Difference between Nonwoven Fabrics and Woven Fabric and Knit Fabric

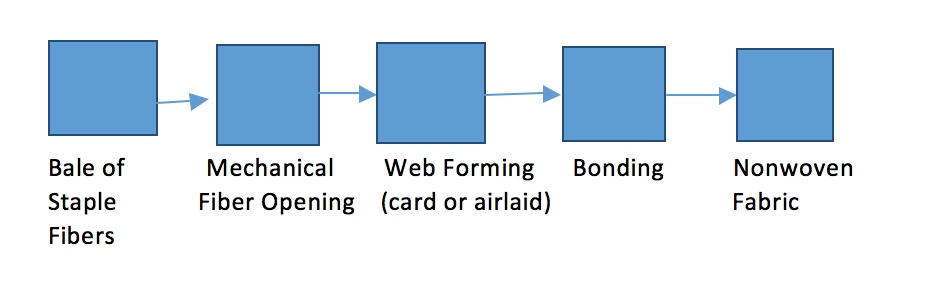

Production of Nonwoven Fabrics from Staple Fibers

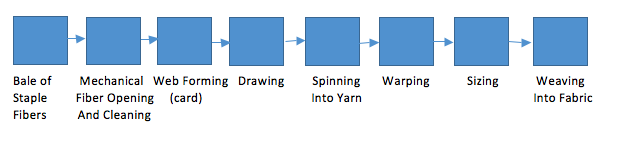

Production of Woven Fabrics from Staple Fibers

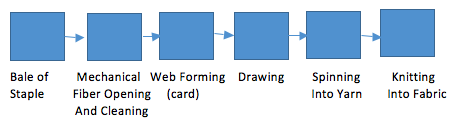

Production of Knit Fabrics from Staple Fibers

As you can see from the diagrams, producing nonwoven fabrics has fewer steps than woven or knit fabrics. Also, the production speed for making staple fiber nonwoven fabrics is much faster (100 to 400 yards per minute) than woven fabrics (0.5 to 6 yards per minute) and knit fabrics (2 to 16 yards per minute). Because of the higher speeds and reduction of steps, nonwoven fabrics cost much less to produce.

Nonwoven Fabrics

The fibers are bonded together by mechanical bonding (fiber entanglement), chemical bonding (fibers are chemically bonded together with glue-like compounds), or thermal bonding (where low-melt fibers are used and heat is used to melt the fiber to each other). Nonwoven fabrics are lighter and weaker than woven or knit fabrics. They don’t have much memory (for example, if you bend your elbow the fabric will retain that position and leave a pucker in the fabric) or laundering durability, making them unsuitable in durable clothing applications. Since they are cheap to produce, they’re ideal for single-use products such as wipes, medical products, feminine hygiene products disposable diapers, etc.

Woven Fabrics

Weaving, the process of joining individual threads together at right angles to one another has been around for millennia. From basket weaving to loom-weaving, the process of weaving was already known in the Paleolithic era, as early as 27,000 years ago.

In woven fabrics, threads or yarns are placed perpendicular to one another, then attached together through a pattern called “warp” and “weft”. This creates fabric. Woven fabrics are produced on a loom. The loom joins two sets of yarns by weaving one set between the other. The two sets of yarns are perpendicular to each other. One set is called the warp and runs the length of the fabric.

Generally, woven fabrics are stronger and more structurally sound than non-woven fabrics. It’s why they’re used to make many of the items we wear on our skin: the cotton shirt, the silk of a dress, or the wool of a sweater. Woven cloth is flexible but not overly stretchy, so it is able to retain its shape well. Also, woven fabrics are strong making woven cloth well-suited to machine washing and durable use.

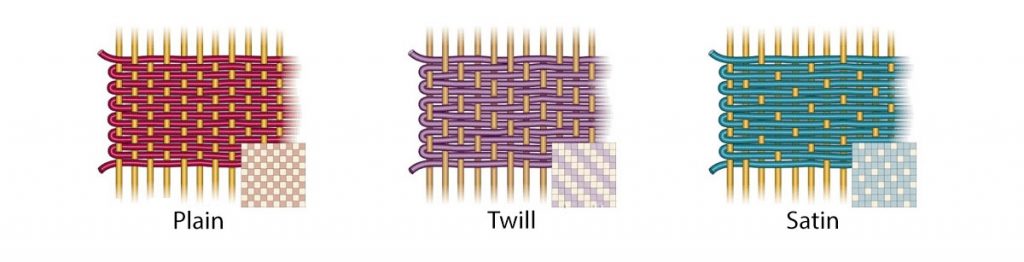

There are all kinds of different weave styles that give different types of fabrics as a result. Most of the clothing is made of using three main types of weaves: twill, satin and plain weave. Each style has its own advantages and specific application.

Woven fabrics are produced on a loom. The loom joins two sets of yarns by weaving one set between the other. The two sets of yarns are perpendicular to each other. One set is called the warp and runs the length of the fabric. The loom will raise some other warp yarns and some down, ultimately creating a shed. The fill or weft yarn is placed in the shed parallel to the ward yarn and the shed closes. Now the yarns that down went up, and the ones that were up to go down, creating another shed as another fill yarn is put through. Many different fabric constructions (like plain weave, twill weave, etc.) can be created by changing which yarns are opened up or pulled down in the shed. Woven fabrics are durable to washing and can be finished to yield many different properties (like being flame-retardant or water-repellant). They do not have much stretch because of the tightness of the yarns in the fabric. Yarn properties are important for the fabric’s performance. If you want a more stretchy fabric you can add some elastomeric fibers (think Spandex) to the yarn.

- Look: If you look closely at the material you will see that the fibers are weaved in a crisscross form. A great way to visualize it is to think of the classic woven basket. Two sets of yarn are interlaced at right angles. The yarn that is horizontal (from left to right) is referred to as the weft. The yarn that is vertical (top to bottom) is referred to as the warp. If you feel that the stitches aren’t clear enough, you can use a magnifying glass to take a look at the fabric. The fibers, pieces of thread or yarn, are weaved in a crisscross form. The basket-like weave is a distinctive feature of the woven fabric.

- Stretch: Woven fabrics are typically not very stretchy. When pulled it may stretch slightly along the warp, but will hardly stretch along the weft. So if you are after a stretchy material a woven fabric is probably not the best choice for you.

- Wrinkle: Doing a wrinkle test will help you determine whether your fabric is woven or knit. Take a small piece and ball it up in your fist and press hard. If it creases, then this is probably a woven fabric.

- Shrinkage: Unlike knit fabrics, woven fabric isn’t prone to shrinking. However, if you use very hot water, you might experience some shrinking. The only way you can maintain a piece made of woven fabric is to use a material that has already been shrunk in the manufacturing process. The higher the percentage of natural fibers like cotton in your fabric, the more prone to shrinking it will be.

- Fraying: Woven fabrics are susceptible to fraying. That is why it is best to finish the fabric with a serger or zigzag stitch in order to prevent fraying.

What are the Different Types of Woven Fabric?

Here, we’ll look into the different types of woven fabric and their qualities. It’s essential to consider these qualities when thinking about which woven fabric to choose for curtains or upholstery.

There are many types of woven fabric

1. Plain Weave Woven Fabric

Plain weave woven fabric is a common option for curtain and upholstery textiles, due to its simple and plain criss-cross weave. It’s manufactured to be durable and long-lasting, while various thread strengths can be used to enhance resilience. Striped patterns can also be created within plain weave woven fabric, by altering the colour of the warp textiles.

Also known as the Tabby weave, it is one of the most basic construction. The weft thread is passed over the first warp thread, then under the second, again passed over the third, then under the fourth and this process is continued till you reach the end of your warp threads. These alternating rows produce a high number of intersections making the fabrics very strong.

Since the warp yarns used on the front and back are exactly the same, these fabrics are reversible. There are three kinds of plain weave – waft rib, weft rib and matt weave.

The plain woven fabrics are used both in fashion and furnishings. Some woven fabric examples in this weave are cotton,

Cotton Poplin

Chambray

Broadcloth

Calico

Gingham

Linen

Oxford Cloth

Percale

Shirting

Muslin

Chiffon

Gingham

Canvas

Chintz.

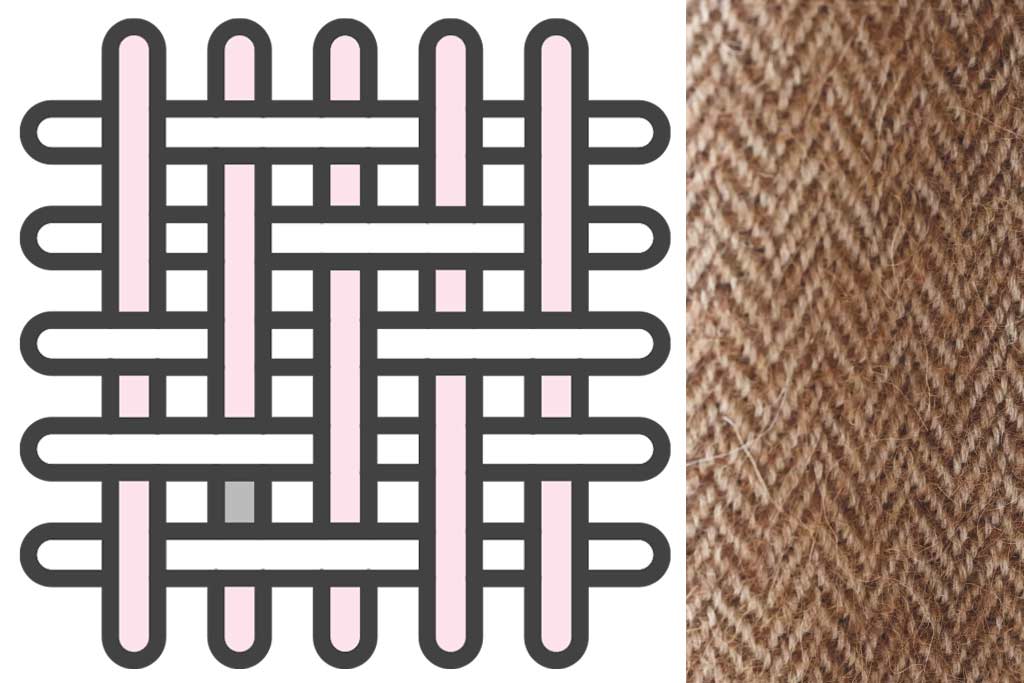

2. Twill Woven Fabric

Twill woven fabric is a great choice for upholstery textiles. It’s woven differently, as the threads are re-organised to create a diagonal pattern within the fabric. The way twill woven fabric is created makes it a more durable option for upholstery projects.

This Manhattan drape fabric created with a twill weave is ideal for curtains. Its slub qualities add textural curiosity, while concentrated yarns produce a uniform, structured drape.

In a twill weave, the weft thread is taken over two or more warp threads to create a diagonal pattern. This characteristic diagonal line that goes across the fabric is what makes it stand apart from other weaves.

This pattern makes it very durable and stain-resistant. The high thread count in the pattern leaves the fabric strong and long-lasting. It is a favorite fabric for workwear.

The most common and popular twill weave fabric is denim. Other woven fabric examples in twill weave are.

Gabardine

Herringbone

Tweed

Chino

Drill

Cavalry Twill

Satin Weave

Bengaline

Twill Suiting

3. Satin Woven Fabric

Satin woven fabric is one of the more complicated types of woven fabrics. It has a high lustre effect. The yarns are infused into the weave so that they reflect light, creating a luxurious, shiny appearance. Satin woven fabric is often less durable, so more suited to curtains than upholstery.

The satin woven Elixir fabric by Edmund Bell is exquisitely crafted. Available in 15 alluring colours, the intricate design captures an iridescent sparkle for an interesting interior design development.

Satin weave is made by using three or more weft threads going over one warp thread or the opposite, one weft thread over three or more warp.

The scattering of weft yarn farthest from the warp makes it more indistinct. No lines are formed in the face of the fabric in this weave as no two interweaves or interlacings are adjacent to each other. This gives the face a smooth shiny look.

However, the back will show lines making the face and back show different from each other. The less interlacing also makes the fabric more pliable and less wrinkled. In satin weaving yarns are used are shiny filament yarns to produce a lustrous finish.

Satin clothing is widely used in fancy dresses especially wedding dresses and drapery lines

4. Herringbone Weave Woven Fabric

Herringbone weave fabric is easily recognisable by the chevron shapes created within the weave. This adds a noticeable aesthetic touch to the textile, which can have a great impact within any room. It often infuses wool yarns into the weave, making herringbone weave fabric the quintessential cosy upholstery choice.

This Aspen upholstery fabric is sophisticatedly woven with a herringbone structure. Subtle and carefully mixed with various coloured yarns, Aspen is an exemplary herringbone weave upholstery fabric.

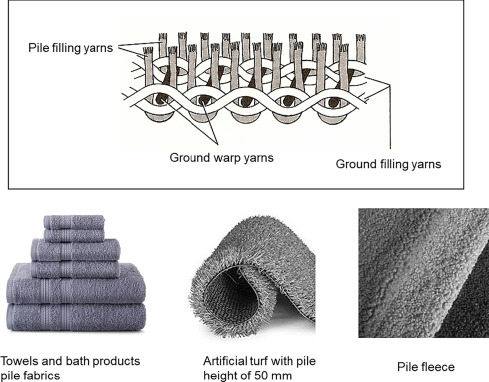

5. Pile Weave Woven Fabric

Pile weaves incorporate additional yarns into the weave during the process. They stand up to create a more tactile texture within fabrics, and they are then cut to form a ‘nap’. A nap on woven fabrics is the raised surface formed by these additional yarns and threads. One prevalent example of a pile weave woven fabric is velvet.

This Lustre upholstery fabric triumphantly embraces the pile weave, with luxe chenille yarns that evoke a crushed velour look.

6. Woven Fabric for Curtains

Woven fabrics are the key go-to choice when choosing curtain textiles. This is because woven fabrics have many preferable qualities over other types of fabrics. For example, curtain fabrics need to be durable enough in order to drape well over windows. Knit fabrics are therefore not an option for curtain textiles, as stretchy fabric would drape badly and lose shape over time.

Woven curtain fabrics by Edmund Bell are the definitive choice when it comes to selecting curtain fabrics. With an exquisite range of on trend curtain textiles, their woven curtain fabrics are intriguing and enduring.

Woven fabrics are the key go-to choice when choosing curtain textiles

7. Woven Fabric for Upholstery

On a similar note, woven fabrics are the most appropriate option when selecting upholstery textiles. Knit fabrics are now used for some purposes, such as easy fit sofa covers. However, when selecting your base upholstery textile, woven fabric is the superior choice. Upholstery textiles need durability, in order to withstand the impact of daily use.

8. Edmund Bell: Weaving Quality Textiles since 1855

Woven fabrics for upholstery and curtains by Edmund Bell can provide you with all you need to elevate your living or commercial spaces. Weaving quality textiles since 1855, our woven techniques have developed over time. We curate stylish yet extremely durable upholstery and curtain textiles, with a number of safety enhancing qualities.

Examples Of Woven Fabric

To help you get a better understanding of woven fabrics and what they are here are a few that you have likely been in contact with or utilized not knowing that they are in fact a woven material.

- Canvas: Canvas is a heavy, plain weave fabric that is extremely strong and durable. It is an industrial fabric but is very popular in industrial workwear as well as tents.

- Chino: The classic preppy trousers are in fact a woven material! A medium weight tight twill weave that has a slight shine to it. Perfect for uniforms and that “smart casual” look.

- Crepe: With a slightly crinkled look, crepe is a popular and light summery fabric.

- Denim: The wardrobe staple year in and year out is in fact woven. A medium-weight twill weave, with a warp that is usually indigo and a weft that is white.

- Muslin: A super affordable woven fabric. Muslin is a stiff unfinished plain weave fabric. It is commonly used by designers in order to create garments for testing patterns, before producing the final results using a more costly fabric.

Does woven fabrics stretch?

Stretchability of woven fabrics depend on the fiber used (if spandex is used, ofcourse, there will be stretch) and also the type of weave (twill weave will stretch more than plain weave) and grainline (diagonal grain of the woven fabrics stretch but lengthwise there is usually no stretch); But compared to knit fabrics, wovens do not stretch.

Which woven fabrics are suitable for upholstery or cushions?

Cotton duck, linen, Velvet, Jacquard, Microfiber, polyester fabrics are usually used for making upholstery and cushions. Polyester and Nylon fabrics with water-resistent coatings can be used for outdoor upholstery.

What are the advantages of woven fabrics as a dressmaking material?

Woven fabrics generally have good resistance to deformation or stretching over time. This is a very important consideration for me. They are also quite breathable. And easy to sew with – very easy to make pleats and other fabric manipulations. All these are because of the structural stability of woven fabrics.

What can damage woven fabrics?

Rough handling, Excessive pressure, improper care, exposure to high temperatures, moths and humidity – these can damage woven fabrics over time.

Which are the best wovens for making clothes?

Cotton, linen, silk, wool, rayon, denim are universally popular woven fabrics for making clothes.

What are some light weight woven fabrics?

Chiffon, Georgette, Organza, Voile, Crepe, Lawn, Batiste, Muslin, Gauze and Taffeta.

Characteristics of Woven Fabric

Face and back of a woven fabric

The woven fabrics have a front and back, the front being the side that is shown outside and the back being the inside or the underside of the cloth. Not all fabrics are reversible, ie, you can equally use the face and back of the cloth. For example, a plain weave fabric has the same front and back due to the kind of interlacing that is used. However, those fabrics made especially of satin weave have different front and back, face side soft and backside matt.

A method of weaving 2 layers of fabrics together on the same loom creates a Double cloth. This fabric is strong and you may not want a lining for clothes made of a double cloth. Double-face cloth is different from a double woven cloth – A Double-face woven fabric doesnot have two layers but the patterns/colors on either sides of the fabric may be different.

Count of woven cloth

The number of ends and picks per inch in a woven fabric is called the count of the woven fabric. It is mentioned in numbers – 64 * 64 (Warp count x Weft count) ;This has an impact on how the fabric feels and looks ( a uniform look). In a woven cloth, every end and pick should spread out equidistant from each other – if it doesnot it is said to be a reedy cloth. If it does, it is called a well covered cloth.

When the ends and picks are the same per inch it is called a square woven cloth. When the ends and picks are maximum per inch of equal counts it is called a balanced woven cloth.

Type of yarn used

The feel, texture, size of yarn used for the construction of the fabric determines how it will turn out. A cashmere fabric made of the softest yarn is obviously more silky and soft than a tweed fabric made from textured yarn. Learn more about the different types of yarns used in weaving here.

Grainline of woven fabric

All fabrics have a grain direction. The thread direction in the fabric is referred as the ‘Grain’ or Grainline of the fabric.This is very important in cutting and sewing fabric.

Lengthwise grain refers to the threads that run parallel with the selvedge – this is also called warp threads. Crosswise grain refers to the threads that run across the fabric – this is also called weft threads. The lengthwise and crosswise grainline has to be maintained for the fabric to hang well.

When you cut your fabric at an angle, ie, your warp and weft are 45° to its major seam lines, it is called a bias cut. Bias cut is also known as off-grain or cross-grain cut. The word bias cut is popular in the US and off-grain or cross-grain cut in the UK. The bias cut gives the fabric more drape and fluidity

The woven fabric shrinks more in the lengthwise grain. Woven fabric stretches more in the crosswise grain (though not as much as bias grain)

Generally, woven fabric has no elasticity or stretch having a tight or rigid construction, especially along the lengthwise grain. But sometimes to bring some stretch to the fabric, elastic fibers are woven with the other yarns. A typical example of this kind of woven fabric is stretch denim.

Size of a woven fabric

Depending on the purpose and end-use, woven fabrics are produced in varying widths. The fabric width is the distance from one selvage to the other. It is measured perpendicular to the length. Usually in woven fabrics width is generally 48 inches or 63 inches. If you are selecting a fabric for a dress, go for textiles that have these measurements. But if you are going for furnishing, go for sheets which are wider.

Knit Fabrics

Knitting is defined as forming a fabric utilizing interloping the yarn. Knitting machines do the same interloping of yarn that a hand knitter does. Knit fabrics have stretch because of the looseness of the fabric’s yarn structure (compared to knits and most nonwovens). Because of this looseness, the fabric can tighten up due to the mechanical action in laundering. That’s why knit fabrics shrink. Most current knit fabrics are pre-shrunk before a garment is made from them, which eliminates most shrinkage. Because the yarns in knit fabrics are looped around themselves if you pick a knit fabric the whole length of that course of yarn will unravel. I’m sure you have seen this happen before. Knit fabrics are comfortable and warm, which explains why many sweaters are made from them.

As you can see, there are many differences in these fabrics and there are many uses for each type. The pie in the sky is to produce a comfortable garment of nonwoven fabrics that will be durable, as well as more economical to produce. This has not yet been accomplished—but there’s always hope.

Look:

If you look closely at the material and it appears to have rows upon rows of narrow braids or loops, then it is a knitted fabric.

Stretch:

Knitted fabrics are always stretchier, especially along the weft of the fabric. So do a stretch test to determine if it is knitted.

Wrinkle:

Knitted fabrics are less prone to wrinkling than woven fabrics. Another great way to test your fabric is by scrunching it. When scrunched up woven fabrics maintain some sort of shape, whereas knit fabrics usually collapse back down.

Shrinkage:

They are more prone to shrinking, in comparison to woven fabrics, so make sure care is taken when washing!

Fraying:

Knitted fabrics do not fray, so this is yet another simple way to distinguish what fabric type you possess.

Many types of Knitted Fabric

- Single Jersey

- Single Lacoste

- Double Lacoste

- Single Pique

- Double Pique

- Polo Pique

- French Terry

- All Rib Structures

- All Type of Interlock.

Examples of Knitted Fabrics

Now let us distinguish the difference further by exploring a few examples of knitted fabrics.

Jersey:

A single knit fabric made from natural or synthetic fibers. They are versatile, wrinkle-resistant, durable, and extremely soft. It is very popular in clothing such as t-shirts.

Tricot:

A lightweight knit made of synthetic fibers. It can be knitted quite sheer and light as well as more opaque and medium weight. This makes it popular when creating lingerie.

Rib Knit:

This has a raised vertical texture making it easy to identify. It is more stretchy crosswise and lies flat on one side. Commonly used for necklines, especially turtlenecks.

Fleece Knit:

A durable, stretchy, and warm fabric with a thick, deep pile. It dries quickly making it suitable for activewear.

Interlock Knit:

Similar to rib knit, this fabric is extremely versatile. Heavier and less stretchy than the jersey, both sides are smooth so it doesn’t matter which side you choose to face outwards.

Woven vs Knit

A woven fabric is made using warp and weft yarns whereas knitted fabric uses only a single yarn that loops up and down the knitting machine continuously to give a braided look. Generally, a woven fabric is tough and strong and does not stretch like knitted fabric. That’s why woven fabrics are generally used for upholstery.