100% PET Spunlace Nonwoven

100% PET Spunlace Nonwoven refers to a type of nonwoven fabric made entirely from polyester fibers, specifically Polyethylene Terephthalate (PET), using the spunlace or hydroentanglement process. VnPolyfiber is a renowned supplier of Spunlace Nonwoven fabric from China. VnPolyfiber offers various specifications of Spunlace Nonwoven made from 100% PET or a combination of PET and Rayon Viscose fibers. Both cross-lapped and parallel spunlace options are available. We collaborate with qualified Chinese suppliers to provide our customers globally with very competitive pricing.

Main Applications of Spunlace Nonwoven:

1. Sanitary materials, including medical curtains, surgical garments, surgical masks, medical dressing materials, wound dressings, and medical gauze.

2. Disposable products for women and infants, such as diapers, wipes, and masks.

3. Leather bottom fabric and high-grade wiping cloths.

Product Specifications and Applications:

– Width: 15 cm to 180 cm

– Basis Weight: 40 gsm to 150 gsm

– Spin Finish: Standard hydrophilic

Custom weights and compositions are available, including viscose, polyester, cotton, nylon, and microfiber. The fabric can be produced in plain, perforated forms, as well as in various solid colors and prints.

- Hygiene Products: 100% PET spunlace fabrics are used in the production of wipes, diapers, and other personal care items where softness and strength are important.

- Medical Textiles: Due to its durability and resistance to chemicals, this fabric is ideal for disposable medical gowns, drapes, and sterilization wraps.

- Cleaning Materials: The absorbent and durable nature makes it suitable for industrial and household cleaning wipes.

- Automotive and Industrial Uses: The strength and durability of PET spunlace nonwoven fabrics make them useful in filtration, automotive interiors, and other technical applications.

Advantages of 100% PET Spunlace Nonwoven:

- Eco-Friendly: Being 100% PET, the fabric can be recycled, aligning with sustainability goals.

- High Durability: The use of PET ensures that the fabric is strong, durable, and resistant to wear and tear.

- Versatility: It can be engineered to have different properties depending on the application, such as varying thicknesses, densities, and finishes.

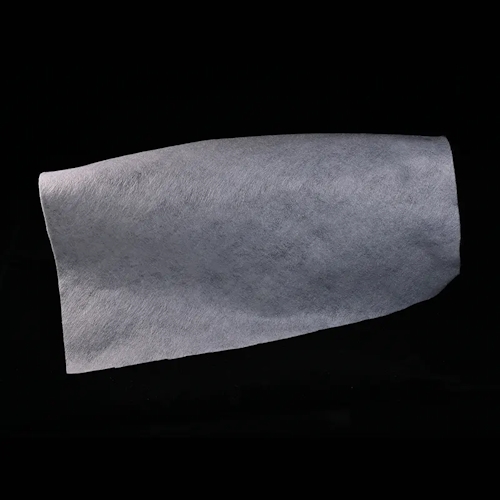

Cross-Lapped Spunlace Nonwoven

Cross-lapped spunlace nonwoven refers to a type of nonwoven fabric created using a combination of spunlacing (hydroentangling) and cross-lapping techniques.

When these two techniques are combined, the resulting fabric benefits from the softness and flexibility of spunlace with the added strength, thickness, and uniformity provided by cross-lapping.

This combination allows manufacturers to produce a nonwoven fabric that meets specific requirements for various industrial and consumer applications.

Key Characteristics:

- Enhanced Strength: The cross-lapping technique provides a more robust structure.

- Uniformity: The crosswise layering ensures consistent thickness and strength across the fabric.

- Softness and Flexibility: Retained from the spunlace process.

Applications: This type of nonwoven fabric is often used in applications requiring durability and softness, such as in automotive interiors, high-quality cleaning wipes, and certain types of apparel linings.

1. Spunlace (Hydroentangled) Nonwoven:

- Spunlacing: This process involves entangling fibers in a web using high-pressure water jets. The force of the water jets binds the fibers together, creating a strong and flexible fabric. Spunlace fabrics are known for their softness, drapability, and good strength. In this process, high-pressure water jets are used to entangle the PET fibers, forming a coherent fabric. This method does not require the use of binders or adhesives, which helps maintain the purity and recyclability of the material.

- Benefits of Spunlace:

- Softness: The fabric remains soft and flexible, even though it is made of synthetic fibers.

- Strength and Durability: The entanglement of fibers provides good mechanical strength.

- Absorbency: Despite being made from synthetic fibers, the spunlace process can impart good absorbency properties to the fabric, making it suitable for wipes and medical applications.

- Applications: This type of fabric is widely used in hygiene products (like wet wipes), medical textiles, and cleaning materials.

2. Cross-lapping:

- Cross-lapping: This is a technique used to create a more uniform and thicker nonwoven fabric. In this process, a fiber web is laid down in layers, typically by first carding the fibers into a web and then layering the web in a crosswise fashion, often at a 90-degree angle. This layering improves the strength, thickness, and isotropic properties of the fabric, meaning it has more uniform strength and texture in all directions.

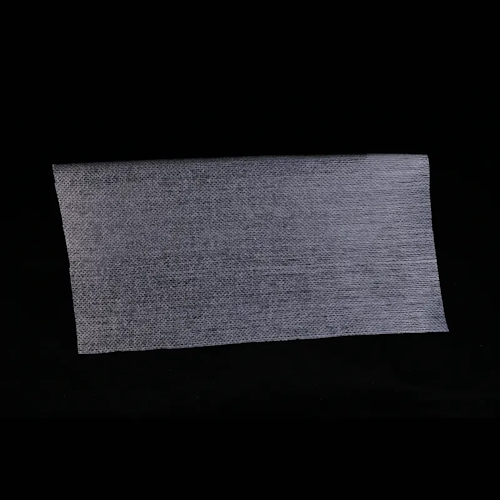

Parallel Spunlace Nonwoven

This type of nonwoven fabric is produced by interlacing fibers with high-pressure water jets. We strive to enhance the value of our customers’ experiences, establishing ourselves as their preferred choice.

Our Spunlace Nonwoven, made from PET and Rayon Viscose fibers, is created through the entanglement of a loose fiber web with multiple rows of high-pressure water jets. The unique interlinking of the fibers in various directions grants the fabric its isotropic property, ensuring uniform strength in all directions.

Parallel Spunlace Nonwoven refers to a nonwoven fabric made using the spunlace (hydroentanglement) process, where the fibers are predominantly aligned in a parallel direction during web formation. This method differs from cross-lapped spunlace nonwovens, where fibers are layered in different directions.

Key Characteristics:

Fiber Alignment:

- Parallel Orientation: In a parallel spunlace nonwoven, the fibers are aligned in the machine direction (MD), meaning they run in the same direction as the production line. This alignment occurs during the carding process, where fibers are combed and laid out in parallel before they are entangled.

- Resulting Properties: The fabric tends to have higher strength and stability in the machine direction compared to the cross direction (CD). However, this can also lead to anisotropic properties, where the fabric has different strengths and elongations in different directions.

Advantages of Parallel Spunlace Nonwoven:

- Directional Strength: The parallel alignment of fibers can be beneficial in applications where higher strength is required in a specific direction, such as in filtration or packaging.

- Efficiency: The parallel process can be more efficient in certain production settings, potentially reducing production time and costs.

Applications:

- Hygiene Products: Used in products like wipes where directional strength might be necessary for effective use.

- Medical Textiles: Suitable for applications like surgical gowns and drapes, where strength in the machine direction is advantageous.

- Industrial Uses: Can be used in filtration, packaging, and other industrial applications where the specific directional properties of the fabric are beneficial.

Comparison with Cross-Lapped Spunlace Nonwoven:

- Directional Properties: Parallel spunlace nonwoven fabrics exhibit more pronounced directional properties (anisotropy) compared to cross-lapped spunlace fabrics, which are more isotropic (uniform in all directions).

- Strength Distribution: In parallel spunlace, strength is greater in the machine direction, whereas cross-lapped spunlace has a more balanced strength distribution across directions.

This makes Parallel Spunlace Nonwoven suitable for specialized applications where the directional strength and efficiency in production are key considerations