Polyester High Tenacity Yarn (HTY)

A yarn containing filaments made from synthetic polymers has a cross-section having at least 5 vertices, a titer of 1 to 7 dtex, and a tenacity of at least 60cN/tex.

The filaments of the high tenacity yarn preferably have a cross-section having 5 to 8 vertices, possibly with indentations between the vertices. The cross-section of the filaments is preferably star-shaped. The high tenacity yarn preferably has a tenacity of 60 to 85 cN/tex, elongation at break of 15% to 35%, a hot-air shrinkage of 4% to 10%, and a stretch recovery of 250 to 400 cN/tex. High Tenacity yarn is also available in different variants like normal shrinkage, low shrinkage & super low shrinkage depending upon the suitable end-use. The high tenacity yarn is excellently suited for use in the manufacture of industrial fabrics, particularly airbag fabrics.

High tenacity yarns have been used in the manufacture of textiles, carpets & tarpaulin. In the manufacture of textile fabrics such as wovens, knitted and crocheted fabrics, and nonwovens from yarns containing synthetic polymer filaments, The most important consideration in the manufacture of these fabrics is the use of yarns with filaments having high tenacity and guaranteeing good foldability. The high tenacity yarns have high durability, toughness, and chemical resistance, and withstand extremely hot environments that can stress conventional multi-filaments to their performance limits.

High Tenacity Yarn

Starting from the high IV polymer, we can produce the high tenacity yarn with special properties to match with the specific usages. The range from this product group very coarse denier for industrial usages. The coarse denier high tenacity yarn is also suitable for the wide range of industrial usage. For example seat belt, convey belt, tire lining, construction, fishing net and safety net. We are able to produce denier range from 500de to 1500de and also black color yarn.

Because polyester has the following advantages in performance:

1) It has good moisture resistance and can maintain its strength after being damp, suitable for use in wet mines.

2) The modulus is high. When designing the conveyor belt, the safety factor can be lower than that of nylon.

3) The constant load elongation is small, the dimensional stability is good, and the conveyor belt tension stroke is small, eliminating the need for re-adjustment due to stretching deformation.

4) High impact resistance, so the tape has good strength and impact fatigue resistance.

Therefore, in the field of conveyor belts in recent years, the consumption of polyester industrial yarns has increased greatly. Especially in coal mine conveyor belts, most of them use conveyor belts with polyester industrial yarns as the core. Make this industry a major consumer of polyester industrial yarn.

High Tenacity Yarn (Finer Range)

Starting from the high IV polymer, we can produce the high tenacity yarn with special properties to match with the specific usages. The range from this product group starting from the fine denier for sewing thread. By the special drawing process, we can provide the high tenacity yarn with low shrinkage that suitable for making sewing thread both core spun Sewing Thread and Polyester Filament Sewing Thread. We are able to produce denier range from 44de to 300de and also develop to produce high tenacity from recycled raw material.

Applications

Automotive

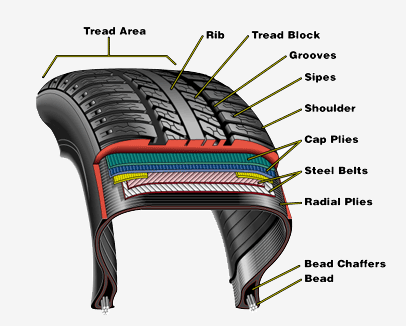

Tire Cord

Tire cords are used as reinforcing materials for tires, designed to keep tires in shape and to enhance durability. We produce Polyester tire cords for general tires. In order to achieve world-class quality, we continuously improve our quality management practices by ingenuous actions, we then enhance customers satisfaction by responding promptly to their demands. Also, Teijin Frontier has been promoting “Eco-minded Adhesive” for Rubber Reinforcing Fiber that does not use resorcinol-formaldehyde (RF) but still achieves the same level of performance as conventional methods.

Car Seat Belt

Seat belt is a vehicle safety device designed to secure the occupation of a vehicle against harmful movement that may result during a collision or a sudden stop. Seat belt functions to reduce the likelihood of death or serious injury in a traffic collision by reducing the force of secondary impacts with interior strike hazards, by keeping occupants positioned correctly for maximum effectiveness of the airbag and by preventing occupants being ejected from the vehicle in as crash or if the vehicle rolls over. TEIJIN Tetoron has long history to be applied to seat belt by its reliable properties

Industry

Fishing Net

All nets must be strong enough to withstand the impact of schools of fish and water pressure, falling tools and people, balls, etc. as well as be able to absorb the impact so as not to hurt or damage whatever they catch. They must also be highly resistant to weather and abrasion since they are mainly used outdoors. By using special polyester that has a higher stretch property than regular polyester, nets highly superior in impact absorption have been manufactured.

Rope

Ropes are used in a variety of ways as hawser for mooring ships, safety lines at construction sites, and in fishing nets such as purse seines, set nets, and trawl nets. They are also used in diverse areas such as electricity, communications, machines, and sports and are available from 3 mm to 150 mm in diameter. Although the raw material used in their making differs according to the required functions, Teijin Tetoron polyester stands out for its many advantageous properties.

Fire Hose

The fire hose is indispensable to enter and move around in a burning structure and to instantly put out fires. To speedily and effectively extinguish fires, various requirements such as ease of use and durability must be met. A special machine to make fire hoses is used to coat the interior and exterior of the tubular woven material with resin.

Webbing Belt

The sling belt is very important in transporting and loading goods as well as in construction and civil engineering work. Belts for general industrial materials such as the lashing belt and others, which are utilized in pallet transportation among others, are widely used in diverse ways especially in the distribution industry.

Sail Cloth

Sail cloths are used for catches the wind and uses it as forward thrust. Our polyester fibers with exceptional durability. So our yarns are perfect material for marine sport textiles. It is used as a material for Sail Cloth and sports kites.

High tenacity yarn with low shrinkage which are stronger and have excellent sew ability that suitable for making sewing thread, both core spun Sewing Thread and Polyester Filament Sewing Thread.

Polyester Mono Yarn (PMY)

Mono Filament Yarn can be made by direct spinning or by splitting Mother yarn. Due to its very good resistance to fuels and chemicals, this type of monofilament is mostly used in the production of filter fabrics for automotive use. Other features of this resin are high stiffness, high mechanical strength even at very low temperature, low water absorption, and good dimensional stability at high temperatures.

Polyester Mono Yarn is also known as single polyester yarns, mother yarn for splitting. Monofilament yarn has a soft touch and good physical properties. Polyester filament yarns are used in knitting & weaving to make a design on frocks & home-textiles and making of webbings. A yarn containing the categories & available in 20D/1, 30D/1, 40D/1, 50D/1 for both Raw white & dope dyed monofilaments. Mono yarn has variations as Semi Dull, Bright Dope Dyed Monofilaments.

The Mono-Filament yarns have high durability, toughness, and chemical resistance.

Production processes of polyester monofilament

The main production processes of polyester monofilament mainly include one-step production process and two-step production process. Among them, the use of high-speed spinning and high-speed stretching and twisting technology is a typical two-step process route, and is currently the most used process route for the production of polyester monofilaments. It is characterized by short process flow and high production efficiency. The spinning speed of high-speed spinning is 3000~600m/min, and pre-oriented yarn (POY) can be obtained. At high winding speeds, the fibers have a certain degree of orientation and the structure is relatively stable. Stretching and twisting is an indispensable process in the production of polyester monofilament, which is called secondary molding. Stretching makes the structural units of the fiber obtain a stable and stable orientation, thereby achieving the purpose of improving the physical and mechanical properties of the finished fiber.

One-step production of polyester monofilament technology uses 8, 10 or 12-hole spinnerets to complete spinning forming, nascent fiber draft orientation, fiber heat setting and winding on the same machine at one time. The monofilament is obtained on the silk cake. After the wound monofilament cake is split by a splitter, a polyester monofilament fiber is obtained.

Polyester Embroidery Thread

Polyester sewing thread is mainly used in sewing all kinds of fabric used for making clothes, bags, dresses, curtains & much more. Polyester Embroidery thread is used for doing embroidery in clothes to fulfill the demands for cheap embroidery work as polyester embroidery thread is priced much lower than viscose embroidery thread which is mainly used in Embroidery works.

Polyester Sewing Thread is made from Polyester Spun yarn & is available in counts like 40/2, 42/2, 45/2, and so on. Whereas Polyester Embroidery Thread is made from Polyester FDY available in various colors and twists like 120/2, 150/2, and so on. Since these are strong fibers, they are resistant to any kind of fraying or breaking. They have founded uses for applications like children’s wear, linens used for commercial purposes in hotels & restaurants, for manufacturing carry bags, kitchen linens, throw rugs & Blankets. Embroidery thread is commonly available in two ply. Polyester embroidery thread is available in various colors known as dyed/colored embroidery threads.

VNPOLYFIBER is proud to have connection and business relationship with some of the biggest manufacturers in China’s polyester industry, specialized in PTA with annual capacity of 5 million MTS, polyester staple fiber (PSF) with annual capacity of 1.2 million MTS and polyester filament yarns including partially oriented yarn (POY), fully drawn yarn (FDY) and drawn texturized yarn (DTY) with annual capacity of 6.3 million MTS. The total annual capacity is 12.5 million MTS.

It is equipped with the world’s state-of-the art technology and machines including Dupont and TMT and Neumag and Barmag,

It has been exporting to more than 90 countries and regions since the year of 2004 with excellent qualtiy and customer service.

Below is the list of product offered by our partnership. Please do not hesitate to contact us for a quote now!