Chemical Fiber Machine, PSF Production

- This complete set of equipment takes polyester chip and bottle flakes and pet lumps as raw material,

- Adopt the melting spinning technology and the technology of variable-frequency drive after drafting, curling, cutting and packaging processing machine to produce polyester staple fiber products with high strength and good elongation.

PRODUCT DETAIL

Recycled Polyester staple fiber is a synthetic man-made fiber made from PET/Polyester waste and post consumed PET bottles. It is used in non-woven carpets, wadding, filtration industries, as a polyfill for stuffing cushions, pillows, soft toys, quilts. It’s also used for spinning yarns and making geotextiles. Hollow Polyester staple fiber gives good resilience properties and is used to make premium pillows, cushions and quilts.

Recycling of PET/Polyester waste and used PET bottles is essential to maintain cleanliness of environment.

Worldwide millions of PET bottle are consumed daily and thrown to trash. PET is also called polyester. Polyester is a synthetic polymer made of purified terephthalic acid (PTA) or its dimethyl ester dimethyl terephthalate (DMT) and monoethylene glycol (MEG).

Since PET bottles are practically non-bio-degradable, it was very difficult to dispose them. New technology was developed in Europe, Korea and finally China which helped in recycling this post consumed PET bottles to make man-made fibers like Recycled Polyester Staple Fiber. These fibers are then used to make non-woven carpet for automobiles, making quilts, yarns, pillows etc.

First bottles arrived in a factory, collected from trash, in bale form. These bales are opened and manually sorted to take out contaminations like iron, PVC, stones etc. Once cleared these PET bottles are crushed to make 12-15 mm flakes and are hot washed in chemical solution containing 2% solution of Sodium Hydroxide. This chemical helps in taking out glue from bottles and also cleaning them. The overall contaminations in PET flakes should not be more than 200 ppm.

These dried flakes are then taken to Extruder for spinning. Spinnerets are available to make either hollow or solid PSF of varying denier (1.2Den 33Den). Filaments coming out of spinning are collected in cans or bobbins. This completes the spinning. Hollow and Solid PSF can be treated to make Siliconized, conjugated, polyfill, harsh, bouncy, anti-static, anti-fungal. In second step these cans are taken to Creel area where many cans or bobbins are combined to make tow and stretched several times in a chemical hot bath to make fiber. These fibers are then dried and relaxed in a relaxer and cut in various cut length before bale packing.

VNPOLYFIBER has been providing Polyester Staple Fiber production line as our core business line, we have the capability to supply you the required production line together with professional technology and after sales service. Besides, we offer various spare parts related to PSF production line at customer requirement.

1. Main production line for spinning

It mainly consists of extruder, filter, spinning insulation beam, thermal agent circulation system, metering pump, pump driving system, spin pack, blasting device, winding machine and yarn can traverse system.

2 Auxiliary production units, including

Dissembling, cleaning, assembling, preheating of spin pack; testing of spinneret and preparation of sand; preparation of finish oil; air conditioning and ventilation; physical and chemical detection.

3 General facilities, including

Electric substation, water supply, compressed air system and other comprehensive facilities.

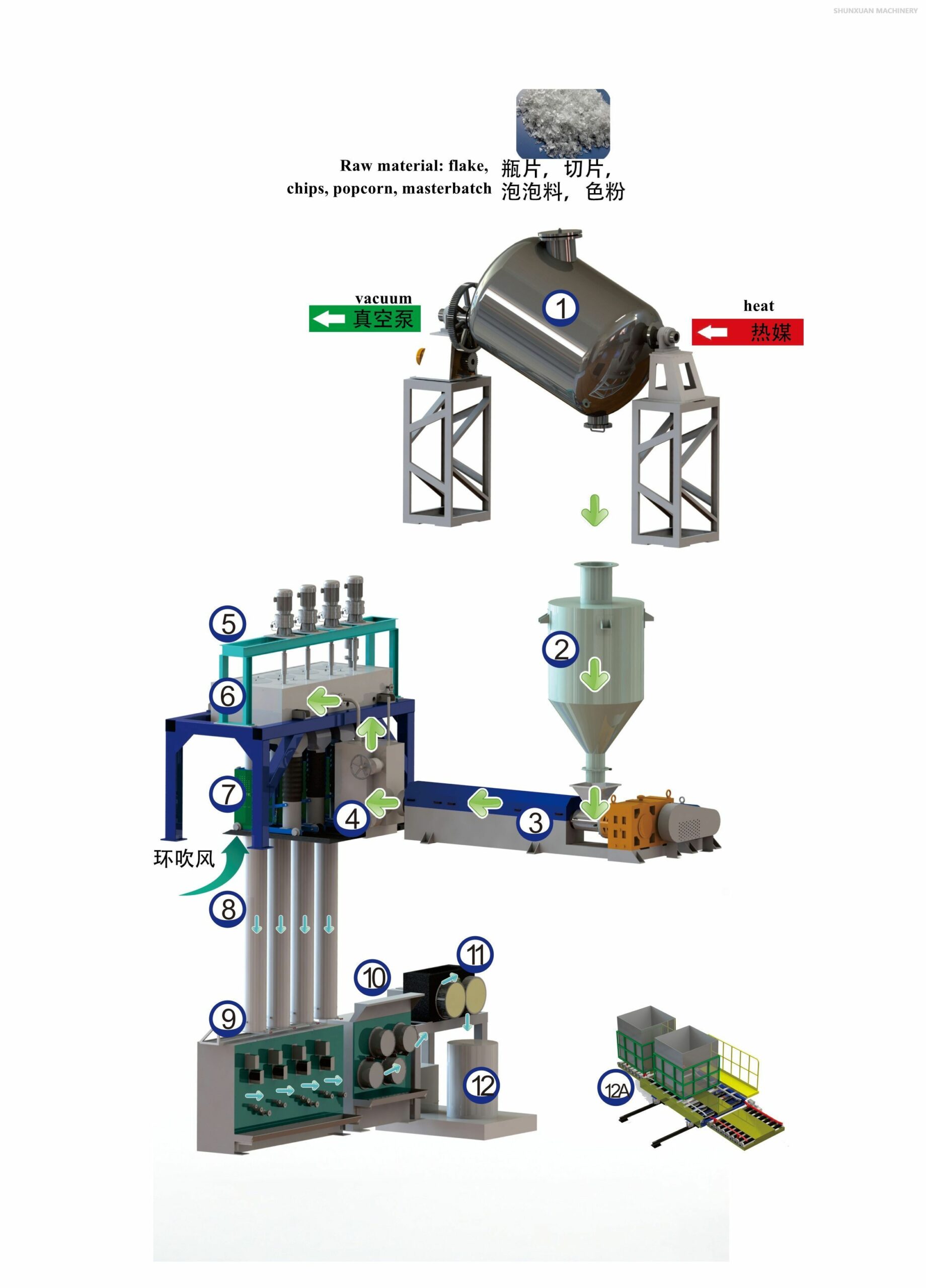

Process flow of polyester staple fiber

Fore spinning Line:

Vacuum Dryer -> Hopper -> Screw Extruder -> Filter -> Spin Beam (Meter Pump System, Spin Pack, Spinneret) -> Quenching Unit -> Interflow Duct -> Draw-off Wall -> Capstan Roller -> Sunflower Gearing unit -> fiber can traverse system

Pre-spinning Line:

Vacuum Drying Machine -> Storage Container -> Screw Extrusion Machine -> Sieve -> Spinning Apparatus (Metered Pump System, Spinning Pack, Spinneret) -> Cooling Unit -> Connecting Passage -> Withdrawal Wall -> Roller System -> Gear System for fiber movement.

Post spinning Line:

According to the spinning process technology, the products are divided into solid recycled polyester staple fiber and hollow recycled polyester staple fiber.

Among them, solid recycled polyester staple fiber is divided into the following four categories:

- Cotton type: The linear density is 1.5-2.1dtex. It is divided into two types: high-tenacity cotton type and normal cotton type. High-tenacity cotton type varies according to its application.

- Medium length type: line density is 2.2-3.2dtex.

- Wool type: divided into fine denier wool type and high denier wool type. The density of fine denier wool fiber is 3.3-6.0dtex. The higher denier fiber density is 6.1-27.78dtex.

- Polyester staple fiber for filling: linear density is 3.33dtex-27.28 dtex.

Hollow recycled polyester staple fiber is divided into two dimensional hollow polyester staple fiber and three dimensional hollow polyester staple fiber.

1.1 Two-Dimensional Hollow Fiber Production Line:

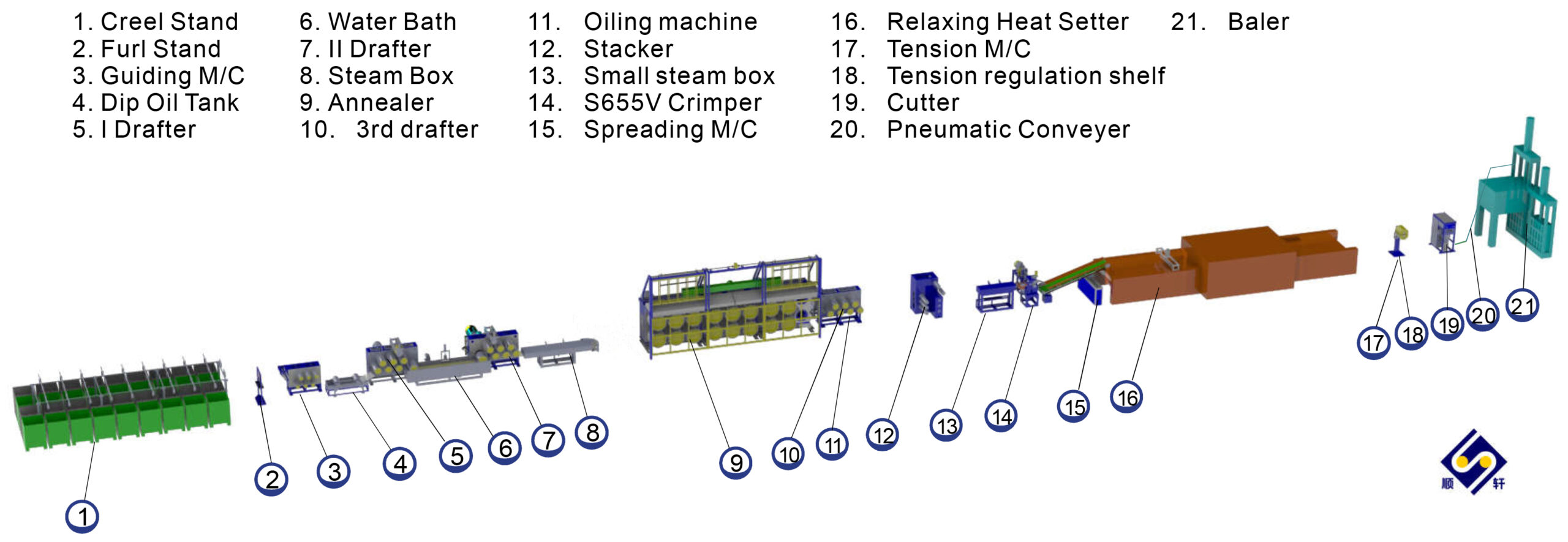

Starting from the can creel, the inlet thread guide leads to the tow guide stand. Next, the fibers go through the dipping bath and then the first draw stand. They continue through the draw bath and the second draw stand. The fibers then reach the draw steam chest and move on to the third draw stand. After that, they pass through the tow stacker and enter the crimper steam box. The fibers are then processed by the crimper and conveyed by the tow conveyer. Next, they go through the relaxer and the tow tension stand before reaching the cutter. Finally, they are transported by the chain plate conveyor and pressed into bales by the baling press.Can Creel -> Inlet Thread Guide -> Tow Guide Stand -> Dipping Bath -> 1st Draw Stand -> Draw Bath -> 2nd Draw Stand -> Draw Steam Chest -> 3rd Draw Stand -> Tow Stacker -> Crimper Steam Box -> Crimper -> Tow Conveyer -> Relaxer -> Tow Tension Stand -> Cutter -> Chain Plate Conveyor -> Baling Press

1.2 Three-Dimensional Hollow Fiber Production Line:

Similar to the two-dimensional line, the process starts with the can creel and the inlet thread guide. The fibers then pass through the tow guide stand and the dipping bath. Next, they go through the first draw stand and the draw bath, followed by the second draw stand. The fibers then reach the draw steam chest and move on to the third draw stand. Instead of a tow stacker, a tension control device is used in this line. The fibers then enter the crimper steam box and are processed by the crimper. After that, they are sprayed with silicon oil by the silicon oil sprayer. Next, the fibers go through the tow tension stand and are cut by the cutter. They then pass through the fiber spreader and the fiber leveler before reaching the relaxer. The fibers are then transported by the chain plate conveying system and pressed into bales by the baling press.

Can Creel -> Inlet Thread Guide -> Tow Guide Stand -> Dipping Bath -> 1st Draw Stand -> Draw Bath -> 2nd Draw Stand -> Draw Steam Chest -> 3rd Draw Stand -> Tension Control Device -> Tow Stacker -> Crimper Steam Box -> Crimper -> Silicon Oil Sprayer -> Tow Tension Stand -> Cutter -> Fiber Spreader -> Fiber Leveler -> Relaxer -> Chain Plate Conveying system -> Baling Press

2. Spinning section:

2-1 Main production unit:

It is mainly composed of drying system, screw extruder, filter, spinning insulation box, heat medium circulation system, metering pump, metering pump transmission device, spinning pack, quenching system, take-up, haul-off unit, traction feeding and traverse system for fiber cans and so on.

2-2 Design basis: Basic design of spinning production line

- Annual production capacity: 6000T

- Finished fiber size: 1.67 Dtex

- Spinning bits: 8 bits

- Spinning pitch: 650mm

- Spinneret specifications: φ 328mm

- Metering pump specifications: 70cc/ R

- Spinning speed

- Mechanical speed: 500~1500m/min

- Process speed: 500~1350m/min

- Specification of fiber cans: 1000×1500mm

Processing section

Precursor fiber tow → Creel & upper & lower guide frames → Oil immersion bath → 1st draw stand → bath draw chest → 2nd draw stand → steam draw chest → 3rd draw stand → stacker → tension frame →steam pre-heater → crimper → spreader → tensionless tow dryer → draw-off tension stand → cutter → baler for stapled fiber.

Recycled bottle flake get dryed first, and goes into screw extruder for melt, then the melt will be purified by filter. Melt get distributed by meter pump and goes into spin beam for the second filtration and then become fiber tow after spinneret and cooling system.

Key Features:

- The equipment has a straightforward and linear design, making it effortless to install and maintain.

- Utilizes top-quality components from renowned global brands for pneumatic, electric, and operational parts.

- Employs a high-pressure double crank mechanism to efficiently control the opening and closing of the die.

- Operates with advanced automation and intelligence, ensuring a clean and pollution-free process.

- Incorporates a linker that seamlessly connects with the air conveyor, enabling direct integration with the filling machine.

Our Service:

- Quick delivery time.

- Round-the-clock online service.

- Guarantee: Key components covered for 1 year.

- Provide lifetime access to reasonably priced parts.

- Extend technical assistance and workshop layout guidance to buyers.

- Customize the layout as per buyer’s requirements.

Packing & Delivery

- Packaging: Export packaging that meets standard requirements.

- Harbor: Any harbor located in China.

- Delivery Time: Within 30 to 40 business days after receiving the initial payment.

Technical Parameter

| Capacity | From 10TPD-300TPD |

| Products | Hollow Conjugate Silicone Fiber, Hollow Non-Conjugate Silicone Fiber, Solid Fiber Silicone/ non Silicone |

| Denier Size | 1.2Den,1.5Den, 3Den, 6Den, 10Den, 15Den, 18Den, 22Den, 25Den, 33Den |

| Cut length | 44, 51, 64, 76, 102 (As per customer requirement) |

| Feel | Siliconised or non siliconised soft as well as harsh feel |

| Tensile strength | 3.5 to 6.3 gm/Denier |

| Elongation: | 18 to 60% |

| Oil Pickup | Minimum 0.20% to 0.35% |

| Crimps | 3 to 5 per cm |

| Color Fastness | 4+ |

Application

Cushions – Pillows – Quilts – Toys – Jacket – Mattress – Non-woven carpet – Automotive felts, speaker felts, geo textiles, polyfill wadding, filter fabrics and other acoustics as well.

| Denier | Cut Length (In mm) | Type | Application |

| 1.2-1.4 | 32,38,51 | Solid High tenacity | Spinning |

| 1.4 | 32,38 | Solid | Spinning |

| 1.4 | 51,64 | Solid | Non-woven, interlining, felt |

| 3, 6, 15 | 32,38,51,64 | Solid Non Siliconized | Padding/ wadding, needle punching, Non-woven interlining, felt |

| 6, 15 | 32,38,51,64 | Solid Siliconized | Stuffing (Filling) plush toy, cushion, pillow, bolster, sofa |

| 7, 15 | 32,51,64 | Hollow, Hollow Conjugate Non Siliconized | Padding/wadding, felt, needle punching |

| 7, 15 | 32,51,64 | Hollow, Hollow Conjugate Siliconized | Stuffing (Filling): plush toy, cushion, pillow, bolster, sofa |

Video

FAQ

1. What do you offer?

We produce recycled hollow conjugated siliconized and non-siliconized polyester staple fiber mainly, we can make hollow fiber (HS/ HD) and virgin polyester staple fiber HCS as well.

2. What is it used for?

Our fiber is widely used in filling, non-woven fabric

3. Are you a factory or a trading company?

We are a factory specialized in polyester staple fiber for many years but now we also have our own professional trading company. We will source many types of textile products such as yarn, PP fibers from others to supply our own customers as well. We also provide our own customers with other related products such as: Foam, Pillows, Cushions, Toys, Down/ Feather,…

4. Where is your factory location?

Our factory locates in the north and the south of Vietnam. You can visit us from Ho Chi Minh City and Hanoi City, Vietnam. You could contact our salesman to fetch you if visiting.

5. Can you accept free sample?

Yes, the hand sample is free when not exceed 1 kilograms. Upon price confirmation, we will provide a sample within 2-3 days; the freight cost will be charged to client.

6. Can you provide ODM service?

Yes, we work on ODM orders. Which means size, material, quantity, design, packing solution, etc, will depend on your requests, and your logo will be customized on our products.

7. How about your quality? What’s the minimum order Quantity (MOQ)?

Please try a trial order, you will know it. The MOQ is 23,000 Kilograms/order, but the price will be lower if you order bulk volume.

8. Can I mix different items in one order?

Sure, you can mix any products we can provide.

9. How can you guarantee the product quality?

We have experienced QC team. We control not only productive process but also raw material. In addition, we have different kinds of testing instrument to help us guarantee the product quality.

10. What’s the payment terms?

L/C at sight, 30% TT in advance are mostly accepted; other terms shall be negotiable by both sides

For more information, please feel free to contact :

Mr. Tony Tan

Mobile number: +84 90 466 5251 (Whatsapp/Wechat/Viber/Signal)