Biodegradable Bicomponent PE/PET Fiber

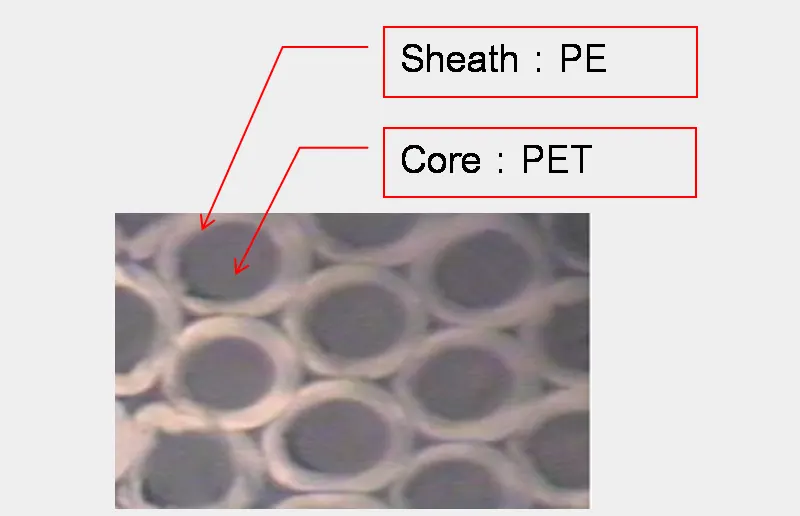

Biodegradable Bicomponent PE/PET Fiber: This fiber features a concentric sheath/core structure, consisting of a low melting point sheath made from Polyethylene and a core material of Polyethylene Terephthalate. It can be produced with standard hydrophilic or hydrophobic spin finishes, and additives are incorporated to enhance its biodegradability.

Product Technical Specification

Standard TDS of 2den 38mm Standard Biodegradable Bicomponent PE/PET Fiber

| Characteristic | Unit | Min | Max | Test Method | Remark |

| Linear Density | dtex | 2.2 | 2.46 | GB/T14335-2008 | |

| Cut length | mm | 37 | 39 | GB/T14336-2008 | |

| Tenacity at peak | cn/dtex | 2.3 | 3.08 | GB/T6504-2017 | |

| Elogation at peak | % | 40 | 80 | GB/T14337-2008 | |

| Crimp n. | n./10mm | 10.5 | 13.5 | GB/T14328-2008 | Adjustable |

| Spin finish | % | 0.3 | 0.4 | GB/T6504-2017 | Adjustbale |

This fiber is an excellent choice for thermal bonding nonwoven fabrics, which are commonly utilized in hygiene products, including feminine and baby care items.

Fiber denier: 2dn ~ 6dn,

Main cut length: 38mm or 51mm,

Spin finish: standard hydrophilic or hydrophobic

Color Bicomponent PE/PET Fiber

Color Bicomponent PE/PET Fiber: Similar to the biodegradable version, this fiber utilizes a sheath/core concentric structure with a low melting point sheath of Polyethylene and a core of Polyethylene Terephthalate. It is available with standard hydrophilic or durable (permanent hydrophilic) spin finishes, with the addition of Titania (TiO2) to improve the whiteness of the fiber.

Technical Specification

Standard TDS of 2den 38mm Standard Color Bicomponent PE/PET Fiber

| Characteristic | Unit | Min | Max | Test Method | Remark |

| Linear Density | dtex | 2.2 | 2.46 | GB/T14335-2008 | |

| Cut length | mm | 37 | 39 | GB/T14336-2008 | |

| Tenacity at peak | cn/dtex | 2.3 | 3.08 | GB/T6504-2017 | |

| Elogation at peak | % | 40 | 80 | GB/T14337-2008 | |

| Crimp n. | n./10mm | 10.5 | 13.5 | GB/T14328-2008 | Adjustable |

| Spin finish | % | 0.3 | 0.4 | GB/T6504-2017 | Adjustbale |

This fiber is well-suited for thermal bonding in nonwoven fabrics, which are commonly utilized in hygiene products, including feminine care and baby care.

Fiber denier: 2dn ~ 6dn,

Main cut length: 38mm or 51mm,

Spin finish: standard hydrophilic or durable(permanent hydrophilic),

Pigment available: green/blue/purple/camel etc

Hydrophilic Bicomponent PP/PET Fiber

Hydrophilic Bicomponent PP/PET Fiber: This fiber also employs a concentric sheath/core structure, featuring a low melting point sheath made from Polypropylene and a core of Polyethylene Terephthalate. It can be produced with either hydrophilic or durable (permanent hydrophilic) spin finishes. Titania (TiO2) is added to enhance the fiber’s whiteness. This fiber is comparable to the PET/PE bicomponent fiber, but utilizes a PP sheath which provides greater elasticity than the PE sheath.

Technical Specification

Standard TDS of 2D 38mm Standard Hydrophilic Bicomponent PP/PET Fiber

| Characteristic | Unit | Min | Max | Test Method | Remark |

| Linear Density | dtex | 2.2 | 2.46 | GB/T14335-2008 | |

| Cut length | mm | 37 | 39 | GB/T14336-2008 | |

| Tenacity at peak | cn/dtex | 2.3 | 3.08 | GB/T6504-2017 | |

| Elogation at peak | % | 80 | 120 | GB/T14337-2008 | |

| Crimp n. | n./10mm | 10.5 | 13.5 | GB/T14328-2008 | Adjustable |

| Spin finish | % | 0.3 | 0.4 | GB/T6504-2017 | Adjustbale |

It is an excellent fiber for thermal bonding nonwoven fabrics, commonly utilized in hygiene products such as feminine care and baby care.

Fiber denier: 2dn ~ 6dn,

Main cut length: 38mm or 51mm,

Luster: raw white/semi dull or full dull,

Spin finish: standard hydrophilic or durable(permanent hydrophilic),

Pigment available: green/blue/purple/camel etc

Hydrophobic Bicomponent PE/PET Fiber

Hydrophobic Bicomponent PE/PET Fiber: This fiber, designed with a concentric sheath/core structure, comprises a low melting point sheath of Polyethylene and a core of Polyethylene Terephthalate. It can be produced with either hydrophobic or durable (permanent hydrophilic) spin finishes, with the addition of Titania (TiO2) to enhance the whiteness of the fiber.

Technical Specification

Standard TDS of 2D 38mm Standard Hydrophobic Bicomponent PE/PET Fiber

| Characteristic | Unit | Min | Max | Test Method | Remark |

| Linear Density | dtex | 2.2 | 2.46 | GB/T14335-2008 | |

| Cut length | mm | 37 | 39 | GB/T14336-2008 | |

| Tenacity at peak | cn/dtex | 2.3 | 3.08 | GB/T6504-2017 | |

| Elogation at peak | % | 40 | 80 | GB/T14337-2008 | |

| Crimp n. | n./10mm | 10.5 | 13.5 | GB/T14328-2008 | Adjustable |

| Spin finish | % | 0.3 | 0.4 | GB/T6504-2017 | Adjustbale |

It is an excellent fiber for thermal bonding nonwoven fabrics, commonly utilized in hygiene products such as feminine care and baby care.

Fiber denier: 1.2dn ~ 6dn,

Main cut length: 38mm or 51mm,

Luster: raw white/semi dull or full dull,

Spin finish: standard Hydrophobic,

Pigment available: green/blue/purple/camel etc

Hydrophilic Bicomponent PE/PET Fiber

Hydrophilic Bicomponent PE/PET Fiber: This fiber exhibits a concentric sheath/core structure with a low melting point sheath of Polyethylene and a core material of Polyethylene Terephthalate. It can be produced with hydrophilic or durable (permanent hydrophilic) spin finishes, incorporating Titania (TiO2) to improve whiteness.

Technical Specification

Standard TDS of 2D 38mm Standard Hydrophilic Bicomponent PE/PET Fiber

| Characteristic | Unit | Min | Max | Test Method | Remark |

| Linear Density | dtex | 2.2 | 2.46 | GB/T14335-2008 | |

| Cut length | mm | 37 | 39 | GB/T14336-2008 | |

| Tenacity at peak | cn/dtex | 2.3 | 3.08 | GB/T6504-2017 | |

| Elogation at peak | % | 40 | 80 | GB/T14337-2008 | |

| Crimp n. | n./10mm | 10.5 | 13.5 | GB/T14328-2008 | Adjustable |

| Spin finish | % | 0.3 | 0.4 | GB/T6504-2017 | Adjustbale |

This fiber is highly suitable for thermal bonding nonwoven fabrics, which are commonly utilized in hygiene products, including feminine care and baby care items.

Fiber denier: 1.2dn ~ 6dn,

Main cut length: 38mm or 51mm,

Luster: raw white/semi dull or full dull,

Spin finish: standard hydrophilic or durable(permanent hydrophilic),

Pigment available: green/blue/purple/camel etc

Bicomponent PE/PET Short Cut Fiber

Bicomponent PE/PET short-cut fiber is a specialized type of bicomponent fiber, designed to be cut into short lengths, typically ranging from a few millimeters to a few centimeters. These fibers are used in a variety of industrial applications where their specific properties—derived from their bicomponent nature—are advantageous.

Core-Sheath Design: Similar to standard bicomponent fibers, these short-cut fibers have a core-sheath structure. The core is typically made of polyethylene terephthalate (PET), which provides strength, while the sheath is made of polyethylene (PE), which offers a lower melting point and bonding capabilities.

Technical Specification

Standard TDS of 2den 6mm Standard Bicomponent PE/PET Short Cut Fiber

| Characteristic | Unit | Min | Max | Test Method | Remark |

| Linear Density | dtex | 2.2 | 2.46 | GB/T14335-2008 | |

| Cut length | mm | 5 | 7 | GB/T14336-2008 | |

| Crimp n. | n./10mm | 4 | 6 | GB/T14328-2008 | Adjustable |

| Spin finish(phil) | % | 0.3 | 0.4 | GB/T6504-2017 | Adjustbale |

This fiber is particularly well-suited for airlaid applications, which are commonly utilized in absorbent and insulation products such as food pads and insulation boards.

Fiber denier: 1.5dn /2dn,

Main cut length: 4/5/6/12mm

Luster: raw white

Spin finish: standard hydrophilic