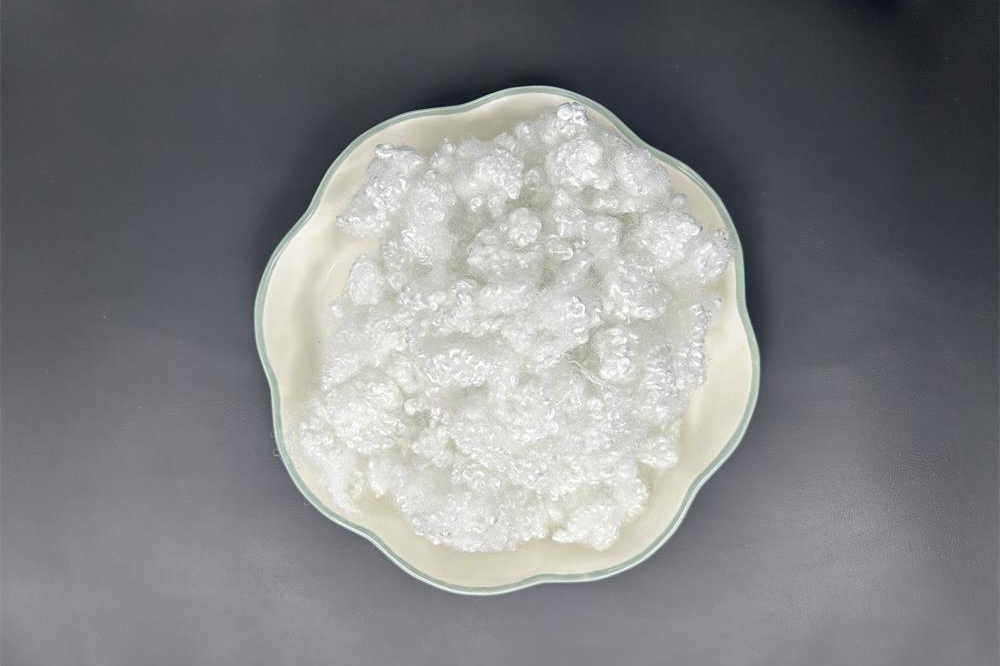

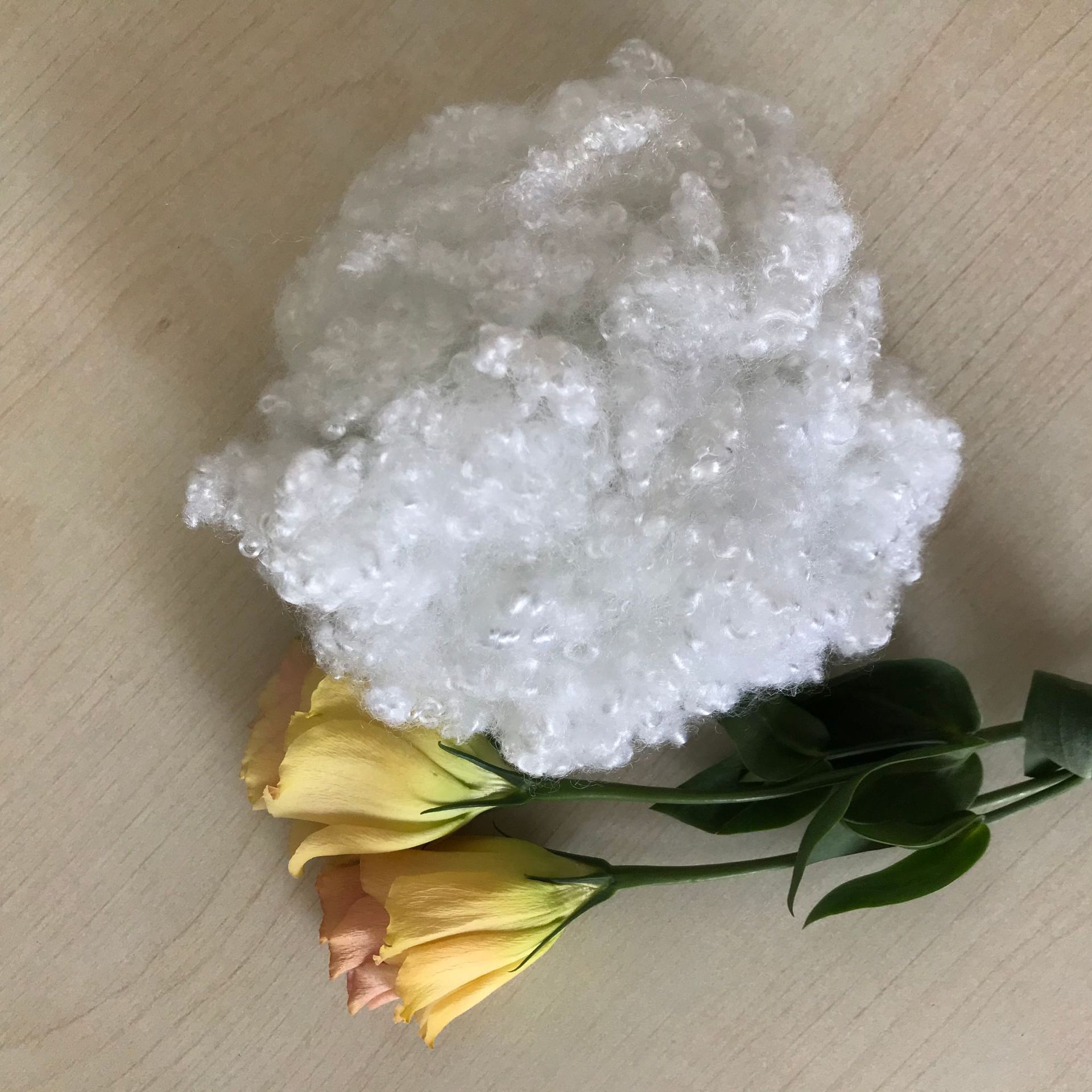

What is Hollow Conjugated Fiber

Polyester hollow fiber is a synthetic fiber derived from polyester polymer with a unique hollow tubular structure. These hollow fibers contain voids within their core, resembling tiny tubes, unlike solid polyester fibers. Hollow conjugated silicon fibers, in comparison to traditional solid fibers, offer superior warmth retention and fluffiness, among other benefits. This innovative design provides them with distinctive performance advantages.

Key characteristics of Hollow conjugated silicon:

1. Demonstrates good tensile strength, high elasticity, puffiness, and anti-static properties.

2. Exhibits excellent fluffiness, moisture wicking, and breathability, providing a plush, gentle feel and comfortable wear.

3. Delivers a glossy finish.

4. Shows resistance to wear and pilling, with the unique hollow tube shape enhancing warmth in the fabric.

Overall, Hollow conjugated silicon finds widespread application in the textile industry for fabrics, thermal insulation materials, home textiles, outdoor equipment, and more. Notably, it is a recycled polyester material, making it a more environmentally friendly option. Balancing comfort with sustainability, Hollow conjugated silicon is increasingly recognized as a crucial and popular product due to its structure and eco-friendly properties.

Specifications:

- Virgin/ Recycled Fiber

- Denier Range 6d~15d

- Spin Finish Siliconized

- Non-Siliconized

- Stiff Touch

- Staple Length 32 mm, 51 mm, 64 mm

- Hollowness 15 ~ 20 %

- Permanent Crimp Excellent Bulkiness

Applications:

- Fillings in the Winter Jackets

- Substitution of Duck’s Feather

- Quilts (High Bulky, Warm, Light)

Pillows (Good Wet Absorption)

Advantages of hollow conjugated polyester fiber

One of the key benefits of hollow conjugated silicon polyester fiber is its unique ability to effectively regulate body temperature. This is achieved through the fiber’s hollow core design, which promotes air circulation to keep the body cool in warm conditions. Additionally, the silicone coating on the fiber aids in retaining body heat, ensuring warmth in cooler climates. As a result, hollow conjugated silicon polyester fiber is a highly suitable option for bedding, offering a comfortable sleeping experience irrespective of the ambient temperature.

Another advantage is its exceptional softness and comfort. This fiber is known for its lightweight and fluffy texture, providing a luxurious and comfortable feel against the skin. Additionally, it is hypoallergenic, minimizing the likelihood of skin irritation or allergic reactions, making it a preferred option for individuals with sensitive skin.

Furthermore, the hollow conjugated silicon polyester fiber offers exceptional durability in addition to its comfort and temperature-regulating benefits. It is highly resistant to wear and tear, maintaining its shape and loft through repeated use and laundering. These qualities make it a favorable option for clothing and upholstery, as it can withstand daily wear and maintain its appearance long-term.

Disadvantages of hollow conjugated polyester fiber

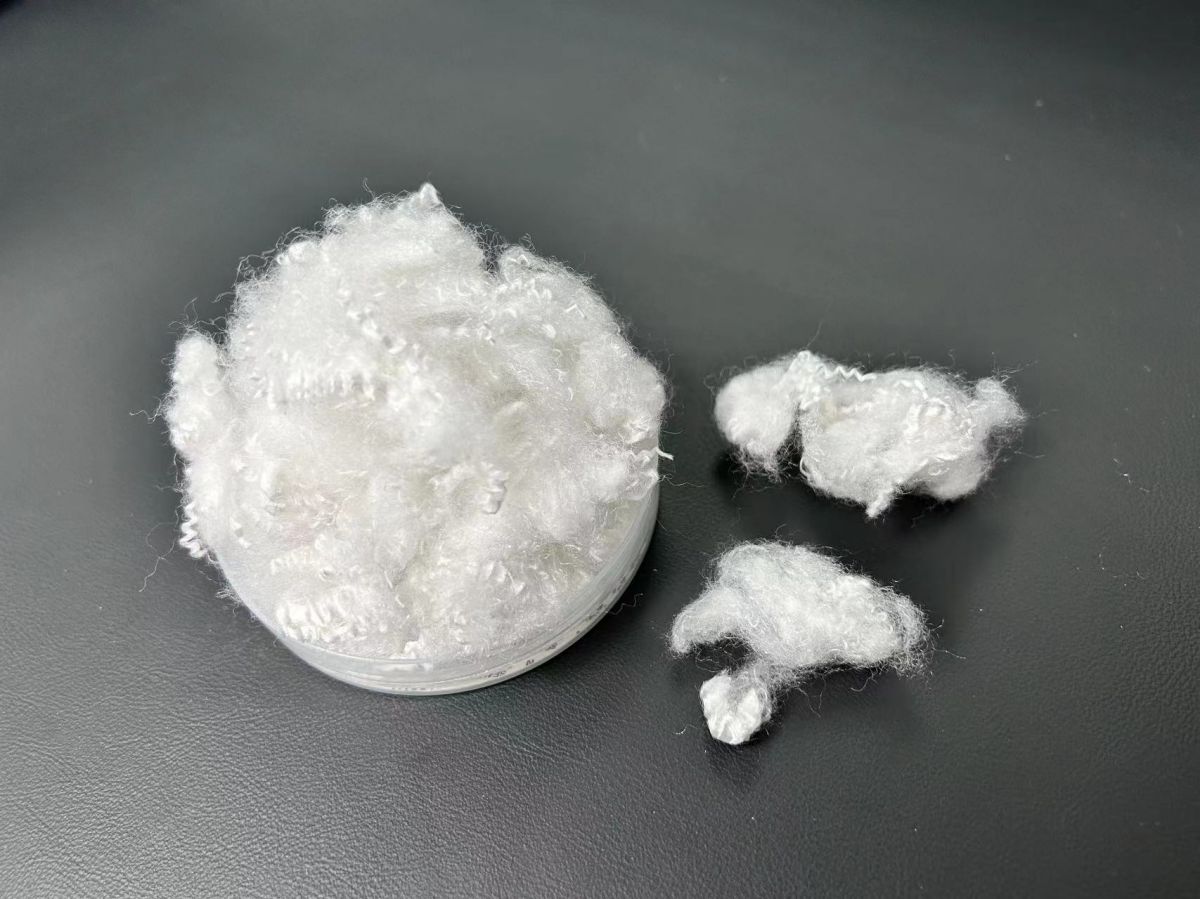

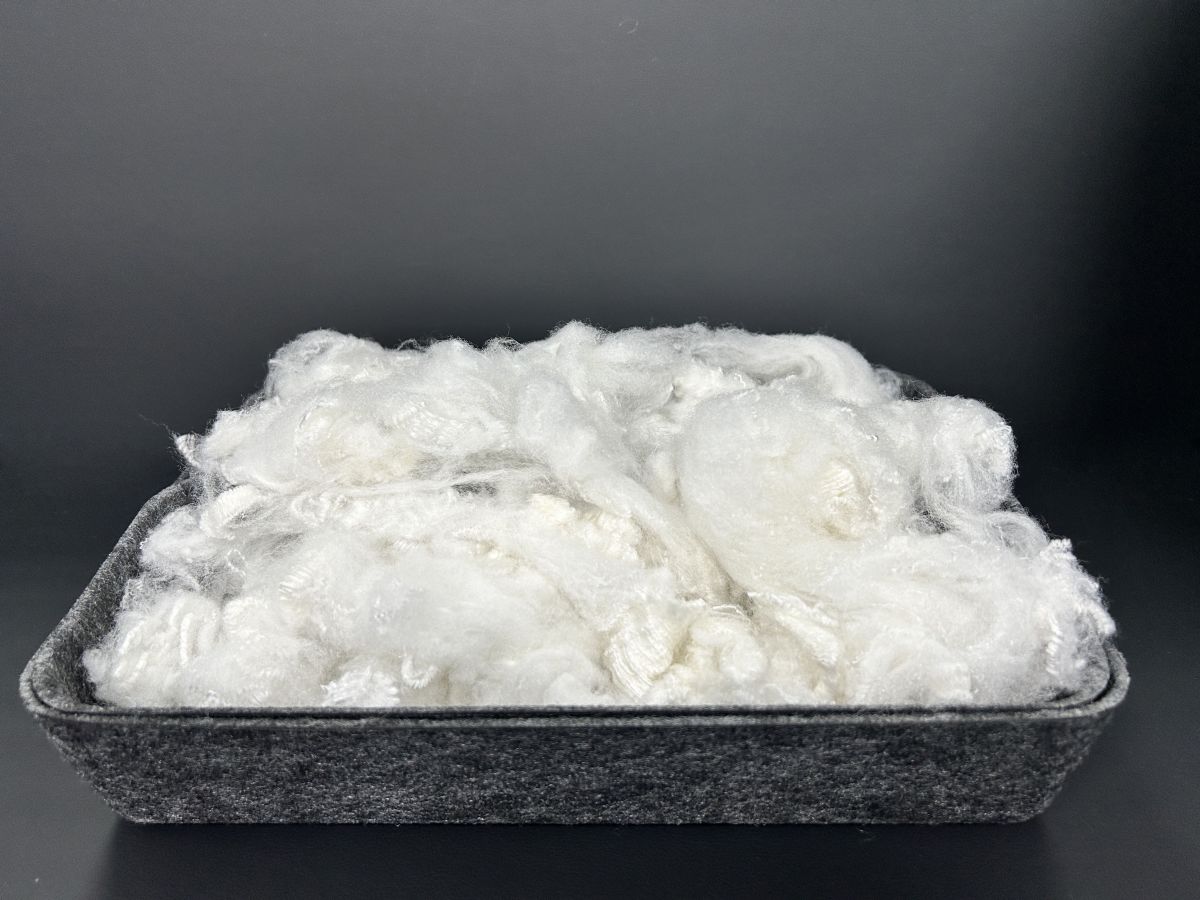

What is Hollow Fiber?

Hollow fiber is a textile material that has a hollow structure inside the fiber. Compared with traditional solid fibers, hollow fibers have unique characteristics and applications. One of the characteristics of hollow fibers, resilience, means that they can be restored to their original state and are not easily deformed, making them very suitable for manufacturing products such as loose cotton, pearl cotton, non adhesive cotton, and hard cotton. Loose cotton is usually used for bedding, such as mattresses and pillows, because it has good support and comfort. Pearl cotton is commonly used for clothing linings and fillers because it is lightweight and warm. Non adhesive cotton and hard cotton are widely used in the manufacturing of sanitary materials, such as sanitary napkins and diapers. The warmth retention of hollow fibers is widely used in daily textiles such as home textiles, clothing, sofas, plush toys, and sanitary materials.

Specifications:

- Virgin Fiber or Regenerated Fiber

- Denier Range 6d~15d

- Spin Finish Siliconized

- Non~Silicon

- Stiff Touch

- Staple Length 32 mm, 51 mm, 64 mm

- Hollowness 20 % ~ 30 %

- Excellent Bulkiness

Applications:

- Fillings in the Winter Jackets

- Mixing with Feathers

- Quilts (High Bulky, Warm, Light)

- Pillows (Good Wet Absorption)

Any other Non-Woven Processing

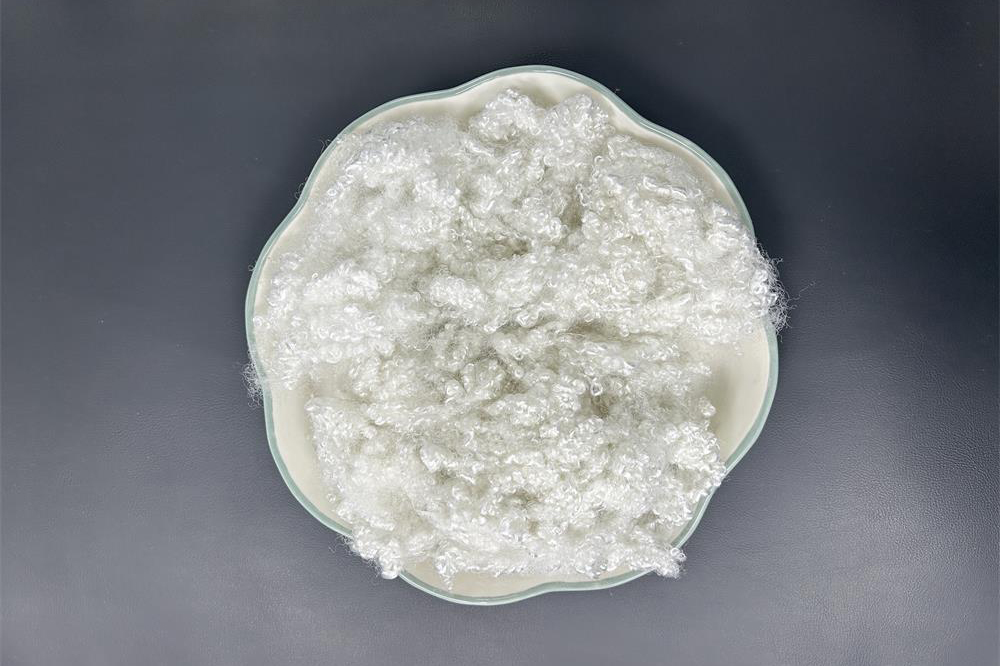

Hollow 3D Conjugate Fiber

Specifications:

- Virgin Fiber or Regenerated Fiber

- Denier Range 6d ~ 15d

- Spin Finish Siliconized

- Non~Siliconized

- Stiff Touch

- Staple Length 32 mm

- 51 mm

- 64 mm

- Hollowness 20 ~ 30 %

- Permanent Crimp Superior Bulkiness

Applications:

- Fillings of Winter Jacket

- Substitution of Ducks Feather

- Quilts (High Bulky, Warm, Light)

- Pillows (Good Wet Absorption)

- Cushions

Any other non-woven Processing.

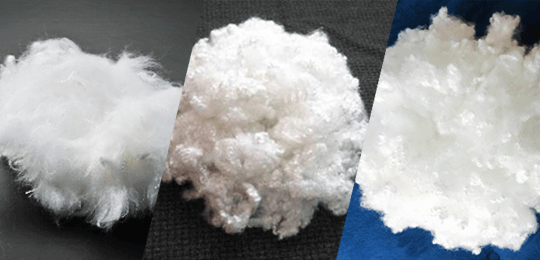

Solid Fiber

Specifications:

- Commonly regenerated fiber

- Denier range 6d ~ 20d

- Spin finish Siliconized

- Non-Siliconized

- Stiff Touch

- Staple Length 32 mm

- 51 mm

- 64 mm

- Crimp Shape Excellently Sharp

Applications:

- Mixing with other fibers

- Well Combined with any type of fibers. Good for Chemical bonding, Thermal bonding, needle Punching or any type for:

- Fillings Padding Wading

- Geotextile

Open Fiber (Fiberfill)

Polyester fiberfill wrap (also known as Dacron) can help improve the aesthetics of practically any seat or cushion. The wrap gives a softer, rounded look, while without it, a cushion would look flat and angular. Fiberfill also helps in sliding foam cushions into their fabric covers.

Medium Fiberfill is suggested for seats, seatbacks, and throw pillows.

Specifications:

- Denier Range 6d ~ 15d

- Spin Finish Siliconized

- Staple Length 32 mm 51 m, 64 mm

Applications:

- Filling of Pillows, Cushions or

Any other non-woven home processing/ furnishings

What is Dacron Fiber?

Dacron is a well-established brand name for a type of polyester fiber known as polyethylene terephthalate (PET), which was developed by the American chemical company DuPont in the early 1950s. The name “Dacron” has become synonymous with polyester in the United States, similar to “Terylene” in the UK and “Tetoron” in Japan. Polyester fibers, including Dacron, have significantly transformed the textile industry owing to their versatility and extensive range of applications.

Characteristics of Dacron Polyester Staple Fiber

– Durability: Dacron fibers exhibit high strength and resistance to stretching, shrinking, and abrasion, making them suitable for products that require durability and withstand regular use and laundering.

– Wrinkle Resistance: A notable feature of Dacron polyester is its exceptional wrinkle resistance, allowing garments crafted from it to maintain a professional appearance without the necessity for frequent ironing.

– Low Moisture Absorption: Dacron is hydrophobic, which means it does not readily absorb moisture. This characteristic contributes to its rapid drying properties and resistance to water-based stains.

– High Tensile Strength: Dacron polyester possesses a high tensile strength, rendering it ideal for heavy-duty applications, including industrial textiles, ropes, and tire reinforcements.

– Colorfastness: The fibers effectively retain dyes, ensuring that fabrics made from Dacron maintain their colors after repeated washings and exposure to sunlight.

– Versatility: Dacron polyester can be produced in various forms, such as staple fibers, continuous filaments, and texturized yarns, enabling its use across a broad spectrum of textile and industrial applications.

Staple Fiber vs. Filament Fiber

Dacron polyester staple fiber consists of short lengths of fiber, typically measuring a few centimeters to several inches. These staple fibers are spun into yarn, similar to natural fibers (such as cotton or wool), and are commonly utilized in the textile industry to create blended fabrics.

– Staple Fiber: These are short fibers twisted together to form yarn. Staple fibers provide a texture akin to that of natural fibers and are frequently blended with other fibers, such as cotton or wool, to enhance the final fabric’s characteristics.

– Filament Fiber: These are long, continuous fibers used in applications that require a smoother and more lustrous finish. Filament fibers are often employed in the production of silky, glossy fabrics.

Uses of Dacron Polyester Staple Fiber

– Apparel: Dacron staple fibers are incorporated into a variety of garments, often blended with natural fibers. This includes items such as shirts, dresses, pants, and outerwear, where blending with cotton or wool improves comfort while preserving the durability and wrinkle resistance of polyester.

– Home Textiles: This fiber is utilized in products including bed linens, upholstery fabrics, curtains, and carpets. Its durability and wear resistance make it an excellent choice for these applications.

– Fillings: Dacron staple fibers are frequently used as filling materials for pillows, comforters, and stuffed toys due to their lightweight, hypoallergenic properties and ability to retain loft.

– Industrial Applications: The fiber finds use in non-woven materials, geotextiles, automotive upholstery, and filtration fabrics, owing to its strength and resistance to chemicals and environmental conditions.

Applications of Dacron

Firstly, people use dacron fiber as a material to wrap cushions to create a sharper and fulfilled appearance. Furthermore, manufacturers can also use dacron fiber to fill the pillow, bolster, bedcover, doll, etc. Dacron is also known as durable material. However, dacron is a form of polyester, whereas polyester is a polymer material. Polyester is composed of ester groups attached to the main chain. Dacron fiber is also known as polyester fiber. Besides, manufacturers can make dacron from recycled polyester material.

Moreover, people used dacron fiber widely in daily life. People use fiber because dacron fiber is considered as :

- Comfortable material

- Easy to wash / washable

- Durable

- Cheap / cost efficient

- Manufacturer can made dacron from recycled polyester

Dacron, along with other polyester fibers, has made a significant contribution to the textile industry by offering a cost-effective alternative to natural fibers, which can often be pricier or less durable. The introduction of polyester fibers, such as Dacron, facilitated the production of affordable, low-maintenance clothing and textiles. This innovation played a key role in making fashion more accessible and spurred the rapid expansion of the global textile market.

Although Dacron polyester staple fiber continues to be widely utilized, the brand name “Dacron” has become less prominent in everyday discussions as polyester has reached widespread usage and is now more commonly referred to by its chemical designation. Nevertheless, Dacron remains a vital component of the history of synthetic fibers and their significance in contemporary textiles.

VNPOLYFIBER also a leading exporter of consumer and industrial PET nonwoven spunbond, polyester regenerated staple fiber (dacron), PET flakes, and rPET (recycled polyester) spun yarn/ sewing thread products in Indonesia. Moreover, VNPOLYFIBER’s mission is to manufacture and supply polyester spunbond textiles and fibers that improve customer’s products and increase their value.

Furthermore, please go to www.vnpolyfiber.com for more information.