What is textile recycling?

Textile recycling is the process of recovering used clothing and other textiles and turning them into new products. This process helps to conserve natural resources and reduce waste, as well as supporting the production of new items in a more sustainable and environmentally friendly way. The process of textile recycling typically involves sorting, grading, and cleaning the textiles, followed by breaking them down into fibers that can be used to produce new products such as insulation, carpet padding, and even new clothing. Textile recycling also helps to reduce greenhouse gas emissions associated with the production of new textiles, as well as reducing the amount of waste that ends up in landfills.

Textile recycling methods

There are two dominant textile recycling methods: mechanical processing and chemical processing. Mechanical processing is mainly performed on regular fibers, while chemical processing focuses on synthetic fibers. There are more processing methods such as repurposing and donating.

- Mechanical recycling: This method involves breaking down the textile fibers into their raw materials, which can then be used to produce new textiles. This process can involve chopping, shredding, or grinding the textiles, and then spinning the fibers into new yarn.

- Chemical recycling: This method uses chemical processes to break down the textiles into their constituent parts, which can then be used to produce new fibers. For example, a process known as depolymerization can be used to dissolve the fibers and then reform them into new, usable fibers.

- Repurposing: This method involves taking used textiles and transforming them into new products without breaking down the fibers. For example, an old T-shirt could be cut up and turned into a reusable shopping bag.

- Donating or reusing: This method involves giving used textiles to organizations or individuals who can use them, either for their original purpose or for repurposing into new products. Donated clothing and other textiles can be used to support those in need, both domestically and internationally.

Textile recycling process

The process of textile recycling typically involves the following steps:

- Collection: Used textiles are collected from a variety of sources, including households, thrift stores, and clothing manufacturers.

- Sorting: The collected textiles are sorted into different categories, such as clothing, linens, and rags. This allows the recyclers to determine which textiles are suitable for mechanical recycling, chemical recycling, or repurposing.

- Cleaning: The textiles are cleaned to remove any dirt, stains, and other impurities.

- Grading: The cleaned textiles are graded based on their quality, color, and fiber content.

- Mechanical Recycling: If the textiles are suitable for mechanical recycling, they are broken down into fibers using processes such as chopping, shredding, or grinding.

- Chemical Recycling: If the textiles are suitable for chemical recycling, they are broken down into their constituent parts using chemical processes such as depolymerization.

- Repurposing: If the textiles are suitable for repurposing, they are transformed into new products without being broken down into fibers.

- Manufacturing: The recycled fibers are used to produce new textiles, such as clothing, linens, and rags.

This process helps to conserve natural resources, reduce waste, and support the production of new items in a more sustainable and environmentally friendly way.

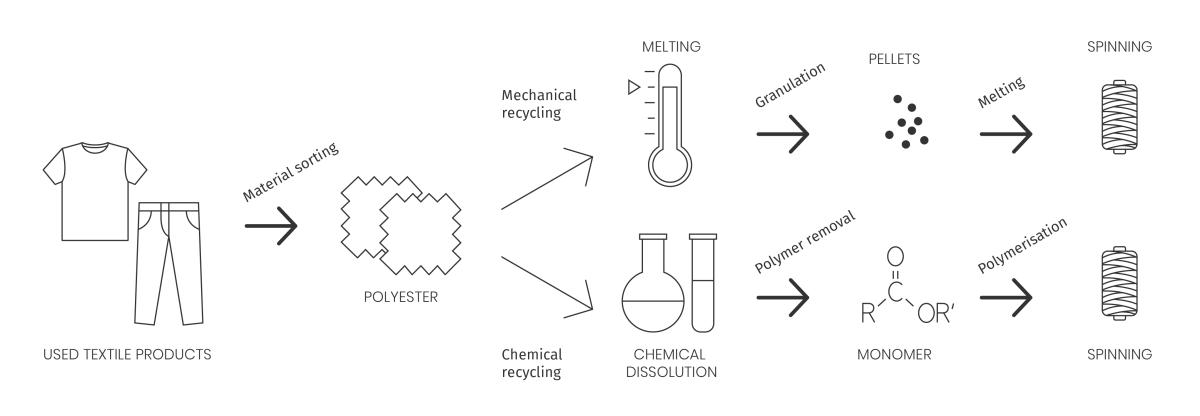

POLYESTER RECYCLED FROM USED TEXTILES

Polyester can be recycled from used clothing (known as post-consumer) or from production off-cuts (known as pre-consumer). Polyester can be recycled both mechanically and chemically. In addition to being used to recreate thread, recycled polyester has numerous outlets: plastics processing, unwoven fabrics or fuels.

Mechanical polyester recycling: to create a polyester thread via a mechanical recycling process, materials must firstly undergo a melting stage to return the polymer to a liquid state. Granulation follows in order to form pellets. Once the polyester is returned to pellet state, it can undergo a classic spinning process.

Chemical polyester recycling: :to create a polyester thread via a chemical recycling process, materials must firstly undergo chemical dissolution to regenerate fibres. Fibres are depolymerised to bring them back to a monomer state. Following this treatment, the polyester can undergo a classic spinning process.

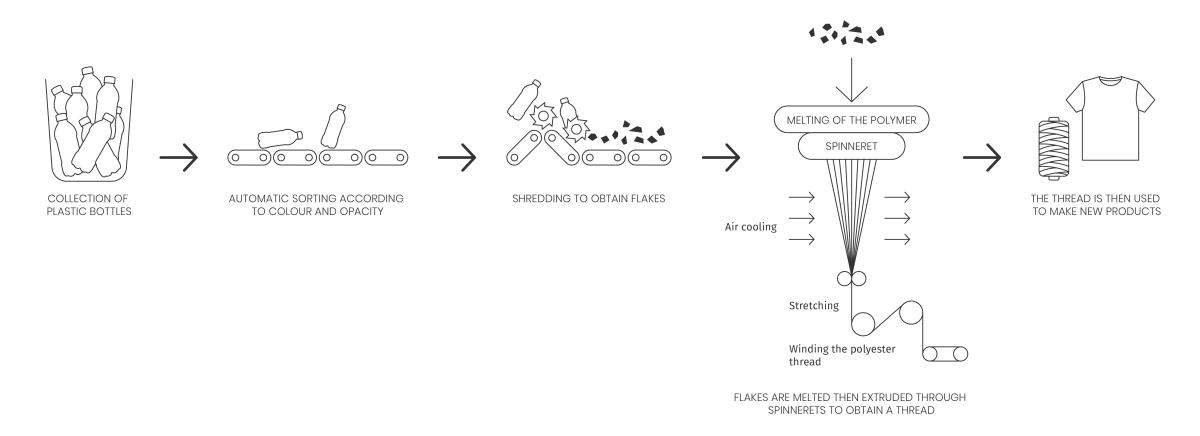

POLYESTER RECYCLED FROM PLASTIC BOTTLES

Products from industries other than the textile industry, such as the PET (Polyethylene Terephthalate) plastic bottles, can be used to create a recycled polyester thread. The product most often made from recycled PET bottles is the fleece jacket. 27 PET bottles are necessary to make one fleece jacket.

PET bottles are collected then baled. They are sorted according to colour and opacity (only transparent, uncoloured bottles are recycled). The tops are separated from the bottle as the plastic is different. The bottles are then ground to obtain flakes.

These flakes are cleaned and undergo a thermal treatment process to take on the form of pellets. The pellets are melted to obtain a paste which is extruded in the form of a filament after passing through a die (plates with small holes). The filaments are coated then stretched to form a thread. The process permits a RPET thread to be obtained. (Recycled Polyethylene Terephthalate).