properties:

The use of virgin fibers in the fabric enhances its biodegradability, ensuring it breaks down more easily at the end of its life cycle. This characteristic helps minimize waste and supports the concept of a circular economy.

Applications of virgin spunlace polyester fibers

1. Apparel:

Experience the comfort and versatility of breathable, moisture-wicking clothing crafted from virgin spunlace polyester. Its gentle touch and resilience make it perfect for performance wear, intimate apparel, and everyday attire.

2. Home textiles:

Elevate your living environment with home textiles constructed from virgin spunlace polyester. Whether it be bed linens or window treatments, this material offers a lavish feel without compromising on strength.

3. Hygience Products:

With its absorbent nature and hypoallergenic attributes, this fabric is well-suited for inclusion in personal care products like baby wipes, facial wipes, and various hygiene essentials.

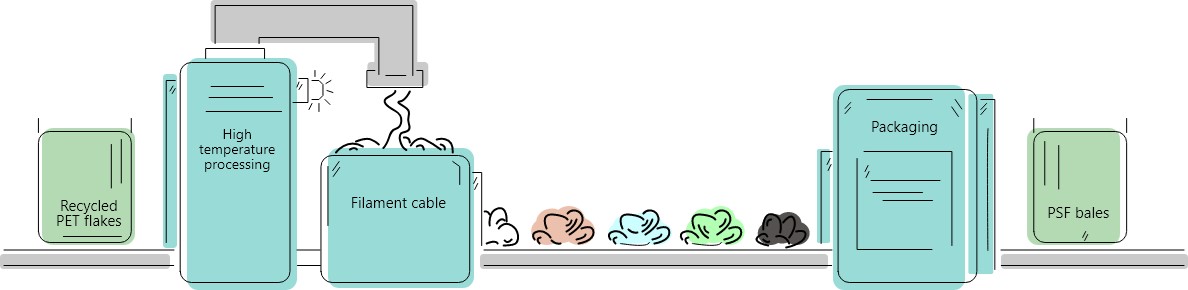

Recycled Polyester Staple Fiber (PSF)

How is recycled polyester different from virgin polyester?

As said earlier, Because the recycling process reconstitutes the fiber on a molecular level, there is no difference between recycled polyester and virgin polyester. Performance and durability, benefits, including high strength and functional versatility of recycled polyester is the same as virgin polyester but with a lower environmental impact.

Why is recycled polyester better?

- Recycled polyester doesn’t require new petroleum to create, lowering the demand for new petroleum extraction and reducing our overall carbon footprint.

- Producing recycled polyester is better for the climate, creating 75% less CO₂ emissions than virgin polyester.

- By providing a use for post-consumer and post-industrial

Advantages of regenerated polyester staple fiber:

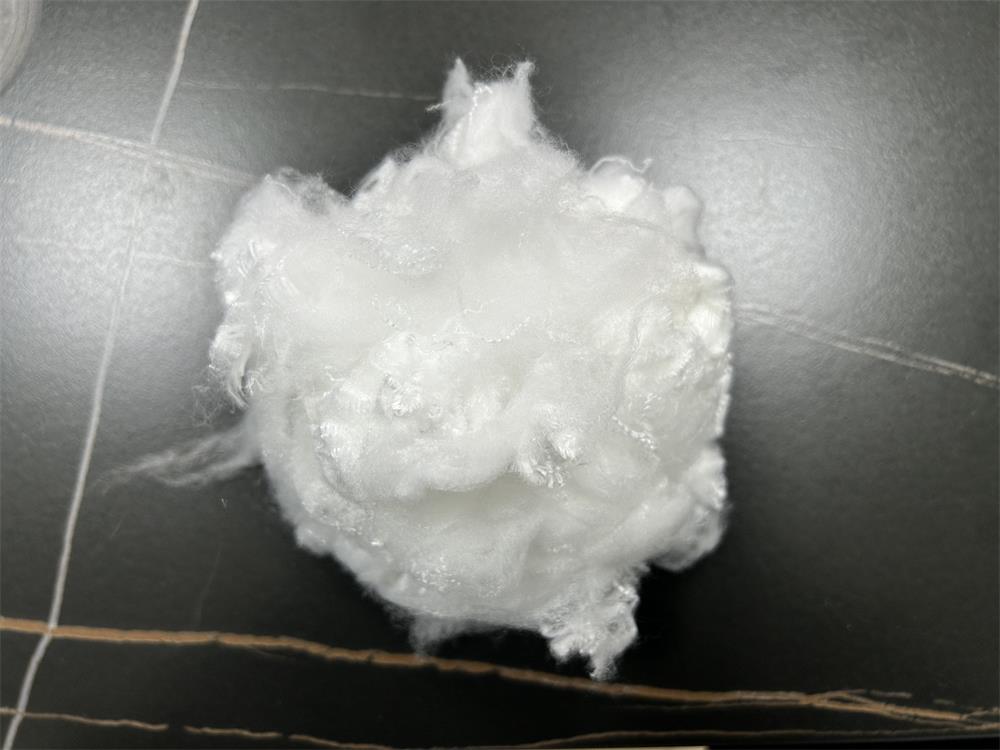

– Warm keeping: The hollow polyester staple fiber is lighter by 20% than ordinary fiber with its hollow Construction. It makes no air convection in fiber to keep warm. It can keep the body warm by wrapping warm air and isolating cold air. The fiber is light and good in warm-keeping.

– Good hygroscopicity: Hollow polyester staple fiber can discharge the moisture quickly in the body skin and keep dry and warm, reduce the uncomfortable sticky feeling with its advantages of special wicking effect and large surface.

– Soft feeling in the hand, good fall: It bright soft, and comfortable feeling in hand to touch the hollow polyester staple fiber fabric. Compared with the daily heavy thermal fabric, it is more easily wet, dry, and comfortable. It is very soft and excellent in pendency.

– Wide application: Hollow polyester staple fiber is a high-quality material for high-grade fabric. Blended with cotton, wool, and viscose fiber, it is widely used to make thin thermal underwear, warm winter casual wear, and sportswear with good warm-keeping, soft feeling, and soft luster. It is also used to make soft and thermal socks and gloves with wear resistance. It is also used to make light and soft tweeds.

Recycled Polyester Staple Fiber Production Process

Application of Regenerated Polyester Fiber

In recent years, there has been a noticeable shift towards sustainable development in the textile industry, driven by increased environmental awareness and consumer demand for eco-friendly products. Manufacturers and consumers are increasingly seeking greener alternatives due to a growing awareness of environmental issues.

One notable innovation in the industry is the use of recycled solid polyester fibers, which has proven to be a game changer with numerous advantages over virgin polyester. Recycled solid polyester fibers have shown extraordinary potential in the textile industry, offering similar qualities to virgin polyester and being suitable for a wide range of textile applications.

These recycled fibers can be seamlessly incorporated into a variety of clothing and accessories, from sportswear and activewear to everyday clothing and home textiles. They can be spun or knitted into various fabrics that provide the same quality and performance as virgin polyester. The versatility of recycled solid polyester fibers allows designers and manufacturers to create sustainable products without compromising on quality or style.

Recycled textile solid polyester fibers present a sustainable solution for the textile industry, maintaining high performance and quality standards.

These fibers are commonly utilized in home decor, providing fabrics with properties similar to those made from virgin polyester. This allows for the creation of elegant and sustainable items such as cushions, upholstery, curtains, and bedding. Manufacturers are able to use recycled materials to produce a variety of textiles, from upholstery to home furnishings.

Recycled polyester fiber is a commonly used filling material for pillows, quilts, and mattresses due to its good loft, stretch, and insulation properties. It serves as a suitable alternative to virgin polyester or down, helping to reduce reliance on virgin polyester and minimize waste in landfills.

The application of recycled polyester fiber in upholstery and cushions provides comfort, support, and durability without flattening over time. Using recycled polyester fibers in upholstery also promotes sustainability by reducing the consumption of new resources.

In the filling applications of toys and plush toys, recycled polyester fibers offer a soft and cuddly feel, making them perfect for creating plush toys. By using recycled polyester fibers in toy manufacturing, the industry can contribute to waste reduction and promote more sustainable practices.

Similarly, recycled polyester fiber is utilized in outdoor equipment such as sleeping bags, jackets, and backpacks for its excellent insulation and moisture-wicking properties. Incorporating recycled polyester in outdoor gear helps companies reduce plastic waste and promote a circular economy fibers

Moreover, recycled polyester fibers can be used in automotive interiors like seat cushions and upholstery for comfort, durability, and abrasion resistance. This practice aids in reducing the environmental impact associated with producing new materials.

The use of recycled polyester fibers in filling applications has numerous benefits, including waste reduction, energy savings, and decreased reliance on virgin materials. By embracing sustainable materials like recycled polyester fibers, industries can contribute to a greener and more environmentally friendly future.

As we prioritize sustainability, the use of recycled polyester fibers in various industries like bedding, upholstery, and fashion plays a crucial role in responsible production and consumption practices. Embracing this environmentally friendly alternative allows manufacturers to reduce their environmental footprint while offering consumers high-quality products without sacrificing performance.

In addition to home decor, recycled textile solid polyester fibers are highly valued in technical textiles. They are utilized in automotive industry applications such as seat upholstery, carpets, and interior panels, as well as outdoor equipment like backpacks, tents, and sportswear. The fibers boast excellent moisture-wicking and quick-drying capabilities. The recycling process involves meticulous steps to ensure the fibers are purified and strengthened, making them suitable for a wide range of textile applications.

Furthermore, these recycled fibers play a crucial role in technical textiles such as nonwovens, geotextiles, and filter materials. Thanks to their high tensile strength and resistance to chemicals and UV radiation, they are ideal for various textile applications.

The increasing adoption of recycled textile solid polyester fibers in the textile industry is a positive step towards a more sustainable and environmentally conscious future. By utilizing recycled textile solid fibers, the textile industry can reduce its environmental impact and meet the growing consumer demand for eco-friendly products. The use of recycled textile solids polyester fibers in textile production can help conserve resources, reduce waste, and support the transition to a circular economy. By choosing this environmentally friendly option, companies can decrease their carbon footprint, minimize waste generation, and conserve resources. Ultimately, the textile industry has the opportunity to lead the way towards a more sustainable future, promoting a circular economy and protecting the planet for future generations.

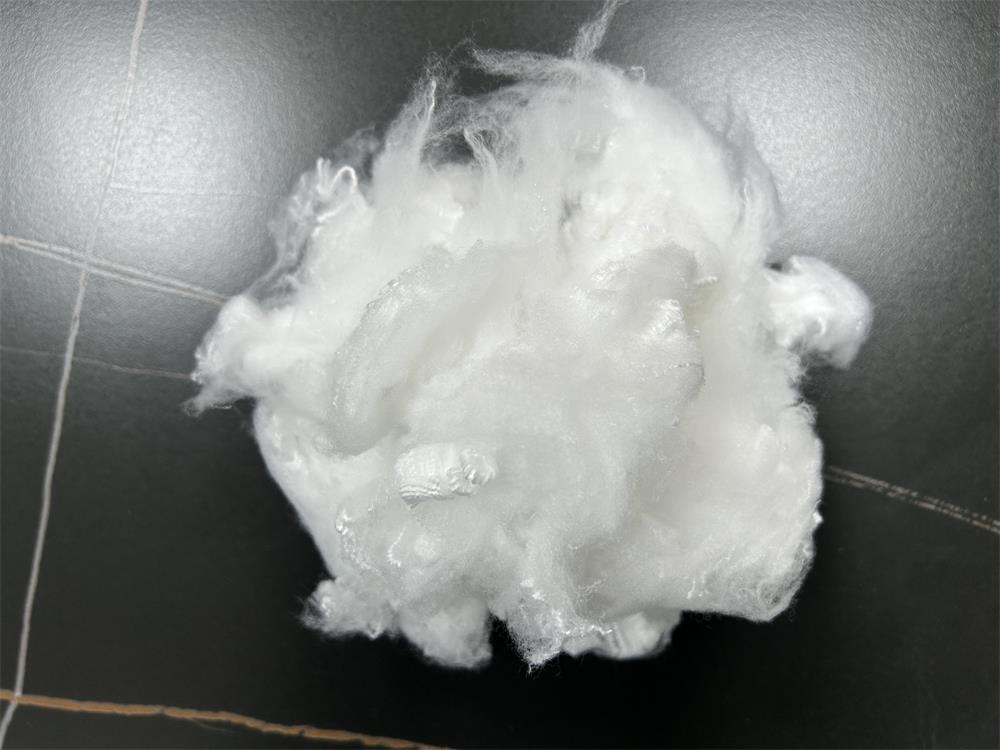

What is Hollow Conjugate Fiber?

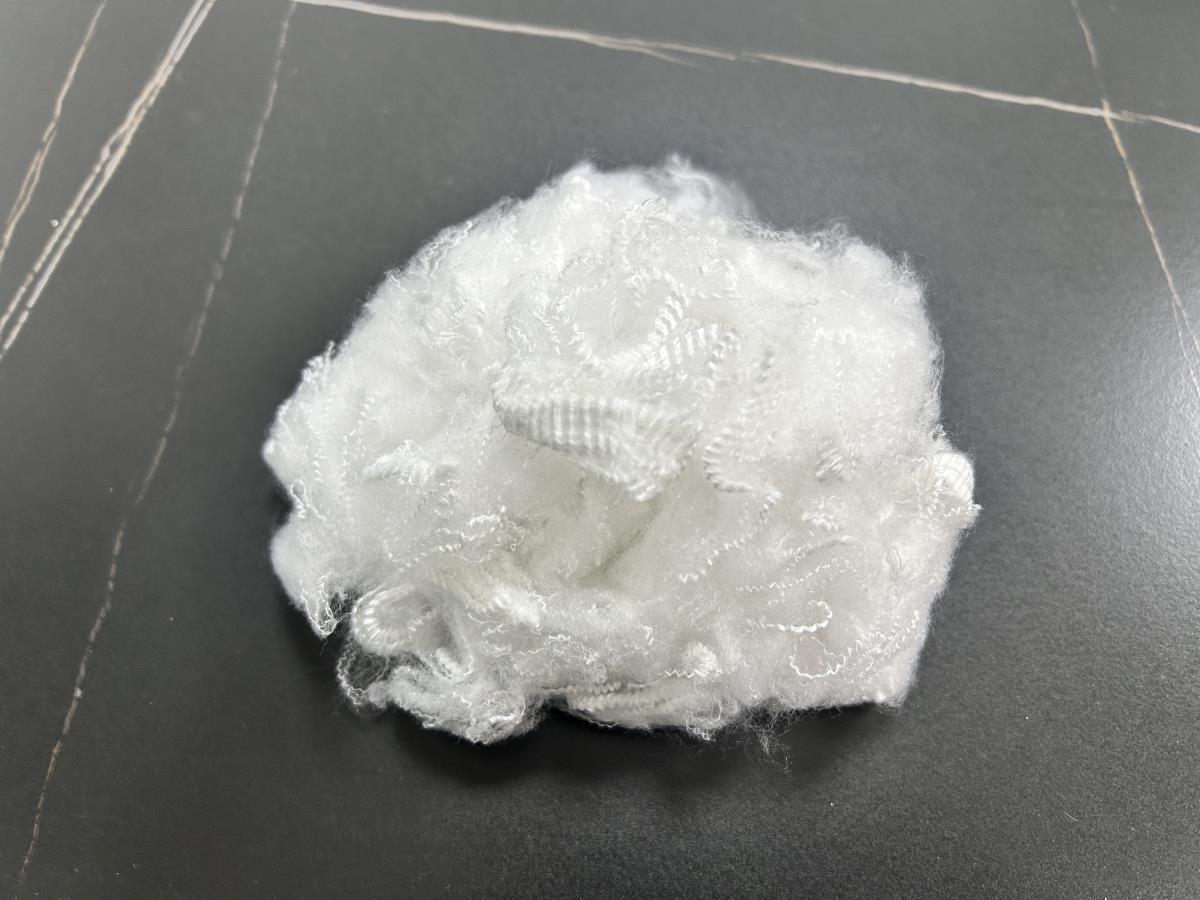

Hollow conjugate fiber means a conjugate fiber maintaining a hollow form

The hollow form that does not fill the section of the fiber and the 3D crimp from heterogeneous polymer provides excellent bulkiness and elasticity and makes light and warm fibers. The lineup includes a product with extra soft feeling obtained through special silicon processing and a product featuring flame retardant property and slick touch through special oiling agent processing.

Three-dimensional crimped fiber is called a spiral three-dimensional crimped conjugated polyester fiber.

Polyester’s wrinkle resistance and heat resistance are superior to other fibers, and its UV resistance and impact resistance are better.

The three-dimensional crimp fiber is a good option as the filling materials of home textiles, such as pillows, cushions, and sofa. The specific requirements are as following:

Fiber length requirements: In general, the fiber lengths include 7D, 12D, and 15D, among which the lower D number indicates longer fiber length, finer fiber fineness, as well as better warmth-keeping ability, fluffiness, and thickness. Fibers of 7D or less are the best options for filling materials.

Fiber shape requirements: In general, there are zigzag-shaped and spiral-shaped fibers. Among these two, the spiral-shaped fibers are better due to their higher saturation force and elasticity, more space between fibers, as well as better warmth-keeping ability and fluffiness.

Fiber structure requirements: In general, there are three types of fiber structures: regular structure, single-hole structure, and porous structure. If the structure of fiber contains a single-space with a certain length, the fiber is called hollow fiber. On the other hand, the porous structure contains four to seven spaces. Due to different structures, filling fiber is different in its appearance and texture. Their warmth-keeping ability, fluffiness, and elasticity also vary

Characteristics of Polyester Staple Fiber: Excellent bulkiness, High resiliency and tenacity, Lightweight, warmth retention, Softness

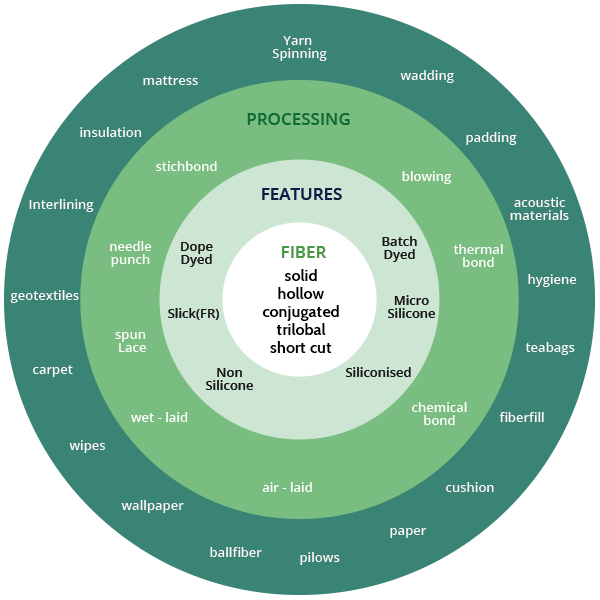

Differentiation of Polyester Staple Fiber

Application of Polyester Staple Fiber: Sofa, Mattress, Padding, Blanket, Pillow Toy