Differences between cotton and polyester staple fiber

COTTON

Cotton is produced from the cotton plant, the cotton fiber taken is from the flower of the plant itself.

This cotton plant itself has the same family with kapok tree that is Malvaceae but has a different genus that is Gossypium.

Cotton flowers begin to bloom when cotton plants are 35-45 days old, while the time required from the point of flowers to bloom takes 25 days.

Cotton fibers have an empty space in the center of the fiber, usually called lumen. When cotton flowers bloom and dry, the lumen will make the fibers shrink so that the fibers become twisted.

Naturally cotton has hydrophobic properties (can not absorb water), the wax layer on the cotton fiber must be removed first to make the cotton that can absorb water.

The use of cotton as a clothing material has been known since 5000 BC, this fact known from the discovery of pieces of cloth made of cotton in Mexico, predicted to come from that year.

Since then, cotton is widely used for various things such as for fabrics, clothing, stuffing pillows, stuffing bolsters, stuffing dolls, furniture and others.

But in the present era the use of cotton began to decrease, because it has been discovered, how to make polymers / synthetic fibers from plastic. Here we will discuss about fiber from polyester.

POLYESTER STAPLE FIBER

Polyester staple fibers are synthetic fibers that generally made from PET plastic.

This polyester has thermoplastic properties that can be melted by fire and re-formed (recyclable). Generally these fiber have no empty space inside, can be produced as tow fiber or cutted with a certain length (if cutted, called polyester staple fiber).

Polyester fiber is a synthetic fiber derived from spinning polyester polycondensated from organic dibasic acid and diol. It is commonly referred to as polyester and is extensively used in clothing fabrics due to its excellent wrinkle resistance, elasticity, dimensional stability, insulation properties, and versatility for individuals of all ages.

The high strength and elastic recovery of polyester fiber make it durable, wrinkle-resistant, and easy to care for without the need for ironing. It also boasts good light resistance, comparable to acrylic fiber and superior to natural fiber fabrics, particularly when placed behind glass. Additionally, polyester fabric exhibits resistance to various chemicals, with little damage from acids and alkalis, and is resistant to mold and moths.

In the current market, polyester fiber sunlight fabric is gaining popularity. This fabric offers a variety of outstanding features including sunshade, light transmission, ventilation, heat insulation, UV protection, fire resistance, moisture resistance, and easy maintenance. It is a highly regarded fabric for modern clothing manufacturing and is favored by many individuals.

These polyester fibers are now commonly used as cotton substitutes because they are easy to produce and less expensive than cotton.

It just has weaknesses that are not easy to absorb water (there are also polyester fibers that can absorb water where the manufacturing process is different, generally fiber with denier under 1D or called microfiber is made in such a way that can absorb water (eg microfiber towel).

All materials from polyester fiber can be washed by washing machine and dried by washing machine.

Use warm water and give the softener at the end of the washing process. When drying do not use high temperature so that polyester fiber does not melt, if you want to iron the fiber use low temperature.

All clothes from polyester fiber material can be washed dry.

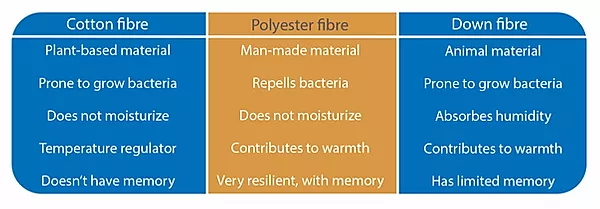

Which one is better, polyester fiber or cotton?

There are varying opinions on the benefits of cotton versus polyester fiber. While some believe cotton is a superior fabric, others argue that polyester is more environmentally friendly. Both materials are used to create different types of clothing, each with its own unique characteristics.

Polyester, also known as polyester fiber, is commonly used in sportswear due to its durability.

The advantage is that it is strong and wear-resistant, has a certain stiffness, is easy to wash and dry, has good color fastness, does not fade or shrink. In the 1980s, it was true that blended polyester fabrics were popular.

However, it is not as breathable as cotton and can feel stifling.

Fear of sparks, impermeable to air, it will become translucent when wet, the fabric will shine in the rubbed areas, and the thermal insulation performance is poor.

In today’s environmentally conscious world, autumn and winter fabrics are often made from polyester, though it may not be the best choice for underwear due to its breathability issues and lower production cost compared to cotton. It is important to use neutral or acidic detergents when cleaning polyester, as alkaline detergents can damage the fabric. Additionally, polyester fabrics do not typically require ironing, as they do not wrinkle as easily as cotton when exposed to water.

On the other hand, cotton is alkali-resistant and can be easily cleaned with standard laundry detergent. It is a breathable fabric that absorbs moisture and allows for perspiration to evaporate. Cotton is often preferred for children’s clothing due to its comfortable nature.

Polyester clothing offers a variety of benefits, including its stiffness, moisture absorption, breathability, resistance to deformation, durability, ease of cleaning, and vibrant color. Additionally, it has high strength and elastic recovery capabilities, making it long-lasting, wrinkle-resistant, and easy to maintain. Furthermore, polyester fabric has superior light fastness, particularly when compared to natural fiber fabrics, especially when placed behind glass.

In order to capitalize on the strengths of both materials, it is common to blend cotton and polyester in varying ratios to achieve the desired qualities in clothing.

Overall, both cotton and polyester have their own advantages and uses, and it is important to consider the specific characteristics of each fabric when choosing the right material for your needs.