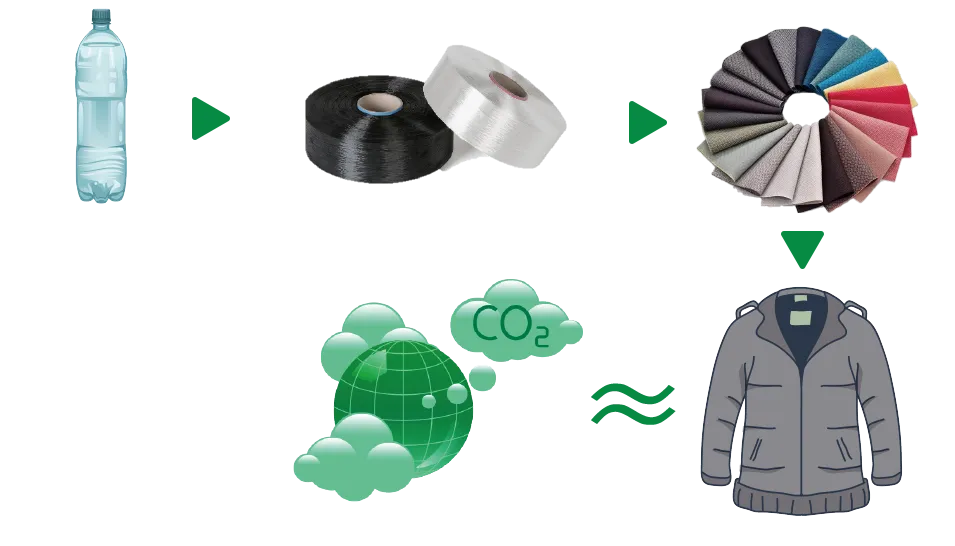

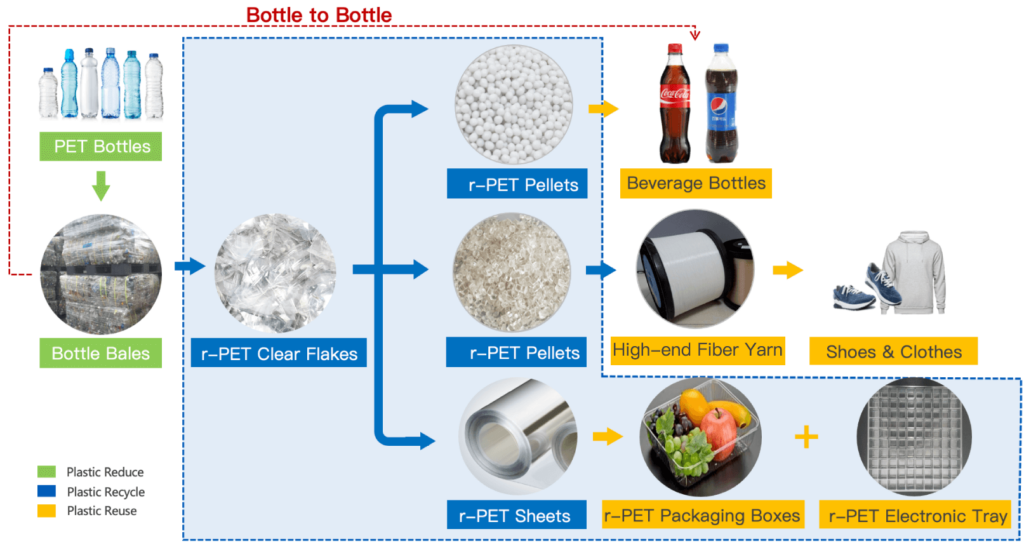

When you buy a product packaged in PET, you’ve chosen a package with an established, accessible end-of-life option—recycling. From a curbside bin or wherever you bring your recycling, PET containers are collected, sorted, processed, cleaned, and then remanufactured into a variety of new products, including fiber for clothing and carpets; fiberfill for soft furnishings and sleeping bags; pallet strapping; food and non-food bottles, and thermoformed packaging such as cups and take-out containers.

WHAT IS PET?

PET stands for polyethylene terephthalate, and is a form of polyester. PET bottles and containers have been safely used to package beverage, food, personal care and household items since the introduction of the first PET bottle in the 1970s; they are easily identified by the #1 code on or near the bottom.

Packaging designers and manufacturers like PET because it’s safe, strong, transparent and versatile, and helps protect product integrity, freshness and taste. Consumers choose it for its clarity, safety, light weight, reseal-ability, shatter-resistance and innovative style. All agree on its recyclability attributes: PET bottles are accepted in virtually all recycling programs in the U.S.; over 60% of U.S. households also have non-bottle PET recycling available to them, and up to 100% of a PET package can be made from recycled PET, which can in turn be recycled again… and again.

Recycling a PET bottle keeps it out of the landfill, but it does much more than that. Recycled PET resin is a valuable manufacturing feedstock that can be reprocessed and reused in bottles over and over again. Recycling instead of landfilling, then using that reprocessed PET material as a raw material for new products, greatly reduces the greenhouse gas and carbon emissions impact and requires less overall energy to produce the new product.

PET is approved as safe for food and beverage content by the U.S. Food and Drug Administration and similar regulating agencies throughout the world. It has been used to package beverages, food and other products for more than 35 years.

PET never contains or produces Bisphenol A (BPA), dioxins or plasticizers.

Polyethylene terephthalate items referenced are derived from terephthalic acid (or dimethyl terephthalate) and mono ethylene glycol, wherein the sum of terephthalic acid (or dimethyl terephthalate) and mono ethylene glycol reacted constitutes at least 90 percent of the mass of monomer reacted to form the polymer, and must exhibit a melting peak temperature between 225°C and 255°C, as identified during the second thermal scan in procedure 10.1 in ASTM D3418, when heating the sample at a rate of 10°C/minute.

There are some misleading beliefs and perceptions about PET plastics out there. Let’s find out the facts to those questions.

Is it better to choose aluminum cans over PET bottles?

According to a 2010 cradle-to-grave cost analysis by Franklin Associates (a solid-waste management consulting group owned by Eastern Research Group, Inc.), PET plastic bottles use less energy, generate less solid waste and create significantly fewer greenhouse gases than aluminum cans.

Are PET plastics bad for the environment?

PET plastics already have a low carbon footprint. But if just 200,000 people each recycled one more PET bottle per day, it would eliminate 2,168 tons of greenhouse gases. And because PET bottles are so recyclable, fewer end up in landfills.

Are PET plastic bottles the most common form of garbage?

Discarded cigarette butts are actually the world’s leading form of garbage, followed by food containers and wrappers. Plastic bottles—all different types—are third. These, as well as aluminum cans and glass bottles, are just a few of the many forms of trash for which we all must take greater responsibility. But if more people were aware of PET’s 100% recyclability, they’d be less inclined to throw PET bottles away.

Does usage of PET bottles create ocean debris?

When you choose to recycle your PET bottle, you’re helping our planet. If you recycle right—in the recycling bin—your PET bottle can be recycled over and over again.

Do PET plastics cause cancer?

That’s not correct. There are no known links between PET and cancer of any kind.

Do PET bottles in landfills leach and contaminate groundwater?

PET bottles are chemically inert, so they pose no risk of leaching or contamination.

Is it better to choose an aluminum can for my beverage than a bottle made of PET?

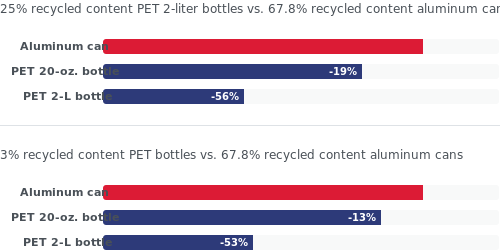

Beverage containers made from PET have a lower carbon footprint than their aluminum counterparts, when you compare the whole life cycle of the product (i.e., making, transporting, using the product). The carbon footprint of a beverage container made with recycled PET can be 15% to 50% lower than its aluminum counterpart.

Is bisphenol-A (BPA) present in water bottles?

PET has never contained bisphenol-A (BPA), nor will it ever.

Is A bottle made of glass rugged like those made of PET?

PET is strong and lightweight—and unlike glass, will not shatter when dropped.

Is boxed water better for the environment?

According to the EPA, many mixed plastic and paper cartons do not get recycled, contributing to the 78 million tons of packaging waste in landfills, as of 2015. Also, boxed water and juices often come with plastic straws and have plastic liners. Water bottles made from PET are 100% recyclable, including the caps! PET is commonly used in food containers, due to its organoleptic properties, imparting no odor or taste in your food or beverage.

Packaging materials can be very different from one another. Some offer varying degrees of performance and clarity. PET offers infinite recyclability, and with a lower carbon footprint, it’s head and shoulders above glass and aluminum. Instead of ending up in landfills, PET bottles and containers can be reprocessed for reuse, over and over, in millions of products. It’s a huge advantage. Accordingly, packaging and plastics made of PET are all imprinted with the #1 recycling symbol.

PET is the world’s most commonly recycled plastic.

There are 265 thousands of jobs created from PET production and recycling in North America alone.

Nearly 1.6 billion pounds of clean recycled PET went back into the production of new products—such as those pictured above—in the U.S. and Canada in 2018.

Beginning in 1988, all plastics were designated a number (1 through 7) to display, as defined today by ASTM International. The code number identifies what kind of resin each particular plastic product is made of. PET has been and always will be identified by the Resin Identification Code 1.

Patented in 1973, the PET plastic bottle has grown in popularity and versatility to become a leading choice for water and beverage bottles. With its infinite recyclability, environmentally positive profile and virtually limitless life cycle, PET can come back to serve us again and again—and not just as another water bottle.

Benefits of PET bottles

PET’s properties allow for superior innovation, both in terms of package design and performance. This allows you to meet customer needs for new and sophisticated product taste profiles with shelf-popping options in the pack sizes your customers are looking for.

PET is well known for its clarity, making it a lightweight, non-breakable alternative to glass and other plastic resins. Consumers are increasingly interested in authentic, “real food” offerings and transparent PET supports this trend.

PET has good barrier properties that protect and preserve the contents of its package. Oxygen transmission is an important factor in ensuring product shelf life and freshness. PET provides almost nine times more protection against oxygen transmission than does PLA and over 40 times more than HDPE.

PET packaging is increasingly lightweight so you use less per package. PET bottles and jars are accepted for recycling in virtually every program in the United States and Canada, and recycled PET material can be used in bottle and thermoformed packaging over and over again. No other plastic resin can make a stronger closed-loop recycling claim.

Why PET Is the Better Option

While people are understandably concerned about plastic pollution, the impact of aluminum and glass containers hasn’t generated the same kind of headlines—but it needs some scrutiny too. Let us show you how they compare.

Aluminum creates more greenhouse gases.

A February 2016 study on gas emissions by the U.S. Environmental Protection Agency, using the widely accepted Waste Reduction Model (WARM), shows that aluminum cans, even when manufactured with recycled materials, generate more tons of carbon dioxide (CO2) per ton of metal than do PET bottles or containers with recycled PET.

Aluminum impacts the environment.

Too many packages become litter and end up in our waterways. Aluminum cans have been discarded into the world’s oceans since their invention in 1959. But, unlike many plastics that float on or near the surface and remain visible to the naked eye, aluminum cans sink. The concerns are:

- Cans accumulate on ocean floors, in delicate coral reefs, and in bays and riverbeds.

- There, they are more difficult to see, collect and recycle.

- Can tabs break off and are ingested by wildlife and fish.

All aluminum starts out as bauxite ore, which must be mined. Mining causes:

- Deforestation

- Land erosion

- Pollution of nearby waterways

Aluminum must also be refined before it’s made into a can or container. The process uses caustic soda and other chemicals to extract aluminum from the ore. According to the EPA’s recent Bauxite and Alumina Production Wastes report, this process leaves behind residual byproducts that can find their way into soil and water, including:

- Uranium

- Thorium

- Radium

Aluminum cans contain a plastic liner.

Food and beverage cans have a plastic liner, often a bisphenol-A (BPA)–based epoxy, which forms a barrier between the product and metal, protecting against foodborne diseases. On its website, the Aluminum Association states its position on BPA: “The Association understands that ongoing research and study is taking place on the safety and efficacy of BPA, and will continue to monitor these developments closely.”

Glass creates more greenhouse gases.

Glass containers create more greenhouse gases than plastic containers. According to Springer.com, an academic publisher dedicated to the advancement of science, its 2008 Life Cycle Assessment (LCA) found that “glass jars produce between a quarter and a third more greenhouse gases than plastic jars.”

Glass transportation costs are higher.

Glass, by nature, is heavier than plastic, weighing up to 10 times more. This makes it more costly to transport and requires more fuel to be consumed and/or more trips to be made, according to PackagingoftheWorld.com. Increased emissions from either or both issues creates even more greenhouse gases.

Shattered glass is dangerous.

Glass shatters if it’s dropped or damaged, which is a safety hazard for consumers. PET bottles and containers are flexible and will not shatter, whether in transit or when tossed into a recycling bin.

Glass fragments are a waste problem.

Broken glass is as dangerous for waste haulers and recyclers to handle and sort as it is for consumers. In fact, according to Solutions.recyclecoach.com, many facilities are not equipped to remove tiny bits of broken glass from other recyclables. Broken glass can also contaminate other recyclables such as paper and cardboard. Today, more and more recycling companies do not accept broken container glass at all.

Life Cycle of a PET Bottle

Collection

Once any residual liquids or foods have been removed or discarded empty PET bottles and containers should be rinsed, if possible, and placed in the proper plastic recycling bin. They should not be replaced in normal trash bin, or they will not be recycled you can also leave PET bottle caps and labels on, unless the label specifically tells you to remove it, as not all the label materials are recyclable.

Separation

A waste hauler delivers the collected recyclables to an intermediate processor who separates plastic from non-plastic and further removes any impurities then sorts the plastic containers by color and or resin ID code. You can help here by only putting only clean recyclables into your receptable. Putting in non-recyclable containers raised cost of recycling as a downstream companies have to set up systems to remove them.

Bailing

After being separated, PET bottles are gathered, baled and sent to PET reclamation center there PET is shredded into flake.

Sink or float

The shredded PET then goes into a water tank, where heavier, denser PET materials drop to the bottom and are retrieved for final cleaning and drying.

Back to the beginning

Clean, dry PET is melted into pellets or sheet, or spun into polyester fibers for use in new bottles or packaging, clothing, carpeting and other items.

PET Plastic Industry World Map

Globally, PET has a recovery rate of 58%. Source: Wood Mackenzie report

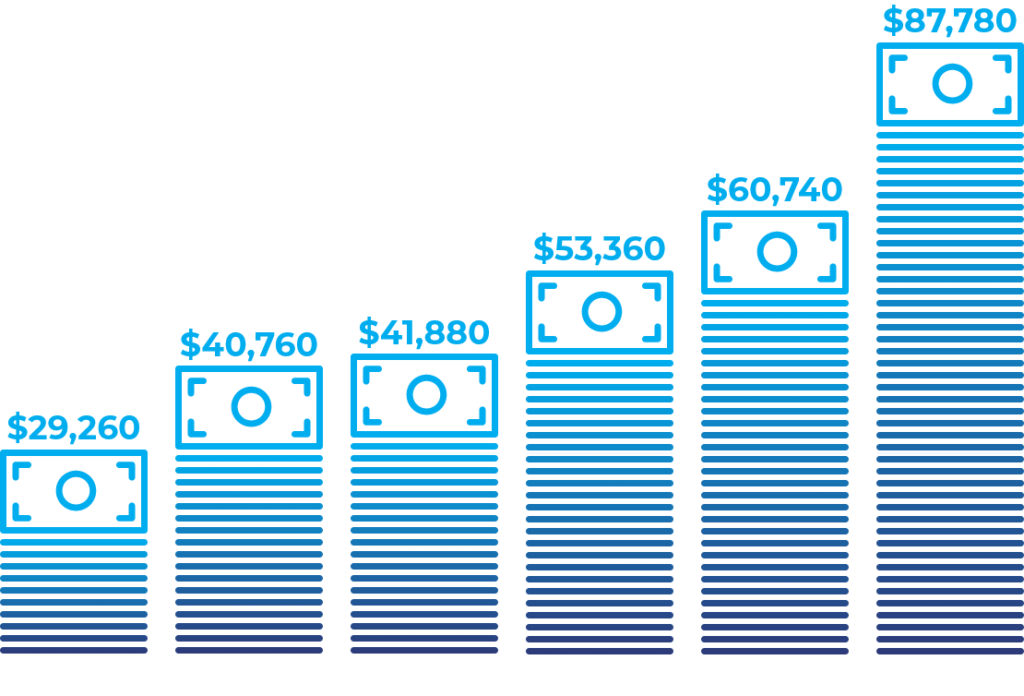

The PET industry is a growing field with a wide range of occupational opportunities.

- Packaging engineer, Chemist, Materials engineer

- Drafters, Administration, Data entry, Accounting

- Sales engineer, Human resources

- Machine operator, Manufacturing, Construction, Tool programmer, Machinist

- Extruding/pressing, Industrial designer, Fabrication/assembly, Maintenance, Facilities manager, Recycler

- Mechanical engineer, Shipping/receiving, Logistics

- Computer technician, Technical writer, Process technician, Mold maker

Plastics industry average annual U.S. wages by occupation. Source: 2019 U.S. Bureau of Labor Statistics

RECYCLING THE UNRECYCLABLE

Today, the majority of plastic packaging material value (USD 80–120 billion annually), is lost to the economy after one single use*. The plastics that don’t immediately end up in landfills are mostly downcycled into low-value applications — and cannot be recycled several times. For example, a high-value water bottle may get recycled into textile fibers, which currently have no sustainable re-use.

But while most of us know that plastic packaging is a high polluter, less attention has been paid to the impact of the textile space in general, and polyester fiber specifically, which makes up 52% of global fiber production.

Roughly 85% of textiles are never recycled, accounting for some 11.3 million tons of waste in the U.S. alone in 2018.

CASE STUDY: TECHNOLOGY CHANGES THE WAY PEOPLE PRODUCE PET PLASTIC AND POLYESTER FIBER

Loop Industries technology transforms PET (polyethylene terephthalate) plastic and polyester fiber waste into high-purity, virgin-quality PET resin that can be used again and again.

Removing dyes, additives, contaminants, as well as other plastics, Loop can handle ALL types of PET plastic and polyester fiber waste, even those that others consider to be unrecyclable.

Decoupling PET and polyester fiber production from fossil fuels by using waste materials, Infinite Loop facilities will also be located near large population centers, where people are consuming and recycling plastic, to create a fully circular plastics ecosystem.

Infinite Loop helps reduce plastic waste and increase plastic recycling rates by upcycling plastic that cannot be processed

Infinitely recyclable: the PET plastic and polyester fiber produced by Infinite Loop can be infinitely recycled without quality degradation