What is Viscose Staple Fiber?

Viscose Staple Fiber (VSF) is a biodegradable fiber derived from natural sources that shares similarities with cotton. Viscose staple fiber is often spinned with cotton, wool or various kinds of synthetic fibers, used in various types of clothing and decorative textiles, which is a chemical fiber used widely. The moisture rate of viscose fiber fits with human body skin very much, good hygroscopicity, wearing comfortable, good spinnability, smooth cool, breathable, antistatic, beautiful dyeing features. Its versatility makes it a popular choice for the production of various textile products including apparel, home textiles, dress materials, knitted wear, and non-woven applications.

VNPOLYFIBER is a prominent exporter of Viscose Staple Fiber from China, providing high-quality products to esteemed buyers worldwide. Our Viscose Staple Fiber is available in different Deniers such as 1.2D, 1.4D, and 1.5D, with cut lengths ranging from 32mm to 36mm. It can be supplied in raw-white or various colors and is packaged in bales, meeting the specifications of the best quality VSF from China.

The production process of viscose staple fiber involves continuous spinning on machines with spinnerettes immersed in a spinbath. The coagulated and regenerated viscose filaments are collected and spun into a tow, passing through various stages including stretching, cutting, CS2 recovery, washing, bleaching, and application of softeners. The fibers are then dried to control moisture levels before final processing.

Regular Viscose staple fiber is regenerated cellulose fiber which is produced with cotton, wood or other natural fibers. Using natural cellulose, after mercerization, aging and sulphofication etc, the soluble cellulose xanthenes is finished, and then dissolved in dilute alkali liquor for the spinning dope, the final viscose fiber is made by wet spinning. Regular Viscose staple fiber has the general physical and mechanical properties and chemical properties, including staple fiber type and filament yarn type, commonly known as man-made cotton, wool and silk.

What are the applications of viscose fiber (rayon fiber)?

Mainly used in the hygiene market, it is an ideal fiber for baby wipes, dry wipes, wet wipes, beauty masks and other hygiene products.

It is derived from high-purity lignocellulose from renewable plantations, has excellent hygroscopicity and a structure that makes fibers more lofty, resulting in soft, skin-friendly nonwoven end products.

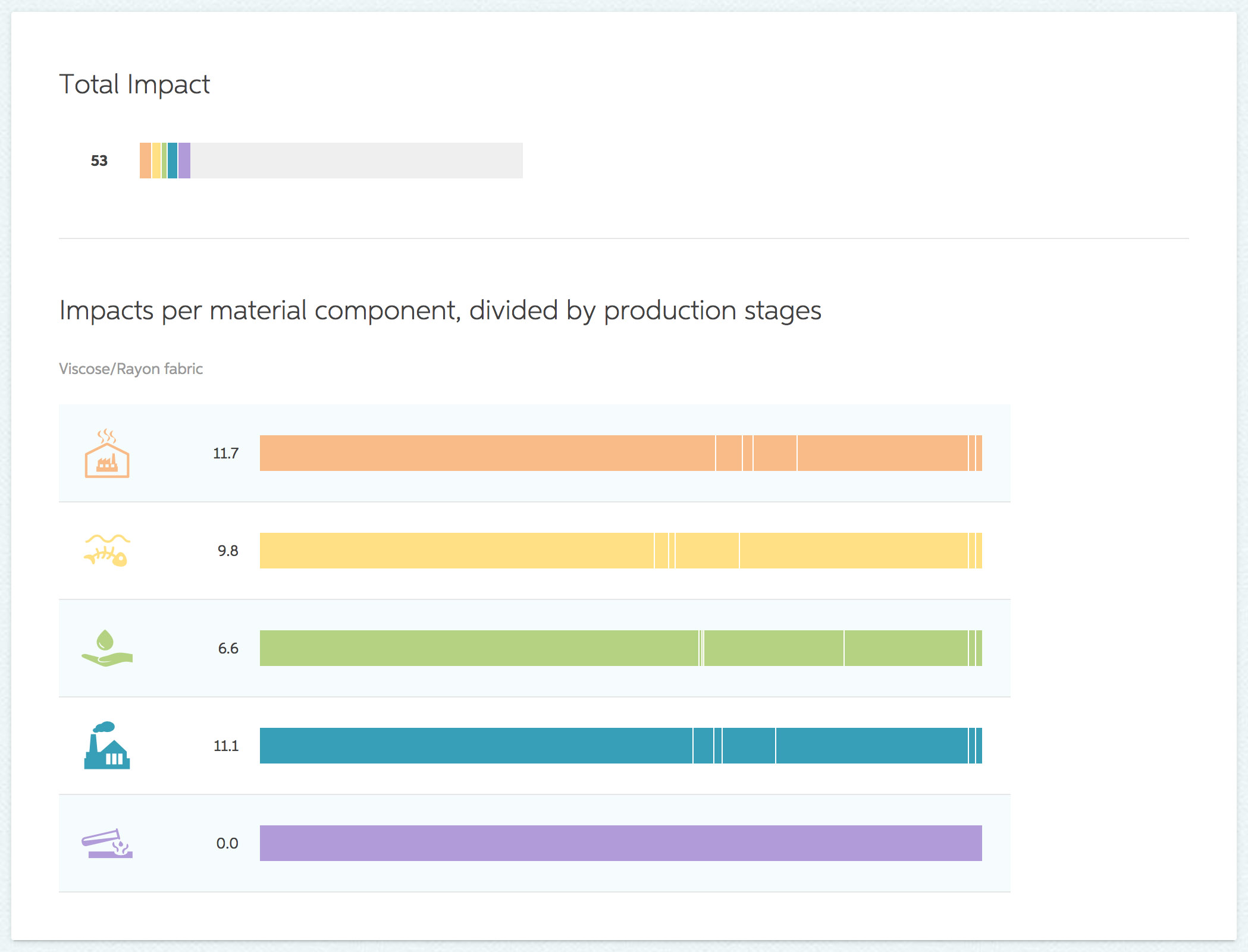

Impacts of viscose

Done well, viscose could be less harmful to the planet than conventionally produced cotton or oil-based synthetics like polyester. Cellulosics made from sustainable raw materials through a closed-loop process are rated higher on the Made-By Environmental Benchmark for Fibres3 than both cotton and viscose (rated E). Currently, however, both the harvesting of the raw material (usually wood but can be bamboo or cotton linters) and the processing with chemicals adversely impact the environment.

The raw wood used often comes from unsustainable sources. (According to the environmental not-for-profit Canopy “of the 6.5 million tonnes of viscose pulp produced annually approximately half (3.3 million tonnes) comes from Ancient and Endangered Forests, such as the carbon-rich peatlands of Indonesia and old-growth boreal forests of Canada.”)

The processing plants generally do not have adequate treatment facilities to stop the chemicals used from polluting water and air.

Viscose fiber production also contributes to more greenhouse gas emissions than cotton production4. The chemicals, in particular carbon disulfide, can be toxic for

workers who come into contact with high concentrations, with the risk of neurological and psychiatric side-effects5. “Cheap production, which is driven by the fast fashion industry, combined with lax enforcement of environmental regulations in China, India and Indonesia, is proving to be a toxic mix.”6

A 2017 report, Dirty Fashion: how pollution in the global textile supply chain is making viscose toxic by the Changing Markets Foundation, found clear evidence that manufacturers using major viscose mills in China, Indonesia and India “…are dumping untreated wastewater, which is contaminating local lakes and waterways”. The report noted a “devastating impact” on local people’s quality of life, including affecting traditional livelihoods like fishing. Researchers also visited areas where pollution is thought to be behind a rise in cancer. Yet it is possible to produce viscose cleanly, using closed-loop processes whereby no chemicals enter the waste stream and sustainable raw materials.

Viscose is produced by a limited number of producers – 10 producers make 80 percent of the world’s viscose, and just two producers account for 40 percent of this. They tend to be clustered geographically within China, Indonesia, and India. This means that a combination of brand pressure, regulatory enforcement, and supplier implementation could clean up viscose production relatively quickly.

Viscose and forests

The environmental not-for-profit Canopy brings together brands and viscose suppliers to commit to and implements sourcing of raw materials that do not destroy forests.

The goals of all partners in CanopyStyle are to:

- Eliminate sourcing from the world’s ancient and endangered forests by 2017.

- Increase the use of alternatives like recycled clothing or left-over straw as feedstock for man-made cellulosic.

- Support innovative conservation solutions and forward protection of Coastal Temperate Rainforests like Vancouver Island, Boreal Forests in Canada and Russia, and in tropical rainforests such as the Amazon and Indonesia.

- Avoid controversial sourcing such as illegal logging or logging in areas where free, prior, and informed consent of indigenous communities has not been given.

- Where points 1 to 4 have been met, use Forest Stewardship Council (FSC) Certification as a tool to ensure sustainable forest management in areas where wood sourcing is acceptable.

More positive alternatives to conventional viscose:

- Lenzing lyocell, in the form of Tencel; and Modal.

- Birla Eco Viscose

- Re:newcell

- Evrnu

Pros and Cons of Bamboo Viscose

Bamboo is the fastest-growing plant in the world. Its cultivation needs no chemical fertilizers or pesticides. It’s now pretty much established that growing bamboo is sustainable.

However, the viscose transformation process requires the use of hazardous chemicals to transform bamboo wood pulp into viscose from bamboo (or bamboo rayon). Viscose is also known as rayon.

This process can be used responsibly and has great potential. But it’s often used irresponsibly and Chinese viscose producers need to get their $#*% together if we want to keep calling this fiber eco-friendly.

This image above shows the viscous liquid (looks like honey) obtained when carbon disulfide and sodium hydroxide are mixed with bamboo wood pulp. It’s a key step in the viscose process. And this is what we should all picture in our heads when we read “viscose or rayon from bamboo”.

Because of the complexity of its transformation process (viscose) and lack of potential for local culture, bamboo is at number 4. And if Chinese viscose producers don’t raise their standards to EU BAT before 2025, this fiber will no longer be on this list.

Pros of bamboo viscose:

- Absorb 35% more CO2 than any other forest.

- Grows without pesticide or insecticide.

- Good yield of fiber per acre.

- Viscose clothes are easy to dye & wash (wrinkle-free).

- Viscose fabrics are comfortable and soft.

- Requires no irrigation water.

- Biodegradable.

Cons of bamboo viscose:

- Making viscose requires sodium hydroxide, sulfuric acid, and carbon disulfide.

- Does not grow and isn’t transformed in Canada or the United States.

How is viscose staple fiber made?

- Cellulose Extraction: The journey begins with wood pulp cellulose. Quality fabric requires cellulose that’s at least 90% pure.

- Alkali Cellulose Conversion: The cellulose dissolves in caustic soda, converting it to alkali cellulose. This step removes impurities.

- Pressing: Alkali cellulose is pressed, creating sheets called “white crumb.”

- Aging and Xanthation: The white crumb ages with oxygen exposure, then reacts with carbon disulfide to form “yellow crumb.”

- Ripening: The yellow crumb ripens for a few hours.

- Filtering and Extruding: After ripening, the yellow crumb is filtered, and any gas bubbles are removed .

- Forming Threads by the Wet Method: The viscose solution is then used to form threads through a wet spinning process.

- Trimming and Drying: The threads are trimmed and dried to create VSF fibers.

Characteristics of viscose staple fiber

- Durable and Soft: Viscose fabric is both durable and soft to the touch.

- Breathable: It allows air circulation, making it comfortable to wear.

- Moisture-Wicking: Viscose absorbs moisture well.

- Versatile: Used in clothing (dresses, blouses, skirts), household items, and even as an alternative to silk

- Softness: VSF fibers are soft and comfortable, making them suitable for clothing and textiles.

- Drapeability: Their excellent drape quality allows for elegant and flowing garments.

- Absorbency: VSF absorbs moisture well, making it ideal for towels, bed linens, and other home textiles.

- Biodegradability: VSF is a natural fiber that decomposes over time, contributing to sustainability.

Usage of viscose staple fiber

VSF finds applications in apparel, dress materials, knitwear, and nonwovens (such as wet wipes and hygiene products)

Viscose fiber manufacturer:

Below is a list of viscose fiber factories that VNPOLYFIBER is working with:

Allmed Medical Products Co.,Ltd.

Anhui Hanlian Color Spun Co.,Ltd.

Anhui Golden Spring Non Woven Fabrics Co.,Ltd.

Anhui Yuhua Textile Limited Company

Bazhou Jinfu Special Yarn Industry Co.,Ltd.

Bofin Textile Co.,Ltd.

Changzhou Texhong Textile Co.,Ltd.

Dalian Ruiguang Nonwoven Group Co.,Ltd.

Great United New Material(Suzhou)Co.,Ltd.

Da Yuan Development No-Wovens Fabric Tian Jin Co.,Ltd.

Danyang Dansheng Textile Co.,Ltd.

Dezhou Aiku Import And Export Co.,Ltd.

Dezhou Hengfeng Group Co.,Ltd.

De Zhou Hua Yuan Eco-Technology Co.,Ltd.

Eastex Industrial Science And Technology Co.,Ltd.

Fuding Aolaite Nonwoven Co.,Ltd.

Fujian Changle Jinyuan Textile Co.,Ltd.

Fujian Long Yuan Textile Co.,Ltd.

Fujian Nanfang Textile Co.,Ltd.

Fujian Sanming Textile Co.,Ltd.

Fujian Changle Second Cotton Textile Factory

Fujian Changle Changyuan Textile Co.,Ltd.

Fujian Changle Jinyuan Textile Co.,Ltd.

Fujian Changle Zhengxin Textile Co.,Ltd.

Fujian Shunyuan Textile Co.,Ltd.

Fujian Xiangyuan Textile Co.,Ltd.

Fujian Yi Lai Shi Ye Co.,Ltd.

Fujian Changle Changyuan Textile Co.,Ltd.

Fuzhou Develop Zone Zhengtai Textile Co.,Ltd.

Fuzhou Xianglong Textile Co.,Ltd.

Fuxin Fu Zhi Yuan Textile Co.,Ltd.

Gaoan Wei Xin Textile Co.,Ltd.

Hainan Xinlong-Nonwovens Inc.,Ltd.

Hangzhou Chun Hui Textile Co.,Ltd.

Hangzhou Da Jia Textile Co.,Ltd.

Hangzhou Dong Feng Textile Co.,Ltd.

Hangzhou Guo Jin Textile Co.,Ltd.

Hangzhou Hongfeng Textile Group Co.,Ltd.

Hangzhou Nbond Nonwovens Co.,Ltd.

Hangzhou Xiaoshan Linfen Textile Co.,Ltd.

Hangzhou X-Yuan Spinning Co.,Ltd.

Hangzhou Yi Jing Textile Co.,Ltd.

Hebei Xue Yang Textile Co.,Ltd.

Henan No.1 Textile Co.,Ltd.

Henan Pingmian Textile Group Co.,Ltd.

Henan Yuzhou Shenyu Textile Co.,Ltd.

HENGFENG GROUP

Hongyang Holding Group Co., Ltd.

High tech branch of Hunan Yunjin Group Co., Ltd.

Huafu Fashion Co.,Ltd.

Huixian Jinyu Textile Co.,Ltd.

Jilin Four Seasons Harvest Textile Co.,Ltd.

Jihua 3542 Textile Co.,Ltd.

Jiamusi Tian He Textile Co.,Ltd.

Jiaxing Heng Rui Textile Co.,Ltd.

Jiaxing Tianzhihau Textile Co.,Ltd.

Jiangsu Bao Da Textile Co.,Ltd.

Jiangsu Dasheng Group Co.,Ltd.

Jiangsu Dong Hua Textile Co.,Ltd.

JIANGSU JIN MILAN TEXTILE CO.,LTD.

Jiangsu Kangni Group Co.,Ltd.

Jiangsu Shazhou Printing And Dyeing Group

Jiangsu Tianhua Color Spinning Co., Ltd.

JINLAN TOP DYED MELANGE

Jiangsu Xinfu Fiber Technology Co., Ltd.

JIANGSU YDTEX GROUP CO.,LTD

Jiangxi Da Jia Natural Special Fiber Co., Ltd.

HUA CHUAN COLORED SPINNING Textile Co.,Ltd.

Jiangsu Jinyuan Textile Co.,Ltd.

Jiangyin Shuang Yuan Nonwoven Co.,Ltd.

Jiangyin Tian Hua Yarn Co.,Ltd.

Wujiang Jingyi Special Fiber Co., Ltd.

Jingzhou AODA Textile Co.,Ltd.

Lan Sha Suzhou Technology Co.,Ltd.

Linz Textile Holding Co., Ltd.

Linyi Kaihang Nonwovens New Material Co.,Ltd.

Linyi Jinling Textile Co.,Ltd.

Shandong Mengyin Huifeng Textile Co.,Ltd.

Nantong Textile Group Co.,Ltd.

Nantong Shuanghong Textile Co.,Ltd.

Nanyang Textile Group Co.,Ltd.

Ningxia Ruyi Technology&Fashion Industry Co.,Ltd

Peixian Longsheng Textile Co.,Ltd.

Peixian New Silk Road Textile Co., Ltd.

Qilu Hongye Textile Group Co.,Ltd.

Qingdao Textile Group Co.,Ltd.

Qingzhou Yinlong Textile Co.,Ltd.

Quanzhou Ming Hen Textile Co.,Ltd.

Rugao City Dingyan Textile Co.,Ltd.

Shandong Binzhou Jinyuan Textile Co.,Ltd.

Shandong Chaoyue Textile Co.,Ltd.

Dahai Group Co.,Ltd.

Shandong Derun New Material Technology Co.,Ltd.

Shandong Dashing Cashmere Textile Co.,Ltd.

Shandong Heyue Nonwoven Material Co.,Ltd.

Shandong Hongtai Textile Technology Co.,Ltd.

Shandong Longhua Textile Co.,Ltd.

Shandong Huaxing Textile Group Co.,Ltd.

Shandong Long Run Textile Co.,Ltd.

Shandong Mengyin Huifeng Textile Co.,Ltd.

Shandong Mingsheng Textile (Group)Co.,Ltd.

Shandong Ruyi Technology Group Co.,Ltd.

Shandong Gaomi Kangtai Textile Co.,Ltd.

Shandong Yongxin Nonwoven Material Co.,Ltd.

Shandong Shenghe Textile Co.,Ltd.

Shandong Shuaike New Material Technology Co.,Ltd.

Shandong Wenshang Ruyi Runfa Textile Co.,Ltd

Shandong Xinguang Co.,Ltd.

Shandong Yanggu Shunda Textile Co.,Ltd.

Shandong Zhenkai New Material Co.,Ltd.

Shanghai Textile Group Dafeng Textile Co.,Ltd.

Shaoxing Chengsheng Textile Co.,Ltd.

Shaoxing Weisheng Color Spinning Co.,Ltd.

Shaoxing Shujieya Nonwoven Material Co.,Ltd.

Siping Xingda Textile Co.,Ltd.

Su Zhou Pu Re-Fiber Textile Technology Co.,Ltd.

Suzhou Sishon Bio-Cellulose Co.,Ltd.

Suzhou Shunjie Spunlaced Composite Material Co.,Ltd.

Suzhou Yongjinda Textile Co.,Ltd.

Su Zhou Zhenlun Spinning Co.,Ltd.

Texhong Textile Group Co.,Ltd.

Taifeng Textile Co.,Ltd.

Weiqiao Textile Co.,Ltd.

Weifang Hengjin Nonwoven Material Co.,Ltd.

Wuxi Si-Mian Textile Co.,Ltd.

Wuxi No.1 Cotton Mill Textile Group Co.,Ltd.

Wujiang Jingyi Special Fiber Co., Ltd.

Wujiang City Zhenzhou Air-Jet Loom Factory

Five Rings(Group)Shareholding Co.,Ltd.

Wuhan Yudahua Textile And Garment Group Co.,Ltd.

Xiajin Fengrun Co., Ltd.

Xiajin Ruixin Textile Co.,Ltd.

Xinhuayuan Textile Co.,Ltd.

Xin Jiang Fulizhenlun Spinning Co.,Ltd.

Xinxiang Guanghua Textile Co.,Ltd.

Xinxiang Longbo Textile Co.,Ltd.

Xuzhou Huasheng Textile Co.,Ltd.

Xuzhou Jiaxin Textile Co.,Ltd.

Xuzhou Jinye Textile Technology Co.,Ltd.

Yichun Jiayi Textile Co.,Ltd.

Yibin Boyang Textile Technology Co.,Ltd.

Intel-Tex(Suzhou)New Textile Materials Technology Co.,Ltd.

Binzhou Yuyue Home Textile Co.,Ltd.

Far Spinning Industry(Wuxi)Co.,Ltd.

Zhangjiagang Hezhong Textile Co.,Ltd.

Zhangjiagang Zhongshi Textile Co.,Ltd.

Changchun Oriental Textile Group Co.,Ltd.

Zhejiang Bailian Nonwoven Technology Co.,Ltd.

Zhejiang Chunyuan Technology Textiles Co.,Ltd.

Zhejiang Dongfei Textile Co.,Ltd.

Zhejiang Hongyang Nonwoven Material Co.,Ltd.

Weida Textile Group Co.,Ltd.

Husheng Non-Woven Fabric Co.,Ltd.

Zhejiang Jinfan Textile Co.,Ltd.

Zhejiang Junfei Textile Co.,Ltd.

Zhejiang Longyouanda Textile Co.,Ltd.

Zhejiang Mingshengda Medical Technology Co.,Ltd.

Zhejiang Senlong Textile Co.,Ltd.

Zhejiang Wang Jin Nonwovens Co.,Ltd.

Hangzhou Zhengda Textile Co.,Ltd.

Zhucheng Fufu Textile Technology Co.,Ltd.

Chinatex G-Way Textiles Co.,Ltd.

Zibo Yinshilai Textile (Group) Co.,Ltd.

Source from Commonobjective. co