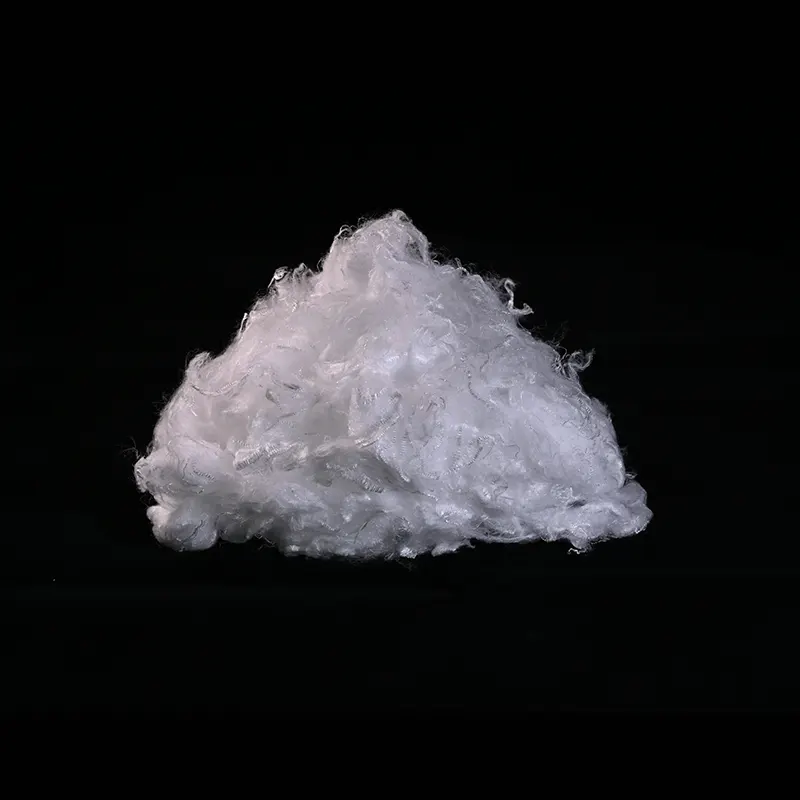

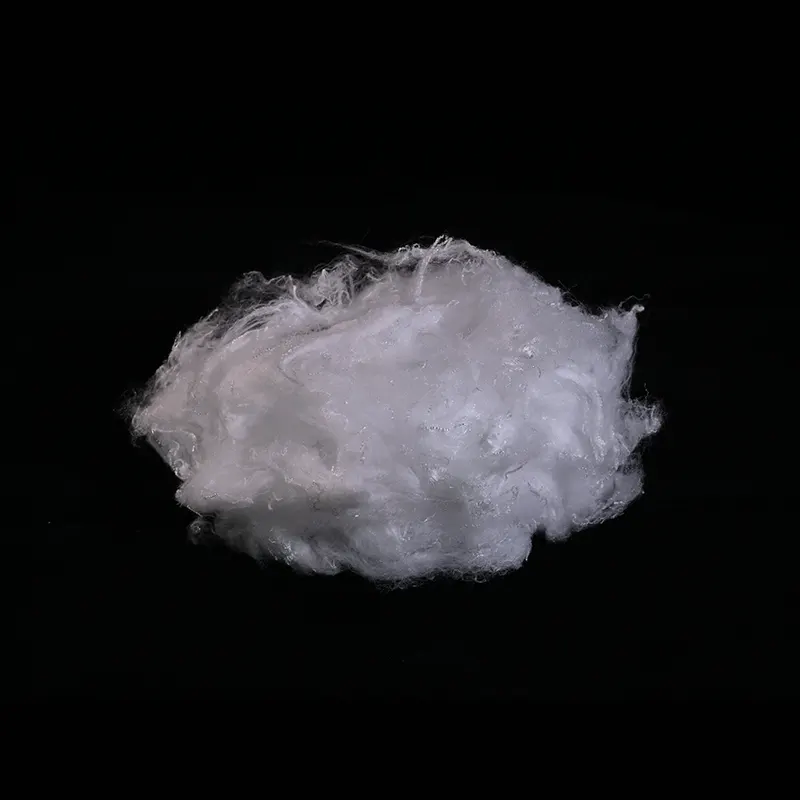

Mono PP fiber

What is Polypropylene (PP)?

Polypropylene (PP): It is a thermoplastic polymer, known for its versatility, chemical resistance, and durability. It is one of the most commonly used plastics in the world, found in everything from packaging materials to automotive parts and textiles.

Characteristics of PP:

- Lightweight: PP has a low density, making it lightweight compared to many other synthetic fibers.

- Chemical Resistance: Resistant to many chemicals, including acids, bases, and solvents, which makes it suitable for various industrial applications.

- Durability: PP fibers are known for their toughness and resistance to abrasion.

- Hydrophobicity: PP is inherently hydrophobic, meaning it repels water, which can be an advantage in certain applications.

- Thermal Stability: PP has good thermal resistance and can maintain its properties over a wide range of temperatures.

Polypropylene staple fiber is made from polypropylene by one-step short – distance spinning process.

The advantage of polypropylene is light texture, its density is only 0.91g/cm3, is a common chemical fiber of extremely light density varieties, the same weight of polypropylene than other fibers to obtain a higher coverage area, so it is an ideal raw material for automobile interior.

Mono PP fiber refers to a fiber made exclusively from polypropylene, without blending with other materials. The term “mono” emphasizes that the fiber is made from a single material (polypropylene) rather than a composite or blend.

Mono PP Fiber for Thermal Bond. It is an ideal fiber for thermal bonding nonwoven fabrics which are widely used for car industrial,decoration etc

By different processing technical,PP stable fiber can be converted into thermal bond nonwovens(mainly by calendar),its widely be used in hygiene market,such as babycare,femicare and wipes etc.It has a high elongation which is needful feature when in calendar process.Spin finish available with both hydrophilic and hydrophobic.

Characteristics of Mono PP Fiber:

- Strength and Elasticity: Mono PP fibers are strong and exhibit good elasticity, making them suitable for various applications that require durability and some degree of flexibility.

- Low Moisture Absorption: Due to its hydrophobic nature, mono PP fiber absorbs very little moisture, which is useful in applications where moisture resistance is important.

- Chemical Resistance: Mono PP fibers are highly resistant to a wide range of chemicals, including most acids and alkalis, making them ideal for use in harsh chemical environments.

- Lightweight: The low density of polypropylene makes mono PP fibers lighter than many other synthetic fibers, which is beneficial in applications where weight is a critical factor.

- Cost-Effective: Polypropylene is relatively inexpensive to produce, making mono PP fibers a cost-effective option for various industrial and consumer applications.

Applications of Mono PP Fiber:

- Nonwoven Fabrics: Widely used in nonwoven textiles, such as in disposable hygiene products (diapers, sanitary napkins), medical textiles (surgical gowns, masks), and filtration materials.

- Geotextiles: Used in civil engineering applications like road construction, erosion control, and soil stabilization, due to their durability and resistance to chemicals and moisture.

- Automotive: Employed in automotive interiors for seat covers, carpets, and soundproofing materials, thanks to their durability and resistance to wear and tear.

- Packaging: Used in packaging materials, particularly in strapping and tying products, where strength and resistance to environmental factors are crucial.

- Carpets and Rugs: Mono PP fibers are often used in the production of carpets and rugs, especially in outdoor settings, due to their resistance to moisture and mildew.

Advantages of Mono PP Fiber:

- Environmental Resistance: Excellent resistance to moisture, chemicals, and environmental stress.

- Cost-Effective: Affordable production and raw material costs make it an economical choice.

- Versatility: Suitable for a wide range of applications, from industrial uses to consumer products.

Product Technical Specifications

Standard TDS of 3den 51mm Standard Mono PP Fiber for Thermal Bond

Fiber denier: 3dn ~ 18dn,

Main cut length: 38mm/51mm/76mm/102mm

Luster: raw white

Spin finish: standard finish

Pigment available: black/blown/blue/yellow etc

| Characteristic | Unit | Min | Max | Test Method | Remark |

| Linear Density | dtex | 3.33 | 3.67 | GB/T14335-2008 | |

| Cut length | mm | 50 | 52 | GB/T14336-2008 | |

| Tenacity at peak | cn/dtex | 2.8 | 3.4 | GB/T6504-2017 | |

| Elogation at peak | % | 220 | 320 | GB/T14337-2008 | |

| Crimp n. | n./inch | 15 | 18 | GB/T14328-2008 | Adjustable |

| Spin finish | % | 0.3 | 0.4 | GB/T6504-2017 | Adjustbale |

Standard TDS of 2den 38mm Standard Mono PP Fiber for hygiene

Fiber denier: 2dn~ 6dn

Main cut length: 38mm/51mm

Luster: raw white,full dull

Spin finish: standard hydrophilic,durable or hydrophobic

| Characteristic | Unit | Min | Max | Test Method | Remark |

| Linear Density | dtex | 2.2 | 2.46 | GB/T14335-2008 | |

| Cut length | mm | 37 | 39 | GB/T14336-2008 | |

| Tenacity at peak | cn/dtex | 2.0 | 2.4 | GB/T6504-2017 | |

| Elogation at peak | % | 350 | 320 | GB/T14337-2008 | |

| Crimp n. | n./inch | 15 | 18 | GB/T14328-2008 | Adjustable |

| Spin finish | % | 0.3 | 0.4 | GB/T6504-2017 | Adjustbale |

Product Production Diagram

These fibers are produced by melting polypropylene pellets and then extruding them through spinnerets to form fine, continuous strands of fiber.

Conclusion:

Mono PP Fiber is a versatile and cost-effective material with a wide range of applications. Its combination of strength, chemical resistance, and lightweight properties make it particularly valuable in industries such as nonwoven textiles, geotextiles, automotive, and packaging. Its hydrophobic nature and durability further enhance its suitability for applications where moisture and chemical resistance are essential