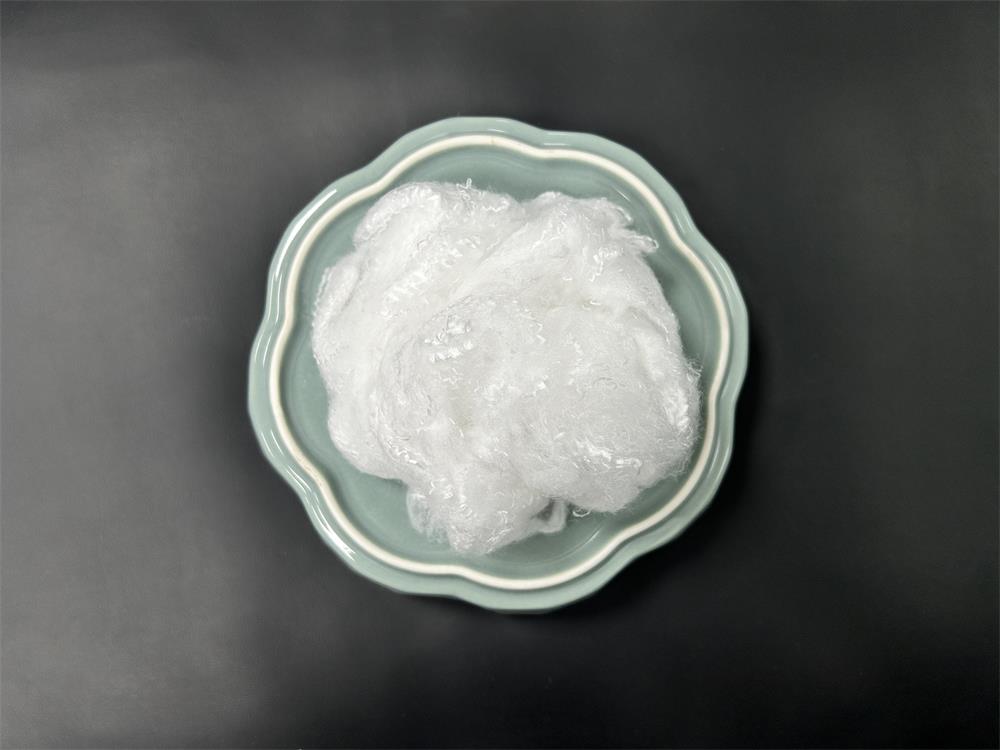

What is Low melting fiber?

In the ever-evolving field of textile technology, innovation is driving the future of fabric development. One standout advancement is low-melt polyester fiber, a groundbreaking material with unique properties and a wide range of applications that are reshaping industries and pushing the boundaries of fabric engineering.

Low melting point polyester fiber is a type of adhesive fiber used in thermal bonding processes. It is a new technology that is conjugately spun from ordinary polyester and modified low melting point polyester, allowing for environmentally friendly bonding at low temperatures. This material offers excellent shape retention and bonding capabilities when combined with other materials.

The versatility and performance of low-melt polyester fibers are impressive. They have a soft feel, strong bonding effect, and stable heat shrinkage performance. In addition, they possess properties such as anti-pilling, abrasion resistance, flame retardancy, anti-deformation, anti-static, and heat resistance.

Low melting point polyester fibers are utilized across various industries, including clothing, industrial textiles, non-woven fabrics, and environmentally friendly alternatives. In the clothing industry, these fibers improve garment construction, enhancing comfort and longevity. In industrial applications, they strengthen composite materials in automotive and construction sectors. Additionally, they contribute to the production of nonwovens with tailored properties for hygiene, filtration, and industrial uses.

Low Melt Co-PET/PET Fiber

Low Melt Co-PET/PET Short Cut Fiber is a bicomponent fiber featuring a sheath/core concentric structure. It utilizes a low melting point sheath made of Polyethylene and a core material of Polypropylene, complemented by a standard hydrophilic spin finish. This fiber is available in super short lengths of 4, 5, 6, and 12 mm, making it suitable for airlaid applications.

This product is supplied by VNPOLYFIBER and is ideal for airlaid products commonly used in absorbent and insulation applications, including food pads and insulation boards.

Product Technical Specification

Standard TDS of 4den 38mm Standard Low Melt Co-PET/PET Fiber

| Characteristic | Unit | Min | Max | Test Method | Remark |

| Linear Density | dtex | 4.4 | 4.67 | GB/T14335-2008 | |

| Cut length | mm | 37 | 39 | GB/T14336-2008 | |

| Tenacity at peak | cn/dtex | 2.6 | 3.1 | GB/T6504-2017 | |

| Elogation at peak | % | 40 | 80 | GB/T14337-2008 | |

| Crimp n. | n./inch | 10 | 12 | GB/T14328-2008 | Adjustable |

| Spin finish | % | 0.3 | 0.4 | GB/T6504-2017 | Adjustbale |

Fiber denier: 2dn ~ 6dn,

Main cut length: 38mm or 51mm

Luster: raw white/semi dull or full dull,

Spin finish: standard finish or hydrophilic finish

Low Melt Co-PET/PET Short Cut Fiber

Low Melt Co-PET/PET Short Cut Fiber is a bicomponent fiber featuring a sheath/core concentric structure. It utilizes a low melting point sheath made of CoPET and a core material of

standard polyester with a melting point of 265°C, complemented by a standard hydrophilic spin finish. This fiber is available in super short lengths of 4, 5, 6, and 12 mm, making it suitable for airlaid applications.

This product is ideal for airlaid products commonly used in absorbent and insulation applications, including food pads and insulation boards.

Product Technical Specification

Standard TDS of 2den 6mm Standard Low Melt Co-PET/PET Short Cut Fiber

| Characteristic | Unit | Min | Max | Test Method | Remark |

| Linear Density | dtex | 2.2 | 2.46 | GB/T14335-2008 | |

| Cut length | mm | 5 | 7 | GB/T14336-2008 | |

| Crimp n. | n./10mm | 4 | 6 | GB/T14328-2008 | Adjustable |

| Spin finish(phil) | % | 0.3 | 0.4 | GB/T6504-2017 | Adjustbale |

Fiber denier: 2dn /4dn,

Main cut length: 4/5/6/12mm

Luster: raw white

Spin finish: standard hydrophilic

Recycled Low Melt Co-PET/PET Fiber

Recycled Low Melt Co-PET/PET Fiber: This is a bicomponent fiber featuring a sheath/core concentric structure. The low melt sheath is composed of CoPET, a modified polyester with a melting point of 110°C, while the core consists of standard polyester with a melting point of 265°C.

This fiber is highly suitable for thermal bonding nonwoven fabrics, which find extensive applications in the automobile and hygiene sectors.

Product Technical Specification

Standard TDS of 4den 38mm Standard Recycled Low Melt Co-PET/PET Fiber

| Characteristic | Unit | Min | Max | Test Method | Remark |

| Linear Density | dtex | 4.4 | 4.67 | GB/T14335-2008 | |

| Cut length | mm | 37 | 39 | GB/T14336-2008 | |

| Tenacity at peak | cn/dtex | 2.6 | 3.1 | GB/T6504-2017 | |

| Elogation at peak | % | 40 | 80 | GB/T14337-2008 | |

| Crimp n. | n./inch | 10 | 12 | GB/T14328-2008 | Adjustable |

| Spin finish | % | 0.3 | 0.4 | GB/T6504-2017 | Adjustbale |

Fiber denier: 2dn ~ 6dn,

Main cut length: 38mm or 51mm

Luster: raw white/semi dull or full dull,

Spin finish: standard finish or hydrophilic finish

Recycled low melting point polyester fibers offer sustainability benefits by using recycled materials and promoting a more sustainable life cycle for products. As the demand for environmentally friendly materials grows, the adoption of these fibers can contribute to a more sustainable and resilient future.