What is Lyocell fiber ?

Lyocell staple fiber has excellent wearability, mechanical properties and processing properties. It is widely used in home textiles, underwear, infant products, clothing, apparel, fabrics, sportswear, tooling, masks, wet wipes, flocking, hygiene materials, medical materials , Precision instrument wipes, special paper, food packaging, industrial filter materials, etc. Can be pure spinning, blended spinning. Blended, interwoven or compounded with cotton, linen, silk, wool and other natural fibers, synthetic fibers, regenerated cellulose fibers, etc., give the fabric a softer and more comfortable skin-friendly feel and diverse styles, and improve the ease of playability of the fabric. It is suitable for various spinning such as ring spinning, compact spinning, Siro spinning, compact Siro spinning, vortex spinning, and rotor spinning. It can be woven, knitted, non-woven and other forms of weaving.

Lyocell staple fiber is made of high quality renewable wood pulp with a new non-toxic and harmless organic solvent,which can not cause pollution to environment, and can be recycled and used again. Cellulose first dissolves then precipitates in organic solvent, so its production process is a physical process and no chemical reaction occur. It belongs to “green manufacturing”. Lyocell staple fiber can be natural degraded or burned into carbon dioxide and water after use and is a environment friendly fiber.

Lyocell staple fiber has not only the characteristics of natural fiber it self such as hygroscopic property, breathability, comfortable property, glossiness, easy dyeing and biodegradability but also good strong stretching property, can be blended easily with other natural fibers and synthetic fibers. It has high wet strength, especially the wet strength is obviously better than that of viscose staple fiber. The fabrics containing lyocell fiber have the comfort of cotton, drape of viscose, strength of the polyester and hand feeling of silk and are suitable for underwear and outwear and also have excellent performance of after -treatment and size stability, coloring, dyeability and washing color fastness. Lyocell staple fiber is a true green fiber. Baoding Swan Fiber Co., Ltd. Is China’s first large-scale lyocell enterprises.

Lyocell staple fiber uses natural, renewable wood pulp as raw material, the whole production process is environmentally friendly,It belongs to “green manufacturing “.Lyocell staple fiber can be natural degraded,coming from and returning to nature .

Lyocell staple fiber has many characteristics, such as a good wet absorption, excellent dry and wet strength, high initial modulus, low shrinkage in water and good dimension stability.

Lyocell staple fiber brings together the advantage of natural fiber and synthetic fiber, with cotton’s comfort,viscose’s drapability,polyester’s strength, wool’s crispy handle and silk’s feel.Made from natural element,but better than natural products.

Normal lyocell staple fiber is easy to be fibrillated, which can make the fabric surface produce a peach skin, sand washing, velvet and other special effects.

Crosslinked lyocell staple fiber is anti-fibrillated, a feature which can make the fabric have a soft hand feeling, good drapability, excellent wet absorption, wearing comfort and so on.

Crosslinked lyocell staple fiber is usually used for knitting sweater, etc.

Lyocell staple fiber has a smoother fiber structure than cotton, with cotton’s comfort, which can make skin feel cool, smooth, dry comfort.

Smooth drapability

Lyocell staple fiber with drapability of viscose and strength of polyester, Lyocell staple fiber has a character of good drapability, fast dry, wrinkle-free and easy care. Warm touchness

Lyocell staple fiber with wool’s crispy handle, Lyocell staple fiber has a fine ad smooth hand feeling, softness, and plump, fluffy in texture.

Exquisite luster

Lyocell staple fiber has the same hand feeling as silk, it’s smooth and has a soft luster, which can give you a second skin feeling.

| Variety and specification | |||

| Variety:1)normal staple fiber :2)crosslinked staple fiber. | |||

| Specification : as the following list | |||

| nominal titre /dtex | staple length /mm(adjustable) | ||

| 1.4 | 38-80 | ||

| 1.67 | 38-80 | ||

| Performance index | |||

| No | Item | normal | crosslinked |

| 1 | Dry breaking strength(cN/dtex)≥ | 3.5 | 3.3 |

| 2 | Wet breaking strength(cN/dtex)≥ | 3.05 | 2.85 |

| 3 | Dry elongation at break%≥ | 14.0 | 12.0 |

| 4 | Wet modulus(cN/dtex5%)≥ | 0.95 | 0.95 |

Application

Lyocell staple fiber has a wide application in high-grade jeans,women’s underwear, shirts, casual clothing, knitting sweater, home textiles, high grade filter material,non-woven fabrics etc.

The antibacterial lyocell fiber is produced with a special biological antibacterial agent, which has no irritation to the skin and is skin-friendly and comfortable. After 50 times of washing, the fiber has excellent antibacterial properties against Staphylococcus aureus, Escherichia coli and Candida albicans, and has long-lasting antibacterial properties. It is used for underwear, infant products, health care products, facial masks, wet wipes, medical sanitary materials, and medical dressings. The fiber material for antibacterial products.

Flame retardant lyocell staple fiber is produced with environmentally friendly flame retardant, with excellent flame retardant performance and long lasting. As a heat-insulating, flame-retardant protective fiber, it has the advantages of high strength and high modulus, skin-friendly and comfortable, flame-retardant without melting, and no secondary hazards. It is a new generation of flame-retardant cellulose fiber. Used in hospitals, nursing homes, cinemas, conference rooms, entertainment venues, hotels, restaurants and other public places such as textile products, home textiles and soft furniture, transportation interior materials, fire protection, welding, smelting and other special operating areas, soft protective equipment, military police National defense supplies such as combat uniforms, etc.

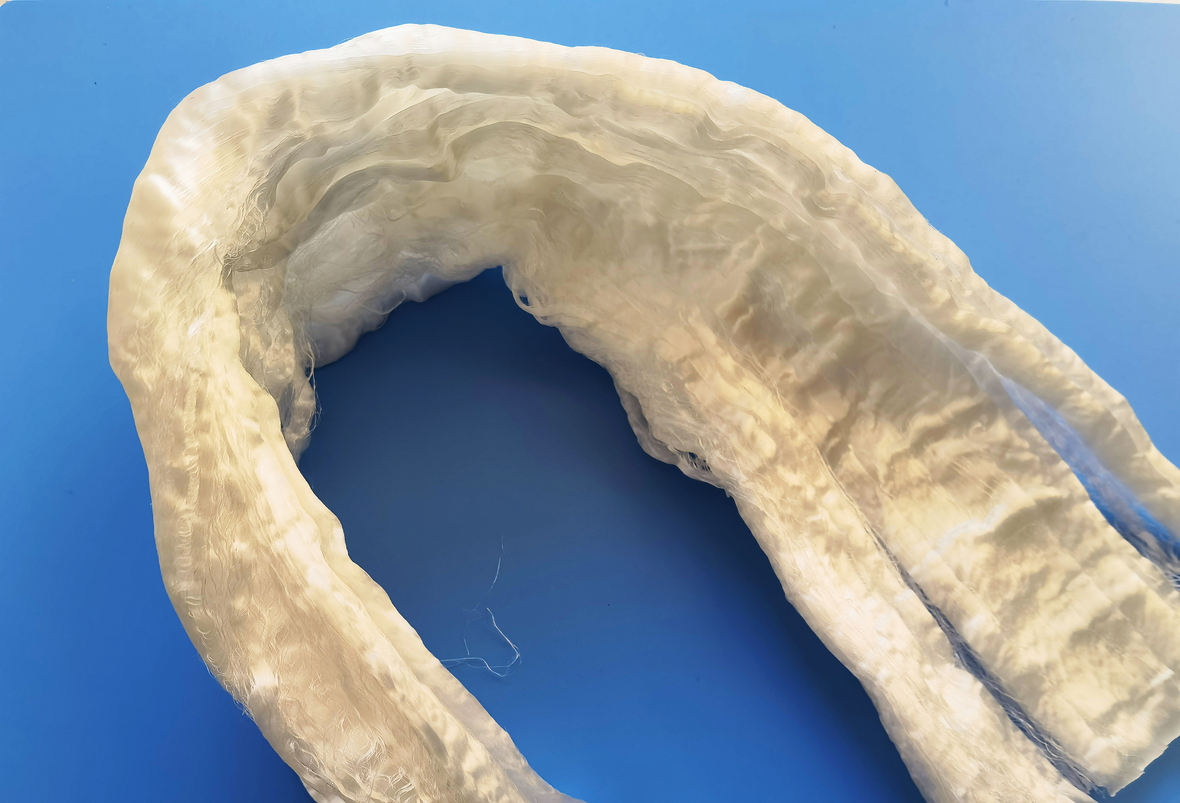

Lyocell fiber tow has excellent physical properties, easy to cut, and processed into short fibers of different lengths for the weaving of non-woven fabrics and flocking products. Main specifications: monofilament fineness 1.20~2.20dtex, total tow fineness 2.6~4.8 million dtex.

The fine-denier lyocell staple fiber is slender, and its fabric is softer and more delicate. Blending with natural fibers and synthetic fibers can make the fabric more soft and comfortable to wear. It is a excellent raw material for underwear, high-end clothing and home textile fabrics, facial masks, and health care products.

Cross-linked lyocell staple fiber has excellent wet processing performance, soft and comfortable fabric, smooth and bright, uniform dyeing, bright color, suitable for the production of high-end knitted apparel and fabrics. Cross-linked and semi-cross-linked lyocell staple fiber products can be produced according to user needs. It is produced with environmentally friendly cross-linking agent, which effectively controls the fiber fibrillation problems of lyocell fiber fabric fuzzing and pilling.

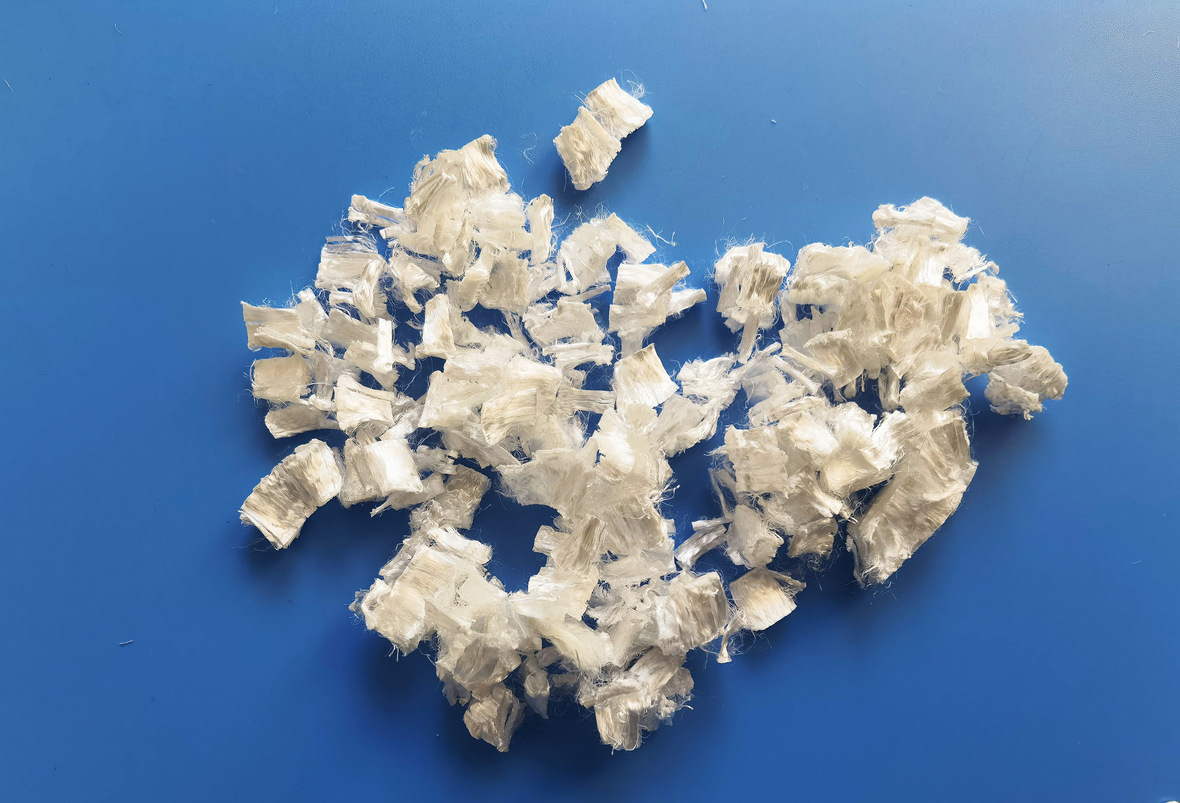

Chopped Lyocell Fiber is widely used in the production of non-woven products such as wet tissues, health care products, beauty care masks, baby products, medical dressings, flushable tissues, facial tissues, tea bags, battery separators, and fillers. Flushable non-woven products produced with lyocell fibers for sanitary materials. The fibers have good tensile strength, can be quickly washed out when discarded and washed, and can be biodegraded in the natural environment.