Carbon fiber

Carbon fiber is a high-performance fiber with excellent mechanical properties, which is about 5 to 10 μm in diameter and mainly composed of carbon atoms.

Typical Categories

- PAN-Based Carbon Fiber

PAN-based carbon fibers are produced from PAN-based precursor fibers. Acrylic fibers with acrylonitrile content above 85% have been found to be ideal precursors. The figure below shows the chemical structure of a PAN homopolymer first introduced as a carbon fiber precursor material. PAN has two desirable properties: first the high carbon content (67.9 %) that leads to a high carbon yield (50-55 %) and second its tendency to establish a ladder structure when heat treated in air.

- Pitch-Based Carbon Fiber

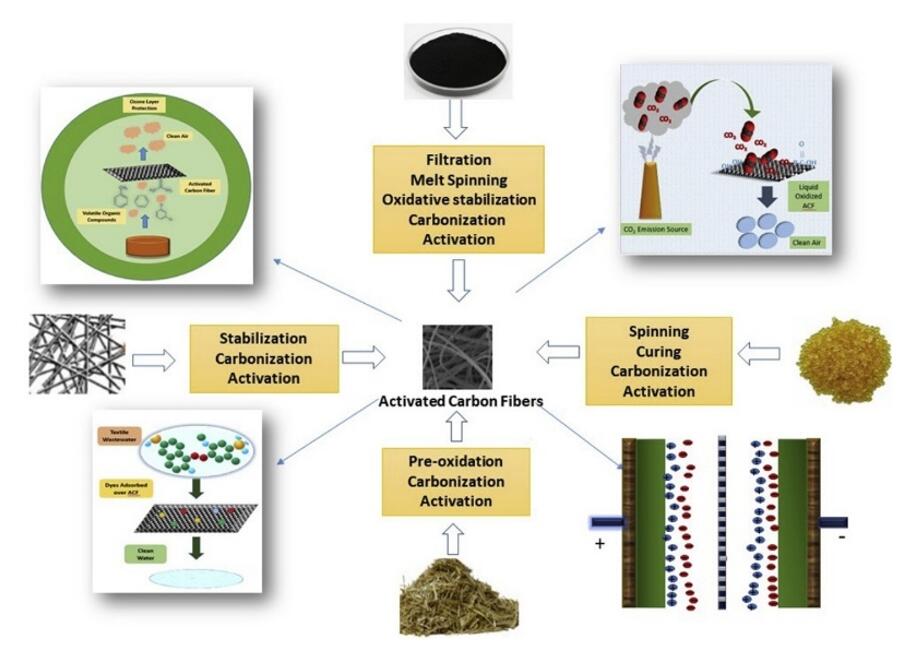

Pitch-based carbon fibers are derived from pitch-based precursors. Pitch was selected as one of the early candidates for carbon fiber precursors due to its high carbon yield (85%). The main advantage of using pitch as a precursor is the production of ultra-high modulus carbon fibers because the graphite crystallite size is significantly larger. However, the graphitic nature of the pitch-based precursors reduced the compressive and transverse properties of the resulting carbon fibers. - Activated Carbon Fiber

Activated carbon fiber (ACF) is a relatively novel fibrous carbon material, which has the advantages of high porosity, high volume capacity, excellent bulk density, fast adsorption kinetics, and good porous storage capacity. - Others

Other carbon fiber production precursors also include cellulose precursors, phenolic precursors, and so on.

Features

- High tensile strength (2∼7 GPa)

- Notable compressive strength

- High Young’s modulus (200∼900 GPa)

- Low density (1.75∼2.20 g/cm3)

- Low thermal expansion

- Excellent electrical and thermal conductivity (~800 Wm-1K-1)

- Ultimate chemical stability

- High temperature resistance

- Good fatigue resistance

- Excellent wear resistance

Applications

- Battery Application

The application of carbon fibers as electrode materials in batteries has been widely studied, such as lithium-ion batteries, lithium-sulfur batteries, sodium-ion batteries, and vanadium redox flow batteries. The effects of carbon fibers and their composites on battery performance were summarized by Shengnan Yang et al.

- Composite Materials

Based on the above-mentioned advantages of carbon fiber, such as high specific tensile strength, high modulus, and excellent wear resistance, carbon fiber occupies an important position in reinforcing advanced composite materials. The obtained composite materials are widely used in aviation, deep sea development, wind power generation, automobiles, construction engineering, sports and leisure and other industrial and civil fields. - Environment and Energy

The general properties of ACF enable it to be used in a variety of environmental and energy applications, including applications in CO2 capture, volatile organic compound removal, wastewater treatment, and energy. For example, some efforts have been made to utilize ACF materials to eliminate volatile organic compounds (VOCs) such as benzene, toluene, xylene, (BTX) organic compounds, etc., especially from enclosed environments.

Ceramic Fiber

Ceramic fiber, also known as aluminum silicate fiber, is a new type of lightweight refractory material. Ceramic fibers come in two forms, continuous (long) and discontinuous (short). Ceramic fibers can be divided into oxide and non-oxide ceramic fibers, which are used as reinforcements for composites.

Features

Ceramic fibers have the features such as:

- Light weight

- High temperature resistance

- Low thermal conductivity

- Good thermal stability

- Corrosion resistance

- Creep resistance

- Good microstructural stability

- Small specific heat

- Mechanical vibration resistance

Therefore, they have been widely used in machinery, metallurgy, chemical industry, petroleum, ceramics, glass, electronics and other industries.

Classification

- Ceramic Oxide Fiber

Typical compositions of these oxide fibers are Al2O3, Al2O3/SiO2 or Al2O3/SiO2/B2O3 mixtures. - Ceramic Nonoxide Fiber

Non-oxide fibers are often described by their constituent elements, as they contain distinct phases and do not have a uniform stoichiometry. Well-known filament fiber compositions are: SiC, Si-C-O, Si-C-N, Si-C-N-O, and Si-B-C-N. Although these fibers can contain a certain amount of oxygen, they do not form typical oxides in the structure and are therefore “non-oxides”. Typical ceramic non-oxide fibers include silicon carbide (SiC) fibers and boron-based fibers.

Production Techniques

There are several production techniques for ceramic fibers:

- CVD technique

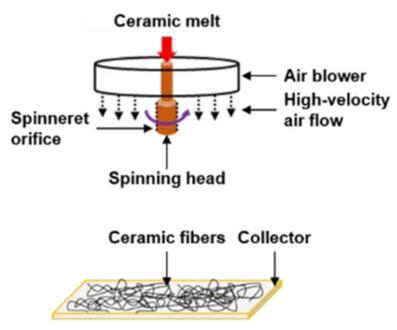

- Melt spinning technique

- Slurry spinning

- Chemical conversion

- Polymer-derived precursor method

- Sol-gel process

- Single-crystal fiber growth technique

Fabrication of ceramic fiber with centrifugal spinning

It is worth noting that, considering the production efficiency and cost, there are also some advanced ceramic fiber technologies commonly used in scientific research.

- Centrifugal Spinning

- Electrospinning

- Solution Blow Spinning

- Self-assembly

- Atomic Layer Deposition

Applications

Ceramic fibers are mainly used in two fields of application: first as thermal insulation material and second for the reinforcement of metals or ceramics. Non-oxide fibers could in future applications substitute carbon fibers, which are also used for ceramic reinforcement, for instance in C/SiC materials. In addition, the effect of ceramic fibers on mechanical properties in other materials has also been explored in some studies. For example, Duoqi Shi et al. studied the effect of ceramic fibers on the high temperature compression properties of SiO2 aerogels. The results show that the modified material exhibits anisotropic mechanical properties.

Microstructure of ceramic-fiber-reinforced SiO2 aerogel. (a) In-planedirectionmicrostructure, (b) out-of-planedirectionmicrostructure

Glass Fiber

Classification

According to the monofilament diameter, glass fibers can be divided into coarse fibers (30 μm), primary fibers (greater than 20 μm), intermediate fibers (10-20 μm), high-grade fibers (3-10 μm) and ultrafine fibers (less than 4 μm). Generally speaking, fibers of 5-10 μm are used as textile products; fibers of 10-14 μm are generally used for roving, non-woven fabrics, chopped fiber mats, etc.

Depending on the glass raw material, types of glass fibers include E-glass, C-glass, S-glass, A-glass, D-glass, R-glass, and EGR-glass, etc. The corresponding physical properties of different types of glass fibers are shown in the figure below. In general, glass fiber has the features of high temperature resistance, non-flammability, corrosion resistance, good heat and sound insulation, high tensile strength, good electrical insulation, low coefficient of linear expansion and dielectric permeability, etc.

Chemical Composition

- E-glass fibers, also known as alkali-free glass fibers, have an alkali metal oxide content < 0.05%.

- C-glass fiber is also known as medium alkali glass fiber, and its alkali metal oxide content is 11.5-12.5%.

- glass fiber is also known as high-alkali glass fiber with an alkali metal oxide content > 15%.

- D- glass fiber contains a large amount of boron trioxide, which provides low dielectric constant properties. This makes glass fibers ideal for fiber optic cable applications.

- S-glass fiber, also known as special glass fiber, is a high-strength glass fiber composed of pure magnesium-aluminum-silicon ternary. S-glass fibers mainly include magnesium-aluminum-silicon-based high-strength and high-elastic glass fibers, silicon-aluminum-calcium-magnesium-based chemical corrosion-resistant glass fibers, lead fibers, high silica fibers, and quartz fibers.

- The chemical composition of different glass fibers in wt% is summarized in the table below for reference.

| Type | (SiO2) | (Al2O3) | TiO2 | B2O3 | (CaO) | (MgO) | Na2O | K2O | Fe2O3 |

|---|---|---|---|---|---|---|---|---|---|

| E-glass | 55.0 | 14.0 | 0.2 | 7.0 | 22.0 | 1.0 | 0.5 | 0.3 | – |

| C-glass | 64.6 | 4.1 | – | 5.0 | 13.4 | 3.3 | 9.6 | 0.5 | – |

| S-glass | 65.0 | 25.0 | – | – | – | 10.0 | – | – | – |

| A-glass | 67.5 | 3.5 | – | 1.5 | 6.5 | 4.5 | 13.5 | 3.0 | – |

| D-glass | 74.0 | – | – | 22.5 | – | – | 1.5 | 2.0 | – |

| R-glass | 60.0 | 24.0 | – | – | 9.0 | 6.0 | 0.5 | 0.1 | – |

| EGR-glass | 61.0 | 13.0 | – | – | 22.0 | 3.0 | – | 0.5 | – |

| Basalt | 52.0 | 17.2 | 1.0 | – | 8.6 | 5.2 | 5.0 | 1.0 | 5.0 |

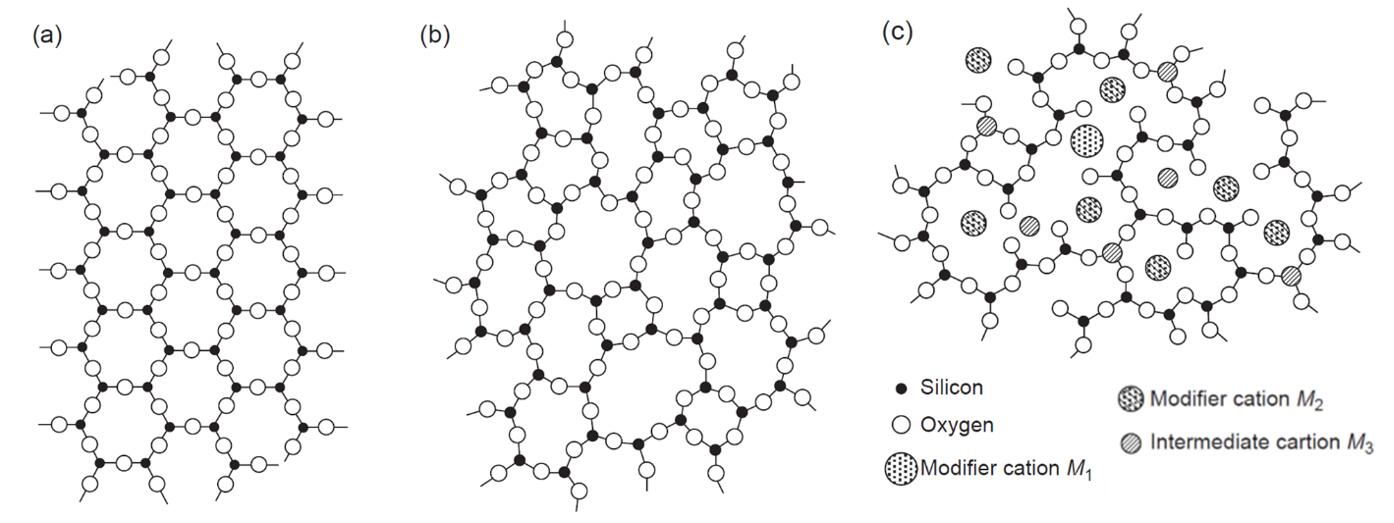

Chemical Structure

The glass structure at the atomic level has been the subject of much theoretical speculation and experimental work. Zachariasen’s model shows that quartz glass is composed of a random network of SiO4 tetrahedra. Schematic diagrams of glass crystals and multicomponent glasses have been proposed. The short-range order but lack of long-range order in the figure (b) is due to the fact that SiO4 tetrahedra are the basic building blocks of amorphous silica, but the orientation of the tetrahedra with each other has some random characteristics. The O atoms at the corners of the tetrahedra are shared between the two tetrahedra. Therefore, the overall chemical composition of glass is SiO2. Although pure silica glasses appear to mostly have random arrangements of atoms beyond the nearest neighbors, when network modifiers (e.g., Na, Ca) and alternative network formers (e.g., B and Al) are introduced, some of the randomness of the structure is compromised.

2D schematic diagram of (a) crystal structure; (b) simple glass; (c) multicomponent glass.

Composite Fiber

Classification

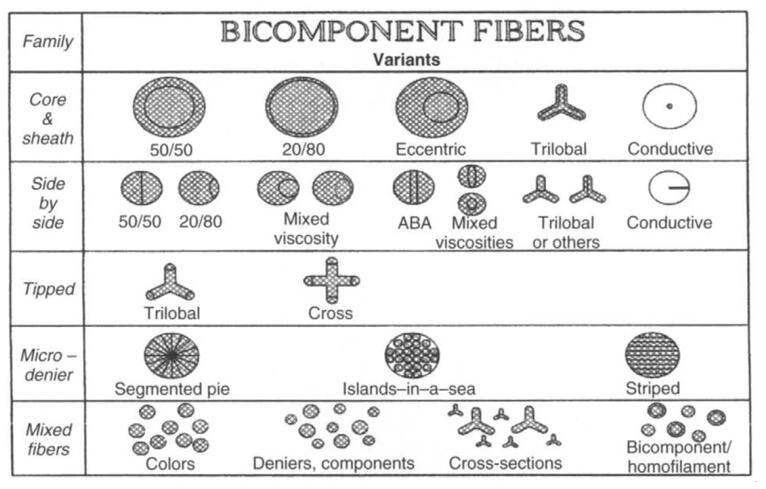

With the right combination of polymers, manufacturing conditions and added additives, multicomponent fibers with desired properties can be obtained. The advantages of composite fibers include increased dyeability, decreased flammability, increased water absorption, increased photothermal stability, increased strength and elastic recovery.

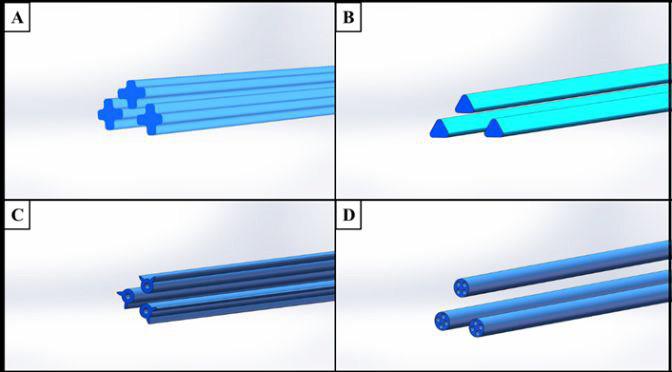

According to the number of phase components, it can be divided into bicomponent and multicomponent composite fibers. Most of the currently developed conjugate fibers are bicomponent fibers. According to the shape of the cross-section, bicomponent fibers include side-by-side, sheath-core, and island-in-the-sea types, etc. The figure below lists some common types of fiber cross-sections.

- Side-by-side type: Side-by-side composite fibers are fibers composed of polymers with different properties or structures arranged side by side and composited along the fiber axis. The ratio of each component can be symmetrical or asymmetrical. The most important feature of this fiber is that it can take advantage of the difference in shrinkage properties of each component to create an ideal wool-like three-dimensional crimp. Therefore, side-by-side composite fibers are mainly used to produce large-volume self-crimping fibers.

- Sheath-core type: This is a fiber in which two polymers are continuously formed along the longitudinal direction of the fiber to form a skin layer and a core layer, respectively. Using the sheath-core structure, special-purpose fibers can be manufactured. For example, the flame-retardant polymer is used as the core and the ordinary polyester is used as the skin to make flame-retardant fibers.

- Island-in-the-sea type: This is a composite fiber in which the dispersed phase polymer is uniformly embedded in the continuous phase polymer. The island component of sea-island fiber is generally polyester (PET) or polyamide (PA), and the sea component compounded with it can be polyethylene (PE), polyamide (PA6 or PA66), polypropylene (PP), polyethylene Vinyl alcohol (PVA), polystyrene (PS), etc.

Typical Product

Polyethylene and polypropylene composite fibers

One of the most commonly used multicomponent fibers includes polyethylene (PE) and polypropylene (PP), which are polymers with different melting points. The resulting material is lightweight, strong, soft and comfortable, dries quickly, and has high abrasion and stain resistance.

Research and Application

As a kind of fiber variety with special style and performance, composite fiber has been widely used in people’s life, industry, medical treatment, optoelectronic communication and other fields, and has become an indispensable fiber material.

In advanced research, composite fibers can be used as luminous fibers. In 2004, Shim investigated the luminescence and mechanical properties of photoluminescent core bicomponent fibers produced in a sheath-core morphology. In 2018, Haolong Xue et al. developed a novel skin-core structure luminous fiber that emits red light in the dark.

Structure of xanthene derivative (a) and luminous fiber (b).

Metallic Fiber

Features

- Metallic fibers have good mechanical properties. They not only have high breaking strength and tensile modulus, but also have good bending resistance and good toughness.

- Metallic fibers have good electrical conductivity and can prevent static electricity. For example, tungsten fibers are used as filaments for incandescent light bulbs. In addition, they are also important materials for protection against electromagnetic radiation and electrical conduction and electrical signal transmission.

- Metallic fibers have high temperature resistance.

- Some metallic fibers have good chemical corrosion resistance and are not easy to be oxidized in the air, such as stainless steel fibers, gold fibers, nickel fibers, etc.

Preparation

There are a variety of preparation methods for metallic fibers, including drawing, spinning, cutting, grinding, and plating metal sintering.

- The drawing method is used to obtain extremely fine fibers with a smooth surface and precise dimensions.

- Spinning method can produce metallic fibers directly from liquid metal.

- The cutting method uses solid metal as raw material, and uses a tool to cut it into fibrous chips, which are mainly used to produce short metallic fibers.

- The grinding method uses high-hardness materials as abrasives, and obtains metallic fibers of the required diameter by grinding the metal.

- The plated metallic sintering method can be used to prepare hollow metallic fibers.

Applications

- Textile Industry

Metallized fabrics mixed with metallic fibers in ordinary textile fibers not only have the wearability of ordinary fabrics, but also have protective properties such as antibacterial, antistatic and anti-electromagnetic radiation. For example, stainless steel fiber textiles can be heated by applying an electric current and can also be used in cut-resistant clothing. - Sound Energy Absorbing Material

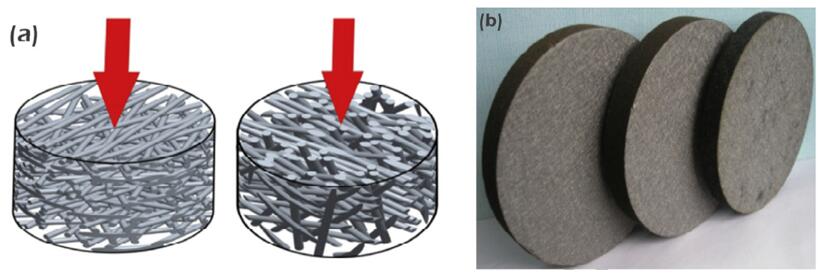

Due to the porous structure, fibrous materials have been widely used for noise reduction. Among them, metallic fiber materials have received great attention in noise reduction applications due to their large specific surface area, high mechanical strength, and good permeability, especially in noise control in harsh environments.

(a) Schematic illustration of sintered fibrous metallic with sound incidence; (b) Test samples of sintered fibrous metal.

- Reinforcing Material

Metallic fibers can be used to reinforce polymers or plastics. This combination ensures high strength, light weight and good fatigue resistance. Continuous metallic fibers can be easily handled. Better flexural properties are observed in some metallic fiber reinforced plastic composites, which also provide higher strength and weight than fiberglass. - Chemical Industry

Metallic fibers can be used as filter screens for chemical agents, processing materials, waste liquid and wastewater filtration, filter screens for high-temperature dust filters, and materials that require high strength, wear resistance, and conductive conveyor belts.

Custom Profiled Fiber

Optional Service Items

By imitating the structural characteristics of natural fibers, the cross-sections of profiled fibers are made into special shapes, instead of being circular or nearly circular like general chemical fibers, in order to obtain some performance improvements. Combining rich experience in R&D and production with advanced technical expertise,

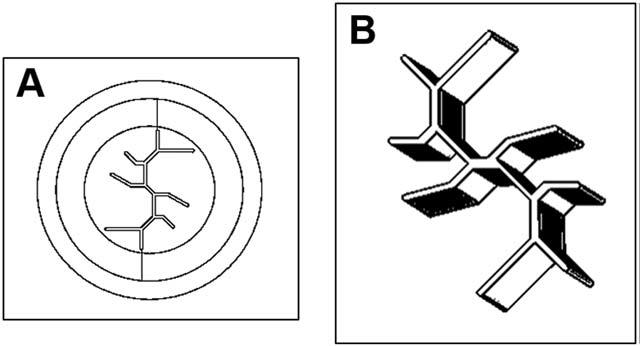

- Optional Cross-Sectional Shape

The cross-sectional shape is the most important parameter in the profiled fiber customization service. We can provide you with a variety of optional cross-sectional shapes, including but not limited to triangular, pentagonal, polygonal, trilobal, multilobal, cross, dumbbell, “L”, “H”, “Y” shape and hollow shape, etc. Different cross-sectional shapes will bring different performance changes to the fibers. For example, triangular fibers have shiny properties, hollow fibers have better bulkiness, and dumbbell-shaped fibers have good elasticity and moisture conductivity.

Several typical profiled fibers

- Optional Fiber Type

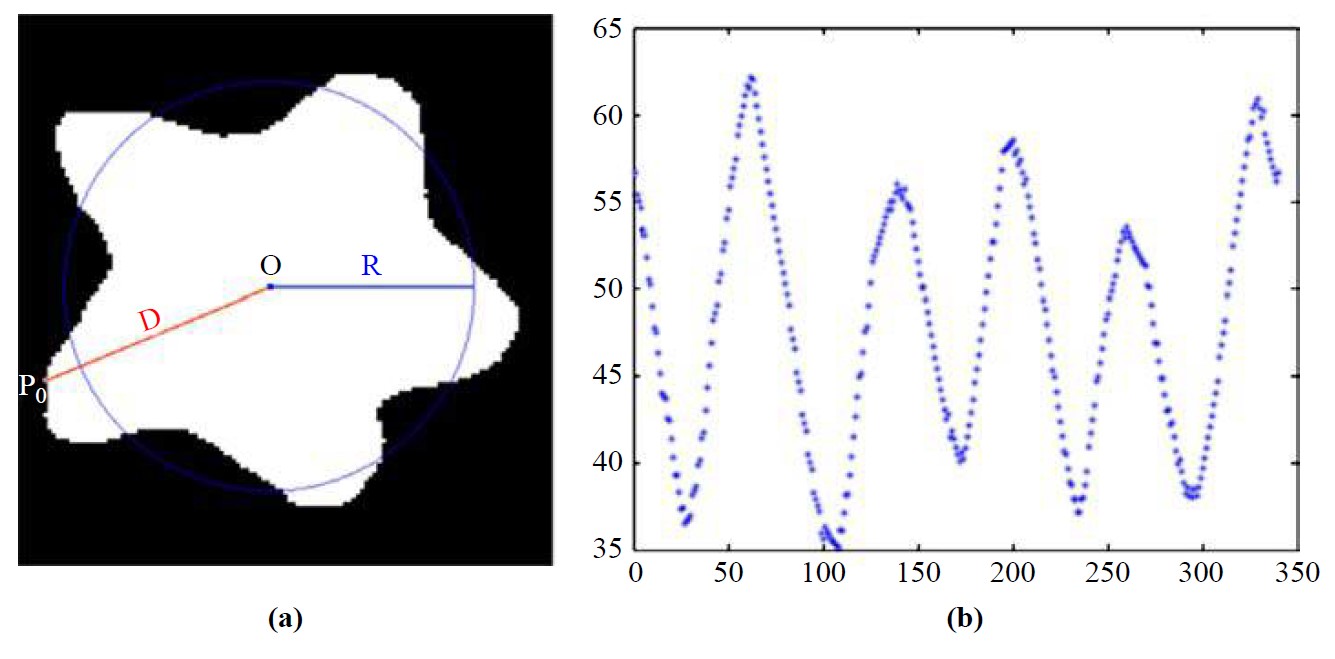

Our customized profiled fibers can be spun into monofilament, multifilament, staple fiber, fiber bundles, etc. according to customer requirements. - Profiled Fiber Analysis Service

Characterizing the cross-sectional shape of shaped fibers is an important part of quality control and performance design. In addition to conventional microscopy techniques, our technical team can perform shape analysis and quantitative characterization of fiber cross-sections with the help of image analysis techniques.

Boundary fluctuation curves of profiled fiber cross sections.

Characteristics

Compared with ordinary round fibers, profiled fibers often show advantages in the following aspects:

- Gloss

- Bulkiness

- Breathability

- Anti-pilling

- Abrasion resistance

- Water absorption

- Dyeability

- Porosity

- Specific surface area

Applications

Based on the above improved properties, in addition to the application in the field of clothing, the special-shaped fibers also show potential in the fields of water treatment, concentration separation, air purification and tissue engineering. For example, studies have shown that fiber cross-sectional shape affects the material’s specific surface area, wicking effect, protein adsorption and other properties, thereby regulating cell behavior and affecting tissue regeneration. Tissue engineering scaffolds can be constructed using grooved cross-section wicking fibers that help enhance cell proliferation.