What is fiber blend ?

Material blends have the objective of associating their properties to obtain a more efficient material. The most frequent blends : cotton/polyester, cotton/elastane and wool / polyamide.

Various processes exist to blend materials:

- Intimate blend of fibres;

- Thread assembly blend;

- Structure composed of different types of thread.

RECYCLABILITY OF BLENDS

Materials composed of blends can be difficult to recycle. In effect during recycling preparation, materials are separated and sorted. To ensure good material sorting, the product composition must be easy to read (label).

Consequently, products composed of lots of materials should be avoided; single-component materials should be preferred.

In addition, the quantity of elastane in a product must not exceed 5% in order to not disrupt recycling ; ideally it should be limited to 2%.

INTIMATE BLEND PROCESS

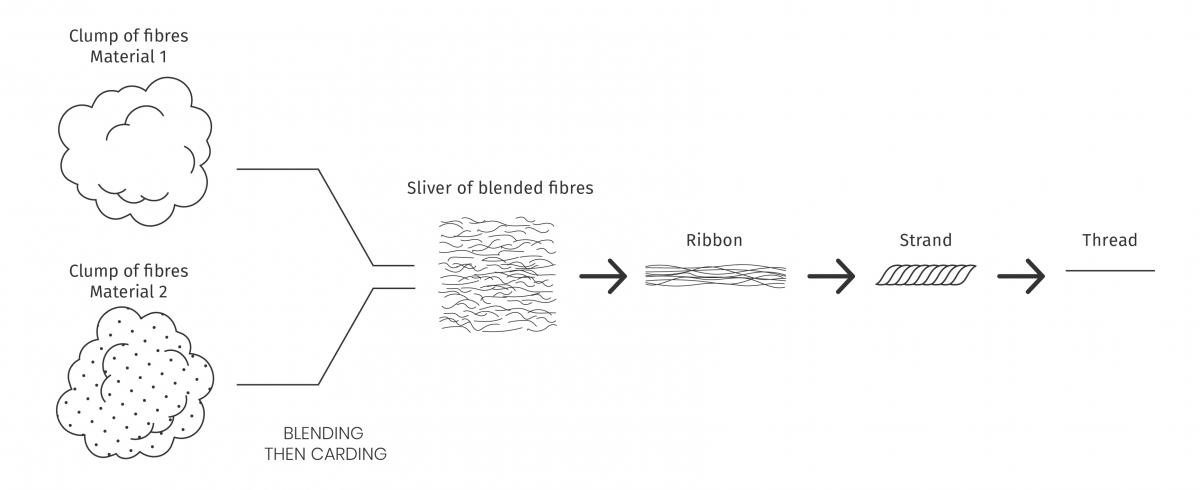

An intimate blend consists in mixing fibres prior to the spinning phase (passage from fibre to thread). The different types of fibre clumps are carded (disentangled and aligned in parallel) to form a sliver. The sliver, composed of several materials, is firstly transformed into a ribbon, then a strand and lastly a thread. The blend is characterised as intimate as it occurs at the fibre stage.

THREAD ASSEMBLY BLEND PROCESS

A thread assembly blend consists in combining two threads of different composition to form a single thread. This blend therefore occurs after the spinning stage (passage from fibre to thread.

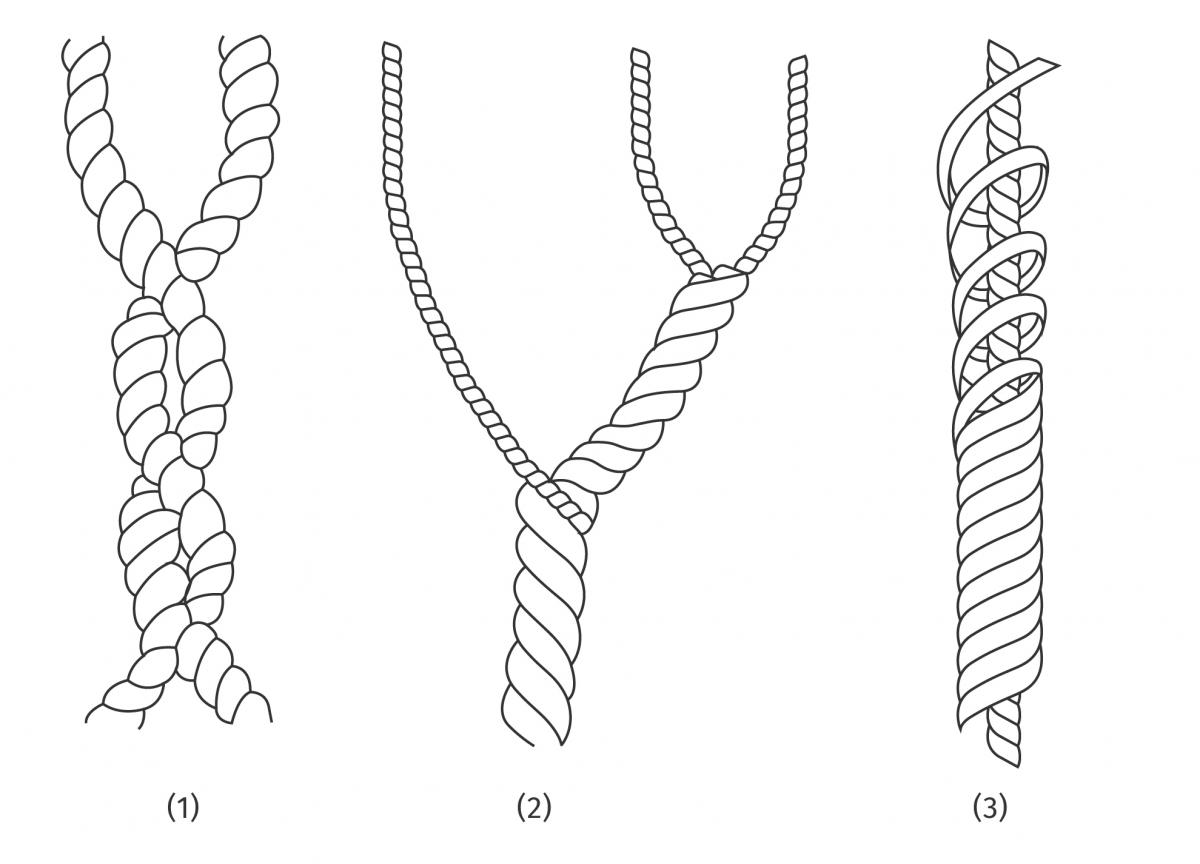

Threads can be assembled in various ways: plied thread, cabled thread or covered thread.

Plied threads consist in two threads twisted together (1), cabled threads are composed of at least two plied threads re-twisted together (2) and covered threads are composed of a cored yarn around which a covering thread is wound (3).

BLENDING PROCESS IN THREAD STRUCTURE

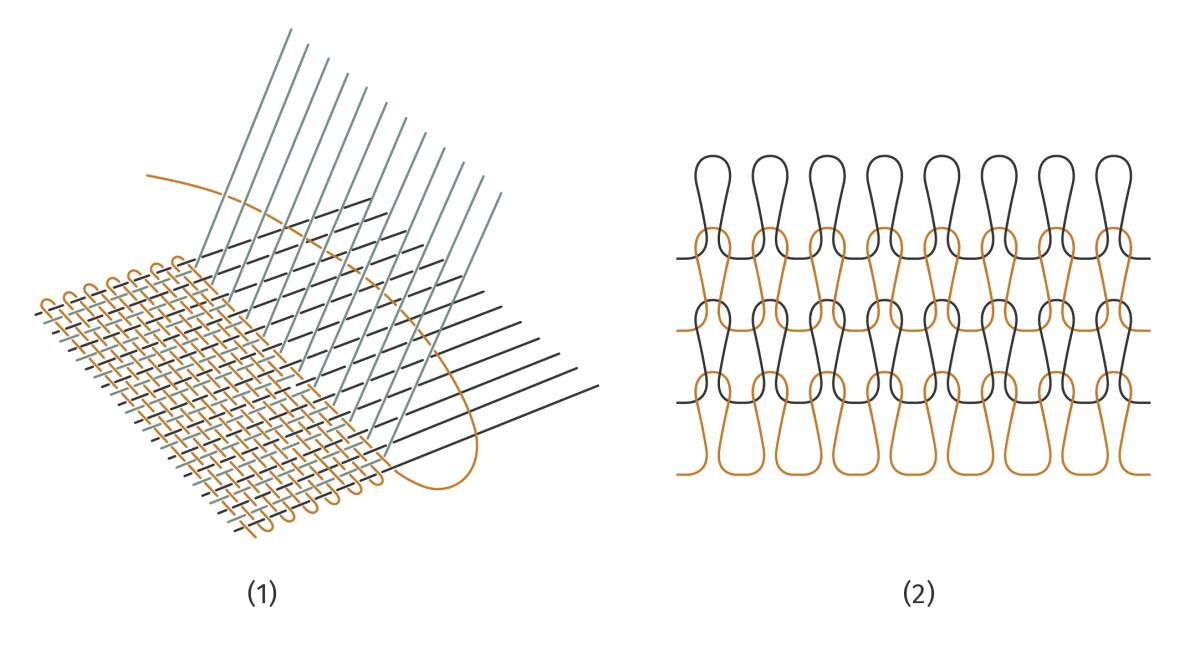

To achieve a material blend within the structure of a fabric (1) or knitwear (2) it is necessary to use several threads of different compositions to produce the fabric.