What is polyamide?

Polyamides are among the most important engineering thermoplastics but are also processed into fibers in very large quantities. Polyamides are tough materials that are characterized by high strength and elongation. Good abrasion and wear resistance as well as water-repellent properties permit many applications, especially in the clothing industry. Best known are Nylon tights, technical fabrics for outdoor textiles or balloon and parachute lines. Various derivatives of the polyamide molecule increase the utility value depending on the requirements for temperature, strength, and elongation.

Polyamide 6

Features: Softness, bulkiness, antistatic, tensile strength

Spinning: Cotton, worst, wool spinning, Garments, Uniform, Dress, Interior, etc.

Non-woven: Needle punching non-woven, Synthetic leather, Interlining, Felt, etc.

Nylon

Nylon staple fiber can be produced hydrophilic or hydrophobic with spinning and drawing technologies. We are also producing Nylon dope dyed staple fiber, which has uniform and clear color.

– Denier: 1.5 ~ 3.0 denier

– Length: 38, 51, 64 mm, VCL

– Capacity: 600 ton/month

– Color: White, Black, Gray

– Packing weight: 250kg/bale, dope dyed : 200kg/bale

| Purpose | Denier | length | Luster | Application | Feature |

|---|---|---|---|---|---|

| Spinning (cotton, woolen, worsted) | 1.5, 2.0 | 38, 51, 64, VCL | SD | Garment, dress, uniform, etc. | Excellent softness Bulkiness Good opening Antistatic Tensile strength |

| Nonwoven (needle punch, thermal bond) | 1.5, 2.0, 3.0 | 38, 51 | SD | Artificial leather, ball, shoes, interlining, felt, carpet, etc. |

Recycled Nylon Fabric

Recycled nylon, also known as nylon return material, is generally produced by smelting and granulating nylon yarn, nylon filament or nylon fabric.

Advantages

- Recycled nylon has good abrasion resistance, heat resistance, oil resistance and chemical resistance, and also greatly reduces the water absorption and shrinkage rate of raw materials, and has excellent dimensional stability and excellent mechanical

Nylon SF (for spinning)

Nylon SF is characteristically soft and strong, and can supplement, substitute, or mix with natural wool. It addresses wool’s weaknesses, increasing productivity and reducing the cost of worsted-spinning manufacturers. Nylon SF can be found in everyday items in the form of cotton roving, woolen, and angora.

– Benefits

1. Soft texture

2. Durable

3. Temperature-resistant

4. Elastic

– Applications

Cotton roving, worsted spinning, woolen

Uniforms, apparel

| Denier | Fiber length | Sheen | Note |

|---|---|---|---|

| 1.5, 2.0, 3.0 | 38, 51, 64 | SD | Hydrophilic, hydrophobic |

Nylon SF (for non-woven fabric)

Nylon SF can be used to make high-density non-woven fabric by blending with PET. The resulting product is referred to as a needle-punching non-woven fabric, which is used to manufacture synthetic leather. It can be treated with hydrophilic oil if PU coating is required.

– Benefits

1. Soft texture

2. Durable

3. Temperature-resistant

4. Elastic

– Applications

Non-woven fabric, interlining, felt, synthetic leather

Car Interiors: Car mats/carpet

| Denier | Fiber length | Sheen | Note |

|---|---|---|---|

| 1.5, 2.0, 3.0 | 38, 51, 64 | SD | Hydrophobic, Hydrophilic |

Dope-dyeing (for carbon-black)

Dope-dye chips in a variety of colors can be mix-spun in polymer form using the master batch method to achieve vibrant and consistent colors that stay. Blackness and colorfastness are superior to those achieved with post-dyeing. Dope-dyed fiber can be mix-spun with other fibers to achieve a wide array of colors.

– Benefits

1. Semi-permanent colors and colorfastness

2. Vibrant and consistent colors

3. Mix-spin results in a variety of colors

– Applications

Apparel, upholstery

Car interior: Car mats/carpet

| Denier | Fiber length | Sheen | Color | Note |

|---|---|---|---|---|

| 1.5 | 38 | SD | Gray, black | for spinning |

| 1.5, 2.0, 3.0 | 38, 51, 64 | SD | Gray, black | for non-woven fabric |

| Sheath | Core |

|---|---|

| PE | PP |

| PE | PET |

| Air-through bonding, Thermal bonding non-woven | |

| Hygiene products; Top sheet, ADL sheet | |

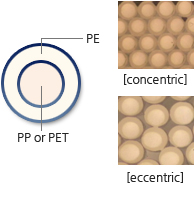

Bi Component Fiber

Bi-component staple fibers are produced by bi-component spinning technologies, which are made of two different polymers with sheath/core structure.

PE/PP or PE/PET staple fibers are suitable for nonwoven processes of hygiene products.

– Material: PE/PP, PE/PET

– Denier: 1.5 ~ 7.0 denier

– Length: 38, 51, 64 mm

– Capacity: 800 ton/month

– Packing weight: 220 kg/bale

– Melting point: PE 130 ℃, PP 160 ℃, PET 260℃

| Sheath/Core | Denier | length | Luster | Nonwoven processing | Feature | Application |

|---|---|---|---|---|---|---|

| PE/PP | 1.5, 2.0, 5.0 | 38, 51 | SD, FD | – Carded thermal bond, – Carded air-through bond | – High-loft – Soft touch – Excellent bulkiness – No harm to skin – Water-absorptive – hydrophilic – hydrophobic | Disposable diaper, feminine napkin, wet tissue, pad, wiper, medical mask, etc. |

| PE/PET | 1.5, 2.0, 5.0 | 38, 51 | SD, FD |

Bi-component compound fiber (for heat-sealing)

Bi-component compound fiber is a compound-spun fiber made from PE and PP, or PE and PET sheath-core. A low-melting-point polymer (PE) acts as the sheath and a high-melting-point polymer (PP or PET) as a core in the making of heat-sealing non-woven fabric. Heat-sealing requires no chemical adhesive due to the low fusion point of the low-melting-point fiber, allowing for an eco-friendly and biologically safe product.

– Benefits

1. Soft texture

2. Bulkiness

3. Water absorption

4. Adhesion at low temperatures

5. Eco-friendly

– Applications

• Personal Hygiene: Diapers, sanitary pads

• Medical: Masks, clothing

• Industrial: Wipes, filters, packaging

| Product | Denier | Fiber length | Sheen | M.P | Note |

|---|---|---|---|---|---|

| PE/PP | 1.5, 2.0, 5.0 | 38, 51 | SD,MD,FD | 130/160’C | hydrophobic |

| PE/PET | 1.5, 2.0, 5.0 | 38, 51 | SD,MD,FD | 130/260’C | Hydrophilic |

Mono filament (PET, NYLON-6, NYLON-66, PBT)

Mono filament is made of a single filament. We are producing NYLON, PET, PBT mono filaments, which look similar but depend on material and diameter, these filaments have various purposes of various applications. Our filament features long-term preservation of transparency and flexibility, especially tensile strength.

A LINE – NYLON6, NYLON66, PET

Capacity : 40 ton/month

Packing : Bobbin type

Application : fishing line, velcro, mesh, filter, industrial weaving

B LINE – PBT BUNDLE

Capacity : 12 ton/month

Packing : Bundle type

Application : cosmetic brush, toothbrush, industrial brush

| Raw material | Diameter (mm) | Dope dyed | Applications |

|---|---|---|---|

| PET mono | 0.10mm ~ 0.32mm | All colors | Weaving, industrial use |

| N-66 mono | 0.15mm, 0.20mm | All colors | Velco, mesh |

| N-6 mono | 0.23mm ~ 0.32mm | All colors | Fishing line, net |

| PBT mono | 0.07mm ~ 0.23mm | All colors | Cosmetic brush, toothbrush |

PBT mono-filament

Straight fiber is elastic and soft, and used to make foundations brushes, eyeshadow brushes, eyeliner brushes, and false eyelashes. Wave-powder fiber, due to its natural wave, distributes make-up evenly and is ideal for making powder brushes.

– Benefits

1. Soft texture

2. Soft texture

3. Elasticity

– Applications

• Makeup brushes: Powder brush, eyeliner brush, false eyelashes

• Art Brushes: Stationery, painting brush

• Toothbrushes: Single bristles, double bristles, colored bristles, special bristles (gold, silver, charcoal, jade)

| Diameter | luster | Note |

|---|---|---|

| 0.07~0.23 | SD, FD, FDP, S-BRT, BRT, BRT-Y, DOPE DYED | Single bristles, double bristles, colored bristles, special bristles (gold, silver, charcoal, jade, anti-bacterial) |

PET mono-filament

– Benefits

1. Good for dope-dyeing and post-dyeing

2. Durable and elastic

3. Supreme colorfastness when dope-dyed

4. Form recovery

5. No wear on finished products

– Applications

• Cello tape, Velcro, ribbons, makeup brushes, hair pieces, toothbrushes, cars (tire/handbrake bristles), cushions

– Product Applications

• Textiles: Clothing, bag, shoes, Velcro, socks

• LOPE: Shoes, bag, camera, fishing gear

• Accessories: Ribbon, lace

• Tailor: Shoes, clothing, spangle

• Base Fabric: Hats, clothing

| Diameter | Sheen | Note |

|---|---|---|

| 0.10~0.32MM | BRT, SD | ALL COLORS |

Nylon mono-filament

Nylon 6 and Nylon 66 are available. Nylon 6 is mainly used to make fishing nets. Nylon 66 has a wide range of applications, including clothing. Items made with Nylon 66 are durable and flexible. Nylon 66 is a mono-filament product made with Donghae Industry’s exclusive technology.

– Benefits

1. Soft texture

2. Smooth texture

3. Elasticity

– Applications

• Fishing nets, scooping nets

| Diameter | Sheen | Note |

|---|---|---|

| 0.104~0.570MM (no. 0.4~12, 100) | BRT, SD | ALL COLORS |